Professional Documents

Culture Documents

Tank Inspection Requirements 40 CFR 60, Subparts K, Ka, KB, 49 CFR 195, and API Standard 653

Uploaded by

Owais Malik0 ratings0% found this document useful (0 votes)

50 views1 pageThe document outlines tank inspection requirements from various regulations and standards including 40 CFR 60, 49 CFR 195, and API Standard 653. It details the specific inspection tasks required, including internal and external inspections, ultrasonic thickness inspections, and pressure testing. The frequencies are provided, ranging from monthly visual inspections to inspections every 5-20 years depending on the type of tank, inspection method, and applicable regulation or standard. Corrosion rates are also factored into determining inspection intervals where applicable.

Original Description:

Original Title

tank reqs

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines tank inspection requirements from various regulations and standards including 40 CFR 60, 49 CFR 195, and API Standard 653. It details the specific inspection tasks required, including internal and external inspections, ultrasonic thickness inspections, and pressure testing. The frequencies are provided, ranging from monthly visual inspections to inspections every 5-20 years depending on the type of tank, inspection method, and applicable regulation or standard. Corrosion rates are also factored into determining inspection intervals where applicable.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

50 views1 pageTank Inspection Requirements 40 CFR 60, Subparts K, Ka, KB, 49 CFR 195, and API Standard 653

Uploaded by

Owais MalikThe document outlines tank inspection requirements from various regulations and standards including 40 CFR 60, 49 CFR 195, and API Standard 653. It details the specific inspection tasks required, including internal and external inspections, ultrasonic thickness inspections, and pressure testing. The frequencies are provided, ranging from monthly visual inspections to inspections every 5-20 years depending on the type of tank, inspection method, and applicable regulation or standard. Corrosion rates are also factored into determining inspection intervals where applicable.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

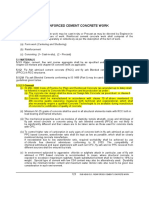

Tank Inspection Requirements

40 CFR 60, Subparts K, Ka, Kb, 49 CFR 195, and API Standard 653

40 CFR 60 API 653 Section 4

TASK Notes K* Ka Kb 49 CFR 195 Inspections

Routine in-service visual inspection (Section 4.3.1) 1 monthly

External inspection (Section 4.3.2) 2 every 5 years or RCA/4N

Ultrasonic thickness inspection (Section 4.3.3) 3, 4,5 every 5 years or RCA/2N

Internal inspection (Section 4.4) 6 10 or 20 years

Breakout tank physical integrity test for tanks not inspected under every calendar year at intervals not

7

49 CFR 195.432 (b) or (c) exceeding 15 months

Physical integrity test of in-service atmospheric and low pressure

7 Per API Standard 653 Section 4

steel aboveground breakout tanks (49 CFR 195.432(b))

Physical integrity test of in-service steel aboveground breakout

7 Per API Standard 510 Section 6

tanks built to API Standard 2510 (49 CFR 195.432(c))

Pnuematic testing for aboveground breakout tanks placed in 7

Per API Specification 12F Section 5.3

service after 10/2/00 built to API Standard 12F

Pnuematic and hydrostatic testing for aboveground breakout 7 Per API Specification 620 Section

tanks placed in service after 10/2/00 built to API Standard 620 5.18

Pnuematic and hydrostatic testing for aboveground breakout 7

Per API Specification 650 Section 5.3

tanks placed in service after 10/2/00 built to API Standard 650

Pressure testing for aboveground breakout tanks placed in 7 Per ASME Boiler and Pressure Vessel

service after 10/2/00 built to API Standard 2510 Code, Sec. VIII, Div. 1 or 2

Gap measurements for external floating roof tanks between within 60 days of initial

within 60 days of initial fill, every 5 years after

primary seal and tank wall fill, every 5 years after

Gap measurements for external floating roof tanks between within 60 days of initial

within 60 days of initial fill, every year after

secondary seal and tank wall fill, every year after

Visually inspect internal floating roof prior to filling

Visually inspect primary seal prior to filling

Visually inspect secondary seal prior to filling

Vessels equipped with a mechanical shoe or liquid-mounted once a year

primary seal, visually inspect the internal floating roof

Vessels equipped with a mechanical shoe or liquid-mounted once a year

primary seal, visually inspect the primary seal

Vessels equipped with a mechanical shoe or liquid-mounted once a year

primary seal, visually inspect the secondary seal

Vessels with double-seal system , visually inspect the vessel every 5 years

Visually inspect the internal floating roof each time vessel is emptied and degassed

Visually inspect the external floating roof each time vessel is emptied and degassed

Visually inspect the primary seal each time vessel is emptied and degassed

Visually inspect the secondary seal each time vessel is emptied and degassed

Visually inspect the slotted membranes each time vessel is emptied and degassed

Visually inspect the gaskets each time vessel is emptied and degassed

Visually inspect the sleeve seals each time vessel is emptied and degassed

* - 40 CFR 60 Subpart K does not require inspections.

Notes:

1. May be performed by owner/operator.

2. Inspection by an authorized API 653 inspector. RCA is the difference between the measured shell thickness and the minimum required thickness in mils, and N is the shell corrosion rate in mils/year, whichever is less.

3. When the corrosion rate is not known the maximum interval shall not exceed 5 years.

4. When the corrosion rate is known the max interval shall be the smaller of RCA/2N years where RCA is the difference between the measured shell thickness and the minimum required thickness in mils, and N is the shell corrosion rate in mils/year, or 15 years.

5. Internal inspection of the tank shall, when the tank is out of service, can be substituted if the internal inspection interval is equal to or less than RCA/2N or 15 years.

6. If the corrosion rate is known the inspection interval shall not exceed 20 years. If the corrosion rate is not known the bottom thickness shall be determined by inspection within the next 10 years to establish corrosion rates.

7. All crude oil breakout tanks and pipeline are potentially subject to 49 CFR 195 (DOT regulation).

You might also like

- Dangerous Goods Guidance Note 10 PDFDocument3 pagesDangerous Goods Guidance Note 10 PDFDan DumbravescuNo ratings yet

- API 570 QuizDocument6 pagesAPI 570 Quizjacquesmayol100% (1)

- Chapter IP-10 Inspection, Examination, and TestingDocument5 pagesChapter IP-10 Inspection, Examination, and TestingatierneyNo ratings yet

- CFR 2011 Title49 Vol3 Part178 SubpartcDocument89 pagesCFR 2011 Title49 Vol3 Part178 SubpartcAssemNo ratings yet

- Pipeline and Hazardous Materials Safety Admin., DOT 178.35Document3 pagesPipeline and Hazardous Materials Safety Admin., DOT 178.35Alvaro Rojas AnzolaNo ratings yet

- SACIC-Q-1026 Rev.01 Precast Concrete Compressive Strenght Insp.Document2 pagesSACIC-Q-1026 Rev.01 Precast Concrete Compressive Strenght Insp.Muhammad AbrarNo ratings yet

- Batch Plant Inspection: DSA Forms DSA PublicationsDocument4 pagesBatch Plant Inspection: DSA Forms DSA PublicationsMichael HaleyNo ratings yet

- API 510 Section 1Document2 pagesAPI 510 Section 1Mohamed Abd El DayemNo ratings yet

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNo ratings yet

- Tsec ManualDocument88 pagesTsec Manualmba213No ratings yet

- Rutgers Lib 36802 - PDF 1Document4 pagesRutgers Lib 36802 - PDF 1PeterNo ratings yet

- 2021 Bonanza Power Plant, CCR Units Annual PE Inspection (11!9!21) - SignedDocument11 pages2021 Bonanza Power Plant, CCR Units Annual PE Inspection (11!9!21) - Signedonline reviewNo ratings yet

- API 510 - Pressure Vessel Inspection Code: Reconstruction, Should Not Be Used For Maintenance InspectionDocument4 pagesAPI 510 - Pressure Vessel Inspection Code: Reconstruction, Should Not Be Used For Maintenance InspectionFauzi IlhamNo ratings yet

- A Guide To The Implementation of API 653Document3 pagesA Guide To The Implementation of API 653Anbarasan PerumalNo ratings yet

- Enbridge Pipeline Repair Workplan WeldingDocument23 pagesEnbridge Pipeline Repair Workplan WeldingJesus MaestreNo ratings yet

- Dayton Superior Bar Splice ICC ReportDocument8 pagesDayton Superior Bar Splice ICC ReportEric GardnerNo ratings yet

- Understanding API ICP653 Worksheet-02 PDFDocument223 pagesUnderstanding API ICP653 Worksheet-02 PDFCharlie Chong100% (2)

- Pumps and Valves Watts Bar Nujclear Power Plant: Unit 1Document69 pagesPumps and Valves Watts Bar Nujclear Power Plant: Unit 1Miloud BekhitiNo ratings yet

- 45 Samss 009Document6 pages45 Samss 009Waleed MedhatNo ratings yet

- Nde MapDocument8 pagesNde MapjorgekarlosprNo ratings yet

- 2008sc SC Xiii Coalboiler Draft 4 15 08Document8 pages2008sc SC Xiii Coalboiler Draft 4 15 08Majid KhanNo ratings yet

- (Vol I), 2021 Amendment Rules For Classification and Surveys, Nov 2021Document47 pages(Vol I), 2021 Amendment Rules For Classification and Surveys, Nov 2021Prasetyo Adhi KurniawanNo ratings yet

- TD-032 CFFC - STD - Rev5Document33 pagesTD-032 CFFC - STD - Rev5swLuNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System SpecificationGOSP3 QC MechanicalNo ratings yet

- API 510 Exam May 2021Document30 pagesAPI 510 Exam May 2021Ahmed ShakirNo ratings yet

- Final Draft STR No TI STR 006 Rev 05Document5 pagesFinal Draft STR No TI STR 006 Rev 05lovely jiNo ratings yet

- REFERENCE - 213 EGA Statement of Structural Inspections - Rev.051917Document39 pagesREFERENCE - 213 EGA Statement of Structural Inspections - Rev.051917susie hwangNo ratings yet

- Special Inspections and Tests: @seismicisolationDocument3 pagesSpecial Inspections and Tests: @seismicisolationpriya giriNo ratings yet

- API 653 NotesDocument10 pagesAPI 653 Notesamine bouizarNo ratings yet

- Sub Head 5.0: Reinforced Cement Concrete WorkDocument16 pagesSub Head 5.0: Reinforced Cement Concrete WorkPritam DharNo ratings yet

- Clause Wise CommentsDocument1 pageClause Wise Commentsrajitkumar.3005No ratings yet

- APP143 - Quality Control and Supervision of Precast Concrete ConstructionDocument13 pagesAPP143 - Quality Control and Supervision of Precast Concrete ConstructionimaugustwongNo ratings yet

- IBR Involvement in Power Plant RM ProjectDocument9 pagesIBR Involvement in Power Plant RM ProjectRanendraNo ratings yet

- Inspection and Repair of Storage Tanks 1710346228Document113 pagesInspection and Repair of Storage Tanks 1710346228Jayapal BhukyaNo ratings yet

- Asme B31.3Document2 pagesAsme B31.3Gilmar MarquesNo ratings yet

- Api 570 Quiz-2Document34 pagesApi 570 Quiz-2jacquesmayol0% (1)

- Api 653 Exam 2018Document21 pagesApi 653 Exam 2018Akram AlhaddadNo ratings yet

- Is 1652 BatteryDocument11 pagesIs 1652 BatteryNikunj KumarNo ratings yet

- Enbridge Pipeline Repair Workplan Welding PDFDocument23 pagesEnbridge Pipeline Repair Workplan Welding PDFquiron2014No ratings yet

- Reconditioning of ValvesDocument6 pagesReconditioning of ValvesPaul PhiliphsNo ratings yet

- TCI Services, Inc. Kevin Kupitz Levi LaughlinDocument29 pagesTCI Services, Inc. Kevin Kupitz Levi LaughlinChristian CoboNo ratings yet

- Cylinder RequalificationDocument49 pagesCylinder Requalificationjayaprakash D MNo ratings yet

- API 653 Insection IntervalsDocument34 pagesAPI 653 Insection IntervalsMIRCEA130586% (7)

- Daily Revise - Practice Southern InspectionDocument113 pagesDaily Revise - Practice Southern Inspectionajayachuth97No ratings yet

- 45 Samss 008Document8 pages45 Samss 008Eagle SpiritNo ratings yet

- API RP 4G Operation, Inspection, Maintenance, and Repair of Drilling and Well Servicing StructuresDocument1 pageAPI RP 4G Operation, Inspection, Maintenance, and Repair of Drilling and Well Servicing StructuresinsaanNo ratings yet

- TDI33 Tank Inspection Suitaility For Service API 653 Sec 4Document29 pagesTDI33 Tank Inspection Suitaility For Service API 653 Sec 4Faizal SattuNo ratings yet

- C14.1265935-1-Nonreinforce Concrete Sewer, CulvertDocument4 pagesC14.1265935-1-Nonreinforce Concrete Sewer, Culvertphett sopanhchaknaNo ratings yet

- Inspection Form For Precast Prestressed Concrete Product PlantsDocument8 pagesInspection Form For Precast Prestressed Concrete Product PlantsAbdi Septia PutraNo ratings yet

- Api653 Question N°02Document4 pagesApi653 Question N°02korichiNo ratings yet

- ItpDocument68 pagesItpShabeer Ahammed100% (2)

- DOT Guide 31 Requal Cylinders Revised 5-17-04Document4 pagesDOT Guide 31 Requal Cylinders Revised 5-17-04ariazzzhNo ratings yet

- Program Studi Teknik Mesin S1 Fakultas Teknik Universitas Riau 2020Document5 pagesProgram Studi Teknik Mesin S1 Fakultas Teknik Universitas Riau 2020fakhrul roziNo ratings yet

- Inspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Document4 pagesInspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Shubham ShuklaNo ratings yet

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Applicability: Compliance: BackgroundDocument2 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Applicability: Compliance: BackgroundKarol KrzysztoszekNo ratings yet

- Qcpi 5Document2 pagesQcpi 5Hausland Const. Corp.No ratings yet

- QAPtanks 27453 345417Document1 pageQAPtanks 27453 345417wasim akramNo ratings yet

- API RP 4G Operation, Inspection, Maintenance, and Repair of Drilling and Well Servicing StructuresDocument1 pageAPI RP 4G Operation, Inspection, Maintenance, and Repair of Drilling and Well Servicing Structuresmartahan manurungNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- PM - Phonon Diagnostic TechnologyDocument30 pagesPM - Phonon Diagnostic TechnologyOwais MalikNo ratings yet

- PetroMaster - Completed Projects List 2005-2018Document8 pagesPetroMaster - Completed Projects List 2005-2018Owais MalikNo ratings yet

- MECCOCT18-12576: Relaxation Cracking - Investigation of Several Failures in Petrochemical PlantsDocument13 pagesMECCOCT18-12576: Relaxation Cracking - Investigation of Several Failures in Petrochemical PlantsOwais MalikNo ratings yet

- MECCOCT18-12335: Risk Management of High Temperature Hydrogen Attack in RefineriesDocument9 pagesMECCOCT18-12335: Risk Management of High Temperature Hydrogen Attack in RefineriesOwais MalikNo ratings yet

- MECCOCT18-12629: Managing Corrosion in NGL Plant Through Establishment of IOWDocument8 pagesMECCOCT18-12629: Managing Corrosion in NGL Plant Through Establishment of IOWOwais MalikNo ratings yet

- MECCOCT18-12374: Corrosion and Scaling Prediction Using Different Indices For Formation Water SamplesDocument9 pagesMECCOCT18-12374: Corrosion and Scaling Prediction Using Different Indices For Formation Water SamplesOwais MalikNo ratings yet

- Meccoct18 12449Document15 pagesMeccoct18 12449Owais MalikNo ratings yet

- NACE Paper No. MECCOCT18-12290: Friction Stir Diffusion Cladding of 5052 Aluminum Alloy On Cold-Rolled Carbon SteelDocument13 pagesNACE Paper No. MECCOCT18-12290: Friction Stir Diffusion Cladding of 5052 Aluminum Alloy On Cold-Rolled Carbon SteelOwais MalikNo ratings yet

- MECCOCT18-12586: Determination of The Degradation of A AISI TP321 Stainless Steel TubeDocument7 pagesMECCOCT18-12586: Determination of The Degradation of A AISI TP321 Stainless Steel TubeOwais MalikNo ratings yet

- MECCOCT18-12493: The Use of Computational Fluid Dynamics (CFD) To Resolve Corrosion Problems in Refinery Process UnitsDocument10 pagesMECCOCT18-12493: The Use of Computational Fluid Dynamics (CFD) To Resolve Corrosion Problems in Refinery Process UnitsOwais MalikNo ratings yet

- Meccoct18 12555Document9 pagesMeccoct18 12555Owais MalikNo ratings yet

- MECCOCT18-12339: Corrosion Protection in Amine Treating UnitsDocument13 pagesMECCOCT18-12339: Corrosion Protection in Amine Treating UnitsOwais MalikNo ratings yet

- MECCOCT18-12285: External Corrosion Investigation of 36 Inch Trunkline Case Study: A Possible AC/DC InterferenceDocument15 pagesMECCOCT18-12285: External Corrosion Investigation of 36 Inch Trunkline Case Study: A Possible AC/DC InterferenceOwais MalikNo ratings yet

- MECCOCT18-12292: NACE Paper NoDocument9 pagesMECCOCT18-12292: NACE Paper NoOwais MalikNo ratings yet

- MECCOCT18-12533: Influence of Film Thickness and Porosity On The Performance of The FBE CoatingDocument6 pagesMECCOCT18-12533: Influence of Film Thickness and Porosity On The Performance of The FBE CoatingOwais MalikNo ratings yet

- Creep of Outlet Pigtail Tubes of Steam Reformer and Grain Size Effect On Creep of An Incoloy 800H MaterialDocument12 pagesCreep of Outlet Pigtail Tubes of Steam Reformer and Grain Size Effect On Creep of An Incoloy 800H MaterialOwais Malik100% (1)

- Microstructural Evolution and Change in Hardness in Type 304H Stainless Steel During Long-Term CreepDocument4 pagesMicrostructural Evolution and Change in Hardness in Type 304H Stainless Steel During Long-Term CreepOwais MalikNo ratings yet

- SRS 635Document62 pagesSRS 635Owais MalikNo ratings yet

- Failure Analysis of Reformer Tubes: Technicalarticle-Peer-ReviewedDocument6 pagesFailure Analysis of Reformer Tubes: Technicalarticle-Peer-ReviewedOwais MalikNo ratings yet

- Technology For The Examination of Boiler Tubing Dissimilar Metal Welds, Revision 1Document198 pagesTechnology For The Examination of Boiler Tubing Dissimilar Metal Welds, Revision 1Owais MalikNo ratings yet

- Integrated Boiler Tube Failure Reduction/Cycle Chemistry Improvement ProgramDocument96 pagesIntegrated Boiler Tube Failure Reduction/Cycle Chemistry Improvement ProgramOwais MalikNo ratings yet

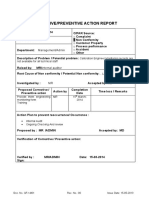

- Corrective/Preventive Action Report: Calibration Engineer Monitoring Records Are Not Available For All Technical StaffDocument1 pageCorrective/Preventive Action Report: Calibration Engineer Monitoring Records Are Not Available For All Technical StaffOwais MalikNo ratings yet

- Failure Analysis and Remaining Life Assessment of Service Exposed Primary Reformer Heater TubesDocument21 pagesFailure Analysis and Remaining Life Assessment of Service Exposed Primary Reformer Heater TubesOwais MalikNo ratings yet

- Centricast Materials For High-Temperature Service: J. H, D. JDocument5 pagesCentricast Materials For High-Temperature Service: J. H, D. JOwais MalikNo ratings yet

- Level Switch Vibration Liquiphant S FTL 70 71 TIDocument20 pagesLevel Switch Vibration Liquiphant S FTL 70 71 TIHerman SandyNo ratings yet

- TICO Pro Spotter Repair Manual 1Document211 pagesTICO Pro Spotter Repair Manual 1Ivailo Zapryanov0% (1)

- Management Accounting (Tilburg University) Management Accounting (Tilburg University)Document20 pagesManagement Accounting (Tilburg University) Management Accounting (Tilburg University)Afriliani100% (1)

- AP8 q1 Mod1 Ang Katangiang Pisikal NG Daigdig v3Document34 pagesAP8 q1 Mod1 Ang Katangiang Pisikal NG Daigdig v3Leah BatillerNo ratings yet

- Application of TCSC To Enhance Power Transfer CapabilityDocument20 pagesApplication of TCSC To Enhance Power Transfer Capabilitykubera uNo ratings yet

- Liberal Pluralism 1Document24 pagesLiberal Pluralism 1Ma. Rica CatalanNo ratings yet

- Difference Between FERA and FEMADocument3 pagesDifference Between FERA and FEMAshikshaNo ratings yet

- Haier Oven ManualDocument206 pagesHaier Oven ManualAmar KonathalaNo ratings yet

- SDDSDDocument2 pagesSDDSDKaushalya PereraNo ratings yet

- Practice Test 1Document6 pagesPractice Test 1Glenn XyzzyllyzzyxNo ratings yet

- Product Cycle TheoryDocument10 pagesProduct Cycle TheoryPalak Sonam Paryani100% (1)

- Sem3 MCQ HRMDocument8 pagesSem3 MCQ HRMvenkat annabhimoju50% (2)

- Gifty Kyeiwa BotweDocument144 pagesGifty Kyeiwa BotweAnnabelle ColemanNo ratings yet

- AdvtDocument5 pagesAdvtMohd KazimNo ratings yet

- Master of Science in Analytics - Georgia TechDocument3 pagesMaster of Science in Analytics - Georgia TechSamir Yaddua Torres OrjedaNo ratings yet

- Burke - Oxidizing and Reducing AgentsDocument607 pagesBurke - Oxidizing and Reducing AgentscapranzoloNo ratings yet

- Automatic Account Determination (MM-FI)Document19 pagesAutomatic Account Determination (MM-FI)Ankit BudheNo ratings yet

- E DLetterDocument4 pagesE DLetterDhruba Kumar SethiNo ratings yet

- Protect - MNS Motor Management INSUM: Technical InformationDocument53 pagesProtect - MNS Motor Management INSUM: Technical InformationAbhijith Sreevalsam100% (1)

- MC 10136780 9999Document13 pagesMC 10136780 9999henrysaputra168No ratings yet

- SURGE Info SessionDocument19 pagesSURGE Info SessionR1ULTRAMAXNo ratings yet

- Job SatisfactionDocument59 pagesJob SatisfactionMahesh Manda100% (1)

- Electronic Theses and Dissertations (Etds)Document208 pagesElectronic Theses and Dissertations (Etds)jasimnddNo ratings yet

- Fas - Ul.p.3.005 Zic-4aDocument4 pagesFas - Ul.p.3.005 Zic-4aShashish AshuNo ratings yet

- Rapport Annuel 2020 2021 EnglishDocument29 pagesRapport Annuel 2020 2021 EnglishOusseynou NdiayeNo ratings yet

- Basic Fishing CourseDocument103 pagesBasic Fishing CourseAhmed100% (1)

- HSG Lop 11 2022-2023 KEYSDocument7 pagesHSG Lop 11 2022-2023 KEYSHà Trần Thị ThuNo ratings yet

- How To Setup Haproxy As Load Balancer For Nginx On Centos 7: Basic Concept With HaproxyDocument7 pagesHow To Setup Haproxy As Load Balancer For Nginx On Centos 7: Basic Concept With HaproxyJoselyn Apaza FernándezNo ratings yet

- Barriers For Deconstruction and Reuse:Recycling of Construction Materials - CIB 2014 PDFDocument186 pagesBarriers For Deconstruction and Reuse:Recycling of Construction Materials - CIB 2014 PDFNadine MuffelsNo ratings yet

- Direct Shear Test ResultDocument7 pagesDirect Shear Test ResultDeepak Kr GuptaNo ratings yet