Professional Documents

Culture Documents

Benefits of Steel RC Shear Walls in Building Structures - ETN-D-8-21

Uploaded by

Babrak Khan NoorzoiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Benefits of Steel RC Shear Walls in Building Structures - ETN-D-8-21

Uploaded by

Babrak Khan NoorzoiCopyright:

Available Formats

ENGINEERING Benefits of Steel Reinforced Concrete

ETN-D-8-21 Shear Walls in Building Structures

Technical Note Overview

Steel reinforced concrete shear walls

(structural walls) have been a safe, effi-

Types of Steel Reinforced Con-

crete Shear Wall Systems

A variety of steel reinforced concrete

cient, and cost-effective way to resist lat- shear wall systems are available for low-,

eral forces in building structures for many mid-, and high-rise buildings. Building

years. They are usually located around height and plan geometry, exposure and

elevator and stair openings or between magnitude of wind at the site, the level of

architectural spaces and are ideally suited seismic risk at the site, and architectural

to resist lateral forces due to their large constraints on size and location of the

in-plane stiffness and strength. By them- structural walls are a few of the many fac-

selves or in combination with reinforced tors that must be considered when select-

concrete moment frames, these time-test- ing an appropriate system. The lateral force

ed structural elements have an outstand- resisting systems in Table 1 are recognized

ing performance record when subjected to in the IBC (Ref. 1) and ASCE/SEI 7 (Ref. 2)

the effects from wind and earthquakes. and do not require a special peer review

prior to acceptance by the local authority

The purpose of this Technical Note

having jurisdiction. For lateral force resist-

is to outline the benefits of using steel

ing systems not identified in the IBC or

reinforced concrete shear walls in build-

ASCE/SEI 7, the peer review process can

ing structures. Included is a summary of

take months or even years to complete

different types of shear wall systems and

depending on the size and/or complexity of

inherent benefits related to resiliency, sus-

the building’s structure.

tainability, steel reinforcement, structural

design, and constructability.

Table 1 Types of Steel Reinforced Concrete Shear Wall Systems

System Description

A structural system without an essentially complete frame that provides support

for gravity loads. Bearing walls provide support for all or most of the gravity

Bearing wall

loads, and resistance to lateral forces is provided by the same bearing walls

acting as shear walls. This system is best suited for low- to mid-rise buildings.

A structural system with an essentially complete frame that provides support

Concrete Reinforcing

for gravity loads. The resistance to lateral forces is provided by isolated or

Building frame coupled shear walls only; no interaction between the shear walls and frames

is considered in the lateral analysis and all the lateral forces are allocated to the

walls. This system can be utilized in mid- and high-rise buildings.

Steel Institute

A structural system with an essentially complete frame that provides support

Shear wall-frame for gravity loads. Resistance to lateral forces is provided by moment-resisting

interactive (Dual) frames and shear walls, which resist the lateral forces in proportion to their

relative rigidities. This system is often utilized in high-rise buildings.

Tube-core systems (consisting of a perimeter mo- Resiliency

ment-resisting frame with closely spaced columns and

Steel reinforced concrete buildings are inherently re-

interior shear walls) and outrigger systems (consisting

silient when subjected to anticipated and extraordinary

of interior shear walls connected to perimeter columns

loading events. The reinforcing bars in the structural

by means of outrigger girders) are two other types of

members tie the entire structure together, resulting in

structural systems with steel reinforced concrete shear

a highly redundant structure with multiple load paths;

walls often used in high-rise buildings.

this significantly reduces the possibility of progres-

Steel reinforced concrete shear walls are very ef- sive collapse. The purpose of the minimum structural

fective in limiting lateral deflections, especially in dual integrity reinforcement requirements in ACI 318 (Ref. 3)

systems. Frames tend to deflect in a shear mode when is to improve redundancy and ductility of the structural

subjected to lateral loads, while walls tend to deflect members. Thus, steel reinforced concrete structures

in a flexural mode as a cantilever (see Figure 1). When possess a high level of built-in resiliency at no extra

frames are combined with shear walls, the interaction cost.

between the two results in a stiffer and stronger struc-

Steel reinforced concrete shear walls provide an ad-

tural system: the wall is restrained at the upper levels

ditional benefit: the walls protect elevators and stairs,

by the frame while the frame is restrained at the lower

which are often utilized for occupant egress in case of

levels by the shear wall (see Figure 1).

an emergency.

For tall buildings, limiting the drift at the top of the

Steel reinforced concrete buildings are also inherently

building is often not sufficient to prevent the occupants

fire resistant: the concrete provides passive fire protec-

from experiencing perceptible motion due to wind.

tion at no cost throughout the entire life of the building

During a high wind event, occupants may experience

(Ref. 4). Providing the minimum member thickness for

extreme discomfort. It is common for steel reinforced

strength and serviceability and the minimum concrete

concrete shear walls to be used in Class A buildings

cover to the reinforcing bars in accordance with ACI

because they are very effective in mitigating occupant

318 automatically satisfies fire-resistance requirements

discomfort associated with prolonged occurring wind

for typical occupancies. Supplemental fireproofing is

events.

Diaphragm ሺtyp.ሻ

Rigid frame Shear wall Frame and shear wall

ሺshear mode deformationሻ ሺbending mode connected by diaphragms

deformationሻ

Figure 1 Structural wall-frame interaction.

2 Benefits of Steel Reinforced Concrete Shear Walls in Building Structures

not required, eliminating the time and cost associated need to be placed in the field. Comprehensive informa-

with its application. Because steel reinforced concrete tion on the requirements in ACI 318-19 on Grade 80 and

is not readily damaged by fire, only a clean-up, rather Grade 100 reinforcement is given in Refs. 5 and 6.

than expensive structural repairs, is needed in most

cases to put the building back in service following a fire Structural Design

event. Additionally, local fire officials advocate for steel Design and detailing requirements for steel rein-

reinforced concrete cores to safely access the building forced concrete structural walls have appeared in

when fires occur. many editions of ACI 318 and numerous resources are

available to assist design professionals in their proper

Sustainable Design application. Many consulting firms regularly design

Steel reinforced concrete is made with locally avail- steel reinforced concrete buildings with walls. A wide

able materials, minimizing transportation and staging variety of commercial software is available that enables

costs. Steel reinforcing bars consist of nearly 100 structural engineers to quickly model, design, and detail

percent recycled material. Part of the cement content steel reinforced concrete structural walls of any size

in concrete mixes can be replaced by supplemental and shape. As a result, overall design time and produc-

cementitious materials, such as fly ash and ground tion time for construction documents are significantly

granulated blast furnace slag, to reduce embodied car- reduced.

bon levels. At the end of the structure’s useful service

life, the concrete and reinforcing steel can be recycled. Where the size or shape of a wall must be modified

for architectural reasons or where mechanical open-

Advances in Steel Reinforcement ings must be introduced after initial design, redesign

of a steel reinforced concrete wall can be achieved in a

Recent advances, including substantial new research,

relatively short period of time.

have enabled reinforcing steels of higher strengths to

be a viable option in a variety of applications in steel Constructability

reinforced concrete structures, including buildings with

shear walls. Permissible applications of high-strength A wide variety of formwork systems for steel rein-

steel reinforcement (that is, reinforcement with a yield forced concrete walls are available from many sup-

strength of 80,000 psi or 100,000 psi) were signifi- pliers. Competitive pricing and overall economy are

cantly expanded in ACI 318-19. Grade 80 and Grade 100 achieved by having more than one option for formwork,

longitudinal and transverse reinforcement are permitted which constitutes on average 50 to 60 percent of the

to be used in structural walls in buildings assigned to structure cost. Core formwork systems with integrated

any Seismic Design Category, including special struc- placing booms and rebar laydown areas improve overall

tural walls, which are required in buildings assigned to project logistics and construction efficiency, resulting in

Seismic Design Categories D through F. shorter times to completion. Self-climbing core form-

work systems allow rapid, high-quality steel reinforced

Utilizing high-strength steel reinforcement in concrete concrete core construction for larger tower projects

shear walls typically results in smaller bar sizes and/or a (see Figures 2 and 3). Ganged systems are large wall-

fewer number of bars compared to Grade 60 reinforce- forming units that consist of aluminum or plywood

ment. This translates to improved concrete placement panels joined together and braced by aluminum or

and consolidation and a reduction in reinforcing bar con- steel frames (see Figure 4). Once the system has been

gestion, especially in walls with coupling beams. It also assembled on the ground, it is raised into place by a

results in lower placement costs because fewer bars crane.

Figure 2 One Chicago Square, Chicago, Il Figure 3 Wolf Point West, Chicago, Il

(photo courtesy of James McHugh Construction Company). (photo courtesy of James McHugh Construction Company).

CRSI Technical Note 3

ment for concrete construction with nonprestressed

steel reinforcing bars; continuous inspection is required

only for concrete placement. For structural walls con-

sisting of structural steel, continuous inspection and

field testing is required during construction for welds,

among other things. Such tests require significant time

to complete and repairs to nonconforming welds are

expensive and time consuming, which could lead to

costly delays in construction. Additionally, special in-

spection and tests must be performed for construction

materials and systems that are alternatives to materials

Figure 4 110 N. Carpenter, Chicago, Il and systems prescribed by the IBC (IBC Sect. 1705.1.1);

(photo courtesy of James McHugh Construction Company).

this also can have a significant impact on the overall

In general, concrete construction requires smaller construction schedule and time to completion.

cranes due to lighter crane pick loads compared to

other structural materials. Smaller cranes are more Summary

readily available, less expensive to rent, and are easier Steel reinforced concrete shear walls are a proven,

to assemble, operate, and disassemble. They are also cost-effective way of resisting lateral forces in building

better suited for tight urban sites where it may not be structures. The benefits outlined in this Technical Note

physically possible to utilize a large crane. should be carefully evaluated prior to the selection of a

suitable construction material.

When compared with other materials, steel rein-

forced concrete walls are easier to coordinate with References

other building systems and do not have long lead times

1. International Code Council (ICC). 2018,

associated with offsite detailing, fabrication, shipping,

International Building Code, Washington, D.C.

and staging. This allows projects to be started earlier

and completed sooner. 2. American Society of Civil Engineers (ASCE).

2017, Minimum Design Loads and Associated

Changes in the location and/or the size of openings, Criteria for Buildings and Other Structures, ASCE/

embeds, and MEP penetrations can be accommodated SEI 7-16, Reston, Virginia.

relatively easily and with minimal cost any time during

3. ACI (American Concrete Institute). 2019, Building

the construction of a steel reinforced concrete wall.

Code Requirements for Structural Concrete

Moreover, steel reinforcement that must be modified

and Commentary, ACI 318-19, Farmington Hills,

due to such changes can be ordered, fabricated, and

Michigan.

shipped to the job site quickly when compared to other

structural materials, thereby reducing the possibility of 4. Concrete Reinforcing Steel Institute (CRSI).

construction delays. For shear walls utilizing steel plates 2016, Fire Resistance of Reinforced Concrete

or mass timber, the exact size and location of the open- Buildings, Schaumburg, Illinois.

ings and penetrations must be coordinated months in 5. Concrete Reinforcing Steel Institute (CRSI).

advance prior to fabrication; proposed modifications 2020, Guide to the Use of Grade 80 Reinforcing

during construction are generally very expensive or Bars in ACI 318-19, Schaumburg, Illinois.

impossible to accommodate.

6. Concrete Reinforcing Steel Institute (CRSI).

According to IBC Table 1705.3, periodic inspection is 2020, Guide to the Use of Grade 100 Reinforcing

required for formwork and steel reinforcing bar place- Bars in ACI 318-19, Schaumburg, Illinois.

Contributors: The principal authors of this publication are David Fanella, SE, PE, Senior Director

of Engineering at CRSI and Eamonn Connolly, SE, PE, Director of Engineering at James McHugh Concrete

Construction Company. This Technical Note was reviewed by the Manual of Standard Practice Reinforcing

Committee of CRSI. Steel

Keywords: reinforcing bars, reinforced concrete, reinforced concrete construction, reinforced Institute

concrete shear walls, reinforced concrete structural walls 933 North Plum Grove Rd.

Schaumburg, IL 60173-4758

Reference: Concrete Reinforcing Steel Institute – CRSI [2021], “Benefits of Steel Reinforced Con-

p. 847-517-1200 • f. 847-517-1206

crete Shear Walls in Building Structures”, CRSI Technical Note ETN-D-8-21, Schaumburg, Illinois, 4 pp.

www.crsi.org

Historical: None. New Technical Note.

Regional Offices Nationwide

Note: This publication is intended for the use of professionals competent to evaluate the signifi- A Service of the Concrete Reinforcing Steel Institute

cance and limitations of its contents and who will accept responsibility for the application of the

material it contains. The Concrete Reinforcing Steel Institute reports the foregoing material as

©2021 This publication, or any part thereof, may not be

a matter of information and, therefore, disclaims any and all responsibility for application of the

reproduced without the expressed written consent of CRSI.

stated principles or for the accuracy of the sources other than material developed by the Institute.

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Introduction to Design of Building StructuresFrom EverandIntroduction to Design of Building StructuresRating: 4 out of 5 stars4/5 (22)

- CSS & PMS Philosophy Subject MCQsDocument5 pagesCSS & PMS Philosophy Subject MCQsfaisalkamal mianNo ratings yet

- IELTS Speaking Recent Actual Tests with Suggested Answers Jan-Apr 2021Document193 pagesIELTS Speaking Recent Actual Tests with Suggested Answers Jan-Apr 2021Md Amirul Islam DewanNo ratings yet

- Test 3 July 2018Document8 pagesTest 3 July 2018Mobin Ur Rehman KhanNo ratings yet

- PMS Interview Questions on Governance, Economy and Current AffairsDocument24 pagesPMS Interview Questions on Governance, Economy and Current AffairsRead To LeadNo ratings yet

- Pediatric SpotsDocument318 pagesPediatric Spotsdea_romanNo ratings yet

- A7 Leadership 03junDocument12 pagesA7 Leadership 03junRathnaKumar DorarajNo ratings yet

- Structural Framing SystemDocument6 pagesStructural Framing SystemMelchor Jaramilla Oronos100% (3)

- ITJEGAN'S OptionDocument14 pagesITJEGAN'S OptionMohan0% (1)

- Study of Lateral Load Resisting SystemsDocument11 pagesStudy of Lateral Load Resisting SystemsHema Chandra Reddy KarimireddyNo ratings yet

- 2022 V13i373Document10 pages2022 V13i373muzamilillahi7No ratings yet

- Study of Lateral Load Resisting Systems of Variable Heights in All Soil Types of High Seismic ZoneDocument12 pagesStudy of Lateral Load Resisting Systems of Variable Heights in All Soil Types of High Seismic ZoneMelo PereiraNo ratings yet

- A Proposal For The Classi Cation of Structural Systems of Tall BuildingsDocument9 pagesA Proposal For The Classi Cation of Structural Systems of Tall BuildingsCivilEngClubNo ratings yet

- Earthquake Resistance: Ductility NeedsDocument4 pagesEarthquake Resistance: Ductility NeedssteveassaNo ratings yet

- Seismic Comparison of The Structural SystemsDocument2 pagesSeismic Comparison of The Structural SystemsHasantNo ratings yet

- Shear Wall Design For Seismic ProtectionDocument7 pagesShear Wall Design For Seismic ProtectionshreeshlkoNo ratings yet

- 1 s2.0 S0141029622016194 MainDocument16 pages1 s2.0 S0141029622016194 MainHibretu Kaske KassaNo ratings yet

- Structural Forms Systems For Tall Building Structures: AbstractDocument4 pagesStructural Forms Systems For Tall Building Structures: AbstractHETVI PATELNo ratings yet

- PCS1 Chapter 3Document8 pagesPCS1 Chapter 3Renderizzah FloraldeNo ratings yet

- Remoreras - Module 3 ResearchDocument23 pagesRemoreras - Module 3 ResearchChristian RemorerasNo ratings yet

- Structural Forms Systems For Tall Building Structures: Er. Nishant Rana, SiddhantranaDocument3 pagesStructural Forms Systems For Tall Building Structures: Er. Nishant Rana, SiddhantranaYamini LokhandeNo ratings yet

- Cyclic Behavior of Traditional and Innovative CompositeShear Walls (ASCE) 0733-9445 (2004) 130 - 2Document14 pagesCyclic Behavior of Traditional and Innovative CompositeShear Walls (ASCE) 0733-9445 (2004) 130 - 2Hari Om Tamrakar ce21d019No ratings yet

- Rodrigo PCS002 Tla2pDocument4 pagesRodrigo PCS002 Tla2pChristian John SaludarNo ratings yet

- Seismic Design of Building With ETABSDocument151 pagesSeismic Design of Building With ETABSKawser Hossain100% (1)

- Ijaret 10 02 002Document8 pagesIjaret 10 02 002engahmedalemadNo ratings yet

- PAPERDocument16 pagesPAPERjpzb1892No ratings yet

- Rational Selection of Structural Ductility Capacity and Reinforcement Details For Seismic Design of Reinforced Concrete Shear Wall-Frame StructureDocument12 pagesRational Selection of Structural Ductility Capacity and Reinforcement Details For Seismic Design of Reinforced Concrete Shear Wall-Frame StructurehastomiNo ratings yet

- Curkovic & Dzeba - State of The Art Review On Behaviour and Calculation of Composite Plate Shear Walls - 2016Document10 pagesCurkovic & Dzeba - State of The Art Review On Behaviour and Calculation of Composite Plate Shear Walls - 2016MILL3482No ratings yet

- Analysis of Reinforced Concrete Building With Different Arrangement of Concrete and Steel Bracing SystemDocument5 pagesAnalysis of Reinforced Concrete Building With Different Arrangement of Concrete and Steel Bracing SystemIOSRjournal100% (1)

- Libro de Reforzamiento HORMIGON ARMADO 2022-6Document25 pagesLibro de Reforzamiento HORMIGON ARMADO 2022-6David Magne MamaniNo ratings yet

- General Concepts To Be Followed in Earth PDFDocument5 pagesGeneral Concepts To Be Followed in Earth PDFMarkNo ratings yet

- Analysis of RC Framed Structure With STR PDFDocument4 pagesAnalysis of RC Framed Structure With STR PDFJohn DávilaNo ratings yet

- Heerema2015Document13 pagesHeerema2015Dulio Nils MHNo ratings yet

- 3 Lateral Load Resisting System FDocument33 pages3 Lateral Load Resisting System FReffisa Jiru100% (2)

- 3 Lateral Load Resisting System FDocument33 pages3 Lateral Load Resisting System FUd BsecNo ratings yet

- Ces 822 Assignment 2 PDFDocument3 pagesCes 822 Assignment 2 PDFSaniiNo ratings yet

- Seismic and Wind Analysis of Different Lateral Load Resisting SystemsDocument6 pagesSeismic and Wind Analysis of Different Lateral Load Resisting SystemsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Buildings, Structures, and Nonstructural Components: Earthquake-Resistant Design ConceptsDocument14 pagesBuildings, Structures, and Nonstructural Components: Earthquake-Resistant Design ConceptsMuhammad Irfan ButtNo ratings yet

- Shear Wall NotesDocument7 pagesShear Wall NotesArfath Khan MohammedNo ratings yet

- Shear Wall Design and Analysis in RC BuildingsDocument69 pagesShear Wall Design and Analysis in RC BuildingsLizi CasperNo ratings yet

- Analysis and Design of Shear WallsDocument24 pagesAnalysis and Design of Shear WallsRkkodi100% (3)

- Seismic Analysis of R C Framed Building With Pushover Analysis On EtabsDocument5 pagesSeismic Analysis of R C Framed Building With Pushover Analysis On EtabsVivek KumarNo ratings yet

- Lateral Resisting Systems - Sturdy Structural PDFDocument5 pagesLateral Resisting Systems - Sturdy Structural PDFBharath m.s.v.mNo ratings yet

- Structural Response CharacteristicsDocument31 pagesStructural Response CharacteristicsIzet MehmetajNo ratings yet

- Structural Analysis and Design of Residential Using EtabsDocument1 pageStructural Analysis and Design of Residential Using Etabsinnovative technologiesNo ratings yet

- Types of Structural SytemDocument10 pagesTypes of Structural SytemOlga KosuoweiNo ratings yet

- Precast ConcreteDocument11 pagesPrecast Concretenikka csmNo ratings yet

- 98 s55Document11 pages98 s55Satyajit GhateNo ratings yet

- Study On Effectiveness of Lattice-Frame Walls in RC High-Rise BuildingDocument6 pagesStudy On Effectiveness of Lattice-Frame Walls in RC High-Rise BuildingtheteiNo ratings yet

- Classification of Shear WallDocument23 pagesClassification of Shear WallShivkamal50% (2)

- A Perf-Based Design Approach For Wall With DRC CBDocument17 pagesA Perf-Based Design Approach For Wall With DRC CBSinem Kocabaş ŞirikçiNo ratings yet

- Engineering Structures: SciencedirectDocument15 pagesEngineering Structures: Sciencedirectraul.chiriacNo ratings yet

- 1.1 General: Chapter 1. IntroductionDocument4 pages1.1 General: Chapter 1. Introductionci_balaNo ratings yet

- Ijert Ijert: Seismic Analysis of Reinforced Concrete Frame With Steel BracingsDocument4 pagesIjert Ijert: Seismic Analysis of Reinforced Concrete Frame With Steel BracingsAnonymous Cn9nxU5VNo ratings yet

- Earthquake Resisting System Class NotesDocument17 pagesEarthquake Resisting System Class NotesatulNo ratings yet

- Lecture 6 Design and Detailing of Specia PDFDocument26 pagesLecture 6 Design and Detailing of Specia PDFS. M. Habibul AhsanNo ratings yet

- Basic Mechanisms For Hybrid Masonry StructuresDocument12 pagesBasic Mechanisms For Hybrid Masonry StructuresAndres EscobedoNo ratings yet

- Finite Element Modeling of Reinforced Concrete Cladding PanelsDocument11 pagesFinite Element Modeling of Reinforced Concrete Cladding PanelsTariqul IslamNo ratings yet

- Finite Element Modeling of Reinforced Concrete Cladding PanelsDocument11 pagesFinite Element Modeling of Reinforced Concrete Cladding PanelsTariqul IslamNo ratings yet

- Pages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-3Document1 pagePages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-3Babrak Khan NoorzoiNo ratings yet

- Pages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-5Document1 pagePages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-5Babrak Khan NoorzoiNo ratings yet

- PCA Concrete Floor Slab OpeningsDocument4 pagesPCA Concrete Floor Slab OpeningsRavindra MRNo ratings yet

- Pages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-4Document1 pagePages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-4Babrak Khan NoorzoiNo ratings yet

- Pages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-2Document1 pagePages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-2Babrak Khan NoorzoiNo ratings yet

- Guide To The Use of Grade 100 Reinforcing Bars in ACI 318-19 - ETN-D-6-20Document10 pagesGuide To The Use of Grade 100 Reinforcing Bars in ACI 318-19 - ETN-D-6-20faisaladeNo ratings yet

- ERRATA - December 2020: Design Guide On The ACI 318 Building Code Requirements For Structural ConcreteDocument8 pagesERRATA - December 2020: Design Guide On The ACI 318 Building Code Requirements For Structural ConcreteBabrak Khan NoorzoiNo ratings yet

- CRSI Tech - Note - ETN B 1 15 PDFDocument6 pagesCRSI Tech - Note - ETN B 1 15 PDFrickhuezoNo ratings yet

- PCA Concrete Floor Slab OpeningsDocument4 pagesPCA Concrete Floor Slab OpeningsRavindra MRNo ratings yet

- 2017 05 31 SEAONC Spring Seminar V4Document48 pages2017 05 31 SEAONC Spring Seminar V4Babrak Khan NoorzoiNo ratings yet

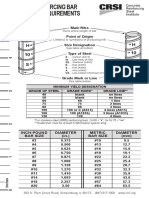

- Astm Reinforcing Bar Marking Requirements: (Inch-Pound)Document2 pagesAstm Reinforcing Bar Marking Requirements: (Inch-Pound)Babrak Khan NoorzoiNo ratings yet

- Frequently Asked Questions (FAQ) About Hot-Dip Galvanized Reinforcing BarsDocument6 pagesFrequently Asked Questions (FAQ) About Hot-Dip Galvanized Reinforcing Barsali tahaNo ratings yet

- 2020 14 Mazzoni GroundmotionselectionDocument139 pages2020 14 Mazzoni GroundmotionselectionBabrak Khan NoorzoiNo ratings yet

- Assembling by Fusion Welding - ETN M 9 16Document4 pagesAssembling by Fusion Welding - ETN M 9 16Babrak Khan NoorzoiNo ratings yet

- Building Code Requirements and Specification For Masonry StructuresDocument339 pagesBuilding Code Requirements and Specification For Masonry StructuresRatha Than100% (9)

- Pacific Earthquake Engineering Research CenterDocument143 pagesPacific Earthquake Engineering Research CenterBabrak Khan NoorzoiNo ratings yet

- AutoCAD Workbook For Architects and EngineersDocument298 pagesAutoCAD Workbook For Architects and Engineerscharichang94% (33)

- Assembling by Fusion Welding - ETN M 9 16Document4 pagesAssembling by Fusion Welding - ETN M 9 16Babrak Khan NoorzoiNo ratings yet

- Pacific Earthquake Engineering Research CenterDocument143 pagesPacific Earthquake Engineering Research CenterBabrak Khan NoorzoiNo ratings yet

- Astm Reinforcing Bar Marking Requirements: (Inch-Pound)Document2 pagesAstm Reinforcing Bar Marking Requirements: (Inch-Pound)Babrak Khan NoorzoiNo ratings yet

- 2017 05 31 SEAONC Spring Seminar V4Document48 pages2017 05 31 SEAONC Spring Seminar V4Babrak Khan NoorzoiNo ratings yet

- SCC800-B2 SmartSite Management System V100R002C00 Installation GuideDocument190 pagesSCC800-B2 SmartSite Management System V100R002C00 Installation GuideHamza OsamaNo ratings yet

- SWOT ANALYSIS - Docx Sime DarbyDocument9 pagesSWOT ANALYSIS - Docx Sime Darbynur azfarinie ruzliNo ratings yet

- LTC exemption and tax on retrenchment compensationDocument2 pagesLTC exemption and tax on retrenchment compensationhanumanthaiahgowdaNo ratings yet

- Can or Can't Esl Worksheet With Animals Vocabulary For Kids PDFDocument2 pagesCan or Can't Esl Worksheet With Animals Vocabulary For Kids PDFופאאכאלד50% (4)

- CatalogueDocument36 pagesCataloguehgwlin100% (1)

- How To Install Elastix On Cloud or VPS EnviornmentDocument4 pagesHow To Install Elastix On Cloud or VPS EnviornmentSammy DomínguezNo ratings yet

- Speidel, M. O. (1981) - Stress Corrosion Cracking of Stainless Steels in NaCl Solutions.Document11 pagesSpeidel, M. O. (1981) - Stress Corrosion Cracking of Stainless Steels in NaCl Solutions.oozdemirNo ratings yet

- 2005 Mapex CatalogDocument20 pages2005 Mapex Cataloggiftsvav100% (1)

- Insertion Mangement Peripheral IVCannulaDocument20 pagesInsertion Mangement Peripheral IVCannulaAadil AadilNo ratings yet

- Carding: Click To Edit Master Subtitle Style by M. Naveed AkhtarDocument35 pagesCarding: Click To Edit Master Subtitle Style by M. Naveed Akhtarshazliarsahd50% (2)

- Chapter 4 Designing Your SolutionDocument22 pagesChapter 4 Designing Your SolutionRamona Isabel UrsaisNo ratings yet

- 7.1. Anemia 2023Document30 pages7.1. Anemia 2023MichellyTjoaNo ratings yet

- Shlokas and BhajansDocument204 pagesShlokas and BhajansCecilie Ramazanova100% (1)

- Density Functional Theory Investigations of Bismuth VanadateDocument7 pagesDensity Functional Theory Investigations of Bismuth VanadateNurSalahuddinNo ratings yet

- Russell Vs Vestil 304 SCRA 738Document2 pagesRussell Vs Vestil 304 SCRA 738Joshua L. De JesusNo ratings yet

- Summative Test in MAPEH 10 1st and 2nd QuarterDocument16 pagesSummative Test in MAPEH 10 1st and 2nd QuarterMeljim ReyesNo ratings yet

- Food Safety Culture Webinar SLIDESDocument46 pagesFood Safety Culture Webinar SLIDESAto Kwamena PaintsilNo ratings yet

- The Strange and Beautiful Sorrows of Ava Lavender by Leslye Walton - PrologueDocument10 pagesThe Strange and Beautiful Sorrows of Ava Lavender by Leslye Walton - PrologueWalker BooksNo ratings yet

- CIMA Financial Accounting Fundamentals Past PapersDocument107 pagesCIMA Financial Accounting Fundamentals Past PapersAnonymous pwAkPZNo ratings yet

- T e 2552731 Describe The Creature Writing Worksheet - Ver - 2Document3 pagesT e 2552731 Describe The Creature Writing Worksheet - Ver - 2Minah ZamanNo ratings yet

- LCP4805-mc Mehta Vs Union of IndiaDocument60 pagesLCP4805-mc Mehta Vs Union of Indiatech hutNo ratings yet

- Different Type of Dealers Detail: Mfms Id Agency Name District Mobile Dealer Type State Dealership NatureDocument1 pageDifferent Type of Dealers Detail: Mfms Id Agency Name District Mobile Dealer Type State Dealership NatureAvijitSinharoyNo ratings yet

- Report For Court, Sale of Dowling College Brookhaven CampusDocument26 pagesReport For Court, Sale of Dowling College Brookhaven CampusRiverheadLOCALNo ratings yet

- Lirik LaguDocument34 pagesLirik LaguAdjie SatryoNo ratings yet

- Alison North - Sparkle Hoof The UnicornDocument9 pagesAlison North - Sparkle Hoof The Unicornlili francoNo ratings yet

- Ch01 Standard Methods and PractisesDocument44 pagesCh01 Standard Methods and PractisesUsman FarooqNo ratings yet

- Armenian Question in Tasvir-İ Efkar Between 1914 and 1918Document152 pagesArmenian Question in Tasvir-İ Efkar Between 1914 and 1918Gültekin ÖNCÜNo ratings yet

- EthicsDocument10 pagesEthicsEssi Chan100% (4)

- Exam On Multiculturalism: - Acculturation Process of Immigrants From Central and Eastern Europe in SwedenDocument60 pagesExam On Multiculturalism: - Acculturation Process of Immigrants From Central and Eastern Europe in SwedenMarta santosNo ratings yet

- Self Unbound Ego Dissolution in PsychedelicDocument11 pagesSelf Unbound Ego Dissolution in Psychedelicszucsanna123456789No ratings yet