Professional Documents

Culture Documents

PVElite Ref

PVElite Ref

Uploaded by

Ryan Goh Chuang HongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PVElite Ref

PVElite Ref

Uploaded by

Ryan Goh Chuang HongCopyright:

Available Formats

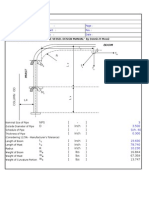

PV Elite 2010 Licensee: GULF STEEL WORKS 1

FileName : DC-7235-011-012-D-0003-001 Rev 03_LIFTING LUG-----

Lifting Lug Calcs : Left Side Step: 10 12:27p Jul 29,2010

Lifting Lug Calculations: Lug(s) on Left End of Vessel

Input Values:

Lifting Lug Material SA-516 60

Lifting Lug Yield Stress Yield 220.64 N/mm²

Total Height of Lifting Lug w 325.0000 mm

Thickness of Lifting Lug t 30.0000 mm

Diameter of Hole in Lifting Lug dh 90.0000 mm

Radius of Semi-Circular Arc of Lifting Lug r 95.0000 mm

Height of Lug from bottom to Center of Hole h 175.0000 mm

Offset from Vessel OD to Center of Hole off 155.0000 mm

Lug Fillet Weld Size tw 12.0000 mm

Length of weld along side of Lifting Lug wl 325.0000 mm

Length of Weld along Bottom of Lifting Lug wb 30.0000 mm

Thickness of Collar (if any) tc 0.0000 mm

Diameter of Collar (if any) dc 0.0000 mm

Impact Factor Impfac 1.50

Sling Angle from Horizontal 90.0000 deg

Number of Lugs in Group 2

Lifting Lug Orientation to Vessel: Perpendicular

Lift Orientation : Horizontal Lift

PV Elite does not compute weak axis bending forces on the lugs. It is

assumed that a spreader bar is used.

Computed Results:

Force Along Vessel Axis Fax 0.00 N

Force Normal to Vessel Fn 56475.05 N

Force Tangential to Vessel Ft 0.00 N

Converting the weld leg dimension (tw) to the weld throat dimension.

Weld Group Inertia Calculations:

Weld Group Inertia about the Circumferential Axis Ilc 0.553E+08 mm**4

Weld Group Centroid distance in the Long. Direction Yll 169.856 mm

Dist. of Weld Group Centroid from Lug bottom Yll_b 155.144 mm

Weld Group Inertia about the Longitudinal Axis Ill 690395.750 mm**4

Weld Group Centroid Distance in the Circ. Direction Ylc 15.000 mm

Note: The Impact Factor is applied to the Forces acting on the Lug.

Primary Shear Stress in the Welds due to Shear Loads [Ssll]:

= sqrt( Fax2 + Ft2 + Fn2 )/(( 2 * (wl + wb) ) * tw )

= sqrt(02+02+564752)/((2*(325.0+30.0))*8.4840)

= 9.38 N/mm²

Shear Stress in the Welds due to Bending Loads [Sblf]:

= (Fn*(h-Yll_b)) *Yll/Ilc + (Fax*off *Yll/Ilc) + (Ft*off *Ylc/Ill)

= (56475 *(175.000 -155.144 )) * 169.856 /55305648 +

(0 *0.000 * 169.856 /55305648 ) +

(0 *0.000 * 15.000 /690395 )

= 3.44 N/mm²

Total Shear Stress for Combined Loads [St]:

= Ssll + Sblf

= 9.376 + 3.444

= 12.82 N/mm²

Allowable Shear Stress for Combined Loads [Sta]:

PV Elite 2010 Licensee: GULF STEEL WORKS 1

FileName : DC-7235-011-012-D-0003-001 Rev 03_LIFTING LUG-----

Element and Detail Weights : Step: 5 12:27p Jul 29,2010

Element and Detail Weights

| | Element | Element | Corroded | Corroded | Extra due |

From| To | Metal Wgt. | ID Volume |Metal Wgt. | ID Volume | Misc % |

| | kg | m³ | kg | m³ | kg |

---------------------------------------------------------------------------

10| 20| 1245.00 | 3.18196 | 1011.56 | 3.20179 | 124.500 |

20| 30| 1622.79 | 8.00621 | 1353.77 | 8.04056 | 162.279 |

30| 40| 4459.84 | 28.3297 | 3507.89 | 28.4512 | 445.984 |

40| 50| 1248.31 | 6.15863 | 1041.36 | 6.18505 | 124.831 |

50| 60| 1245.00 | 3.18196 | 1011.56 | 3.20179 | 124.500 |

60| 70| 64.3942 | 0.058379 | 32.1971 | 0.061194 | 6.43942 |

---------------------------------------------------------------------------

Total 9885 48.92 7958 49.14 988

Weight of Details

| | Weight of | X Offset, | Y Offset, |

From|Type| Detail | Dtl. Cent. |Dtl. Cent. | Description

| | kg | mm | mm |

-------------------------------------------------

10|Liqd| 899.305 | -233.333 | 900.000 | HC+H2O

10|Insl| 50.3209 | -325.000 | 0.00000 | Ins: 10

10|Nozl| 10.5114 | -489.898 | 0.00000 | 2" S

20|Sadl| 542.425 | 680.000 | 1589.50 | LEFT SADDLE

20|Plat| 500.757 | 475.000 | 0.00000 | PLATFORM - 1

20|Liqd| 2488.38 | 650.000 | 900.000 | HC+H2O

20|Insl| 43.8180 | 650.000 | 0.00000 | Ins: 20

20|Nozl| 550.000 | 550.000 | 1704.80 | 24" A1

20|Nozl| 12.5950 | 1150.00 | 1425.40 | 2" L2A

20|Nozl| 12.5950 | 1150.00 | 1425.40 | 2" L2B

20|Nozl| 0.00000 | 0.00000 | 0.00000 | LIFTING LUG

30|Plat| 2478.88 | 2675.00 | 0.00000 | PLATFORM - 2

30|Liqd| 8805.05 | 2300.00 | 900.000 | HC+H2O

30|Insl| 154.615 | 2300.00 | 0.00000 | Ins: 30

30|Ring| 128.268 | 2480.00 | 0.00000 | SR 1

30|Nozl| 330.829 | 3850.00 | 1750.00 | 700 ID BOOT

30|Nozl| 440.000 | 550.000 | 1704.80 | 24" M1

30|Nozl| 60.2207 | 1150.00 | 1561.92 | 12" W

30|Nozl| 15.5691 | 2650.00 | 1444.45 | 3" V

30|Nozl| 12.5950 | 850.000 | 1425.40 | 2" L1A

30|Nozl| 10.6389 | 850.000 | 1425.40 | 2" L1B

30|Nozl| 12.5950 | 350.000 | 1425.40 | 2" L3A

30|Nozl| 10.6389 | 350.000 | 1425.40 | 2" L3B

30|Nozl| 9.86785 | 786.000 | 1425.40 | 2" L4A

30|Nozl| 9.86785 | 336.000 | 1425.40 | 2" L4B

30|Nozl| 9.86785 | 786.000 | 1425.40 | 2" L5A

30|Nozl| 9.86785 | 336.000 | 1425.40 | 2" L5B

30|Nozl| 9.86785 | 786.000 | 1425.40 | 2" L6A

30|Nozl| 9.86785 | 336.000 | 1425.40 | 2" L6B

30|Nozl| 10.6459 | 3550.00 | 1425.40 | 2" P1

30|Nozl| 10.6459 | 4150.00 | 1425.40 | 2" P2

40|Sadl| 542.425 | 320.000 | 1589.50 | RGT SADDLE

40|Liqd| 1914.14 | 500.000 | 900.000 | HC+H2O

40|Insl| 33.7062 | 500.000 | 0.00000 | Ins: 40

40|Nozl| 131.560 | 550.000 | 1654.00 | 20" B2

40|Nozl| 48.6908 | 760.000 | 1509.54 | 8" B1

50|Liqd| 899.305 | 283.333 | 900.000 | HC+H2O

50|Insl| 50.3209 | 375.000 | 0.00000 | Ins: 50

50|Nozl| 389.001 | 750.000 | 0.00000 | 24" M2

60|Liqd| 56.5928 | 0.00000 | -175.000 | HC+H2O

PV Elite 2010 Licensee: GULF STEEL WORKS 2

FileName : DC-7235-011-012-D-0003-001 Rev 03_LIFTING LUG-----

Element and Detail Weights : Step: 5 12:27p Jul 29,2010

60|Insl| 3.23466 | 0.00000 | -70.0000 | Ins: 60

60|Nozl| 9.12958 | 0.00000 | -175.000 | 2" B3

60|Nozl| 2.81174 | 173.000 | -152.127 | 2" D

Total Weight of Each Detail Type

Total Weight of Saddles 1084.8

Total Weight of Platforms 2979.6

Total Weight of Liquid 15062.8

Total Weight of Insulation 336.0

Total Weight of Stiffeners 128.3

Total Weight of Nozzles 2140.5

---------------------------------------------------------------

Sum of the Detail Weights 21732.0 kg

Weight Summary

Fabricated Wt. - Bare Weight W/O Removable Internals 14227.5 kg

Shop Test Wt. - Fabricated Weight + Water ( Full ) 63114.4 kg

Shipping Wt. - Fab. Wt + Rem. Intls.+ Shipping App. 17543.1 kg

Erected Wt. - Fab. Wt + Rem. Intls.+ Insul. (etc) 17543.1 kg

Ope. Wt. no Liq - Fab. Wt + Intls. + Details + Wghts. 17543.1 kg

Operating Wt. - Empty Wt. + Operating Liquid (No CA) 32605.9 kg

Oper. Wt. + CA - Corr Wt. + Operating Liquid 30486.2 kg

Field Test Wt. - Empty Weight + Water (Full) 64535.0 kg

Note: The Corroded Weight and thickness are used in the Horizontal

Vessel Analysis (Ope Case) and Earthquake Load Calculations.

Note: The Field Test weight as computed in the corroded condition.

Outside Surface Areas of Elements

| | Surface |

From| To | Area |

| | cm² |

----------------------------

10| 20| 91386.6 |

20| 30| 115824. |

30| 40| 408684. |

40| 50| 89095.6 |

50| 60| 91386.6 |

60| 70| 6478.07 |

----------------------------

Total 802854.562 cm²

PVElite is a registered trademark of COADE, Inc. [2010]

PV Elite 2010 Licensee: GULF STEEL WORKS 1

FileName : DC-7235-011-012-D-0003-001 Rev 03_LIFTING LUG-----

Center of Gravity Calculation : Step: 9 12:27p Jul 29,2010

Shop/Field Installation Options :

Platform(s) installed in the Shop.

Insulation is installed in the Shop.

Note : The CG is computed from the first Element From Node

Center of Gravity of Saddles 3500.0 mm

Center of Gravity of Platforms 3436.8 mm

Center of Gravity of Liquid 3513.1 mm

Center of Gravity of Insulation 3533.5 mm

Center of Gravity of Stiffening Rings 3830.0 mm

Center of Gravity of Nozzles 3597.3 mm

Center of Gravity of Bare Shell New and Cold 3490.96 mm

Center of Gravity of Bare Shell Corroded 3482.30 mm

Vessel CG in the Operating Condition 3503.83 mm

Vessel CG in the Fabricated (Shop/Empty) Condition 3498.59 mm

Rigging Analysis Results:

Total Effective Length of Vessel for this analysis 7000.00 mm

Total vessel weight (No Liquid) Twt 150524.19 N

Impact weight multiplication factor Imp 1.50

Design lifting weight, DWT = Imp * Twt 225786.28 N

Elevation of the Tailing Lug (bottom) 700.00 mm

Elevation of the Lifting Lug (top ) 6300.00 mm

Design Reaction force at the tailing lug 112950.12 N

Design Reaction force at the lifting lug 112836.16 N

CG Distance from Tailing Lug 2798.59 mm

CG Distance from the Nearer Lifting Lug 2798.59 mm

Critical Values:

Max Stress Elevation Allowables

N/mm² mm N/mm²

-----------|-----------|---------------|------------------------

Bending | 0.40 | 830.00 | 98.23 (UG-23)

Shear | -0.57 | 10.00 | 82.53 (0.7*S)

-----------|-----------|---------------|------------------------

Forces and Moments at selected elevations (not all analysis points shown):

Distance Bending Moment Bending Stress Shear Force Shear Stress

mm N-m N/mm² N N/mm²

------------------------------------------------------------------------------

0.00 0.0 0.0 -55909.0 -0.5

50.00 11625.1 0.1 -60209.7 -0.4

1350.00 28966.4 0.3 -864.0 0.0

5950.00 27994.6 0.3 -33119.2 -0.2

6950.00 0.0 0.0 0.0 0.0

Unity Check (Actual Stress / Allowable Stress):

Maximum Unity Check is 0.0040 at elevation 829.9999 mm - Must be <=1

Note: The rigging analysis is performed using a uniformly distributed load.

--- Plot data successfully generated ...----

PVElite is a registered trademark of COADE, Inc. [2010]

PV Elite 2010 Licensee: GULF STEEL WORKS 1

FileName : DC-7235-011-012-D-0003-001 Rev 03_LIFTING LUG-----

Vessel Design Summary : Step: 42 12:27p Jul 29,2010

Design Code: ASME Code Section VIII Division 1, 2007 A-09

Diameter Spec : 2800.000 mm ID

Vessel Design Length, Tangent to Tangent 7000.03 mm

Specified Datum Line Distance 0.00 mm

Shell Material Specification SA-516 60 [Normalized]

Stiffening Ring Material Specification SA-516 60

Nozzle Material Specification SA-350 LF2 [Impact Tested]

Nozzle Material Specification SA-516 60 [Normalized]

Nozzle Material Specification SA-106 B

Re-Pad Material Specification SA-516 60 [Normalized]

Internal Design Temperature 140 C

Internal Design Pressure 5.50 bar

External Design Temperature 150 C

External Design Pressure 0.50 bar

Maximum Allowable Working Pressure 7.48 bar

External Max. Allowable Working Pressure 1.16 bar

Hydrostatic Test Pressure 9.73 bar

Required Minimum Design Metal Temperature 0 C

Warmest Computed Minimum Design Metal Temperature -29 C

Wind Design Code ASCE-98\02\05\IBC-03\06\STS-1

Earthquake Design Code ASCE 7-2002

Element Pressures and MAWP: bar

Element Desc | Design Pres. | External | M.A.W.P | Corrosion

| + Stat. head | Pressure | | Allowance

---------------------------------------------------------------------

RIGHT DISH 5.595 0.500 7.484 3.0000

SHELL -1 5.595 0.500 10.551 3.0000

SHELL-2 5.595 0.500 7.725 3.0000

SHELL-3 5.595 0.500 10.551 3.0000

LEFT DISH 5.595 0.500 7.484 3.0000

BOOT DISH 5.703 0.500 13.325 6.0000

Liquid Level: 1000.00 mm Dens.: 969.556 kg/m³ Sp. Gr.: 0.970

Stiffener Ring Specifications:

Elevation mm Selected Type User Description

3830.00 Bar 115.0 x 14. SR 1

Element "To" Elev Length Element Thk R e q d T h k Joint Eff

Type mm mm mm Int. Ext. Long Circ

-----------------------------------------------------------------------

Ellipse 50.0 50.0 16.0 9.6 ------- 1.00 1.00

Cylinder 1350.0 1300.0 18.0 10.9 ------- 0.85 0.85

Cylinder 5950.0 4600.0 14.0 10.9 ------- 0.85 0.85

Cylinder 6950.0 1000.0 18.0 10.9 ------- 0.85 0.85

Ellipse 7000.0 50.0 16.0 9.6 ------- 1.00 1.00

Ellipse 5200.0 0.0 12.0 7.7 ------- 1.00 1.00

Element thicknesses are shown as Nominal if specified, otherwise are Minimum

PV Elite 2010 Licensee: GULF STEEL WORKS 2

FileName : DC-7235-011-012-D-0003-001 Rev 03_LIFTING LUG-----

Vessel Design Summary : Step: 42 12:27p Jul 29,2010

External Pressure Calculations

| | External | External | External | External |

From| To | Actual T. | Required T.|Des. Press. | M.A.W.P. |

| | mm | mm | bar | bar |

----------------------------------------------------------------

10| 20| 12.0000 | 8.08580 | 0.50001 | 1.56594 |

20| 30| 18.0000 | 10.8794 | 0.50001 | 2.51650 |

30|Ring| 14.0000 | 10.8660 | 0.50001 | 1.15991 |

Ring| 40| 14.0000 | 10.3202 | 0.50001 | 1.39022 |

40| 50| 18.0000 | 10.3325 | 0.50001 | 3.01820 |

50| 60| 12.0000 | 8.08580 | 0.50001 | 1.56594 |

60| 70| 10.0000 | 7.29667 | 0.50001 | 4.74114 |

External Pressure Calculations

| | Actual Len.| Allow. Len.| Ring Inertia | Ring Inertia |

From| To | Bet. Stiff.| Bet. Stiff.| Required | Available |

| | mm | mm | mm**4 | mm**4 |

-------------------------------------------------------------------

10| 20| No Calc | No Calc | No Calc | No Calc |

20| 30| 4063.33 | 20074.7 | No Calc | No Calc |

30|Ring| 4063.33 | 9320.50 | No Calc | No Calc |

Ring| 40| 3403.33 | 9320.28 | 2.912E+06 | 5.438E+06 |

40| 50| 3403.33 | 20074.5 | No Calc | No Calc |

50| 60| No Calc | No Calc | No Calc | No Calc |

60| 70| No Calc | No Calc | No Calc | No Calc |

Saddle Parameters:

Saddle Width 230.000 mm

Saddle Bearing Angle 120.000 deg.

Centerline Dimension 1815.000 mm

Wear Pad Width 380.000 mm

Wear Pad Thickness 18.000 mm

Wear Pad Bearing Angle 132.000 deg.

Distance from Saddle to Tangent 730.000 mm

Baseplate Length 2016.000 mm

Baseplate Thickness 20.000 mm

Baseplate Width 250.000 mm

Number of Ribs (including outside ribs) 4

Rib Thickness 14.000 mm

Web Thickness 14.000 mm

Height of Center Web 395.000 mm

Summary of Maximum Saddle Loads, Operating Case :

Maximum Vertical Saddle Load 187857.84 N

Maximum Transverse Saddle Shear Load 17072.39 N

Maximum Longitudinal Saddle Shear Load 43346.55 N

Summary of Maximum Saddle Loads, Hydrotest Case :

Maximum Vertical Saddle Load 345317.50 N

Maximum Transverse Saddle Shear Load 8536.20 N

Maximum Longitudinal Saddle Shear Load 5022.32 N

Weights:

Fabricated - Bare W/O Removable Internals 14227.5 kg

Shop Test - Fabricated + Water ( Full ) 63114.4 kg

Shipping - Fab. + Rem. Intls.+ Shipping App. 17543.1 kg

Erected - Fab. + Rem. Intls.+ Insul. (etc) 17543.1 kg

Empty - Fab. + Intls. + Details + Wghts. 17543.1 kg

Operating - Empty + Operating Liquid (No CA) 32605.9 kg

Field Test - Empty Weight + Water (Full) 64535.0 kg

PVElite is a registered trademark of COADE, Inc. [2010]

You might also like

- 11 Worksheet HydrocarbonDocument2 pages11 Worksheet HydrocarbonAakif RazaNo ratings yet

- Solution: WE1 12 Nov 2008Document9 pagesSolution: WE1 12 Nov 2008aauppalNo ratings yet

- 31-9244 Gdf510pxjxx Gdf520pxjxx Adt521pgjxx Gdt535pxjxx Gdt545pxjxx Gdf610pxjxx Gdf620hxjxx Gdt625pxjxx Gdt635hxjxxDocument73 pages31-9244 Gdf510pxjxx Gdf520pxjxx Adt521pgjxx Gdt535pxjxx Gdt545pxjxx Gdf610pxjxx Gdf620hxjxx Gdt625pxjxx Gdt635hxjxxAPmanualshop zNo ratings yet

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag50% (2)

- V1121 FLPC MS Ga 6024017 PDFDocument219 pagesV1121 FLPC MS Ga 6024017 PDFDarshan PanchalNo ratings yet

- ESR0055024ACAL1004 0cDocument24 pagesESR0055024ACAL1004 0ckayaltharanNo ratings yet

- Flange Mawp Reduction PV Elite PDFDocument8 pagesFlange Mawp Reduction PV Elite PDFDarshan PanchalNo ratings yet

- How To Consider Sea Transportation LoadDocument7 pagesHow To Consider Sea Transportation LoadSharun SureshNo ratings yet

- Design Calculation: Fuel Gas Scrubber TAG NO: V-6011Document239 pagesDesign Calculation: Fuel Gas Scrubber TAG NO: V-6011Peja Jusoh100% (1)

- V-340 OutDocument14 pagesV-340 OutSachin5586No ratings yet

- WRC-107 Lifting Trunnions - Horz. LiftDocument5 pagesWRC-107 Lifting Trunnions - Horz. LiftManoj MulikNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Help For P-V Elite PDFDocument39 pagesHelp For P-V Elite PDFTushar MangratiNo ratings yet

- Skirt Design - For Small VesselsDocument7 pagesSkirt Design - For Small VesselsSakthi VelNo ratings yet

- Tutorial of WRC 107 For TrunnionDocument10 pagesTutorial of WRC 107 For TrunnionGuru MoorthiNo ratings yet

- Page No:-Rev: - Doc., No: - Tag No: - 01. Cover Sheet Manufacture AddressDocument93 pagesPage No:-Rev: - Doc., No: - Tag No: - 01. Cover Sheet Manufacture AddressSiva baalanNo ratings yet

- DC S3-1301 REV.0 OriginalDocument93 pagesDC S3-1301 REV.0 OriginalPeja JusohNo ratings yet

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFBimal DeyNo ratings yet

- Eqn Reference ASME BPVC r1sDocument5 pagesEqn Reference ASME BPVC r1sagarcia654127No ratings yet

- Pressure Vessel Design Old (Eugyene F Megysey)Document31 pagesPressure Vessel Design Old (Eugyene F Megysey)David FonsecaNo ratings yet

- Air Vessel (Final Sent To AI) - 1Document38 pagesAir Vessel (Final Sent To AI) - 1hgagselim2012No ratings yet

- External Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitDocument1 pageExternal Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitSachinNo ratings yet

- 3D Stress CriteriaDocument5 pages3D Stress CriteriaFernando DiezNo ratings yet

- Pressure Vessel Design Training - Course ContentDocument13 pagesPressure Vessel Design Training - Course Contentamol shindeNo ratings yet

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDocument1 pageTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1No ratings yet

- Nozzle Interference Error SolvingDocument2 pagesNozzle Interference Error SolvingSakthi VelNo ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal Sattu100% (1)

- Case Study To Find Tank Nozzle Stiffness, Flexibility and Allowable Loads by API650 Using PASS START PROFDocument15 pagesCase Study To Find Tank Nozzle Stiffness, Flexibility and Allowable Loads by API650 Using PASS START PROFJafer Sayed100% (1)

- PEC EN STN C 13619 17 Mar 2014Document169 pagesPEC EN STN C 13619 17 Mar 2014Raja RamNo ratings yet

- 3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankDocument4 pages3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankNurul HudaNo ratings yet

- Comparative Research Into The Load-Bearing Capacity of Horizontal Pressure Vessels Supported by SaddlesDocument13 pagesComparative Research Into The Load-Bearing Capacity of Horizontal Pressure Vessels Supported by SaddlesMarek AdamczykNo ratings yet

- Spreaer Beam&Lifting Line Beam p3Document2 pagesSpreaer Beam&Lifting Line Beam p3Sabrang LorNo ratings yet

- HE Header E535Document91 pagesHE Header E535rizal mubarokNo ratings yet

- Calculations For Rectangular Storage TankDocument44 pagesCalculations For Rectangular Storage TankSiva ShankarNo ratings yet

- Design of Partition PlateDocument5 pagesDesign of Partition Platepippo2378793No ratings yet

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

- Cone To Shell ReinforcementDocument4 pagesCone To Shell ReinforcementSajal KulshresthaNo ratings yet

- 003-Heat ExchangerDocument299 pages003-Heat ExchangerVijayshanker GuptaNo ratings yet

- Deaera DesignDocument13 pagesDeaera DesignBhanu K PrakashNo ratings yet

- 134004-SEP-MEC-DAT-0004 Rev.B2 PDFDocument11 pages134004-SEP-MEC-DAT-0004 Rev.B2 PDFDhakshina KNo ratings yet

- Tailing Lifting Lug Design 57 V 202 r2Document10 pagesTailing Lifting Lug Design 57 V 202 r2Dinesh KhaparkarNo ratings yet

- Project JG Summit Stage1 Expansion Title: Screening Procedure As Per ASME Section VIII, Div 2. PE3-E6552Document1 pageProject JG Summit Stage1 Expansion Title: Screening Procedure As Per ASME Section VIII, Div 2. PE3-E6552Darshan PanchalNo ratings yet

- Tanky 53 KL Rev.1Document187 pagesTanky 53 KL Rev.1Priyo Jati WahyonoNo ratings yet

- Davit With ElbowDocument2 pagesDavit With Elbownitin400100% (1)

- CAEPIPE Users ManualDocument257 pagesCAEPIPE Users ManualFATIMA TORRADO CASASNo ratings yet

- Piping Engineering - Tank Nozzle Loads 1Document1 pagePiping Engineering - Tank Nozzle Loads 1Nasrul Adli100% (1)

- Wind / Seismic Design For Horizontal Vessels: Longitudinal ForcesDocument2 pagesWind / Seismic Design For Horizontal Vessels: Longitudinal ForcesMasoodMiyanNo ratings yet

- VP 3209 e 031a 02 0013 Rev.dDocument254 pagesVP 3209 e 031a 02 0013 Rev.dSuryaprakashNo ratings yet

- And Dipstick Chart: Scroll Down For InstructionsDocument2 pagesAnd Dipstick Chart: Scroll Down For Instructionspowder18No ratings yet

- Large Horizontal Vessel Supported by Two Saddles Stress AnalysisDocument7 pagesLarge Horizontal Vessel Supported by Two Saddles Stress AnalysisSiva baalan100% (1)

- 16 B 06 HDocument20 pages16 B 06 HVaibhav Bhoir0% (1)

- What Is An ASME Appendix 2 Flange Design PDFDocument1 pageWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanaleNo ratings yet

- Spherical ShellsDocument3 pagesSpherical ShellsEng-CalculationsNo ratings yet

- Openings Reinforced by Elliptical or Obround Nozzles Normal To The Shell Wall (For Cylindrical and Conical Shells) EN13445-3 - 9.4.4.2-1Document1 pageOpenings Reinforced by Elliptical or Obround Nozzles Normal To The Shell Wall (For Cylindrical and Conical Shells) EN13445-3 - 9.4.4.2-1met-calcNo ratings yet

- Nozzle Node No. 4950Document6 pagesNozzle Node No. 4950Christopher BrownNo ratings yet

- 28 Roark Flat PlatesDocument14 pages28 Roark Flat Platesgutmont0% (1)

- Design by AnalysisDocument22 pagesDesign by AnalysisJEELE77No ratings yet

- Output Data: Design CaseDocument3 pagesOutput Data: Design CaseAnonymous RytT6uvX1No ratings yet

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 pagesFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyNo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Vessel Design SummaryDocument3 pagesVessel Design SummaryMiguel HurtadoNo ratings yet

- 22-V-0101-Transportation CaseDocument33 pages22-V-0101-Transportation CasesanjayNo ratings yet

- Newspaper Ad PDFDocument1 pageNewspaper Ad PDFakhilNo ratings yet

- FIVB VB Calendar 20201Document1 pageFIVB VB Calendar 20201akhilNo ratings yet

- Department of Clinical Biochemistry: Fasting Blood Sugar (FBS) 169 MG/DLDocument1 pageDepartment of Clinical Biochemistry: Fasting Blood Sugar (FBS) 169 MG/DLakhilNo ratings yet

- PDFDocument1 pagePDFakhilNo ratings yet

- Assembly Sandwich Machine (ASM) RFP: Kalha RestaurantsDocument4 pagesAssembly Sandwich Machine (ASM) RFP: Kalha RestaurantsakhilNo ratings yet

- ESL Lock Authorization Code Update Procedure PDFDocument1 pageESL Lock Authorization Code Update Procedure PDFakhilNo ratings yet

- Fluid MechanicsDocument35 pagesFluid MechanicsarultkNo ratings yet

- To Study Strength Characteristics of Concrete With Rice Husk AshDocument6 pagesTo Study Strength Characteristics of Concrete With Rice Husk Ashabdulshkur muridNo ratings yet

- AERSEN, Manual IHM InglêsDocument33 pagesAERSEN, Manual IHM Inglêswagner machado de moraes100% (1)

- Lecture 1. Introduction To Various Analytical TechniquesDocument22 pagesLecture 1. Introduction To Various Analytical TechniquesMoiz AhmedNo ratings yet

- Formative Assessment ICP Matter & Acid BaseDocument3 pagesFormative Assessment ICP Matter & Acid BaseDarryl Rafa Vinan HalpitoNo ratings yet

- Laboratory Experiment: Flow Through PipesDocument18 pagesLaboratory Experiment: Flow Through PipesSarah HaiderNo ratings yet

- LEC10-E1236 - Control 1Document8 pagesLEC10-E1236 - Control 1MandolinNo ratings yet

- Super Pikon Na AkoDocument5 pagesSuper Pikon Na AkoSecretNo ratings yet

- E MC 2 WorksheetDocument2 pagesE MC 2 WorksheetVenkata Sairam Mani Sravan Jakkireddy- SNIS182228No ratings yet

- Phillips, J. D. Weathering Instability and Landscape EvolutionDocument18 pagesPhillips, J. D. Weathering Instability and Landscape EvolutionJorge MarquesNo ratings yet

- MDS-C1 Series SPECIFICATIONS MANUAL bnp-c3040 (Eng) DDocument265 pagesMDS-C1 Series SPECIFICATIONS MANUAL bnp-c3040 (Eng) DEdimilson RodriguesNo ratings yet

- Ecodrive03 NC Controller With Parallel Interface Dok Ecodr3 FLP 01vrs fk01 Ae P IndramatDocument283 pagesEcodrive03 NC Controller With Parallel Interface Dok Ecodr3 FLP 01vrs fk01 Ae P Indramatsouza nunesNo ratings yet

- Ber Abd Bei FunctionsDocument3 pagesBer Abd Bei FunctionsChhavi Kaushik100% (1)

- Analytical Methods - Trigonometric MethodsDocument20 pagesAnalytical Methods - Trigonometric MethodsSteven GoddardNo ratings yet

- Atomic PhysicsDocument128 pagesAtomic PhysicsApoorva PrakashNo ratings yet

- KKK Catalog - CMPLTDocument38 pagesKKK Catalog - CMPLTAnonymous kAANwztNo ratings yet

- Process Safety Progress - 2023 - Britton - Avoiding Water Hammer and Other Hydraulic TransientsDocument12 pagesProcess Safety Progress - 2023 - Britton - Avoiding Water Hammer and Other Hydraulic TransientsgajatuNo ratings yet

- SGC SG-230 Smart TunerDocument81 pagesSGC SG-230 Smart TunerRuthCdhara100% (1)

- 10-Chem ATP (SVKM)Document7 pages10-Chem ATP (SVKM)Jashan LoombaNo ratings yet

- Dwnload Full Understanding Weather and Climate 6th Edition Aguado Solutions Manual PDFDocument35 pagesDwnload Full Understanding Weather and Climate 6th Edition Aguado Solutions Manual PDFkotelamalbec6100% (9)

- Rsos.191204 LCTEMDocument24 pagesRsos.191204 LCTEMRamesh SoniNo ratings yet

- Aryl HalidesDocument23 pagesAryl HalidesSteveNo ratings yet

- Pavement Engineering 4300:565 Assignment #5 Spring 2014: Submitted by Mir Shahnewaz Arefin Student Id: 2824475Document8 pagesPavement Engineering 4300:565 Assignment #5 Spring 2014: Submitted by Mir Shahnewaz Arefin Student Id: 2824475Mir Shahnewaz ArefinNo ratings yet

- FM 5130Document66 pagesFM 5130Aswini Kr KarmakarNo ratings yet

- CX06PM To CX08PM Pilot-Operated: 2/2-Way Coaxial Valve Plug-InDocument4 pagesCX06PM To CX08PM Pilot-Operated: 2/2-Way Coaxial Valve Plug-InFelipe Pisklevits LaubeNo ratings yet

- BRE 202 LNG ManualDocument69 pagesBRE 202 LNG ManualAlberto Abrajan100% (1)

- Certificate of Bollard Pull - TRICAHUE IDocument2 pagesCertificate of Bollard Pull - TRICAHUE IRuben Rodriguez100% (1)

- SECTION 16120 Conductors and Cables Rev 0Document49 pagesSECTION 16120 Conductors and Cables Rev 0Ahmed HashimNo ratings yet