Professional Documents

Culture Documents

Lec-S2-Ch-4 - Lesson 6-A

Uploaded by

Omer Ikhlas0 ratings0% found this document useful (0 votes)

36 views11 pagesOriginal Title

Lec-S2-Ch-4 -Lesson 6-A _1122603b1af0b847da7c9be06ec761e0

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views11 pagesLec-S2-Ch-4 - Lesson 6-A

Uploaded by

Omer IkhlasCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 11

Faculty Of Engineering

Petroleum Engineering Department

Production Engineering II

Fourth Stage

Chapter 4:-

Flow Line performance

BSc Petroleum Engineering – Koya University July 2010

MSc Petroleum Engineering- Teesside Uni. United Kingdom October 2013 By:

Petroleum Production Engineering

Sarhad Ahmed 1

Member of Society of Petroleum Engineer (SPE), Onepetro access

© 2006 Weatherford. All rights reserved. Sarhad.ahmed@koyauniversity.org

DPTE

Flow Line Performance

Flow Line performance correlation

@koya university 2018-2019 PENG

© 2006 Weatherford. All rights reserved.

2

DPTE

Flow Line Performance

Flow Line correlation:

• Many correlations for pipeline flow prediction have been developed over

the past 30 or 40 years.

• A review of many of the correlations and the manner in which they were

developed is not required from petroleum engineer rather than simple

correlations used in determining only pressure parameter.

• Since the purpose of this course is to present the best methods to

analyse a production system, only the methods which are widely used at

the present time will be discussed.

@koya university 2018-2019 PENG

© 2006 Weatherford. All rights reserved.

3

DPTE

Flow Line Performance

Flow Line correlation:

The following correlation methods are presented:

1. Eton et.al method HW

2. Dukler, el al., method

1.

3. Beggs and Brill Method + Gilbert (Working Charts)

4. Flanigan Method for Hilly Terrain

5. Hybrid Model

6. G. MONA, Asheim Melhod

@koya university 2018-2019 PENG

© 2006 Weatherford. All rights reserved.

4

DPTE

Flow Line Performance

Flow Line correlation:

Beggs and Brill Method + Gilbert (Working Charts)

• They developed an elegant graphical method for finding the horizontal-

flow pressure losses for Multi-phase flow.

• These approach to the horizontal two-phase flow problem was empirical;

based on measured values of pipe-flow pressure losses. By supposing

that the following measurements have been taken in a large number of

flowing wells:

Flow line length (pipe) Lf, ft.

Flow line size (pipe diameter) df, inch.

Tubing size (tubing diameter) d, inch.

THP pth, psig.

Working pressure of separator psep, psig.

Gross liquid rate, bbl/day.

GLR, Scf/bbl.

Tubing depth D, ft.

@koya university 2018-2019 PENG

© 2006 Weatherford. All rights reserved.

5

DPTE

Flow Line Performance

Flow Line correlation:

Beggs and Brill Method + Gilbert (Working Charts)

@koya university 2018-2019 PENG

© 2006 Weatherford. All rights reserved.

6

DPTE

Flow Line Performance

Flow Line correlation:

Beggs and Brill Method + Gilbert (Working Charts)

Example 5.1:

A well is producing at a rate of 1500 STB/day with a GLR of 600

SCF/STB. No water is being produced and the well is located al a

distance of 6000 ft from the separator. If the separator pressure is fixed

at 120 psig, find the required wellhead pressure for flowline sizes of 2

in. and 3 in.

@koya university 2018-2019 PENG

© 2006 Weatherford. All rights reserved.

7

DPTE

Flow Line Performance

Flow Line correlation:

Beggs and Brill Method

790 psi + Gilbert (Working Charts)

@koya university 2018-2019 PENG

© 2006 Weatherford. All rights reserved.

8

DPTE

Flow Line Performance

280 psi

Flow Line correlation:

Beggs and Brill Method + Gilbert (Working Charts)

@koya university 2018-2019 PENG

© 2006 Weatherford. All rights reserved.

9

DPTE

Flow Line Performance

Flow Line correlation:

Beggs and Brill Method + Gilbert (Working Charts)

Example 5.2-Tutorials:

A well that is to produce at rate of 1500 STB/day with a wellhead

pressure of 400 psig is located 5000ft from the separator. The separator

pressure is fixed at 200 psig. The well is producing no water and the

GLR is 1000 scf/STB. Find the necessary flowline size required for this

well if the terrain between the well and the separator is relatively flat.

@koya university 2018-2019 PENG

© 2006 Weatherford. All rights reserved.

10

End

DPTE

End of Chapter

@koya university 2018-2019 PENG

© 2006 Weatherford. All rights reserved.

11

You might also like

- Lec-S2-Ch-4 - Lesson 6-BDocument30 pagesLec-S2-Ch-4 - Lesson 6-BOmer IkhlasNo ratings yet

- Chapter 2:-: Faculty of Engineering Petroleum Engineering Department Production Engineering II Fourth StageDocument12 pagesChapter 2:-: Faculty of Engineering Petroleum Engineering Department Production Engineering II Fourth StageOmer IkhlasNo ratings yet

- Lec-S2-Ch-3 - Lesson 4Document36 pagesLec-S2-Ch-3 - Lesson 4Omer IkhlasNo ratings yet

- Chapter 2:-: Faculty of Engineering Petroleum Engineering Department Production Engineering II Fourth StageDocument28 pagesChapter 2:-: Faculty of Engineering Petroleum Engineering Department Production Engineering II Fourth StageOmer IkhlasNo ratings yet

- Chapter 2:-: Faculty of Engineering Petroleum Engineering Department Production Engineering II Fourth StageDocument29 pagesChapter 2:-: Faculty of Engineering Petroleum Engineering Department Production Engineering II Fourth StageOmer IkhlasNo ratings yet

- SPE-172435-MS Comparative Analysis of Permanent Downhole Gauges and Their ApplicationsDocument11 pagesSPE-172435-MS Comparative Analysis of Permanent Downhole Gauges and Their ApplicationsSabrina PeñaNo ratings yet

- Spe 131758 Ms - GL and EspDocument11 pagesSpe 131758 Ms - GL and EspSamuel VmNo ratings yet

- The Control Method of Pigging Slug Flow For MultipDocument6 pagesThe Control Method of Pigging Slug Flow For MultipНикита ВязиковNo ratings yet

- Piping Supervisor - AmbeDocument8 pagesPiping Supervisor - Ambesharan21v0% (1)

- Chapter 1:-: Faculty of Engineering Petroleum Engineering Department Production Engineering II Fourth StageDocument37 pagesChapter 1:-: Faculty of Engineering Petroleum Engineering Department Production Engineering II Fourth StageOmer IkhlasNo ratings yet

- CFD Analysis of Phenomena Attributed To Pigging Run in A Straight PipelineDocument10 pagesCFD Analysis of Phenomena Attributed To Pigging Run in A Straight PipelineHarshad ChavanNo ratings yet

- Paper 93 Spe 159484 Adipec 2012Document12 pagesPaper 93 Spe 159484 Adipec 2012MuhanadNo ratings yet

- Delaying Transition to Turbulence in Pipe FlowDocument18 pagesDelaying Transition to Turbulence in Pipe FlowitspriyankaNo ratings yet

- Supervisión Tremendo - PCPDocument17 pagesSupervisión Tremendo - PCPmanuel cabarcasNo ratings yet

- Spe 192139 MsDocument10 pagesSpe 192139 MssariNo ratings yet

- Impact of Operating and Health Conditions On Aero Gas Turbine Hot Section Creep Life Using A Creep Factor ApproachDocument13 pagesImpact of Operating and Health Conditions On Aero Gas Turbine Hot Section Creep Life Using A Creep Factor ApproachRafael ChiavegattoNo ratings yet

- An Innovative Approach To Drill A Extended Reach Well Using High Torque ConnectionDocument4 pagesAn Innovative Approach To Drill A Extended Reach Well Using High Torque ConnectionCristian LemosNo ratings yet

- V003t05a002 Ipc2018 78097Document15 pagesV003t05a002 Ipc2018 78097c885ffmfrrNo ratings yet

- TS 4 - 3 Randeep AgarwalDocument18 pagesTS 4 - 3 Randeep AgarwalAsep FirmansyahNo ratings yet

- Determination of Cyanide Content On WastewaterDocument9 pagesDetermination of Cyanide Content On WastewaterRicleto EspinosaNo ratings yet

- Latin IAHR Trabajo Completo Ingles JournalDocument12 pagesLatin IAHR Trabajo Completo Ingles JournalMauriNo ratings yet

- A Model To Estimate The Failure Rates of Offshore PipelinesDocument11 pagesA Model To Estimate The Failure Rates of Offshore Pipelinesrovlad2000No ratings yet

- A Summary of Artificial Lift Failure, Remedies and Run Life Improvements in Conventional and Unconventional WellsDocument8 pagesA Summary of Artificial Lift Failure, Remedies and Run Life Improvements in Conventional and Unconventional WellsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Data in BriefDocument7 pagesData in BriefRandy SooknananNo ratings yet

- Kim 2015 IOP Conf. Ser. Mater. Sci. Eng. 72 042044 PDFDocument8 pagesKim 2015 IOP Conf. Ser. Mater. Sci. Eng. 72 042044 PDFHema KumarNo ratings yet

- Riopipeline2019 1117 Ibp1117 19 Versao Final para e PDFDocument8 pagesRiopipeline2019 1117 Ibp1117 19 Versao Final para e PDFMarcelo Varejão CasarinNo ratings yet

- Reservoir Fluid Data Acquisition Using Advanced Mud Logging Gas in Shale ReservoirsDocument17 pagesReservoir Fluid Data Acquisition Using Advanced Mud Logging Gas in Shale ReservoirshijoetigreNo ratings yet

- Jhanjra MinesDocument69 pagesJhanjra MinesRathla Naveen100% (1)

- SPE-184215 - Hybrid System - ESP and GL - Aplication From Conceptual To Pilot TestDocument13 pagesSPE-184215 - Hybrid System - ESP and GL - Aplication From Conceptual To Pilot TestDede PratamaNo ratings yet

- Kumashiro 2019 IOP Conf. Ser. Earth Environ. Sci. 240 072006Document10 pagesKumashiro 2019 IOP Conf. Ser. Earth Environ. Sci. 240 072006emerson william vidalNo ratings yet

- Meng2019 Article ProductionLoggingViaCoiledTubiDocument7 pagesMeng2019 Article ProductionLoggingViaCoiledTubiSteven H. Vera IllanesNo ratings yet

- Surely FinalDocument104 pagesSurely FinalAbhay SuwalNo ratings yet

- 1 151125221535 Lva1 App6892Document40 pages1 151125221535 Lva1 App6892Darmawan PutrantoNo ratings yet

- BTG TTC Presentation Albany Panel 2010Document19 pagesBTG TTC Presentation Albany Panel 2010LauraGarciaAyalaNo ratings yet

- Production Optimization in Well 6 of Habiganj Gas Field, Bangladesh: A Prospective Application of Nodal Analysis ApproachDocument12 pagesProduction Optimization in Well 6 of Habiganj Gas Field, Bangladesh: A Prospective Application of Nodal Analysis ApproachBesma CherifNo ratings yet

- Conference and Exhibition 2019Document10 pagesConference and Exhibition 2019Marcelo Varejão CasarinNo ratings yet

- Polypropylene Production Simulation With Cape-Open Interfacing of Pro/ii and gPROMSDocument15 pagesPolypropylene Production Simulation With Cape-Open Interfacing of Pro/ii and gPROMSAhmadNo ratings yet

- Quality Control in Welding Repair of Pelton RunnerDocument8 pagesQuality Control in Welding Repair of Pelton RunnerDheeraj ThakurNo ratings yet

- Machinery turnaround practicesDocument11 pagesMachinery turnaround practicesAmar NatourNo ratings yet

- CFD Evaluation of Sand Erosion Wear Rate in Pipe Bends Used in Technological InstallationsDocument9 pagesCFD Evaluation of Sand Erosion Wear Rate in Pipe Bends Used in Technological InstallationsABHISEK BABUNo ratings yet

- Riopipeline2019 1138 Rio Paper Rev01 PDFDocument11 pagesRiopipeline2019 1138 Rio Paper Rev01 PDFMarcelo Varejão CasarinNo ratings yet

- Carbon Footprint and Embodied Energy of PVC, PE, and PP Piping: Perspective On Environmental PerformanceDocument7 pagesCarbon Footprint and Embodied Energy of PVC, PE, and PP Piping: Perspective On Environmental PerformanceChris BryanNo ratings yet

- Surely FinalDocument104 pagesSurely FinalAbhay SuwalNo ratings yet

- IBP1099 - 19 Deep Water Pip Installation Using Reel-Lay MethodDocument12 pagesIBP1099 - 19 Deep Water Pip Installation Using Reel-Lay MethodMarcelo Varejão CasarinNo ratings yet

- Technology Environment Economy Assessment of High 2022 International JournaDocument20 pagesTechnology Environment Economy Assessment of High 2022 International JournaPrashant HNo ratings yet

- E MseptSOR2022Document239 pagesE MseptSOR2022Abhishek TiwariNo ratings yet

- Electric Company : Drying Procedure For PipelinesDocument19 pagesElectric Company : Drying Procedure For Pipelineschandrakit047No ratings yet

- Cementing Program For 9 58 Inch CasingDocument42 pagesCementing Program For 9 58 Inch CasingMarvin OmañaNo ratings yet

- IPTC-22235-MS Foams To Control Slugging Issues in Pipeline - From Lab To SimulationDocument9 pagesIPTC-22235-MS Foams To Control Slugging Issues in Pipeline - From Lab To SimulationLuky HendraningratNo ratings yet

- PMR Follow Up Situation 1 Mar 2021Document24 pagesPMR Follow Up Situation 1 Mar 2021AhmedNo ratings yet

- Creep Calculation of Extradosed BridgeDocument9 pagesCreep Calculation of Extradosed Bridgesiva_ascinfratechNo ratings yet

- A New Single-Sided Blind Riveting Method For Joining Dissimilar MaterialsDocument5 pagesA New Single-Sided Blind Riveting Method For Joining Dissimilar MaterialsharisNo ratings yet

- Draft: On The Economics of The Use of Biomass Fuels in Gas Turbine Cycles: Gasification vs. Externally FiringDocument6 pagesDraft: On The Economics of The Use of Biomass Fuels in Gas Turbine Cycles: Gasification vs. Externally FiringOnnuri WonNo ratings yet

- Determination of Basic Wind Speed For The Design oDocument9 pagesDetermination of Basic Wind Speed For The Design oMd. Ariful IslamNo ratings yet

- Modeling of Severe Slug and Slug Control With OLGA: SPE Production & Operations August 2006Document31 pagesModeling of Severe Slug and Slug Control With OLGA: SPE Production & Operations August 2006Paul OhiorNo ratings yet

- SPE 173016 MS - PDF Casing UnlockedDocument14 pagesSPE 173016 MS - PDF Casing UnlockedJorge FernandoNo ratings yet

- Kimberley Pipeline Project ReviewDocument20 pagesKimberley Pipeline Project ReviewhopexanddreamxNo ratings yet

- Galaby 2019Document11 pagesGalaby 2019GERARDO TORRES RUIZNo ratings yet

- Plaster Method Statement for Thermal Power ProjectDocument6 pagesPlaster Method Statement for Thermal Power ProjectSumit OmarNo ratings yet

- Reservoir SimulationDocument12 pagesReservoir SimulationOmer IkhlasNo ratings yet

- Gas Reservoir 1Document49 pagesGas Reservoir 1Omer IkhlasNo ratings yet

- Gas Reservoir 2Document30 pagesGas Reservoir 2Omer IkhlasNo ratings yet

- Introduction To Reservoir EngineeringDocument78 pagesIntroduction To Reservoir EngineeringOmer IkhlasNo ratings yet

- Application MB For Oil ReservoirsDocument44 pagesApplication MB For Oil ReservoirsOmer IkhlasNo ratings yet

- Eclipse Assignment 2: Reservoir DataDocument3 pagesEclipse Assignment 2: Reservoir DataOmer IkhlasNo ratings yet

- Unu GTP 2013 27 PDFDocument34 pagesUnu GTP 2013 27 PDFdeasyarianti33No ratings yet

- Gas Condensate ReservoirsDocument29 pagesGas Condensate ReservoirsOmer IkhlasNo ratings yet

- Pressure Traverse CurvesDocument16 pagesPressure Traverse CurvesLoh Chun Liang86% (7)

- 12.1 Wte-Lect. No.12 (2SPP)Document21 pages12.1 Wte-Lect. No.12 (2SPP)Omer IkhlasNo ratings yet

- 15.1 Wte-Lect. No.15 (2SPP)Document10 pages15.1 Wte-Lect. No.15 (2SPP)Omer IkhlasNo ratings yet

- Natural Gas Engineering Course BookDocument23 pagesNatural Gas Engineering Course BookSarbast Taqana100% (1)

- 9.1 Wte-Lect. No.09 (2SPP)Document8 pages9.1 Wte-Lect. No.09 (2SPP)Omer IkhlasNo ratings yet

- 10.1 Wte-Lect. No.10 (2SPP)Document10 pages10.1 Wte-Lect. No.10 (2SPP)Omer IkhlasNo ratings yet

- RS - Lecture 4 PDFDocument19 pagesRS - Lecture 4 PDFOmer IkhlasNo ratings yet

- Diagnostic Fracture Injection Test (DFIT) Well Testing EngineeringDocument6 pagesDiagnostic Fracture Injection Test (DFIT) Well Testing EngineeringOmer IkhlasNo ratings yet

- RS - Lecture 9Document32 pagesRS - Lecture 9Omer IkhlasNo ratings yet

- Reservoir Simulation: Lecture 1: IntroductionDocument19 pagesReservoir Simulation: Lecture 1: IntroductionOmer IkhlasNo ratings yet

- 14.1 Wte-Lect. No.14 (2SPP)Document18 pages14.1 Wte-Lect. No.14 (2SPP)Omer IkhlasNo ratings yet

- Reservoir Simulation Lecture 4: End-Point Scaling, Pseudo PropertiesDocument19 pagesReservoir Simulation Lecture 4: End-Point Scaling, Pseudo PropertiesOmer IkhlasNo ratings yet

- Reservoir Simulation Models: Black Oil and CompositionalDocument26 pagesReservoir Simulation Models: Black Oil and CompositionalOmer IkhlasNo ratings yet

- RS - Lecture 3Document37 pagesRS - Lecture 3Omer IkhlasNo ratings yet

- RS - Lecture 7Document33 pagesRS - Lecture 7Omer IkhlasNo ratings yet

- RS - Lecture 5Document38 pagesRS - Lecture 5Omer IkhlasNo ratings yet

- RS - Lecture 2 PDFDocument26 pagesRS - Lecture 2 PDFOmer IkhlasNo ratings yet

- RS - Lecture 6Document23 pagesRS - Lecture 6Omer IkhlasNo ratings yet

- 1.1. Wte-Lect. No.01 (2SPP)Document14 pages1.1. Wte-Lect. No.01 (2SPP)Omer IkhlasNo ratings yet

- Atoms & Ions Worksheet 1 /63: Atomic Number and Mass NumberDocument4 pagesAtoms & Ions Worksheet 1 /63: Atomic Number and Mass Numbercate christineNo ratings yet

- X Physics Formula Sheet ReducedDocument3 pagesX Physics Formula Sheet ReducedGAMEFLOW PLAYSNo ratings yet

- Ansaldo List of Cleaning AgentDocument2 pagesAnsaldo List of Cleaning AgentEDB100% (1)

- Kinematics Particle Straight LineDocument51 pagesKinematics Particle Straight LineisamalhassanNo ratings yet

- Velocity-Head Coefficients in Open ChannelsDocument56 pagesVelocity-Head Coefficients in Open Channelsprabhat3karnNo ratings yet

- Pascua Project For Module 2 Problem Set With SolutionDocument14 pagesPascua Project For Module 2 Problem Set With SolutionDJ KillNo ratings yet

- Gas Spring Test Data Gas Spring Test DataDocument3 pagesGas Spring Test Data Gas Spring Test DataRaja Sekaran SajjaNo ratings yet

- Aristotle Joseph - 211462101002 Internship ReportDocument43 pagesAristotle Joseph - 211462101002 Internship ReportDoraemonNo ratings yet

- Earth Sci Experiment 1Document9 pagesEarth Sci Experiment 1jnnpctngNo ratings yet

- So You Want To Learn Physics... - Susan FowlerDocument48 pagesSo You Want To Learn Physics... - Susan FowlerYianniNo ratings yet

- Kalman FilterDocument5 pagesKalman Filterhricha aryalNo ratings yet

- Profil Paparan Radiasi Instalasi Radiologi - Dwi RochmayantiDocument5 pagesProfil Paparan Radiasi Instalasi Radiologi - Dwi RochmayantiFadila Nur'AeniNo ratings yet

- Qaamuuska Ereybixinta Fisigiska: English SoomaaliDocument51 pagesQaamuuska Ereybixinta Fisigiska: English SoomaaliIrir SamaleNo ratings yet

- CSE Alagappa Syllabus 1st YearDocument69 pagesCSE Alagappa Syllabus 1st YearindraNo ratings yet

- Free Surface Modeling Methods - CFD-101 - FLOW-3DDocument7 pagesFree Surface Modeling Methods - CFD-101 - FLOW-3Dcopdeposu2071No ratings yet

- Water and Gas Coning 1 PDFDocument15 pagesWater and Gas Coning 1 PDFBunga Arafah100% (2)

- April 14Document7 pagesApril 14rossana rondaNo ratings yet

- Crown FC4500Document192 pagesCrown FC4500Cl LeeNo ratings yet

- #1 Basic ConceptsDocument66 pages#1 Basic ConceptsSara TesfayeNo ratings yet

- ICU Medical Gas NeedsDocument4 pagesICU Medical Gas NeedsGamerBro IDNo ratings yet

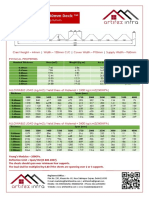

- ARTIFEX INFRA - 44mm Decksheet ProfileDocument1 pageARTIFEX INFRA - 44mm Decksheet ProfileAmit SharmaNo ratings yet

- Running Head: NANOTECHNOLOGYDocument7 pagesRunning Head: NANOTECHNOLOGYpurity NgasiNo ratings yet

- The Compozer - A Method To Improve Characteristics of Soft Clays by Inclusion of Large Diameter Sand ColumnsDocument7 pagesThe Compozer - A Method To Improve Characteristics of Soft Clays by Inclusion of Large Diameter Sand ColumnsMohammed KhennoufNo ratings yet

- A.C Lecture 2Document5 pagesA.C Lecture 2mamnd tahaNo ratings yet

- Cheat Sheet - ElectromagnetismDocument26 pagesCheat Sheet - Electromagnetismu2100128No ratings yet

- Tutorial 6: Mechanical Engineering (16Mech60C) Module Leader: DR - Mohamed Zaky Tas: Sameh Mahdy & Eman ZayedDocument3 pagesTutorial 6: Mechanical Engineering (16Mech60C) Module Leader: DR - Mohamed Zaky Tas: Sameh Mahdy & Eman Zayedsherif115040 BueNo ratings yet

- Pi 2000 Mahle PDFDocument8 pagesPi 2000 Mahle PDFHIDRAFLUIDNo ratings yet

- The 2020 Magnetism Roadmap: Journal of Physics D: Applied PhysicsDocument45 pagesThe 2020 Magnetism Roadmap: Journal of Physics D: Applied PhysicsFrancisco EstrellaNo ratings yet

- University of Cambridge International Examinations General Certificate of Education Advanced Subsidiary Level and Advanced LevelDocument24 pagesUniversity of Cambridge International Examinations General Certificate of Education Advanced Subsidiary Level and Advanced LevelAshfaaq SkadamNo ratings yet

- Relate Tables, Graphs, and Equations: BatchesDocument2 pagesRelate Tables, Graphs, and Equations: Batchesahmeeeeeeeeee.expmdNo ratings yet