Professional Documents

Culture Documents

Full Length Drift Inspection Procedure

Uploaded by

Defi Jodi PermanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Full Length Drift Inspection Procedure

Uploaded by

Defi Jodi PermanaCopyright:

Available Formats

SECTION V

Prepared By GJR 10/26/09

Approved

ANCILLARY Engineer RJH 10/20/09

Approved

SPECIFICATION Dir Engr DR 10/21/09

(GENERIC) Approved

GGM QA GTF 10/29/09

REVISION 006 10/16/09

SUBJECT: FULL LENGTH DRIFT/END DRIFT INSPECTION PROCEDURE

1.0 SCOPE

1.1 This document sets forth the procedure for the drifting of Hunting proprietary connections.

2.0 REFERENCES

2.1 The latest edition of the following documents shall form part of this specification:

2.1.1 API Specification 5CT

2.1.2 API RP5A5

3.0 EQUIPMENT

3.1 The following equipment is required to perform a drift inspection:

3.1.1 Appropriate size drift for product being inspected.

1. Drift Length Tolerance: -0.000" to +0.125"

2. Drift Diameter Tolerance: -0.000 to +0.005"

NOTE: The drift length tolerance is for that length of the drift that is within the given drift diameter

tolerance. The taper or bevel shall not be part of the specified drift length. See Fig. # 1.

Drift.dwg

Drift O.D.

Drift Length

Note: O.D.-1, O.D.-2, and O.D.-3, shall be measured

in both positions A and B (90° appart).

O.D.-1, O.D.-2, O.D.-3, and Drift Length are

critical dimensions.

Fig. # 1: Drift critical dimensions.

3.1.2 Appropriate size O.D. micrometer or equivalent.

3.1.3 Appropriate size vernier dial caliper or equivalent.

3.1.4 Appropriate size steel scale or equivalent.

3.1.5 Bright light source or equivalent.

H:\degeorge\my files\word\ancillary-generic\drift-006 Page 1 of 4

SECTION V

Prepared By GJR 10/26/09

Approved

ANCILLARY Engineer RJH 10/20/09

Approved

SPECIFICATION Dir Engr DR 10/21/09

(GENERIC) Approved

GGM QA GTF 10/29/09

REVISION 006 10/16/09

SUBJECT: FULL LENGTH DRIFT/END DRIFT INSPECTION PROCEDURE

4.0 CERTIFICATION

4.1 The O.D. micrometer shall be calibrated in accordance with the manufacturer's specifications on a

four (4) month interval or prior to the start of each manufacturing order.

4.2 The vernier dial caliper shall be calibrated in accordance with the manufacturer's specifications on

a four (4) month interval or prior to the start of each manufacturing order.

4.3 Certifying agency shall issue a written certification of O.D. micrometer / vernier dial caliper

calibration. The document shall include the following data:

4.3.1 Name of certifying agency

4.3.2 Name of individual performing calibration

4.3.3 Specification to which gage was calibrated

4.3.4 Date calibration was performed

4.3.5 Date next calibration due

4.3.6 Gage description

4.3.7 Gage serial number

4.3.8 Calibrator Serial Number

4.4 Recalibration and certification are required anytime a gage is dropped or following any repairs to

the assembly or dial indicator.

5.0 VERIFICATION

5.1 Verify that the appropriate O.D. micrometer or vernier dial caliper has been procured.

5.2 Verify that the procured gages are within valid certification dates.

5.3 Using a properly calibrated vernier dial caliper or O.D. micrometer, measure the drift diameter to

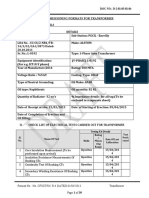

the nearest 0.001" on each end and in the middle of the drift. Measure with sufficient number of

readings to determine the largest and the smallest diameters. Record the measurements.

5.4 Using a steel scale, measure the overall length of the mandrel excluding rounded or tapered

leading edges.

5.5 Measuring devices shall be the same temperature as the drift mandrel. (The same temperature

means within 5°F of each other after being stabilized for 30 minutes.)

5.6 If a drift mandrel is found to be out of tolerance, all tubes drift tested between that time and the

previous acceptable verification shall be redrifted with an acceptable drift.

NOTE: Any drift mandrel found to be out of tolerance shall not be used.

H:\degeorge\my files\word\ancillary-generic\drift-006 Page 2 of 4

SECTION V

Prepared By GJR 10/26/09

Approved

ANCILLARY Engineer RJH 10/20/09

Approved

SPECIFICATION Dir Engr DR 10/21/09

(GENERIC) Approved

GGM QA GTF 10/29/09

REVISION 006 10/16/09

SUBJECT: FULL LENGTH DRIFT/END DRIFT INSPECTION PROCEDURE

6.0 VERIFICATION FREQUENCY

6.1 The drift mandrel’s specified length and diameters shall be verified at the following frequency:

6.1.1 Prior to the start of an order.

6.1.2 At the start of each shift.

6.1.3 At shift change.

6.1.4 After the final shift of the day.

6.1.5 At the completion of the order.

7.0 INSPECTION FREQUENCY

7.1 A full length drift shall be performed as required by the purchase order at a 100% frequency.

7.2 For threaded and coupled pipe, an end drift shall be performed following each coupling buck-on at

a 100% frequency.

8.0 INSPECTION PROCEDURE

8.1 Assure the drift mandrel is at the same temperature as the pipe being inspected.

8.2 Remove thread protectors and visually inspect to assure the pipe to be inspected is clean. Using a

bright light source verify that the tube I.D. is free of debris.

8.3 Using appropriate caution to prevent damage to any threaded or machined surface, carefully insert

the appropriate drift mandrel inside the tube I.D. from the box end.

8.4 Insert the drift mandrel to a depth in the tube equal to the length of the drift into the I.D. for end

drifting or equal to the entire length of the tube for full length drift. Use a force equal to or less

than the weight of the mandrel.

8.5 Use appropriate caution to prevent damage to the threaded area when removing the drift mandrel

from the tube I.D.

9.0 ACCEPTANCE/REJECTION

9.1 If the drift mandrel passes freely through the required drift length, the tube has passed the drift test

and is acceptable.

9.2 Any tube in which the mandrel does not pass freely through the required drift length or stops due

to an obstruction shall be rejected.

9.3 All tubes that fail the drift test shall have a red paint band painted adjacent to the box and a red

paint band in the area that the drift stopped with the words “No Drift to XX.XXX” stenciled

clearly adjacent to the red band, where XX.XXX is the size of the drift.

9.4 All rejects shall be clearly identified as “reject” to protect against out-of-tolerance material being

shipped as prime material.

9.5 Any discrepancies shall be clarified and dispositioned by Hunting’s Q.A. Department before any

further processing or delivery.

H:\degeorge\my files\word\ancillary-generic\drift-006 Page 3 of 4

SECTION V

Prepared By GJR 10/26/09

Approved

ANCILLARY Engineer RJH 10/20/09

Approved

SPECIFICATION Dir Engr DR 10/21/09

(GENERIC) Approved

GGM QA GTF 10/29/09

REVISION 006 10/16/09

SUBJECT: FULL LENGTH DRIFT/END DRIFT INSPECTION PROCEDURE

10.0 REWORK

10.1 All tubes which fail the drift test shall be visually inspected on both O.D. and I.D. to assure the

tube straightness and tube cleanliness on the I.D. surface.

10.2 Following a cleaning of the tube I.D. surface, re-drift the tube in accordance with 8.3 - 8.5.

10.3 Acceptance/rejection shall be as specified above in Section 9.0 of this document.

NOTE: In case of dispute, a precision steel drift mandrel made to the appropriate ISO/API

dimensions shall be used to resolve whether the lengths are acceptable or rejectable.

11.0 IDENTIFICATION

11.1 All tubes that pass the drift test shall be stenciled “END DRIFT” or "FULL LENGTH DRIFT"

adjacent to the box as applicable.

11.2 All tubes that fail the drift test shall be painted as described on section 9.0 of this document.

H:\degeorge\my files\word\ancillary-generic\drift-006 Page 4 of 4

You might also like

- State Energy Inspection Services Instruction # Manual 8.0 Standard Operating Procedure Revision Effective DateDocument3 pagesState Energy Inspection Services Instruction # Manual 8.0 Standard Operating Procedure Revision Effective DateGabriela MotaNo ratings yet

- Proceso Cold RollingDocument7 pagesProceso Cold RollingFernando FiallosNo ratings yet

- Jsa TubularDocument2 pagesJsa TubularRonniNo ratings yet

- 10.75 BC CSGDocument1 page10.75 BC CSGharyantoNo ratings yet

- HMC Spec 001 - Welding and Fabrication of Structural SteelDocument29 pagesHMC Spec 001 - Welding and Fabrication of Structural SteelJohnnyNo ratings yet

- 4260Document10 pages4260Lipika GayenNo ratings yet

- QAP for Flange InspectionDocument2 pagesQAP for Flange InspectionGOPINATH KRISHNAN NAIRNo ratings yet

- Engineering Manager Bahja C6.13Document1 pageEngineering Manager Bahja C6.13Geetha_jagadish30No ratings yet

- Receipt Inspection NS2A4Document11 pagesReceipt Inspection NS2A4islam atifNo ratings yet

- Hole Openers NS 1 A4 WatermarkedDocument13 pagesHole Openers NS 1 A4 Watermarkedislam atifNo ratings yet

- 5 5 DP-HT55-repDocument1 page5 5 DP-HT55-repChristopher Jones100% (1)

- A388 PDFDocument9 pagesA388 PDFnegg 348No ratings yet

- STD-InSP-0006 (Flange Inspection Procedure)Document3 pagesSTD-InSP-0006 (Flange Inspection Procedure)airbroom100% (1)

- Cold Rolling Info GuideDocument11 pagesCold Rolling Info Guide72espoNo ratings yet

- Used Thread Inspection / Repair Procedures: Dimensional Inspection Method / QP200-007 / Rev. UDocument45 pagesUsed Thread Inspection / Repair Procedures: Dimensional Inspection Method / QP200-007 / Rev. UIvan MauricioNo ratings yet

- API 6A Conformance AssessmentDocument2 pagesAPI 6A Conformance AssessmentMacelNo ratings yet

- Ut FormulaDocument1 pageUt FormulaMuhammad ZariqNo ratings yet

- EMI Buggy Cal 5Document2 pagesEMI Buggy Cal 5John DolanNo ratings yet

- VGS 23.3.2 Rev 4 (MPI (Flourescent) For Equinor) )Document21 pagesVGS 23.3.2 Rev 4 (MPI (Flourescent) For Equinor) )Rod RoperNo ratings yet

- NDT-PT InspectionDocument15 pagesNDT-PT InspectionIvan MauricioNo ratings yet

- Thread Gauging Techniques: Ansi/Asme Straight ThreadsDocument14 pagesThread Gauging Techniques: Ansi/Asme Straight ThreadsChandrasekhar SonarNo ratings yet

- Reasons For Using Cementing PlugsDocument12 pagesReasons For Using Cementing PlugsMohamad ZamriNo ratings yet

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Document22 pagesP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal MenonNo ratings yet

- PT-Liquid Penetrant Testing Procedure R01 - 2 2Document12 pagesPT-Liquid Penetrant Testing Procedure R01 - 2 2George Ogbeche100% (1)

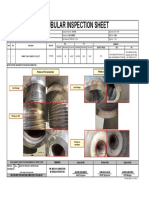

- Tubular Inspection Sheet - 2021-001 Part 2Document2 pagesTubular Inspection Sheet - 2021-001 Part 2Aldrin Hernandez100% (2)

- Antony Mervin - SR - qa.QC EngineerDocument6 pagesAntony Mervin - SR - qa.QC EngineerantonyNo ratings yet

- Odessa Office Tubing SpecsDocument1 pageOdessa Office Tubing SpecsGeorge IkpeNo ratings yet

- Schoeller-Bleckmann Darron CatalogueDocument35 pagesSchoeller-Bleckmann Darron CatalogueDon Braithwaite100% (2)

- Consumable Control FormsDocument5 pagesConsumable Control FormsvsnaiduqcNo ratings yet

- 18 - Fork Lift Defect - OptDocument4 pages18 - Fork Lift Defect - OptMoataz NazeemNo ratings yet

- API E-165 Standard Test Method For Liquid Penetrant Examination PDFDocument20 pagesAPI E-165 Standard Test Method For Liquid Penetrant Examination PDFDaniel GamioNo ratings yet

- SRINIVASAN CHANDRAN's ResumeDocument4 pagesSRINIVASAN CHANDRAN's ResumePaul PhiliphsNo ratings yet

- VGS 23.1.4 Rev 3 (UT of Weld Overlay For Equinor)Document18 pagesVGS 23.1.4 Rev 3 (UT of Weld Overlay For Equinor)Rod RoperNo ratings yet

- Work Instruction FOR: Charpy Impact TestDocument4 pagesWork Instruction FOR: Charpy Impact TestmahendraNo ratings yet

- Rotary Sub-Thread Checking Procedure-JSSbrochureDocument4 pagesRotary Sub-Thread Checking Procedure-JSSbrochureMinakshi SawantNo ratings yet

- Running Procedure: Voestalpine Tubulars GMBH & Co KG Voestalpine Tubulars GMBH & Co KGDocument16 pagesRunning Procedure: Voestalpine Tubulars GMBH & Co KG Voestalpine Tubulars GMBH & Co KGSumesh DethanNo ratings yet

- LPT As Per Asme & IsoDocument2 pagesLPT As Per Asme & IsosbmmlaNo ratings yet

- Thread Protector Testing - PTR-7.3.10-7-LCSG-FULL-PLASTIC-API-5-CT-PERFORMANCE-TEST-REPORTDocument38 pagesThread Protector Testing - PTR-7.3.10-7-LCSG-FULL-PLASTIC-API-5-CT-PERFORMANCE-TEST-REPORTInChy Rencarnation PoseidonNo ratings yet

- Casing and Tubing Crossovers: ScopeDocument4 pagesCasing and Tubing Crossovers: Scopeislam atifNo ratings yet

- LIQUID PENETRANT TESTING PROCEDUREDocument23 pagesLIQUID PENETRANT TESTING PROCEDURESerajahmad56No ratings yet

- Used Thread Inspection / Repair Procedures: Dimensional Inspection Method / QP200-007 / Rev. TDocument44 pagesUsed Thread Inspection / Repair Procedures: Dimensional Inspection Method / QP200-007 / Rev. TIvan MauricioNo ratings yet

- NDE-Penetrant TestDocument2 pagesNDE-Penetrant TestCandy KendeeNo ratings yet

- Used Thread Inspection / Repair Procedures: Dimensional Inspection Method / QP200-007 / Rev. TDocument44 pagesUsed Thread Inspection / Repair Procedures: Dimensional Inspection Method / QP200-007 / Rev. TIvan MauricioNo ratings yet

- API 4G - E5 Addendum 2Document4 pagesAPI 4G - E5 Addendum 2KATHERINE RIVERANo ratings yet

- Welding Repairing Tubing ProcedureDocument6 pagesWelding Repairing Tubing ProcedurealidadNo ratings yet

- Specification: 70.78412 Revision: I Date: August 13, 2010 Specification - General Procedure - Brinell and Rockwell Hardness TestingDocument4 pagesSpecification: 70.78412 Revision: I Date: August 13, 2010 Specification - General Procedure - Brinell and Rockwell Hardness Testingstephen lewellenNo ratings yet

- Ultrasonic Test Report: Testing TechniqueDocument2 pagesUltrasonic Test Report: Testing TechniqueMd RizwanNo ratings yet

- NS-1-70. Hardness TestingDocument2 pagesNS-1-70. Hardness TestingWHWENNo ratings yet

- API Threading Work InstructionsDocument55 pagesAPI Threading Work Instructionsjbeck-6100% (2)

- Cementing Tools: General RequirementsDocument4 pagesCementing Tools: General Requirementsislam atifNo ratings yet

- Advance Energy API 4G Inspection ReportDocument90 pagesAdvance Energy API 4G Inspection ReportMohamed Ismail100% (1)

- Quality Docs DEP 17 0803Document7 pagesQuality Docs DEP 17 0803Edwin MPNo ratings yet

- Leopard General and in Stal Tion InformationDocument18 pagesLeopard General and in Stal Tion InformationChandrasekhar SonarNo ratings yet

- Ferroxyl Test For Iron ContaminationDocument9 pagesFerroxyl Test For Iron ContaminationteokalNo ratings yet

- Tubular Inspection Sheet - 2021-002 Pg.1Document1 pageTubular Inspection Sheet - 2021-002 Pg.1Aldrin HernandezNo ratings yet

- Field inspection criteria for JFEBEAR threaded connectionsDocument5 pagesField inspection criteria for JFEBEAR threaded connectionsGabriel Ibarra100% (2)

- Drift 005Document4 pagesDrift 005tofa01100% (1)

- Runkcconvertible All 003Document10 pagesRunkcconvertible All 003Cong BuiNo ratings yet

- NO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last CalibrationDocument39 pagesNO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last Calibrationmayur dhandeNo ratings yet

- DPDocument19 pagesDPMohammad HusanNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarPopovici AlexandruNo ratings yet

- VAM Connection Data Sheets Manual: A. General CommentsDocument4 pagesVAM Connection Data Sheets Manual: A. General CommentsDileep KumarNo ratings yet

- Compatible Tubing Ts6Document28 pagesCompatible Tubing Ts6Defi Jodi Permana0% (1)

- VAM Connection Data Sheets Manual: A. General CommentsDocument4 pagesVAM Connection Data Sheets Manual: A. General CommentsDileep KumarNo ratings yet

- Farr 20000Document1 pageFarr 20000Defi Jodi PermanaNo ratings yet

- APAC Report Issue 130 End-October 2018Document21 pagesAPAC Report Issue 130 End-October 2018Defi Jodi PermanaNo ratings yet

- 5.500 s135 FH DSTJ Drill Pipe Rental Saltire EnergyDocument3 pages5.500 s135 FH DSTJ Drill Pipe Rental Saltire EnergyDefi Jodi PermanaNo ratings yet

- Compatible Tubing Ts6Document28 pagesCompatible Tubing Ts6Defi Jodi Permana0% (1)

- Mccoy Chrome MasterDocument1 pageMccoy Chrome MasterDefi Jodi Permana100% (1)