Professional Documents

Culture Documents

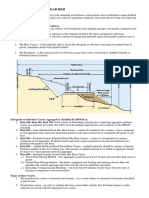

General Purpose Renders: Product Datasheet

Uploaded by

Hka IsmailOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Purpose Renders: Product Datasheet

Uploaded by

Hka IsmailCopyright:

Available Formats

General Purpose Renders

PRODUCT DATASHEET

September 2018 | EuroMix Dry Mortar System | VERSION 1

1. Identification 3. Performance

1.1 Introduction EuroMix General Purpose Renders have been formulated to achieve

EuroMix General Purpose Renders are factory produced renders consisting of excellent workability, water retention and consistent rate of hardening.

dried sands, cement and other additives. The hardened render should have adequate bond, compressive strength

and durability.

1.2 Authority

EuroMix General Purpose Renders are manufactured under a registered ISO 4. Silo

9001 Quality System.

Materials used comply with the following standards: EuroMix General Purpose Renders are delivered to site in a Silo complete

with all necessary mixing equipment.

Sand BS EN 13139 After connecting power and water supplies, the system is ready for

use. Once the water flow rate is adjusted to give render of the required

Cement BS EN 197-1 workability, it is simply a question of push-button operation to produce

Lime BS EN 459-1 consistently high quality render whenever it is needed.

The Silo Mixing Station will discharge the render directly into a tub.

Admixtures BS EN 934-3

This equipment can be used by any site operative once they have been

Pigments BS EN 12878 given basic instruction and issued a Trained Operators Card by a EuroMix

Service Technician.

Admixtures do not contain calcium chlorides. Water added on site should be

clean and free from impurities. EuroMix General Purpose Renders should be 5. Bags

used in accordance with BS EN 13914.

EuroMix General Purpose Renders are also available in 25Kg and bulk bags.

2. Description 5.1 Mixing Instructions

2.1 Manufacture Place the product into a traditional concrete mixer. Start the mixer and add

All raw materials and end products are subject to regular quality control approximately 4 to 5 litres of clean water per 25Kg of dry product.

procedures and testing. Mix continuously for 3 to 4 minutes until the required workability and

Dried sand and other materials are weighed and mixed under computer consistency is achieved.

control with rigorous quality control procedures. Over mixing will be detrimental to strength and durability of the render.

Do not add any additional materials. All components required are within the mix.

2.2 Render Strength Classes

Do not re-temper or add further water after initial set.

EuroMix General Purpose Renders comply with BS EN 998-1 as set out in

the table below. 5.2 General Information

Euromix General Purpose Renders are suitable for use as backing and

Properties Categories Values

finishing coat in external rendering and internal plastering. They are available

Range of compressive CS I 0.4 to 2.5 N/mm2 in any strength category or traditional mix type for hand or spray application.

6. Prices and Conditions of Sale

strength at 28 days

CS II 1.5 to 5.0 N/mm2

CS III 3.5 to 7.5 N/mm2 Our local sales representative will be pleased to provide quotations for

specific projects. All quotations are subject to our Conditions of Sale, a copy

CS IV ≥6 N/mm2 of which is available on request.

Render Mix Nominal Cement: Nominal Cement: 7. Health & Safety

Designation Sand by Volume Lime: Sand For health and safety information – see Material Safety Datasheet.

(i) 1:3 1:¼:3

8. Technical Services

(ii) 1:3/4 1:½:4/4½

8.1 Render Testing

(iii) 1:5/6 1:1:5/6 Where site testing of render is required, strict adherence to recommended

testing procedures is essential. Contact EuroMix for further advice or

(iv) 1:7/8 1:2:8/9 assistance.

EMAIL: VISIT US: Helpline:

info@cpieuromix.com www.euromix.com 0845 850 9090

You might also like

- Ucrete SpecsDocument10 pagesUcrete SpecspsrikanthanNo ratings yet

- RADICON SOP MAN 013 Painting and Paint SystemsDocument23 pagesRADICON SOP MAN 013 Painting and Paint SystemsGoogle facebookNo ratings yet

- Ucrete MF - TdsDocument3 pagesUcrete MF - TdsAbdul YaskarNo ratings yet

- Miadata 02Document4 pagesMiadata 02johnNo ratings yet

- RADICON - SOP MAN 013 Painting and Paint SystemsDocument23 pagesRADICON - SOP MAN 013 Painting and Paint SystemsBlainNo ratings yet

- UntitledDocument11 pagesUntitledRodrigo LeanosNo ratings yet

- Enviroline 199+ds+eng PDFDocument4 pagesEnviroline 199+ds+eng PDFMohamed NouzerNo ratings yet

- Ucrete MF: Heavy Duty Polyurethane Hybrid Flooring SystemDocument3 pagesUcrete MF: Heavy Duty Polyurethane Hybrid Flooring SystemSean HarshaNo ratings yet

- GRP Culvert Mammal Shelf Specification Design LifeDocument4 pagesGRP Culvert Mammal Shelf Specification Design LifeTesteNo ratings yet

- Pro C901, Pro C901S Installation GuideDocument24 pagesPro C901, Pro C901S Installation GuideGuer NdNo ratings yet

- Enviroline 2405 Application Guidelines: Protective Coatings Technical SupportDocument12 pagesEnviroline 2405 Application Guidelines: Protective Coatings Technical SupportskNo ratings yet

- Variable Resistive Inks (Vri) : Technical Data SheetDocument2 pagesVariable Resistive Inks (Vri) : Technical Data SheetDebidas KunduNo ratings yet

- Macropoxy C400V3Document2 pagesMacropoxy C400V3nellyNo ratings yet

- Adhesive Bonding of Aluminum Facings in Foam and Beam Type SheltersDocument4 pagesAdhesive Bonding of Aluminum Facings in Foam and Beam Type SheltersEric GozzerNo ratings yet

- Firemaster Technical Manual Eurobond PanelsDocument24 pagesFiremaster Technical Manual Eurobond PanelsjeddijNo ratings yet

- Adhesive Bonding of Aluminum Facings in Foam and Beam Type SheltersDocument4 pagesAdhesive Bonding of Aluminum Facings in Foam and Beam Type SheltersAhmad Zubair RasulyNo ratings yet

- Section 09 62 19 - Laminate Flooring - 2016Document8 pagesSection 09 62 19 - Laminate Flooring - 2016Roland James ArimadoNo ratings yet

- Nitomortar FC (B)Document2 pagesNitomortar FC (B)Mansoor AliNo ratings yet

- Masonry Mortar: 1. Application 5. BagsDocument1 pageMasonry Mortar: 1. Application 5. BagsHka IsmailNo ratings yet

- Fosroc Nitomortar FC (B) : Constructive SolutionsDocument2 pagesFosroc Nitomortar FC (B) : Constructive SolutionsVincent JavateNo ratings yet

- E 1801 - 00 Rte4mdetmdaDocument3 pagesE 1801 - 00 Rte4mdetmdaHoward Gallegos MontenegroNo ratings yet

- Fosroc Nitoflor FC140: Constructive SolutionsDocument4 pagesFosroc Nitoflor FC140: Constructive SolutionsVincent JavateNo ratings yet

- Specifications of Painting WorksDocument7 pagesSpecifications of Painting WorksSiddharth Gamare100% (1)

- Cafco FENDOLITE®-MIIDocument4 pagesCafco FENDOLITE®-MIIAnonymous 24lnhhNo ratings yet

- NUFORM Wall Finishing GuideDocument20 pagesNUFORM Wall Finishing GuidemartadijayaNo ratings yet

- MSDS-002 Sureflow 100Document45 pagesMSDS-002 Sureflow 100joker batmanNo ratings yet

- Protective Coating System For Electric Motors: WI37.MTS.173.A25 Revision 0Document5 pagesProtective Coating System For Electric Motors: WI37.MTS.173.A25 Revision 0Ardian P NoviatmokoNo ratings yet

- Prime 209Document3 pagesPrime 209Helmi Jameel100% (2)

- 03 48 00clcDocument6 pages03 48 00clcmp4 ghad mp4No ratings yet

- ISO 12944 5 C5 Paint System WilkoDocument5 pagesISO 12944 5 C5 Paint System Wilkojayakumar100% (3)

- Miadata 11Document4 pagesMiadata 11johnNo ratings yet

- Z21 Blockwall Mortar SpecificationDocument4 pagesZ21 Blockwall Mortar SpecificationAnonymous qabSVjzrANo ratings yet

- ISO 13007-1 E - Adhesives DDocument11 pagesISO 13007-1 E - Adhesives DGIAPNo ratings yet

- Ucrete MF TdsDocument3 pagesUcrete MF TdsjesuriNo ratings yet

- Fosroc Nitoflor FC140: Constructive SolutionsDocument4 pagesFosroc Nitoflor FC140: Constructive SolutionsVincent JavateNo ratings yet

- Reply To The Engineer Comments-25-3-23 PDFDocument2 pagesReply To The Engineer Comments-25-3-23 PDFMrDeathnetNo ratings yet

- Adhesive Bonding of Aluminum Facings in Foam and Beam Type SheltersDocument4 pagesAdhesive Bonding of Aluminum Facings in Foam and Beam Type SheltersEdmundo Jaita CuellarNo ratings yet

- IPS M TP 168-Material Standard For Acrylic Silicon Finish Paint For Temperature Applications Up To 200°CDocument11 pagesIPS M TP 168-Material Standard For Acrylic Silicon Finish Paint For Temperature Applications Up To 200°Cseguridadyambiente641No ratings yet

- Waterproofing Treatment and Installation Work Procedure FOR SRA - 03 Raj InfiniaDocument6 pagesWaterproofing Treatment and Installation Work Procedure FOR SRA - 03 Raj InfiniaThink itNo ratings yet

- WaterWastewater Industry Guide BR UkDocument6 pagesWaterWastewater Industry Guide BR UkKing SabiNo ratings yet

- PDS Thioflex 600 SGDocument5 pagesPDS Thioflex 600 SGAjay PrasadNo ratings yet

- Conbextra Ep65Document3 pagesConbextra Ep65Angelo Carlo MalabananNo ratings yet

- 03 35 00sesDocument17 pages03 35 00sesHitesh SachaniNo ratings yet

- Fosroc Nitomortar FC: High Strength Trowel Grade, Epoxy Resin Fairing Coat, Repair Mortar, Bedding and AdhesiveDocument2 pagesFosroc Nitomortar FC: High Strength Trowel Grade, Epoxy Resin Fairing Coat, Repair Mortar, Bedding and AdhesiveVincent JavateNo ratings yet

- Industrial Coating ApplicationDocument22 pagesIndustrial Coating ApplicationaamirsaddiqNo ratings yet

- G16S-0205-04 - Shop Coat Galv Surf (Duplex)Document3 pagesG16S-0205-04 - Shop Coat Galv Surf (Duplex)puwarin naja100% (1)

- Conbextra EP75 PDFDocument3 pagesConbextra EP75 PDFKhaerul SidikNo ratings yet

- Ucrete MF Flooring - BASF Data Sheet ADocument4 pagesUcrete MF Flooring - BASF Data Sheet A翟庆祥No ratings yet

- 99999-9-3SS-AFTC-00002 Mosaic TilesDocument14 pages99999-9-3SS-AFTC-00002 Mosaic Tilesmido medoNo ratings yet

- SECTION 04 05 13 Masonry MortaringDocument6 pagesSECTION 04 05 13 Masonry MortaringJuanPaoloYbañezNo ratings yet

- Scope of JobDocument6 pagesScope of JobSHIVAM JOHRINo ratings yet

- Guidance Note - No.2 Guide To Correct Specification of Powder Coated AluminiumDocument2 pagesGuidance Note - No.2 Guide To Correct Specification of Powder Coated AluminiumAnwar100% (1)

- Excavations and Backfilling: European Commission Compound - Phnom Penh - CambodiaDocument9 pagesExcavations and Backfilling: European Commission Compound - Phnom Penh - CambodiaSasi KumarNo ratings yet

- 143 EEX Gerotor Pump UnitDocument48 pages143 EEX Gerotor Pump UnitBerk KoçNo ratings yet

- TCI Powder Coatings: Guide To The Application & Troubleshooting of Electrostatic CoatingsDocument44 pagesTCI Powder Coatings: Guide To The Application & Troubleshooting of Electrostatic CoatingsOmar SalasNo ratings yet

- Dr. Fixit Pidicrete CF 111: Water Reducing Admixture For ConcreteDocument1 pageDr. Fixit Pidicrete CF 111: Water Reducing Admixture For Concretenickdash09100% (1)

- Iso 12944Document4 pagesIso 12944Kiran Kumar Yanmangandla100% (2)

- Connector Industry: A Profile of the European Connector Industry - Market Prospects to 1999From EverandConnector Industry: A Profile of the European Connector Industry - Market Prospects to 1999No ratings yet

- Automotive Paints and CoatingsFrom EverandAutomotive Paints and CoatingsHans-Joachim StreitbergerNo ratings yet

- Reactive Distillation: Status and Future DirectionsFrom EverandReactive Distillation: Status and Future DirectionsKai SundmacherRating: 1 out of 5 stars1/5 (1)

- IJOGST - Volume 3 - Issue 4 - Pages 67-77Document11 pagesIJOGST - Volume 3 - Issue 4 - Pages 67-77Hka IsmailNo ratings yet

- Units of Measure: SolidsDocument3 pagesUnits of Measure: SolidsHka Ismail100% (1)

- Safety Data Sheet: Section 1: IdentificationDocument4 pagesSafety Data Sheet: Section 1: IdentificationHka IsmailNo ratings yet

- Fresh and Clean Bio Max Safety Data SheetDocument2 pagesFresh and Clean Bio Max Safety Data SheetHka IsmailNo ratings yet

- Bio-Clean Products Safety Data Sheet: 1. IdentificationDocument3 pagesBio-Clean Products Safety Data Sheet: 1. IdentificationHka IsmailNo ratings yet

- Material Safety Data Sheet: Medpro Defense Bioclean DisinfectantDocument4 pagesMaterial Safety Data Sheet: Medpro Defense Bioclean DisinfectantHka IsmailNo ratings yet

- Testing For Halide IonsDocument5 pagesTesting For Halide IonsHka IsmailNo ratings yet

- CH 227 What Did You Do? What Did You Observe? What Does It Mean?Document2 pagesCH 227 What Did You Do? What Did You Observe? What Does It Mean?Hka IsmailNo ratings yet

- Microscale Gas Chemistry: Preparing Bromine WaterDocument2 pagesMicroscale Gas Chemistry: Preparing Bromine WaterHka IsmailNo ratings yet

- 20% Sodium Bromide Solution - Water Treatment ProductsDocument3 pages20% Sodium Bromide Solution - Water Treatment ProductsHka IsmailNo ratings yet

- Masonry Mortar: 1. Application 5. BagsDocument1 pageMasonry Mortar: 1. Application 5. BagsHka IsmailNo ratings yet

- Technical Information: Truspread Dry Silo MortarsDocument4 pagesTechnical Information: Truspread Dry Silo MortarsHka IsmailNo ratings yet

- Green Island Cement Company Limited: Contact Details Registration No. HOKLAS 037 Page 1 of 1Document8 pagesGreen Island Cement Company Limited: Contact Details Registration No. HOKLAS 037 Page 1 of 1Hka IsmailNo ratings yet

- Natural Pozzolan As A Partial Substitute For Cement in ConcreteDocument11 pagesNatural Pozzolan As A Partial Substitute For Cement in ConcreteHka IsmailNo ratings yet

- Pozzolanic Cement in Qaseem Factories: Dana Al-KhalfahDocument5 pagesPozzolanic Cement in Qaseem Factories: Dana Al-KhalfahHka IsmailNo ratings yet

- Properties and Performance of Lateritic Soil in Road Pavements (University of Queensland, Australia)Document10 pagesProperties and Performance of Lateritic Soil in Road Pavements (University of Queensland, Australia)Encik ComotNo ratings yet

- Potato Production in AeroponicsDocument15 pagesPotato Production in AeroponicsRieko KristianNo ratings yet

- Ks2 Science 2011 Test BDocument20 pagesKs2 Science 2011 Test BzurichasNo ratings yet

- Pollination and Its AgentsDocument6 pagesPollination and Its AgentsdebbyhooiNo ratings yet

- Auroville-Mud Construction TechniqueDocument37 pagesAuroville-Mud Construction TechniqueAr Nizya NoushadNo ratings yet

- Sandy SoilDocument17 pagesSandy SoilAnan S MaishnamNo ratings yet

- Punjab Irrigation System Improvement Project Appropriation Request (AR-DJT/RJP-02/01)Document205 pagesPunjab Irrigation System Improvement Project Appropriation Request (AR-DJT/RJP-02/01)muhammad iqbalNo ratings yet

- 1 - Introduction To AggregateDocument22 pages1 - Introduction To AggregateFatin HazwaniNo ratings yet

- nrcs142p2 053291Document8 pagesnrcs142p2 053291Yhuli ZwitterzzajawchNo ratings yet

- GET Horticulture Level 1Document8 pagesGET Horticulture Level 1Karen SwanepoelNo ratings yet

- Soil MechDocument21 pagesSoil MechAhsan AbbasNo ratings yet

- 2 Constructing The Roadbed WTH Assignments PDFDocument4 pages2 Constructing The Roadbed WTH Assignments PDFAngelo John R. Javinez50% (2)

- RHS Water in The GardenDocument6 pagesRHS Water in The Gardenglynis100% (2)

- Grade Vi Epp Agri TQ, Tos, Answers KeyDocument9 pagesGrade Vi Epp Agri TQ, Tos, Answers KeyHydon Biñas Libradilla100% (2)

- Snap Beans Production GuideDocument12 pagesSnap Beans Production GuideDiana Rose MaduroNo ratings yet

- Model Bankable ProjectsDocument19 pagesModel Bankable ProjectsChiranth ChandNo ratings yet

- 117 NPM - 8. Agronomy Guidelines Review Report Draft March 22, 2016Document74 pages117 NPM - 8. Agronomy Guidelines Review Report Draft March 22, 2016EfremWakjiraHodeNo ratings yet

- Mehan Garden P1Document3 pagesMehan Garden P1Zianne CalubNo ratings yet

- Medicinal Plants of JamaicaDocument86 pagesMedicinal Plants of Jamaicano1dubakoorNo ratings yet

- Grade 5 Science SoilDocument3 pagesGrade 5 Science SoilSuvashreePradhanNo ratings yet

- Plants Used in Constructed Wetlands With Horizontal-ReviewDocument24 pagesPlants Used in Constructed Wetlands With Horizontal-Reviewmaan3949100% (2)

- Coriander PerennialDocument1 pageCoriander Perennialios007No ratings yet

- IFC File Analyzer IfcDocument223 pagesIFC File Analyzer IfcRojas F. LuisNo ratings yet

- Plan For CID No. 21ID0029-2Document10 pagesPlan For CID No. 21ID0029-2Lara FloresNo ratings yet

- East Ring Road (STC)Document3 pagesEast Ring Road (STC)mohamed ayadNo ratings yet

- AAB Ahmednagar 22-12-2015 PDFDocument1 pageAAB Ahmednagar 22-12-2015 PDFbharatNo ratings yet

- Nnabis Less Days Ton/ha: Crop Name: Ca Soil Type: Soil Growth Stage: Crop Cycle: 103 Yield Goal: 60Document3 pagesNnabis Less Days Ton/ha: Crop Name: Ca Soil Type: Soil Growth Stage: Crop Cycle: 103 Yield Goal: 60Dario BaronaNo ratings yet

- TWAD Board's Water Testing Laboratories PDFDocument2 pagesTWAD Board's Water Testing Laboratories PDFShakthidhar RaoNo ratings yet

- Listado AciDocument10 pagesListado AciRicardo Celi Macias100% (1)

- And Applied Manganese: Understanding Plant NutrientsDocument4 pagesAnd Applied Manganese: Understanding Plant Nutrientsanon_952599291No ratings yet