Professional Documents

Culture Documents

Welding Procedure Specification (WPS)

Welding Procedure Specification (WPS)

Uploaded by

Rejoy babyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification (WPS)

Welding Procedure Specification (WPS)

Uploaded by

Rejoy babyCopyright:

Available Formats

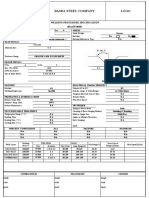

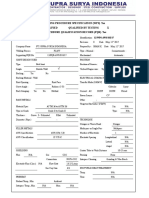

WELDING PROCEDURE SPECIFICATION (WPS)

IDENTIFICATION

Company Name Quality Fab.

WPS No. QFAB-WPS-002

Revision 00 POSITION

Date 05-08-2015 Position of V Fillet N/A

Groove

Supporting PQR QFAB-PQR-002

Vertical Dow

Revision 00

Progression n

Date 04-08-2015 Up √

Welding Process SMAW

Code AWS D1.1:2010

Type Manual Machine Semi Auto

POSTWELD HEAT TREATMENT

JOINT DESIGN USED

Heating Method N/A

Type Single Double N/A

Backing Yes No Temperature Rise Rate N/A

Backing Material None Bead Thickness : 16mmSoak Temperature N/A

Root Gap 2.5±0.5mm Root Face 1.5±0.5 mm

Holding Time N/A

Groove Angle 60°± 10° Radius (J-U) N/A

Temperature Fall Rate N/A

Back Gouging: No Method None

Other N/A

BASE METALS PREHEAT

Preheat Temp., Min

Group 1 to Group Ambient (27°C)

Material Spec. EN10025

1 Inter pass Temp., Min N/A

Material Grade S 275JR Heat No-F653870 Inter pass Temp., Max 210°C

Thickness 3 mm to 32 mm Fillet - ALL

Dia (Pipe) N/A

FILLER METALS

Root & Hot Pass Filling & Cap ELECTRICAL CHARACTERISTICS

SFA Specification A 5.1 A 5.1 Transfer Mode (MIG)

AWS Classification E-7018 E7018 Short Circuiting N/A Globular

N/A

F-number F4 F4

Spray N/A Pulsed N/A

Electrode Dia 2.5mm 3.2mm

Current

AC N/A DCEP DECN

Other None

Tungsten Electrode N/A

Size N/A Type

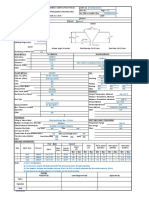

WELDING PROCEDURE SPECIFICATION (WPS)

SHIELDING TECHNIQUE

Flux N/A Stringer Bead Weave Bead

Electrode-Flux (Class) N/A

Multi-pass Single Pass

Gas N/A

Composition N/A Number of Electrodes Single

Flow Rate N/A Electrode Spacing

Gas Cup Size N/A Longitudinal N/A Lateral N/A Angle N/A

Contact Tube to Work

N/A

Distance

Peening None

Wire Brushing

Inter pass Cleaning

Grinding

WELDING PROCEDURE

Pass or Process Filler Metal Polarity Current Travel

Weld Layers Speed

(s) Class Dia. Amps Volts(max) (mm/min) Remarks

(mm) (max)

1 SMAW E-7018 2.5 DCEP 70-90 22-26 65 Preheat Temp:

2 SMAW E-7018 2.5 DCEP 80-100 22-26 80 Ambient (27°C)

3 SMAW E-7018 3.2 DCEP 90-115 24-27 80

4 SMAW E-7018 3.2 DCEP 70-90 17-19 80 Inter pass

5 SMAW E-7018 3.2 DCEP 70-90 17-19 80 Temp.

Max:210°C

Joints Details

T = 16mm, R = 2.5 ± 0.5mm, F= 1.5 ±0.5mm, a 60°± 10°.

Manufacturer Verification Company

Quality Fabricators Company W.L.L Industrial Support Services Co

Name

Signature

Date

You might also like

- Pre Qualified WPSDocument1 pagePre Qualified WPSkapsarcNo ratings yet

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- Aluminum Defects After AnodizingDocument41 pagesAluminum Defects After AnodizingSON100% (1)

- Wps Repair WorDocument1 pageWps Repair WorMajdi JerbiNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (3)

- Well Intervention and WorkoverDocument43 pagesWell Intervention and WorkoverSAI KIRAN KOOCHIMANCHI100% (2)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- 07.4 111 FW ML PF WPS 20mm ENGDocument1 page07.4 111 FW ML PF WPS 20mm ENGViktorNo ratings yet

- Wps Butt AWSDocument4 pagesWps Butt AWSMohd Ashraf75% (4)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Procedure Qualification Record (PQR) : Filler Metals AWS Specification AWS ClassificationDocument3 pagesProcedure Qualification Record (PQR) : Filler Metals AWS Specification AWS ClassificationRejoy babyNo ratings yet

- WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelDocument1 pageWPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelAhmed Gomaa100% (1)

- Computer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Document1 pageComputer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Erick GoyesNo ratings yet

- PWPS 005Document2 pagesPWPS 005Mehrdad RezaeiNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Aramco Hot Tap Welding Procedure Rev 1Document3 pagesAramco Hot Tap Welding Procedure Rev 1BWQNo ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- Procedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Document2 pagesProcedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Menad SalahNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- WPS Welding Performance SpecialistDocument2 pagesWPS Welding Performance SpecialistGobinath GovindarajNo ratings yet

- Procedure Qualification Record (PQR) Form: JointsDocument12 pagesProcedure Qualification Record (PQR) Form: JointsAl Fatih Darussalam YasfiNo ratings yet

- QC E7018 CJP B-L1a OverheadDocument1 pageQC E7018 CJP B-L1a Overheadwmajordan13No ratings yet

- WDI-WPS-072 Rev.00 SMAW 2Document4 pagesWDI-WPS-072 Rev.00 SMAW 2MohamedNo ratings yet

- WPS-PTR 01-05-15Document1 pageWPS-PTR 01-05-15majdi jerbiNo ratings yet

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Document1 pageQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13No ratings yet

- Petroleum Equipment Assembly & Metal Structure JSC: N/A N/ADocument2 pagesPetroleum Equipment Assembly & Metal Structure JSC: N/A N/AKhôi ĐàoNo ratings yet

- WPS PTR 01-08-09Document1 pageWPS PTR 01-08-09majdi jerbiNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Wps 7018 SmawDocument1 pageWps 7018 SmawErick VazquezNo ratings yet

- Quy trình hàn vết nứt vành lò dùng que KNCF3 PDFDocument3 pagesQuy trình hàn vết nứt vành lò dùng que KNCF3 PDFDương Quang KhánhNo ratings yet

- Annex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document2 pagesAnnex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Daniel ZapataNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- P WPS Smaw Ceym 001 021Document1 pageP WPS Smaw Ceym 001 021juan carlos garavitoNo ratings yet

- Preliminary - Welding Procedure Specification (WPS)Document1 pagePreliminary - Welding Procedure Specification (WPS)Rudi DaNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- BGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Document1 pageBGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Eswar Enterprises QcNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- WPS-CR 01-06-15Document1 pageWPS-CR 01-06-15majdi jerbiNo ratings yet

- WPS CR 01-08-09Document1 pageWPS CR 01-08-09majdi jerbiNo ratings yet

- Aic Asf PQR 0121Document2 pagesAic Asf PQR 0121AHMED MEDANYNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- Welder Peformance Qualification Record: Pearl GTL Project - Liquid Processing Unit (C5)Document3 pagesWelder Peformance Qualification Record: Pearl GTL Project - Liquid Processing Unit (C5)SANUNo ratings yet

- WPS TTR 01-08-09Document1 pageWPS TTR 01-08-09majdi jerbiNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi Jerbi100% (1)

- Je C 006 WPSDocument4 pagesJe C 006 WPScameron toolseeNo ratings yet

- WPS NewDocument1 pageWPS NewErica SandersNo ratings yet

- PQR - 1Document1 pagePQR - 1janardan.sfeNo ratings yet

- WPS-ASME SEC IX-for PSODocument3 pagesWPS-ASME SEC IX-for PSOSultan ZebNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Report-Welder Qualification TestDocument4 pagesReport-Welder Qualification TestRejoy babyNo ratings yet

- Wqt-1-13-W-1-3g-Smaw-Alclad-Aws D1.1Document1 pageWqt-1-13-W-1-3g-Smaw-Alclad-Aws D1.1Rejoy babyNo ratings yet

- Inspection Test Plan: Fabrication and Instalation of PipingDocument3 pagesInspection Test Plan: Fabrication and Instalation of PipingRejoy babyNo ratings yet

- ITP For Site Installation of Pipe Rev 1 15.07.10Document4 pagesITP For Site Installation of Pipe Rev 1 15.07.10Rejoy babyNo ratings yet

- Danem Engineering Works - WLL.: Quality Control & Inspection Test PlanDocument11 pagesDanem Engineering Works - WLL.: Quality Control & Inspection Test PlanRejoy babyNo ratings yet

- Itp For Piping QPDocument4 pagesItp For Piping QPRejoy baby100% (2)

- Outotec: Danem Engineering Works WLL Doha - QatarDocument4 pagesOutotec: Danem Engineering Works WLL Doha - QatarRejoy babyNo ratings yet

- Inspection Test Plan: Fabrication and Instalation of PipingDocument3 pagesInspection Test Plan: Fabrication and Instalation of PipingRejoy babyNo ratings yet

- Itp For Re-Slurry Tank - R-1Document8 pagesItp For Re-Slurry Tank - R-1Rejoy babyNo ratings yet

- Danem Engineering Works - WLL: Inspection & Test PlanDocument3 pagesDanem Engineering Works - WLL: Inspection & Test PlanRejoy babyNo ratings yet

- Consolidated RT TemplateDocument2 pagesConsolidated RT TemplateRejoy babyNo ratings yet

- QP Specification For Painting & Wrapping of Metal Surfaces PDFDocument89 pagesQP Specification For Painting & Wrapping of Metal Surfaces PDFRejoy babyNo ratings yet

- Painting Procedure 4288 Danem 28-04-13Document24 pagesPainting Procedure 4288 Danem 28-04-13Rejoy baby100% (1)

- Painting Spec 7J48N-00-23-17-001Document29 pagesPainting Spec 7J48N-00-23-17-001Rejoy babyNo ratings yet

- High-Temperature Braze Applications: Ready To Meet Your NeedsDocument2 pagesHigh-Temperature Braze Applications: Ready To Meet Your Needsjohn davidsNo ratings yet

- Acgih Manual 1998 (401-500)Document100 pagesAcgih Manual 1998 (401-500)HéctorNo ratings yet

- Report 21 Sluice Gates Ee Sp2 3 b22 + Ee Sp2 3 b26 + Ee Sp2 3 b28Document20 pagesReport 21 Sluice Gates Ee Sp2 3 b22 + Ee Sp2 3 b26 + Ee Sp2 3 b28HuthaifahM.DagamsehNo ratings yet

- One Arm 2x4 Outdoor Sofa - Sectional Piece - Ana WhiteDocument27 pagesOne Arm 2x4 Outdoor Sofa - Sectional Piece - Ana WhiteWilliam JamesonNo ratings yet

- Exercises Topic 4 Heat TreatmentsDocument14 pagesExercises Topic 4 Heat TreatmentsClara Barbero SánchezNo ratings yet

- Tool Steel Alloy Cr12MoVDocument5 pagesTool Steel Alloy Cr12MoVMujjo Sahb100% (1)

- Prosedur Pembersihan AreaDocument10 pagesProsedur Pembersihan AreaAddrian Putra PNo ratings yet

- Chevron Specification TAM-MN-2Document9 pagesChevron Specification TAM-MN-2Burak GülenNo ratings yet

- Paint Matrix - NPE ProjectDocument2 pagesPaint Matrix - NPE Projectridwan muhammadNo ratings yet

- Kinetika ReaksiDocument77 pagesKinetika ReaksiafrizalfaoniNo ratings yet

- 03-Proses Produksi 01Document29 pages03-Proses Produksi 011D03 KusnadiNo ratings yet

- Product and Technical Data Sheet MBL 45Document1 pageProduct and Technical Data Sheet MBL 45Industria e mishit CalabriaNo ratings yet

- Jun M. de LeonDocument5 pagesJun M. de LeonHarry DemeterioNo ratings yet

- A-Method Statement Painting and Touch-Up Painting For Furnace-CDocument20 pagesA-Method Statement Painting and Touch-Up Painting For Furnace-CTrương Đông HưngNo ratings yet

- Crude Oil - 2Document9 pagesCrude Oil - 2husseinNo ratings yet

- Paper Manufacturing Case PDFDocument2 pagesPaper Manufacturing Case PDFAshrav GuptaNo ratings yet

- Graesser ExtractorDocument1 pageGraesser Extractorsushant_jhawerNo ratings yet

- Types of Cast IronsDocument11 pagesTypes of Cast IronsawesomeyogeshwarNo ratings yet

- Experiment 5 MountingDocument6 pagesExperiment 5 MountingMohanadAlrofuNo ratings yet

- Pallet Adirondack ChairDocument29 pagesPallet Adirondack Chairmvd2704No ratings yet

- 3D Printing Method of Fabrication For Metals, Ceramics, and Multi-Materials Using A Universal Self-Curable Technique For Robocasting PDFDocument8 pages3D Printing Method of Fabrication For Metals, Ceramics, and Multi-Materials Using A Universal Self-Curable Technique For Robocasting PDFoguNo ratings yet

- Mastertop 1700m 12-04Document2 pagesMastertop 1700m 12-04djrote4No ratings yet

- Installation of HDPE Lining On R.C TankDocument3 pagesInstallation of HDPE Lining On R.C TankTamil Da Rasckalz100% (1)

- Tainless Teel Inks: Installation Guide and Users ManualDocument7 pagesTainless Teel Inks: Installation Guide and Users ManualJohn WalesNo ratings yet

- Sandvik - Welding Handbook PDFDocument365 pagesSandvik - Welding Handbook PDFRoberto100% (2)

- Brosur Osmonic Aquamatic EjectorDocument4 pagesBrosur Osmonic Aquamatic EjectorErwin AjahNo ratings yet

- Manufacturing Considerations in DesignDocument6 pagesManufacturing Considerations in DesignKRISHNA KANT GUPTANo ratings yet

- Ethiopian Airlines Enterprise Aviation Maintenance Technician SchoolDocument5 pagesEthiopian Airlines Enterprise Aviation Maintenance Technician SchoolyihesakNo ratings yet