Professional Documents

Culture Documents

Carrier Capacity and Commitment: Susan Beaver & Caleb Warner July 29, 2013

Uploaded by

Jakkana PremOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carrier Capacity and Commitment: Susan Beaver & Caleb Warner July 29, 2013

Uploaded by

Jakkana PremCopyright:

Available Formats

Carrier Capacity and

Commitment

Susan Beaver & Caleb Warner

July 29, 2013

OTM_SIG_July 29, 2013

Page 1

Who We Are – RockTenn

Overview ♦ One of North America’s leading integrated manufacturers of

corrugated and consumer packaging

Net Sales ♦ $9.2 billion (LTM 1Q FY2013)

Employees ♦ 26,000

Production ♦ 9.3 million tons of mill capacity

♦ 100 billion square feet of converting production

♦ Approximately 60% integrated

Locations ♦ 213 operating facilities, primarily in North America

LTM 1Q FY2013 LTM 1Q FY2013

Net Sales: $9.2 billion Segment Income: $741 million (1)

Consumer Consumer

Packaging Packaging

& Recycling & Recycling

34% 47%

Corrugated Corrugated

Packaging Packaging

66% 53%

(1) Excludes $6.7 million of post-closure losses at Matane and $0.4 million of acquisition inventory step-up expense

OTM_SIG_July 29, 2013

Page 2

RockTenn’s Core Business Principles

RockTenn will be the most respected company in our

business by:

♦ Providing superior paperboard, packaging and marketing solutions for

consumer products companies at very low costs

♦ Investing for competitive advantage

♦ Maximizing the efficiency of our manufacturing processes by optimizing

economies of scale

♦ Systematically improving processes and reducing costs throughout the

company

♦ Seeking acquisitions that can dramatically improve the business

OTM_SIG_July 29, 2013

Page 3

Who We Are

Containerboard

Recycling Consumer Corrugated Packaging

Mills

♦ 2nd largest North American ♦ One of the largest ♦ 2nd largest North American ♦ 2nd largest North American

producer of paper recyclers in North producer of coated producer of corrugated packaging

containerboard America managing over recycled paperboard ♦ 2nd largest North American

8 million tons of (CRB)

♦ Largest producer of white ♦ Net Sales of approximately $6.2

recycled fiber annually

top linerboard ♦ Net Sales approximately billion (LTM 1Q FY2013)

♦ Net sales of $1.15 $925 million (LTM 1Q ♦

♦ 4,500 employees 15,780 employees

billion (LTM Q1 FY FY2013)

♦ 13 mills in the U.S. and 2013) ♦ 101 converting facilities

♦ 11 mills in the U.S. throughout U.S., Canada, Mexico

Canada

♦ 850 employees

♦ Approximately 45% ♦ Products include:

♦ Approximately 70%

♦ 32 U.S. recycling plants integrated

integrated ♦ Corrugated containers

♦ Trading operations ♦ All wholly-owned North ♦

♦ All North American mills Preprint linerboard

headquartered in American mills are

are certified to the SFI ♦ Retail ready packaging

Atlanta certified to the SFI Fiber

Fiber Sourcing standard

Sourcing standard and ♦ Food service packaging

and Triple Chain-of- ♦ 3 international trading

Triple Chain-of-Custody ♦ All North American mills are

Custody (SFI,FSC and offices

(SFI,FSC and PEFC) certified to the SFI Fiber Sourcing

PEFC) certified

♦ Manage 100% certified standard and Triple Chain-of-

RockTenn fiber supply Custody (SFI, FSC and PEFC)

and marketing certified

OTM_SIG_July 29, 2013

Page 4

RockTenn and OTM

♦ Upgraded to version 6.2.8 on June 8, 2013

♦ For 11 US corrugated mills, orders are planned for outbound

rollstock shipments and inbound recycle shipments

♦ 150 active carriers

♦ Plan orders into shipments on receipt

– Orders can create one or many shipments

♦ Tender via EDI and e-mail

♦ Receive shipment status updates via EDI from carriers

♦ Receive shipment status updates from internal systems

♦ Receive actual shipment data, re-rate and settle without invoices

from carriers

♦ Return shipment cost data to upstream systems for use in product

invoicing

OTM_SIG_July 29, 2013

Page 5

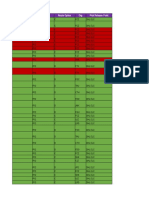

Carrier Capacity & Commitment:

OTM Options

Definition Pros/Cons RockTenn

Implementation

Capacity Maximum number of Ensures that carriers will Current State

Management shipments per carrier not be overwhelmed with

in a defined time shipments

period

Commitment Minimum number of Prioritizes Commitment (Near) Future State

Count shipments per carrier Count carriers before

in a defined time lowest cost

period

Commitment Shipments spread over Splits the lane volume Past State

Allocation carriers by lane by across carriers

defined percentage Can be problematic if

volume is volatile

OTM_SIG_July 29, 2013

Page 6

RockTenn’s Business Requirements

♦ Driven by Logistics Operations and Procurement

♦ Business Goals

– Improve capacity and service while remaining cost neutral

– Be a more shipper friendly company

– Allocate a specific number of shipments per day per carrier

– Improve tender acceptance percentage

– Reduce number of spot shipments

– Better alignment of logistics operations and procurement

– First right of refusal for preferred carriers regardless of cost

OTM_SIG_July 29, 2013

Page 7

Current Configuration – Capacity Limits

♦ Capacity Limits

– Prevents any single carrier from being flooded with shipments

• Daily volume is volatile as it is driven by customer demand

– May vary by day, carrier, and location

– Effective during tender process rather than when shipments are built

– Can be executed without bulk planning

♦ Rate Quality Factor

– Used to prefer capacity carriers over non-capacity carriers

OTM_SIG_July 29, 2013

Page 8

Current Configuration – Capacity Limits

♦ Planning Parameters

– Set commitment parameters

♦ Rate Quality Factors

– Set on Rate Offerings to determine carrier order for tendering

♦ Time Period Definition

– Set to Day of Week

OTM_SIG_July 29, 2013

Page 9

OTM Set up Steps

♦ Define the lane FAKE FAKE

♦ Create capacity group ID’s

♦ Create capacity limits

– When done thru UI, OTM automatically creates capacity usage

– Define time window for limit

♦ Update rate offering with capacity group and check box to track

capacity usage

FAKE FAKE

FAKE FAKE

FAKE

OTM_SIG_July 29, 2013

Page 10

On-going maintenance

♦ Update capacity limit

– Increasing capacity presents no issues

– Decreasing the existing limit is challenging

• Set current limit to expire and create new limit

• Manually update capacity usage table

• Check box for override has no effect

♦ Remember to set up when adding new carriers, if applicable

OTM_SIG_July 29, 2013

Page 11

Capacity Limit Issues

♦ Auto-numbering

– Exceeded maximum threshold

– Check capacity usage auto numbering rules

♦ Communication - Procurement, OTM, Carriers

– What does the capacity limit mean?

♦ Changing carrier

– If a carrier is at maximum capacity, the carrier will not display when

changing Service Provider unless ignore constraints is enabled

– OTM may change shipment date to accommodate capacity limit if the LPD

(Late Pick Up Date) is not populated

♦ When expiring capacity, OTM asks “Do you want to deactivate

commitments already in use?”

– Can’t have overlapping usage

– Doesn’t impact shipments that are already built

OTM_SIG_July 29, 2013

Page 12

Commitment Allocation

♦ Commitment Allocation

– Also known as SPA (Service Provider Allocation)

– % by lane

– Executed at time of shipment build

– Should add up to 100%

– Parameters can be configured as to how a tender decline is tracked

against Commitment Allocation

OTM_SIG_July 29, 2013

Page 13

Commitment Allocation Example

♦ Example (with parameter ‘decrease commitment usage when tender

decline’ set to true):

• Carrier A = 50%

• Carrier B = 50%

• Shipment 1 goes to A; A accepts; 100:0

• Shipment 2 goes to B; B accepts: 50:50

• Shipment 3 goes to A; A declines; shipment 3 proceeds to B 33:66

• Shipment 4 goes to A because they are under their 50%;

FAKE1

FAKE2

OTM_SIG_July 29, 2013

Page 14

Commitment Allocation Issues

♦ Tender Declines

– Carrier A has declined substantial number of loads. Carrier A will

receive all tenders on lane in an attempt to reach % commitment due to

parameter setting

♦ High volume on a lane for a time period may cause more loads to

tender to a carrier than can handle

♦ Mode Profile must be defined in planning parameter set

OTM_SIG_July 29, 2013

Page 15

Commitment Count

♦ Commitment Count

– Minimum number of loads per carrier per time period

– Executed at time of shipment build

– Highest priority is fulfilling commitment regardless of cost

FAKE FAKE

OTM_SIG_July 29, 2013

Page 16

Commitment Count Example

Commitment Lane A Lane B Lane C

♦ OTM determines the

Carrier 1 1 300 600 600

Carrier 2 1 550 700 675

lowest cost solution

Carrier 3 1 400 900 800 while filling

commitment

Low Cost: $1500 – 1st order is for lane A

Cost with Commitment: $1675 Carrier 3 is selected

– 2nd order is for lane B

Carrier 1 is selected

– 3rd order is for lane C

Carrier 2 is selected

OTM_SIG_July 29, 2013

Page 17

Commitment Count Issues

♦ Explaining how the process works is difficult

♦ In order to generate best cost solution, bulk planning is required

♦ Carrier may be flooded on high volume lanes

♦ Determining commitment count is difficult if your volumes fluctuate

♦ Insufficient volume on a lane will not fill commitments

– Example: 10 commitment count and only 5 shipments

OTM_SIG_July 29, 2013

Page 18

Overall Lessons Learned

♦ Business requirements need to be clearly defined

– Is the goal to spread shipments across carrier base?

– Is the goal to always award to lowest cost carrier?

– Is the goal to guarantee loads per carrier?

♦ Definition of commitment

– Procurement versus OTM

• Actual pick up versus planned pick up

♦ Requires tuning and maintenance

♦ Education

– Why is OTM working this way?

OTM_SIG_July 29, 2013

Page 19

Questions?

OTM_SIG_July 29, 2013

Page 20

You might also like

- Site Surveys for OTM ExpansionDocument19 pagesSite Surveys for OTM ExpansionNithiyananth DNo ratings yet

- Consolidated Container Company Investor OverviewDocument16 pagesConsolidated Container Company Investor OverviewollieNo ratings yet

- Corwn, Cork and Seal - Group 6 - 2Document6 pagesCorwn, Cork and Seal - Group 6 - 2Sumit RajNo ratings yet

- SRF-interacts-with-Institutional-Investors-in-Mumbai (India Tyre Cord Fabrics)Document25 pagesSRF-interacts-with-Institutional-Investors-in-Mumbai (India Tyre Cord Fabrics)ChanduSaiHemanthNo ratings yet

- Economics Group 5 RajmaDocument17 pagesEconomics Group 5 RajmaNidhi TiwariNo ratings yet

- GA2 - SM - Group A10Document10 pagesGA2 - SM - Group A10Saumya SharmaNo ratings yet

- Contactplasma - About UsDocument29 pagesContactplasma - About UsNgoc QuyenNo ratings yet

- Paper Excellence - Global ProducerDocument4 pagesPaper Excellence - Global ProducerPaper Excellence CanadaNo ratings yet

- Institutional Presentation: March 2012Document46 pagesInstitutional Presentation: March 2012Klabin_RINo ratings yet

- Clideunion-Vendor Info - API 610Document46 pagesClideunion-Vendor Info - API 6108400065602979100% (1)

- Grupo Bimbo Investor Presentation 1Q18Document21 pagesGrupo Bimbo Investor Presentation 1Q18LauraNo ratings yet

- Export Small Green Cardamom Project ReportDocument27 pagesExport Small Green Cardamom Project ReportK K JayanNo ratings yet

- Management Plan: 28th April 2017Document24 pagesManagement Plan: 28th April 2017MBI TABENo ratings yet

- 97 Countries: Complete Farm Mechanization SolutionDocument35 pages97 Countries: Complete Farm Mechanization SolutionharendraNo ratings yet

- Cargill 2016 Annual ReportDocument20 pagesCargill 2016 Annual Reportヒルデガルダ HILDEGARDE0% (1)

- Group 9 - Financial Analysis of Shree Renuka SugarsDocument23 pagesGroup 9 - Financial Analysis of Shree Renuka SugarsNeerajKumarNo ratings yet

- Institutional Presentation: July 2012Document44 pagesInstitutional Presentation: July 2012Klabin_RINo ratings yet

- The Food Processing Sector in India: Madras Consultancy Group, ChennaiDocument18 pagesThe Food Processing Sector in India: Madras Consultancy Group, Chennairohit7853No ratings yet

- Paper Business: Segment Revenue (R'million) Underlying Operating Profit (R'million) Operating Assets (R'million)Document2 pagesPaper Business: Segment Revenue (R'million) Underlying Operating Profit (R'million) Operating Assets (R'million)kago khachanaNo ratings yet

- Group11 SecB Case4 DiaperIndustryDocument9 pagesGroup11 SecB Case4 DiaperIndustryaabfjabfuagfuegbfNo ratings yet

- Baird 2010 Industrials Conference 2010 Industrials ConferenceDocument30 pagesBaird 2010 Industrials Conference 2010 Industrials ConferencevbrajuNo ratings yet

- 08.00 Raju Goyal CTO UltraTech CementDocument11 pages08.00 Raju Goyal CTO UltraTech CementParamananda SinghNo ratings yet

- Abaca: Internationa L Trade FORDocument17 pagesAbaca: Internationa L Trade FORMWhiteNo ratings yet

- IOC Supply Chain Optimisation Aug 2014Document41 pagesIOC Supply Chain Optimisation Aug 2014AvinawNo ratings yet

- Driving The Global Cannabis Industry: February 2019Document22 pagesDriving The Global Cannabis Industry: February 2019Sameer MahomedNo ratings yet

- Apex Frozen Foods Limited: Not RatedDocument6 pagesApex Frozen Foods Limited: Not Ratedarif420_999No ratings yet

- Presentacion NN CaguasDocument17 pagesPresentacion NN CaguasUpendraAkurajuNo ratings yet

- Industry & Customer InsightsDocument15 pagesIndustry & Customer InsightsSusmeet BiswasNo ratings yet

- Business Plan Presentation V4Document40 pagesBusiness Plan Presentation V4Shakil Jowad RahimNo ratings yet

- Earnings Presentation (Company Update)Document13 pagesEarnings Presentation (Company Update)Shyam SunderNo ratings yet

- Apresentao APIMECV03 INGDocument39 pagesApresentao APIMECV03 INGKlabin_RINo ratings yet

- Cement - PACRA Research - Mar'22 - 1648648517Document34 pagesCement - PACRA Research - Mar'22 - 1648648517Ammad TahirNo ratings yet

- Transnational StrategyDocument37 pagesTransnational Strategyvatsyk100% (1)

- Scientific GlassDocument9 pagesScientific GlassLajwanti M JethwaniNo ratings yet

- DOW Presentation at ECPA GA Jan262017 SharedDocument35 pagesDOW Presentation at ECPA GA Jan262017 SharedYu-Chih LinNo ratings yet

- Organigraph Group PresentationDocument7 pagesOrganigraph Group PresentationSatish SeshayyaNo ratings yet

- Reckitt Benckiser StratagemDocument10 pagesReckitt Benckiser StratagemChandan GoyalNo ratings yet

- Presentation 12122018Document15 pagesPresentation 12122018FelipeNo ratings yet

- Barrier EPN Pres 02-13-07Document41 pagesBarrier EPN Pres 02-13-07PermadiBayuAjiNo ratings yet

- Contingency Measures: Trade EffectsDocument42 pagesContingency Measures: Trade EffectsBIKRAMJIT KUNDU MBA IB 2018-20 (KOL)No ratings yet

- Paper and Packaging - PACRA Research - Nov'22 - 1667673640Document25 pagesPaper and Packaging - PACRA Research - Nov'22 - 1667673640Ali ArsalanNo ratings yet

- Group 7 - Section B - NFDocument8 pagesGroup 7 - Section B - NFSiddharthNo ratings yet

- Confection BusinessDocument18 pagesConfection BusinessTim813No ratings yet

- Crown Cork Strategy Case StudyDocument9 pagesCrown Cork Strategy Case StudySandeep Yamgekar100% (1)

- Three Years Business Plan KCP 2019-2021 FinalDocument18 pagesThree Years Business Plan KCP 2019-2021 Finalfhadli kunNo ratings yet

- Merger and AcquisitionDocument17 pagesMerger and Acquisitionshubham JaiswalNo ratings yet

- Quality First: Building Quality Culture and Capabilities: Experience Sharing by LupinDocument20 pagesQuality First: Building Quality Culture and Capabilities: Experience Sharing by LupinhuykhiemNo ratings yet

- Food Processing Notes For UPSC CSEDocument14 pagesFood Processing Notes For UPSC CSESuraj Chopade100% (1)

- Group E - PepsiCoDocument10 pagesGroup E - PepsiCoVatsal MaheshwariNo ratings yet

- Institutional PresentationDocument45 pagesInstitutional PresentationKlabin_RINo ratings yet

- Olam InvestorPresentation Aug2018Document49 pagesOlam InvestorPresentation Aug2018Trade NerdNo ratings yet

- EOS B Group 11 The Disposable Diaper Industry in 1974Document7 pagesEOS B Group 11 The Disposable Diaper Industry in 1974aabfjabfuagfuegbfNo ratings yet

- Presentedto: Sir Fareed Fareedy: By: Amna Nazar Saba Nazar Simran Tariq Zona ZaidiDocument11 pagesPresentedto: Sir Fareed Fareedy: By: Amna Nazar Saba Nazar Simran Tariq Zona ZaidiGohar AbidNo ratings yet

- Tronox Investor Presentation: November 2021Document42 pagesTronox Investor Presentation: November 2021Dyala AshrafNo ratings yet

- DRDGold Jan 2010 PresentationDocument10 pagesDRDGold Jan 2010 PresentationAla BasterNo ratings yet

- Forward Integration or Horizontal Expansion Rev TheoDocument32 pagesForward Integration or Horizontal Expansion Rev TheoJawad FarisiNo ratings yet

- Recycling Waste Materials Business PlanDocument53 pagesRecycling Waste Materials Business Planbilalcivic100% (4)

- Towel Sector - PACRA Research - Jan'22 - 1642852101Document24 pagesTowel Sector - PACRA Research - Jan'22 - 1642852101Hamza AsifNo ratings yet

- From Kitchen to Consumer: The Entrepreneur's Guide to Commercial Food PreparationFrom EverandFrom Kitchen to Consumer: The Entrepreneur's Guide to Commercial Food PreparationRating: 3 out of 5 stars3/5 (1)

- OTM_essentials_2Document117 pagesOTM_essentials_2Jakkana PremNo ratings yet

- RNL FutureDocument13 pagesRNL FutureJakkana PremNo ratings yet

- E92130 01Document56 pagesE92130 01RajiRajeshNo ratings yet

- 1 Delivery Id:: Bts Option B So-Ss: 125071740 Delivery Interfaced To Otm With Pdate SysdateDocument4 pages1 Delivery Id:: Bts Option B So-Ss: 125071740 Delivery Interfaced To Otm With Pdate SysdateJakkana PremNo ratings yet

- Otm Tables Related PDFDocument130 pagesOtm Tables Related PDFJakkana PremNo ratings yet

- Move OM To ShipDocument1 pageMove OM To ShipJakkana PremNo ratings yet

- Oracle® Transportation Management: Administration Guide Release 6.1 Part No. E16550-04Document148 pagesOracle® Transportation Management: Administration Guide Release 6.1 Part No. E16550-04Jakkana PremNo ratings yet

- Otm Training InfoDocument3 pagesOtm Training InfoJakkana Prem100% (1)

- Carrier Capacity and Commitment: Susan Beaver & Caleb Warner July 29, 2013Document20 pagesCarrier Capacity and Commitment: Susan Beaver & Caleb Warner July 29, 2013Jakkana PremNo ratings yet

- DHL ELC R12 Status ReportDocument27 pagesDHL ELC R12 Status ReportJakkana PremNo ratings yet

- IRCTC e-Ticket Electronic Reservation SlipDocument3 pagesIRCTC e-Ticket Electronic Reservation SlipKartik Modi100% (1)

- Form XVI - Muster Roll: Premkumar Jakkana Jakkana PentayyaDocument3 pagesForm XVI - Muster Roll: Premkumar Jakkana Jakkana PentayyaJakkana PremNo ratings yet

- QuestDocument1 pageQuestJakkana PremNo ratings yet

- UnwantedDocument1 pageUnwantedJakkana PremNo ratings yet

- Ship Unit LineDocument5 pagesShip Unit LineJakkana PremNo ratings yet

- Ship UnitDocument12 pagesShip UnitJakkana PremNo ratings yet

- Chapter 7: Introduction To Regular Income Tax: 1. General in CoverageDocument19 pagesChapter 7: Introduction To Regular Income Tax: 1. General in CoverageJulie Mae Caling Malit33% (3)

- Types of Price DiscountsDocument53 pagesTypes of Price DiscountsAmit RajNo ratings yet

- Microeconomics Chapter 1 IntroDocument28 pagesMicroeconomics Chapter 1 IntroMc NierraNo ratings yet

- Problems 3) Inadequate Expertise (Lack of Knowledge and Skills)Document3 pagesProblems 3) Inadequate Expertise (Lack of Knowledge and Skills)ROS SHAHNo ratings yet

- Balancesheet of Infosys LTD As On 31st March 2018-2020Document29 pagesBalancesheet of Infosys LTD As On 31st March 2018-2020Tapan AnkleshwariaNo ratings yet

- Chapter 7 - FranchisingDocument49 pagesChapter 7 - FranchisingAlice GasparNo ratings yet

- Milkovich/Newman: Compensation, Ninth Edition: Defining Internal AlignmentDocument29 pagesMilkovich/Newman: Compensation, Ninth Edition: Defining Internal AlignmentAbdullahiNo ratings yet

- M10 TodaroSmith013934 11 Econ C10Document35 pagesM10 TodaroSmith013934 11 Econ C10Neil Jasper CorozaNo ratings yet

- Income Approach MCQsDocument8 pagesIncome Approach MCQsAnirban DeyNo ratings yet

- Abhishek Raj CVDocument4 pagesAbhishek Raj CVSairam VundavilliNo ratings yet

- Financial Analysis and Business Valuation of Viet-Y SteelDocument6 pagesFinancial Analysis and Business Valuation of Viet-Y SteelsenNo ratings yet

- Questions FinanceDocument3 pagesQuestions Financeanish narayanNo ratings yet

- Laws Pertaining To Private Personal and Commercial RelationsDocument10 pagesLaws Pertaining To Private Personal and Commercial RelationsJean TubacNo ratings yet

- Inventory VoucherDocument2 pagesInventory VoucherPAWAN KUMARNo ratings yet

- Cost Sheet Format To CustomersDocument32 pagesCost Sheet Format To Customersthetrilight2023No ratings yet

- ResumeDocument2 pagesResumechantellrambergNo ratings yet

- Can We Build It?: Should We Build It?: If We Build It, Will They Come?Document12 pagesCan We Build It?: Should We Build It?: If We Build It, Will They Come?anisa aprianiNo ratings yet

- Lesson 3 Outlining The Concepts Applied Across SAP ERP ApplicationsDocument25 pagesLesson 3 Outlining The Concepts Applied Across SAP ERP ApplicationsAsharNo ratings yet

- Air India - Indian Airlines MergerDocument14 pagesAir India - Indian Airlines MergerMridu ChadhaNo ratings yet

- Asset Integrity BV F 2143 IntroDocument39 pagesAsset Integrity BV F 2143 IntroHafizuddin PjoeNo ratings yet

- 02C) Financial Ratios - ExamplesDocument21 pages02C) Financial Ratios - ExamplesMuhammad AtherNo ratings yet

- Planilla de Jornales-Trabajos en GeneralDocument13 pagesPlanilla de Jornales-Trabajos en GeneralYacquelin ReyesNo ratings yet

- Anne Camille Mora - ResumeDocument1 pageAnne Camille Mora - ResumeIan Shain YapNo ratings yet

- List of Scheduled Commercial Banks: (Refer To para 2 (B) of Notification Dated October 08, 2018)Document2 pagesList of Scheduled Commercial Banks: (Refer To para 2 (B) of Notification Dated October 08, 2018)Vikram PhalakNo ratings yet

- Andrew-Carter, IncDocument18 pagesAndrew-Carter, IncCharysa JanuarizkaNo ratings yet

- Procter & GambleDocument2 pagesProcter & Gamblehayatun nufusNo ratings yet

- SITARAM JINDAL FOUNDATION DONATION APPLICATIONDocument2 pagesSITARAM JINDAL FOUNDATION DONATION APPLICATIONRs WsNo ratings yet

- Codes of Ethics and Business ConductDocument6 pagesCodes of Ethics and Business Conductjaycebelle ugat100% (1)

- The New B2B Marketing Playbook: Executive SummaryDocument11 pagesThe New B2B Marketing Playbook: Executive Summaryaggold616No ratings yet

- Record of Revision: Rev. No. Section Contractor's Comment Incorporated (Y/N) Sub-Contractor's ResponseDocument32 pagesRecord of Revision: Rev. No. Section Contractor's Comment Incorporated (Y/N) Sub-Contractor's ResponseMuhammad TeguhNo ratings yet