100% found this document useful (2 votes)

4K views1 pageFlowmeter Selection Chart

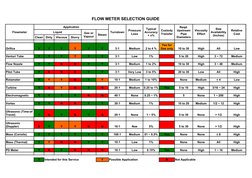

The document provides a flow meter selection guide comparing various flowmeter types based on their suitability for different applications considering factors like liquid or gas measurement, operating pressure and temperature, required accuracy, upstream pipe size, viscosity effect, turndown ratio, availability of sizes, and relative cost. It lists common flowmeter types like orifice, venturi tube, flow nozzle, pitot tube, rotameter, turbine, electromagnetic, vortex, ultrasonic, mass, and positive displacement meters and evaluates them on the listed parameters to aid in selecting the right flow measurement technology for an application.

Uploaded by

milton1987Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

4K views1 pageFlowmeter Selection Chart

The document provides a flow meter selection guide comparing various flowmeter types based on their suitability for different applications considering factors like liquid or gas measurement, operating pressure and temperature, required accuracy, upstream pipe size, viscosity effect, turndown ratio, availability of sizes, and relative cost. It lists common flowmeter types like orifice, venturi tube, flow nozzle, pitot tube, rotameter, turbine, electromagnetic, vortex, ultrasonic, mass, and positive displacement meters and evaluates them on the listed parameters to aid in selecting the right flow measurement technology for an application.

Uploaded by

milton1987Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd