Professional Documents

Culture Documents

FANTECH - Ventilateur Sécheuse DPV22-2 - Specification

Uploaded by

david messierOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FANTECH - Ventilateur Sécheuse DPV22-2 - Specification

Uploaded by

david messierCopyright:

Available Formats

Guide Specification Item #: E400003

Rev Date: 2016-06-23

DPV22-2

Dryer Exhaust Duct Power Ventilator

Description

A integral centrifugal fan and positive pressure sensing switch intended for installation in the 101.6 mm (4 in) diameter exhaust duct of a single

household clothes dryer, to maintain airflow to extend the length of the dryer exhaust duct. The fan may also be termed a dryer exhaust duct power

ventilator (DEDPV). Motor bearings are a permanently sealed, self lubricating ball type. DPV22-2 fan is backed by Fantech’s Five Year Warranty.

Installation Notes:

1. Pressure switch diaphragm must be mounted vertically. Failure to orient the diaphragm vertically may result in improper operation

2. Fan must be mounted a minimum of 1.5m (5 feet) linear (not equivalent) feet from the dryer and maximum 12m (40 feet) linear.

A secondary lint trap can be used where required and in applications where excessive dryer lint generation is likely or to increase the time

interval between routine maintenance of the (DPV22-2) (see installation manual)

3. Fan should be inspected periodically, depending on amount of usage, and cleaned as necessary

Guide Specifications for Model DDPV22-2 Clothes Dryer Vent Booster System

Inline fan shall be of the centrifugal, direct driven type.

Construction

Housing

Fan housing shall be constructed of heavy gauge galvanized sheet metal

Fan shall be supplied with externally mounted electrical terminal box with pre-wired 1.8m (6 foot) long power cord with NEMA 5-15 style plug

Capacitor shall be located within electric terminal box

Motor

Motorized impeller shall be an external rotor type, class B insulation, totally enclosed permanent split capacitor

Motor shall use permanently sealed self lubricating ball bearing type

Motor shall be equipped with automatic reset thermal overload protection

Motor shall be acceptable for continuous duty

Wheel

Fan wheel shall be of the backward inclined centrifugal type with a well designed inlet venturi for maximum performance

Motorized impeller shall be both statically and dynamically balanced as one integral unit to provide for vibration free performance

Impellers shall be molded of high impact polypropylene

Control

A visual error indicator shall be placed in a readily visible area to signal system malfunction.

Control shall perform a cool down cycle with the clothes dryer booster fan at the end of the clothes drying cycle.

Control shall turn off the clothes dryer booster fan if the air stream temperature goes beyond 260°C (500°F) for more than 15 seconds

Integral positive pressure switch shall be mounted on the fan and prewired to the terminal strip provided in fan electrical junction box

Pressure switch shall be set to 20 Pa (0.08 in.wg) static pressure

Pressure switch shall incorporate a delay-on-break timer cycle to maintain fan performance for intervals of 10 minutes until drying cycle is

complete

Code Approval

Fan airflow performance shall be certified by HVI

Clothes dryer booster fan shall be certified for dryer booster applications by a recognized certification body in Canada such as UL, CSA or ETL.

Clothes dryer booster fan shall comply with the requirements specified in CSA 22.2 no.113-15 clause 12.

Rating shall include approval for residential dryer exhaust and air stream temperatures not to exceed 75 ˚C (167 ˚F)

DPV22-2 shall be manufactured under the authority of Fantech, Inc., Lenexa, KS.

Canada 50 Kanalflakt Way • Bouctouche, NB E4S 3M5 • 1.800.565.3548 • www.fantech.net

Fantech reserves the right to make technical changes.

For updated documentation please refer to www.fantech.net

You might also like

- TT Silent Install Manual ServiceDocument20 pagesTT Silent Install Manual ServiceCARMAINNo ratings yet

- 2 Installation Maintenance - FantechDocument12 pages2 Installation Maintenance - FantechLoi Chan TuNo ratings yet

- Inst General FantechDocument12 pagesInst General FantechCau VoNo ratings yet

- AHU MaintenanceDocument8 pagesAHU MaintenancePrakash MallickNo ratings yet

- Inline Centrifugal Fans ManualDocument11 pagesInline Centrifugal Fans ManualELWAN NAOVAL HAPID ALFANA -No ratings yet

- TS-02 Ventilation Fans - Toilet & BasementDocument11 pagesTS-02 Ventilation Fans - Toilet & BasementPraveen KumarNo ratings yet

- Air ConditioningDocument41 pagesAir Conditioningjulio73cesarNo ratings yet

- 32 5042 04 - 12012011Document8 pages32 5042 04 - 12012011Gerardo ZamoranoNo ratings yet

- Extractor Helicocentrifugo TT Pro 150 Vents ManualDocument20 pagesExtractor Helicocentrifugo TT Pro 150 Vents ManualHumberto LamusNo ratings yet

- Instrument Air SystemDocument16 pagesInstrument Air SystemDony RamdhaniNo ratings yet

- VRV VRV S Indoor Units Guide SpecDocument29 pagesVRV VRV S Indoor Units Guide SpecKatcherr CherrNo ratings yet

- DBF110 Dryer Exhaust Booster System Installation InstructionsDocument4 pagesDBF110 Dryer Exhaust Booster System Installation InstructionstylerdurdaneNo ratings yet

- Installation instructions for DBF4XL dryer exhaust booster fanDocument4 pagesInstallation instructions for DBF4XL dryer exhaust booster fanplumwood1No ratings yet

- VAQ Station For Climate Control: Application NotesDocument11 pagesVAQ Station For Climate Control: Application NotesAnkit JainNo ratings yet

- SB LT32575Document14 pagesSB LT32575zzapiecheNo ratings yet

- Industrial ElkonDocument8 pagesIndustrial ElkonsherryNo ratings yet

- Section 15850 - Air Handling and Distribution Equipment: Part 1 - GeneralDocument11 pagesSection 15850 - Air Handling and Distribution Equipment: Part 1 - GeneralParmanLotimNo ratings yet

- PCVVN1520 VRV4SDocument36 pagesPCVVN1520 VRV4SPepe PradaNo ratings yet

- AP Specs 2008Document39 pagesAP Specs 2008Ghiban ConstantinNo ratings yet

- Fan Coil UnitsDocument2 pagesFan Coil UnitsAhmadNo ratings yet

- Instruction Manual Citric Acid Transfer PumpDocument27 pagesInstruction Manual Citric Acid Transfer PumpSuresh Dharmaraju100% (1)

- Project: Global Hospitals, Chennai. Client: M/s. Global Hospitals, ChennaiDocument2 pagesProject: Global Hospitals, Chennai. Client: M/s. Global Hospitals, ChennailakshminarayananNo ratings yet

- Manual - (Ducted Split Units)Document4 pagesManual - (Ducted Split Units)zebidiansNo ratings yet

- Oil Filter Installation & ServiceDocument16 pagesOil Filter Installation & ServicemdhelicoptersNo ratings yet

- LG Multi V SPECDocument21 pagesLG Multi V SPECJavier SordoNo ratings yet

- 22 电控说明书-英Document27 pages22 电控说明书-英刘巍No ratings yet

- Donaldson Process Chiller Manual MiniDocument31 pagesDonaldson Process Chiller Manual MiniTasos Mythbuster50% (6)

- Erection Instructions For Baghouse FilterDocument13 pagesErection Instructions For Baghouse FilterAnonymous xVCLWJNo ratings yet

- R011. TAEevoTech PDFDocument40 pagesR011. TAEevoTech PDFphukaifrNo ratings yet

- Aprilaire 5000 Installation ManualDocument8 pagesAprilaire 5000 Installation Manualzoid33No ratings yet

- Maquet Servo 900c - User ManualDocument105 pagesMaquet Servo 900c - User Manualpaola_96No ratings yet

- Operating Instructions for Synchronous GeneratorDocument56 pagesOperating Instructions for Synchronous Generatorkazishah100% (1)

- Spec Labgard Nu 565 Series 1 Class II Type b2 Biosafety CabinetDocument4 pagesSpec Labgard Nu 565 Series 1 Class II Type b2 Biosafety CabinetRajeesh P RaviNo ratings yet

- Turbine Enclosure Ventilation SystemDocument17 pagesTurbine Enclosure Ventilation SystemAsifNo ratings yet

- Tech Specification VSDDocument9 pagesTech Specification VSDDony SaputraNo ratings yet

- Daikin Indoor Units Written Guide SpecificationDocument34 pagesDaikin Indoor Units Written Guide SpecificationM Khaerul UmamNo ratings yet

- Manual Fan VerticeDocument20 pagesManual Fan VerticeDoaa MetwallyNo ratings yet

- VN VN: Operation ManualDocument40 pagesVN VN: Operation Manualpampalini88No ratings yet

- Technical Passport For FanDocument4 pagesTechnical Passport For FanGeorgi MihalevNo ratings yet

- Air Blower ManualDocument16 pagesAir Blower ManualshaiknayeemabbasNo ratings yet

- OM005 Halton CaptureJetOperationMaintenanceDocument26 pagesOM005 Halton CaptureJetOperationMaintenanceRaul Jaime Flores GuardiaNo ratings yet

- 6.1 General: InstallationDocument7 pages6.1 General: InstallationDen EdiNo ratings yet

- 'TTA IOM R22 Jan10Document28 pages'TTA IOM R22 Jan10Luong DaoNo ratings yet

- WineZone Air Handler System Installation GuideDocument29 pagesWineZone Air Handler System Installation Guideconstantin.iacomi3837No ratings yet

- MAC 10 LEDC 4x4 IOM - 0217Document20 pagesMAC 10 LEDC 4x4 IOM - 0217lsisniegasNo ratings yet

- Hvac Technical SpecificationsDocument6 pagesHvac Technical SpecificationsAbdul JabbarNo ratings yet

- Aftercooler - Test: Shutdown SIS Previous ScreenDocument7 pagesAftercooler - Test: Shutdown SIS Previous ScreenKeron Trotz100% (1)

- Jet FansDocument8 pagesJet FansTin ThanNo ratings yet

- 2x1400 Sayhoot Technical Documents CompletedDocument17 pages2x1400 Sayhoot Technical Documents Completedengnajeeb75No ratings yet

- Installation Operation Maintenance: HFO Fan CoilsDocument12 pagesInstallation Operation Maintenance: HFO Fan CoilsRd GzNo ratings yet

- MANUAL DE SERVIÇO Umidificador - 60 TAKAOKADocument28 pagesMANUAL DE SERVIÇO Umidificador - 60 TAKAOKAVinicius Belchior da SilvaNo ratings yet

- Air Conditioning: Annexure - 1Document11 pagesAir Conditioning: Annexure - 1narengoeshighNo ratings yet

- Manual Newport Breeze E150 9493Document63 pagesManual Newport Breeze E150 9493minhhoan200660% (5)

- Selection of ActuatorDocument6 pagesSelection of ActuatorHarshal KolheNo ratings yet

- PHPHDocument23 pagesPHPHFARIDNo ratings yet

- Installation and operating instructions for Weishaupt oil burners L, RL, and M Sizes 1 and 3Document40 pagesInstallation and operating instructions for Weishaupt oil burners L, RL, and M Sizes 1 and 3Игорь88% (16)

- Oil-injected screw air systemDocument19 pagesOil-injected screw air systemkareemNo ratings yet

- Catalogue Daikin VRV IV SDocument34 pagesCatalogue Daikin VRV IV SHung Tran75% (12)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Watts - Dar Price List - 2018Document112 pagesWatts - Dar Price List - 2018david messierNo ratings yet

- Truck acceleration behavior study and acceleration lane length recommendationsDocument10 pagesTruck acceleration behavior study and acceleration lane length recommendationsPanji Ginaya TaufikNo ratings yet

- What Is PAS 170 - The Definitive Guide - ATG AccessDocument14 pagesWhat Is PAS 170 - The Definitive Guide - ATG Accessdavid messierNo ratings yet

- Protective Bollard Design For High Speed Impact Energy AbsorptionDocument93 pagesProtective Bollard Design For High Speed Impact Energy Absorptiondavid messierNo ratings yet

- Stopper Bollard Datasheet 200420 v2Document1 pageStopper Bollard Datasheet 200420 v2david messierNo ratings yet

- WINNIPEG - 448-2017 - Division - 23-Heating, - Ventilation - & - ACDocument18 pagesWINNIPEG - 448-2017 - Division - 23-Heating, - Ventilation - & - ACdavid messierNo ratings yet

- RELIANCE FOUNDRY - Crash Rated Bollard BrochureDocument2 pagesRELIANCE FOUNDRY - Crash Rated Bollard Brochuredavid messierNo ratings yet

- Operating Instructions: Century Fire Hydrant B-50-B18 HYDRANT B-50-B24 HYDRANTDocument8 pagesOperating Instructions: Century Fire Hydrant B-50-B18 HYDRANT B-50-B24 HYDRANTdavid messierNo ratings yet

- JM - CalCoat 127 - Data SheetDocument1 pageJM - CalCoat 127 - Data Sheetdavid messierNo ratings yet

- AVR Playground: User ManualDocument29 pagesAVR Playground: User Manualdavid messierNo ratings yet

- HILTI - Approval-document-ASSET-DOC-LOC-722Document1 pageHILTI - Approval-document-ASSET-DOC-LOC-722david messierNo ratings yet

- WM 20120515 ######## R1428 Règlement Sur La Prévention Des IncendiesDocument43 pagesWM 20120515 ######## R1428 Règlement Sur La Prévention Des Incendiesdavid messierNo ratings yet

- WM 20130122 ######## R1439 Règlement Visant À Modifier Le Règlement de Construction 1391Document2 pagesWM 20130122 ######## R1439 Règlement Visant À Modifier Le Règlement de Construction 1391david messierNo ratings yet

- WM 20100506 ######## R1391 Règlement de ConstructionDocument24 pagesWM 20100506 ######## R1391 Règlement de Constructiondavid messierNo ratings yet

- BS100 2x54W T5Document4 pagesBS100 2x54W T5david messierNo ratings yet

- WM 20010927 ######## R1296 Règlement de ConstructionDocument27 pagesWM 20010927 ######## R1296 Règlement de Constructiondavid messierNo ratings yet

- Voting Pads Using AVR Over RS-485: Most of Us Have Seen The TV Game ShowDocument6 pagesVoting Pads Using AVR Over RS-485: Most of Us Have Seen The TV Game Showdavid messierNo ratings yet

- Low Ambient Temperature Heat Pump FSLRDM 10232604310Document2 pagesLow Ambient Temperature Heat Pump FSLRDM 10232604310david messierNo ratings yet

- Atmega 128Document391 pagesAtmega 128vishnu91No ratings yet

- Velometer 6000apand Velometer Jr. 8 1 0 0 Series AnemometersDocument1 pageVelometer 6000apand Velometer Jr. 8 1 0 0 Series Anemometersdavid messierNo ratings yet

- 2980237B-Alnor HVAC Handbook 2005Document61 pages2980237B-Alnor HVAC Handbook 2005Josip FerčecNo ratings yet

- Air Measuring Instrumentation: Rugged. Reliable. ProfessionalDocument16 pagesAir Measuring Instrumentation: Rugged. Reliable. Professionaldavid messierNo ratings yet

- Commercial Refrigeration Product Catalog 2009Document79 pagesCommercial Refrigeration Product Catalog 2009Tengku Anindya ParamithaNo ratings yet

- EBT720 Series Electronic Balancing ToolsDocument4 pagesEBT720 Series Electronic Balancing Toolsdavid messierNo ratings yet

- Naima GuideDocument36 pagesNaima GuideJebús Eduardo MenesesNo ratings yet

- Plug & & Play Play: Product ProfileDocument2 pagesPlug & & Play Play: Product Profiledavid messierNo ratings yet

- VANCOUVERT Kitchen Ventilation Details ChecklistDocument6 pagesVANCOUVERT Kitchen Ventilation Details Checklistdavid messierNo ratings yet

- Hydraulic Design ManualDocument478 pagesHydraulic Design ManualnourNo ratings yet

- BOMA BEST 3.0 Application GuideDocument123 pagesBOMA BEST 3.0 Application Guidedavid messierNo ratings yet

- 4008 Series Catalogue 2011 (External)Document39 pages4008 Series Catalogue 2011 (External)Rayner Aloysius67% (9)

- Viscosity - WikipediaDocument35 pagesViscosity - WikipediaHamza MurtazaNo ratings yet

- Che203fe 21920Document2 pagesChe203fe 21920Khiara Claudine EspinosaNo ratings yet

- Vestas 3.0MW V90-GeneralSpecificationDocument31 pagesVestas 3.0MW V90-GeneralSpecificationBrayden McLean100% (1)

- METAL ARTS - Career Studies Certificate: Program InfoDocument1 pageMETAL ARTS - Career Studies Certificate: Program InfoBobbyNo ratings yet

- Air Conditioner: 01 - Classification of Air Conditioning SystemsDocument3 pagesAir Conditioner: 01 - Classification of Air Conditioning Systemsshubhadipete123No ratings yet

- HSE Alert-42 Safety While Welding Cutting & Grinding 17.06.13Document1 pageHSE Alert-42 Safety While Welding Cutting & Grinding 17.06.13ajeet kumar singhNo ratings yet

- LUKAS Compact CylindersDocument5 pagesLUKAS Compact CylindersMilan BanovicNo ratings yet

- Lab Practical 3 Noor SyazwanDocument5 pagesLab Practical 3 Noor SyazwanNoor Syazwan NasirNo ratings yet

- General Heat Conduction EquationDocument18 pagesGeneral Heat Conduction EquationTamoor TariqNo ratings yet

- Fordson Major ManualDocument47 pagesFordson Major ManualHassan GDOURANo ratings yet

- SD100 D C Serie 187201Document176 pagesSD100 D C Serie 187201Gustavo100% (2)

- Technical Data Sheet Mpt16La 220-240V 50Hz 1 R404A: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet Mpt16La 220-240V 50Hz 1 R404A: Compressor Model Voltage RefrigerantmustafaNo ratings yet

- Gravitation NotesDocument3 pagesGravitation NotesrajeshdraneNo ratings yet

- Experimental Research of Beams With Corrugated Web: Vladimir Zubkov, Alexey LukinDocument6 pagesExperimental Research of Beams With Corrugated Web: Vladimir Zubkov, Alexey LukinTamir EnkhNo ratings yet

- BATCH SETTLING OF SOLID SLURRIES: MOTIVATION, OBJECTIVES, THEORY, EXPERIMENTAL PROCEDURE AND CALCULATIONDocument25 pagesBATCH SETTLING OF SOLID SLURRIES: MOTIVATION, OBJECTIVES, THEORY, EXPERIMENTAL PROCEDURE AND CALCULATIONSUYASH SUNIL ABNAVE PGP 2020 BatchNo ratings yet

- MP E842 Fault CodesDocument188 pagesMP E842 Fault CodesSARAMQR100% (4)

- GATE 2007 CHEMICAL ENGINEERING EXAM REVIEWDocument23 pagesGATE 2007 CHEMICAL ENGINEERING EXAM REVIEWVammsy Manikanta SaiNo ratings yet

- Review UASDocument6 pagesReview UASkarenNo ratings yet

- Essential in WeldingDocument3 pagesEssential in WeldingBelle SantosNo ratings yet

- ASTM A333 Grade 6 Seamless Pipe SupplierDocument4 pagesASTM A333 Grade 6 Seamless Pipe SupplierRajendra FittingsNo ratings yet

- Hand-Off-Automatic Controls Chapter SummaryDocument30 pagesHand-Off-Automatic Controls Chapter SummaryJohn Paul DaliopacNo ratings yet

- 330 Preheating: B H R C B B RDocument2 pages330 Preheating: B H R C B B RStephen RajNo ratings yet

- Design of Walls and Shear WallsDocument19 pagesDesign of Walls and Shear WallsMay100% (1)

- Mil-B-8976 (Asg) : I 6 February 1969Document12 pagesMil-B-8976 (Asg) : I 6 February 1969kkpatel87No ratings yet

- ROLLS ROYCE Gasturbines - tcm92-4977Document20 pagesROLLS ROYCE Gasturbines - tcm92-4977Vipin Thathiriyat100% (3)

- Ah 100 Technical PDFDocument526 pagesAh 100 Technical PDFAnonymous 9TYJjFNo ratings yet

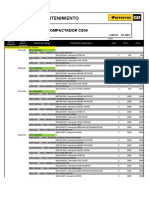

- Programa de Mantenimiento RodilloDocument2 pagesPrograma de Mantenimiento Rodillohugo luna100% (2)

- RSUDocument48 pagesRSUfrank1220uNo ratings yet

- Triaxial Compression Test On Cohesive Soil: Lab Report NoDocument6 pagesTriaxial Compression Test On Cohesive Soil: Lab Report NoYousif MawloodNo ratings yet