Professional Documents

Culture Documents

Name of Customer Name of Project TE-112045 WFC Print Out

Name of Customer Name of Project TE-112045 WFC Print Out

Uploaded by

Javier EspinosaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Name of Customer Name of Project TE-112045 WFC Print Out

Name of Customer Name of Project TE-112045 WFC Print Out

Uploaded by

Javier EspinosaCopyright:

Available Formats

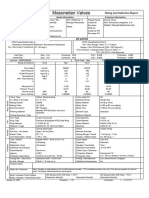

Instrumentos WIKA Colombia S.A.S.

Customer: Name of Customer Name: Name

Instrumentos WIKA Colombia S.A.S.

Cr 63 # 98-25

Project: Name of Project Date: Date

Barrio Andes

Bogotá

Ref. -No.: Reference

phone: +5716240564

fax: no fax

Calculation email: info@wika.co

Tag-No.: TE-112045

result:

good web: www.wika.co

Thermowell Calculation Program v2.8.2

Results to ASME PTC 19.3 TW - 2016

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

Description Description

WIKA / ASME WIKA / ASME

Result: Process data: 1

Result Eval. good Temperature T 120,00 °F

Frequency ratio r 0,02 fw/fnc Pressure P 204,00 psig

Ratio limit fw/fnc rmax_ 0,40 Max.velocity v 2,14 ft/s

Safety fatigue dyn 272,10 / Med.density rho 61,65 lb/ft3

Safety bending stat 841,60 / Dyn. viscosity my mPa s

Safety pressure Sp 35,47 /

Optimized length (rmax) Uopt / Lopt in.

Note code /

Pipe data:

Inner diameter Di 7,500 in.

Shielded length SL / Lo in.

Usable nozzle length *) UNL / in.

Nozzle inner diameter *) NID / in.

*) for support collar

Thermowell sketch

Thermowell data:

WIKA model TW15 Name

Connection screwed

Shape tapered Name

Insertion length U/L 7,000 in.

Optimized length Uopt / in.

Stepped length US / Ls 0,000 in.

Step radius RS / rB 0,000 in.

0,000

4a awRoot radius

tapered R / rA

TW15, TW50 Q in.

Bore diameter B / db 0,250 in.

Root diameter Q/A 0,860 in.

Tip diameter V/B 0,620 in.

Tip thickness Tt / Tt 0,250 in.

Material data:

Grade mat 316 Name

Spec. weight D(T) 0,289 lb/in3

Youngs modul E(T) 27992,3 ksi

Factor for temp. FT 0,982 /

Fatigue strength Sf(T) 5303,1 psi

Max.all.stress 1.5S(T) 29190,0 psi

Press. strength S(T) 19460,0 psi

Fatigue class class B

WIKA has made every reasonable attempt to validate the calculation procedure contained in this spread sheet, however, responsibility for validation rests solely with the user.

This WIKA ASME PTC 19.3 TW - 2016 spread sheet copyright © 2019 (compatible with Excel 2007/2010) is intended to assist the experienced designer of thermowells and should

not be considered as a replacement for professional engineering.The end user is responsible to assure that the calculation method is compatible to the process conditions.

For further information see Operation Instruction.

You might also like

- Cable CalculationsDocument9 pagesCable CalculationsMohamed Mostafa0% (1)

- Megger Test Form-NewDocument2 pagesMegger Test Form-NewShahadad PNNo ratings yet

- Hotel Engineering & MaintenanceDocument2 pagesHotel Engineering & MaintenanceKamlesh ChouhanNo ratings yet

- Amp-Load ScheduleDocument6 pagesAmp-Load ScheduleMohamed Mostafa100% (1)

- PTC 19.3Document1 pagePTC 19.3TATA STEELNo ratings yet

- Steam Control ValveDocument3 pagesSteam Control ValvedpdcpNo ratings yet

- 3827-E10-063 - Modulating Control Valve - EDocument6 pages3827-E10-063 - Modulating Control Valve - EMohamed Elsaid El ShallNo ratings yet

- Load Schedule Calculation Sheet: Electrical Department Project Name: Project No.: Panel Data: Main Feeder DataDocument7 pagesLoad Schedule Calculation Sheet: Electrical Department Project Name: Project No.: Panel Data: Main Feeder DataDardakNo ratings yet

- B-6326-PR-00-0046-002 Rev 6Document15 pagesB-6326-PR-00-0046-002 Rev 6sushilNo ratings yet

- 3827-E10-066 - Knife Gate (On-Off) Control Valve - DDocument2 pages3827-E10-066 - Knife Gate (On-Off) Control Valve - DMohamed Elsaid El ShallNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Cuu Long Joint Operating Company: Calculation: Su Tu Trang FFD-P1 Line SizingDocument9 pagesCuu Long Joint Operating Company: Calculation: Su Tu Trang FFD-P1 Line SizingVăn HoàngNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- 3827-E10-067 - High Performance Butterfly Valve - BDocument2 pages3827-E10-067 - High Performance Butterfly Valve - BMohamed Elsaid El ShallNo ratings yet

- Load Schedule Calculation SheetDocument6 pagesLoad Schedule Calculation SheetlakshminarayananNo ratings yet

- Abb Spa - Process Automation Division: Projet Rehabilitation Du Train 200 de L'Usine GPL Rhourde NoussDocument32 pagesAbb Spa - Process Automation Division: Projet Rehabilitation Du Train 200 de L'Usine GPL Rhourde NoussAbdessalem BougoffaNo ratings yet

- Ele Vir Flush Ring 160 0001 To 0008Document16 pagesEle Vir Flush Ring 160 0001 To 0008rahul o gNo ratings yet

- Flow Element: Base Maximum Flow Min Flow Property MethodDocument4 pagesFlow Element: Base Maximum Flow Min Flow Property Methodscploperation.2x50 CommonNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- VALVULA VAPOR Joseestrada PDFDocument5 pagesVALVULA VAPOR Joseestrada PDFRaulRodriguezNo ratings yet

- Cl17-011-Dat-El-Sacyr-005a-006 (Ri)Document17 pagesCl17-011-Dat-El-Sacyr-005a-006 (Ri)jorgeNo ratings yet

- HFX-FI2021-6428 DT 24-05-21 LPI of 8 NMDC # SBMH 0510Document1 pageHFX-FI2021-6428 DT 24-05-21 LPI of 8 NMDC # SBMH 0510fast fastNo ratings yet

- c40 4202730541 50 11kv DV Safering XT Manual RmuDocument21 pagesc40 4202730541 50 11kv DV Safering XT Manual Rmubaljeet negiNo ratings yet

- 3827-E10-062 - Two Position Valve - DDocument4 pages3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallNo ratings yet

- Gs01f06a00 50eDocument8 pagesGs01f06a00 50eDaniloNo ratings yet

- UT ReportDocument5 pagesUT ReportAnonymous tlznGAqNo ratings yet

- List Applicable WPS Piping & PipelineDocument6 pagesList Applicable WPS Piping & PipelineFerdie OSNo ratings yet

- 01 - 25284124-8230-26-000-0004 - REV.02 - Piping - List - O & U UndergroundDocument2 pages01 - 25284124-8230-26-000-0004 - REV.02 - Piping - List - O & U UndergroundRajeev KumarNo ratings yet

- 01 25284124-8230-26-000-0006 REV.02 Piping List EXISTING PIPE RACKDocument2 pages01 25284124-8230-26-000-0006 REV.02 Piping List EXISTING PIPE RACKRajeev KumarNo ratings yet

- Pengadaan Meter Turbin Tahun 2021: PonoDocument2 pagesPengadaan Meter Turbin Tahun 2021: PonoArfan NNo ratings yet

- DGN-205 Doc. Rev.03 PDFDocument3 pagesDGN-205 Doc. Rev.03 PDFHEMANTNo ratings yet

- Xinjiang Beixin Road & Bridge Group Co. LTD: XBRB - Lab - BDocument13 pagesXinjiang Beixin Road & Bridge Group Co. LTD: XBRB - Lab - BAhmedNo ratings yet

- 01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InDocument2 pages01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InRajeev KumarNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- Cable CalculationsDocument9 pagesCable CalculationsFasil ENo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- Fit-Up Piping B192-5ADocument54 pagesFit-Up Piping B192-5APrathamesh OmtechNo ratings yet

- CLC PDFDocument1 pageCLC PDFAnonymous qXdGlWLDMTNo ratings yet

- Untitled. - Complete PDFDocument5 pagesUntitled. - Complete PDFDrMahmoud AbbasNo ratings yet

- Refrigerated Pertamina Tanjung Sekong Merak Visual Examination Welding Repair ReportDocument2 pagesRefrigerated Pertamina Tanjung Sekong Merak Visual Examination Welding Repair ReportNauval Labiby N M100% (1)

- 01 25284124-8230-26-000-0011 REV.01 Piping List HCDSDocument1 page01 25284124-8230-26-000-0011 REV.01 Piping List HCDSRajeev KumarNo ratings yet

- WEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTDocument2 pagesWEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTLuanNo ratings yet

- Pipebook Work Package 1Document39 pagesPipebook Work Package 1Renaldo akbarNo ratings yet

- Fe-103, Fe-104 8''Document2 pagesFe-103, Fe-104 8''Vikram JitNo ratings yet

- 01 25284124-8230-26-104-0001 REV.02 Piping List CT1Document1 page01 25284124-8230-26-104-0001 REV.02 Piping List CT1Rajeev KumarNo ratings yet

- CT-1205CL-SMT Datasheet - MAGNETIC BUZZER INDICATOR - CUI IncDocument3 pagesCT-1205CL-SMT Datasheet - MAGNETIC BUZZER INDICATOR - CUI IncrstramirezNo ratings yet

- MN 176323 24Document3 pagesMN 176323 24nawaz.ahmed.spnutra.comNo ratings yet

- 315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevADocument3 pages315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevAanwar sadatNo ratings yet

- Co ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionDocument2 pagesCo ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionBalaji SelvarajNo ratings yet

- Laporan KerjaDocument1 pageLaporan Kerjagenta abadiNo ratings yet

- Solenoid Controlled Relief ValvesDocument10 pagesSolenoid Controlled Relief ValvesRenjithSivaNo ratings yet

- Danfoss Scroll Compressor HRP060T4LP6 121L1726Document4 pagesDanfoss Scroll Compressor HRP060T4LP6 121L1726Delarenus SianiparNo ratings yet

- WPS & PQR VVSPLDocument3 pagesWPS & PQR VVSPLBhargav BbvsNo ratings yet

- HAJ-AR-UDR-001 Rev.0 - 1.08.2023Document4 pagesHAJ-AR-UDR-001 Rev.0 - 1.08.2023divakar.panigrahiNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- 2 Wire DC: Voltage Size 110VDC 10,12,18,20,25 48VDC 10,12,18 24VDC 10 Voltage OptionsDocument2 pages2 Wire DC: Voltage Size 110VDC 10,12,18,20,25 48VDC 10,12,18 24VDC 10 Voltage OptionsJavier EspinosaNo ratings yet

- Asco Series 214 Gas Shutoff CatalogDocument8 pagesAsco Series 214 Gas Shutoff CatalogJavier EspinosaNo ratings yet

- F05/FA05 & F07/FA07 Base Adapter: IQT3-1-STDDocument2 pagesF05/FA05 & F07/FA07 Base Adapter: IQT3-1-STDJavier EspinosaNo ratings yet

- Controlwave Micro: Cwmicro Product Data SheetDocument11 pagesControlwave Micro: Cwmicro Product Data SheetJavier EspinosaNo ratings yet

- P6E BB 6000psig-CDIDocument4 pagesP6E BB 6000psig-CDIJavier EspinosaNo ratings yet

- Smartrack Side Panel Latch Installation: Owner'S Manual AddendumDocument1 pageSmartrack Side Panel Latch Installation: Owner'S Manual AddendumJavier EspinosaNo ratings yet

- Calculo Ultrasonico Lavalin 8inDocument1 pageCalculo Ultrasonico Lavalin 8inJavier EspinosaNo ratings yet

- Type 1 Drawing Rosemount 5408 Radar Level Transmitter 2d PDF en 327202Document5 pagesType 1 Drawing Rosemount 5408 Radar Level Transmitter 2d PDF en 327202Javier EspinosaNo ratings yet

- G1e 001 PDFDocument31 pagesG1e 001 PDFlkirankarthikNo ratings yet

- A Critical Review of Engineered Geopolymer Composite 2022 ConstructionDocument25 pagesA Critical Review of Engineered Geopolymer Composite 2022 ConstructionYoukhanna ZayiaNo ratings yet

- Formula For EstimateDocument3 pagesFormula For EstimatePaoleene CunananNo ratings yet

- PCI Sandwich Wall Panels SOA Guide Rev (1!11!11)Document62 pagesPCI Sandwich Wall Panels SOA Guide Rev (1!11!11)Nuno FerreiraNo ratings yet

- Magnetic Nanocomposite Materials For High Temperat PDFDocument6 pagesMagnetic Nanocomposite Materials For High Temperat PDFSaleem SalluNo ratings yet

- SLOPE 0.5%: Standard Artificial Turf Full Pitch PlanDocument3 pagesSLOPE 0.5%: Standard Artificial Turf Full Pitch PlanAli AafaaqNo ratings yet

- Ferry Viscoelastic Properties of Polymers PDFDocument2 pagesFerry Viscoelastic Properties of Polymers PDFLinda0% (1)

- Construction and Building Materials: Guo Li, Lei Dong, Zhu'an Bai, Ming Lei, Jianmin DuDocument7 pagesConstruction and Building Materials: Guo Li, Lei Dong, Zhu'an Bai, Ming Lei, Jianmin DuHaniel FcNo ratings yet

- Columns SpecificationDocument2 pagesColumns SpecificationAaftab MukadamNo ratings yet

- Q4Document15 pagesQ4dramiltNo ratings yet

- Sikasil SG-18: Structural Silicone AdhesiveDocument2 pagesSikasil SG-18: Structural Silicone AdhesiveMochamad Ardie NoegrohoNo ratings yet

- AGC Safety Glass Technical Information 2008 enDocument10 pagesAGC Safety Glass Technical Information 2008 enzoranmiskovicNo ratings yet

- Initial and Final Setting of CementDocument10 pagesInitial and Final Setting of CementSaleha AnuarNo ratings yet

- APA Guide - Non Residential Roof Systems PDFDocument36 pagesAPA Guide - Non Residential Roof Systems PDFVo Kien CuongNo ratings yet

- TG3070Document815 pagesTG3070Jason SecretNo ratings yet

- Weld Mesh Panel ReportDocument1 pageWeld Mesh Panel ReportMahfooz AlamNo ratings yet

- Experiment No: - 02 Name of Experiment: - The Bending System. ObjectivesDocument5 pagesExperiment No: - 02 Name of Experiment: - The Bending System. ObjectivesNewton ShikderNo ratings yet

- Tech Tip 12 - Compatible MetallizationDocument2 pagesTech Tip 12 - Compatible MetallizationBehPoSengNo ratings yet

- G3 Module 5 - Intro To ElectricityDocument51 pagesG3 Module 5 - Intro To ElectricityEthan BlackNo ratings yet

- Prelim Exam (Reviewer Answer Key)Document3 pagesPrelim Exam (Reviewer Answer Key)ravenNo ratings yet

- Technique For Strengthening of Masonry Wall Panels Using Steel StripsDocument19 pagesTechnique For Strengthening of Masonry Wall Panels Using Steel StripsBalaji CreatNo ratings yet

- Trestle foundations-TR-9 RaftDocument15 pagesTrestle foundations-TR-9 RaftSripara KrishnaNo ratings yet

- Aluminium Structural Design-Springer-Verlag Wien (2003)Document398 pagesAluminium Structural Design-Springer-Verlag Wien (2003)Ho Wing FungNo ratings yet

- Nonlinear Analysis of Reinforced ConcreteDocument178 pagesNonlinear Analysis of Reinforced ConcreteAlexandru Hernest100% (2)

- PWD - Rate - Schedule - 2022 - Civil WorksDocument390 pagesPWD - Rate - Schedule - 2022 - Civil WorksImran Hossain RoniNo ratings yet

- Iscodes For BMCP - 16390284 - 2023 - 03 - 08 - 18 - 48Document5 pagesIscodes For BMCP - 16390284 - 2023 - 03 - 08 - 18 - 48kiran868626No ratings yet

- Pemodelan Struktur (Kuliah As3)Document144 pagesPemodelan Struktur (Kuliah As3)Bogie Prastowo MahardhikaNo ratings yet

- Vess FireDocument21 pagesVess FirecsNo ratings yet

- Nozzle & Connection: Tank Data SheetDocument1 pageNozzle & Connection: Tank Data SheetDarkvaderNo ratings yet