Professional Documents

Culture Documents

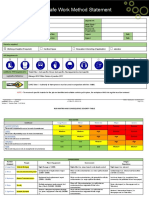

MFMF-1-PC-043 Attachment E Safety Plan Rev1

Uploaded by

Thomas JohnOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MFMF-1-PC-043 Attachment E Safety Plan Rev1

Uploaded by

Thomas JohnCopyright:

Available Formats

Document ID: MFMF-1-PC-043 Rev1

KINGDOM OF SAUDI ARABIA

POWER & WATER UTILITY COMPANY

FOR JUBAIL & YANBU (MARAFIQ)

ATTACHMENT “E”

HSE AND FIRE PREVENTION MANAGEMENT PLAN

RFP Collective No. YNB-PR5221

REPLACEMENT OF POTABLE WATER PIPELINES AT T&D

COMPLEX - YANBU

POWER & WATER UTILITY COMPANY

FOR JUBAIL & YANBU (MARAFIQ)

HSE & FIRE PREVENTION MANAGEMENT PLAN

TABLE OF CONTENTS

ARTICLE PAGE

DESCRIPTION

NO. NO.

1.0 HEALTH, SAFETY & ENVIRONMENT (HSE) OBJECTIVES 4

2.0 RESPONSIBILITIES 4

2.1 Contractor Project General Manager 4

2.2 Contractor Project Supervisors 4

2.3 Contractor Project HSE Officers 5

2.4 Field Supervisors / Foremen 5

2.5 Employees 5

3.0 PROCEDURES 6

3.1 Risk Assessment 6

3.2 Permit to Work (PTW) 6

3.3 Emergency 6

3.4 Personnel Protective Equipment (PPE) 6

3.5 Vehicles / Equipment 7

3.6 Compressed Gas Cylinders 7

3.7 Welding / Cutting 7

3.8 Electrical Hand Tools 8

3.9 Ladders 8

3.10 Confined Space Entry 9

3.11 Lifting Operation / Equipment 9

3.12 Scaffolding 9

3.13 Fire Prevention 10

3.14 Housekeeping 10

Page 2 of 14 RFP Collective No. YNB-PR5221

3.15 Prevention of Falling Objects 10

3.16 Welfare & Medical Facilities 10

3.17 Laydown Areas 11

3.18 Disciplinary Action 11

4.0 TRAINING 11

4.1 Safety Induction 11

4.2 Permit to Work (PTW) 11

4.3 Breathing Apparatus & Equipment Certification 12

4.4 Supervisor Briefing 12

4.5 Standby Watchman (for Confined Space Entry) 12

4.6 Schedule of Training & Number of Manpower 12

5.0 SAFETY INFORMATION, GUIDELINES AND COMMUNICATION 12

5.1 Tool Box Talk 12

5.2 Team Talks 13

5.3 Health, Safety & Environment Letters 13

5.4 Health, Safety & Environment Posters 13

6.0 HEALTH, SAFETY & ENVIRONMENT REPORTING 13

6.1 HSE Suggestions 13

6.2 Near-miss / Injury Reporting 13

7.0 HEALTH, SAFETY & ENVIRONMENT MONITORING 14

Page 3 of 14 RFP Collective No. YNB-PR5221

HSE & FIRE PREVENTION MANAGEMENT PLAN

1.0 HEALTH, SAFETY AND ENVIRONMENT (HSE) OBJECTIVES

To manage and carry out all activities associated with the project until completion of the following main

objectives:

ZERO (0) Injuries and ZERO Fires

ZERO (0) Reported cases of ill health

ZERO (0) Property & Environmental Damage

Disposal of wastes in accordance with the company (MARAFIQ) procedures

These objectives are achieved through:

a) Establishment of a high level of awareness and discipline.

b) Identification of areas of high risks and carry out risk assessments.

c) Provision of information, instruction, training and supervision of contractor personnel with respect

to method of statements, Permit to Work and other safety requirements to control risks associated

with the nature of contractor’s works.

d) Promotion of a positive approach to health, safety and environment.

e) Monitoring the effectiveness of the management systems of Health, Safety and Environment

performance by conducting regular scheduled audits/inspections and tracking of incidents.

2.0 RESPONSIBILITIES

2.1 CONTRACTOR PROJECT GENERAL MANAGER

Contractor Project General Manager has overall and ultimate responsibility for all matters relating to

Health, Safety and Environment. He will be responsible for full compliance with the contract

requirements with regard to the Health, Safety and Environment by their respective companies. He

shall ensure that HSE & fire prevention management plan & annual safety action plan are in place

and are monitored and reviewed for effectiveness. He shall ensure compliance with Clause # 22 of

MARAFIQ safety manual. He shall provide status of HSE performance every month to MARAFIQ

Safety section through MARAFIQ coordinating department, and provide HSE officer for managing

and advising safety on site and coordinating with MARAFIQ Safety section. Number of safety officers

and / or safety manager required shall depend on the nature of contract work, risks and number of

employees and shall be appointed by the contractor in consultation with MARAFIQ Projects

Department and MARAFIQ Safety section and shall be specified in Safety Plan.

2.2 CONTRACTOR PROJECT SUPERVISORS

Directly responsible for cascading and implementing MARAFIQ safety policy / procedures

requirements and ensuring strict adherence and compliance by contractor personnel under his

control.

Page 4 of 14 RFP Collective No. YNB-PR5221

2.3 CONTRACTOR PROJECT HSE OFFICERS

To ensure certain level of competency & knowledge, the contractor HSE Officer(s) shall be

interviewed, evaluated & approved by MARAFIQ Industrial Security Department – Safety section,

and feedback to MARAFIQ sponsoring department manager.

The main responsibilities of the contractor HSE Officer are as follows:

To co-ordinate and monitor implementation of the requirements of MARAFIQ HSE manual and

arrange continuous and formal daily safety monitoring to ensure compliance and effectiveness.

Prepare regular toolbox safety letters & monitor the appropriate cascading of safety

information along with site supervisors and managers.

To liaise with and support area engineers/supervisors to promote safety awareness in their

area of control.

To detect, identify, analyze, control and eliminate recognized hazardous acts, condition,

behavior and violation.

To investigate and report immediately in writing all accidents, unsafe acts/conditions and near-

misses which occurred at work site. The report shall be submitted to contractor Project

General Manager, MARAFIQ sponsoring department manager & Safety section.

To prepare & review risk assessments & monitor effective implementation.

To monitor correct use of safety barriers, both solid (e.g., covering holes/open handrail) and

soft (e.g., isolating areas with tape), including timely removal.

To co-ordinate with MARAFIQ safety representatives and set the safety inspection schedule as

required, and report / correct findings immediately.

To audit and record “on-the-job” and toolbox talks by supervisors.

2.4 FIELD SUPERVISORS/FOREMEN

Contractor’s field supervisors are responsible for ensuring effective implementation of Safety

& Fire Prevention Management Plan in all areas under their direct control.

Field supervisor’s reports shall include inspections, tool-box meeting and near-misses. These

reports should be given to the contractor HSE Officer(s) immediately.

Are responsible for implementing HSE rules, regulations and work site procedures during all

phases of work at MARAFIQ site.

To anticipate HSE problems in their work areas and take the necessary actions.

To report any incident/accident, unsafe acts/conditions and near misses to their HSE Officer.

To ensure work places are kept clean during and at the end of the work.

To inspect and report any defect for any equipment and take the necessary action.

To ensure that employees have received adequate information or instruction to carry out their

work safe and as required.

To Inform the working crew of the requirements of the Permit to Work Certificates & Risk

Assessments.

To correct unsafe acts/conditions raised by observers.

Page 5 of 14 RFP Collective No. YNB-PR5221

2.5 EMPLOYEES

Each employee is responsible to comply with MARAFIQ safety rules, regulations and to follow

his supervisor/foreman’s instructions.

To immediately report any hazardous situation and accident to his supervisor/foreman.

To keep his workplace clean and tidy.

All employees shall make every endeavor to ensure that working conditions are maintained in

a healthy, safe and environmentally acceptable standard.

All employees will act responsibly and take all necessary precautions to protect themselves and

their fellow workers and other persons who may be affected by their activities from injury, and

prevent illness.

3.0 PROCEDURES

Following are the general requirements. Contractor shall fully comply with MARAFIQ safety manual

requirements, Permit to Work & isolation procedures and risk assessment.

3.1 RISK ASSESSMENT

Risk assessments for high risk activities shall be carried out before start of work.

Where jobs are identified as high risk, a written risk assessment must be prepared & reviewed

by the contractor and should be verified by MARAFIQ coordinating department & Safety

section and approved by Operations department/area owner.

Team supervisors shall cascade all risk control measures stipulated in the written risk

assessment to their subordinates and apply on site.

3.2 PERMIT TO WORK (PTW)

Work shall be carried out in compliance with the MARAFIQ PTW procedure (SP-014). It is a

requirement that all permit issuers/receivers have completed the MARAFIQ PTW safety course

successfully and passed the written and oral test.

3.3 EMERGENCY

On hearing the emergency fire or gas alarm in the area of work, the following steps must be

carried out by all personnel:

Dial 341-9911 for Jubail and 396-6333 for Yanbu – and inform help desk of the emergency

Stop the assigned job, turn off the equipment and proceed to Emergency Assembly area, if safe

to do so.

Walk across wind direction to the designated Emergency Assembly area in case of a gas alarm.

If you are driving a vehicle, stop, stop engine, and vacate the vehicle (leaving the key in the

ignition if the vehicle is parked at undesignated parking area) and walk towards the assembly

area.

Do not return to work until emergency is declared over by notification from immediate

supervisor.

Page 6 of 14 RFP Collective No. YNB-PR5221

3.4 PERSONNEL PROTECTIVE EQUIPMENT (PPE)

Safety helmet, safety shoes, long sleeve shirt/coverall and eye protection are mandatory.

Ear defenders (plugs or muffs) must be worn in areas where hazardous noise level exists.

Respiratory protection must be worn where possibilities of dust, fumes or toxic gases exist.

Full body harnesses must be used when working at high elevations.

Work permit & risk assessment will define any additional PPE according to the nature of work

and area involved.

3.5 VEHICLES/EQUIPMENT

Vehicles/equipment shall be driven/operated only by the authorized drivers/operators who

have a valid driving license.

Drivers must obey MARAFIQ traffic rules and regulations. The use of safety belts is required for

driver and all passengers.

Vehicles must be parked properly in designated parking areas and should not obstruct

firefighting equipment & emergency exit.

Drivers shall ensure that any material extending more than one meter beyond the front or rear

of the vehicle shall have a red flag, fastened at the end of the load.

When parking or leaving the vehicle outside the approved parking areas, the engine must be

shut off, the parking brake engaged and the key shall be left in the car.

Vehicles/equipment must be checked and maintained in good condition all the time.

Re-fuelling of vehicle/equipment is prohibited while engine is running.

3.6 COMPRESSED GAS CYLINDERS

Ensure that all cylinders are labeled with the correct contents.

Oil and grease must never be used on the movable parts of oxygen cylinders.

Gas cylinders shall never be vented into the atmosphere.

Store cylinders in upright position and secure them in the shade.

Place valve cap on cylinders when not in use.

Store gas cylinders containing flammable/combustible gases away from those containing

oxygen or highly reactive materials as per standards.

Store empty cylinders separately, clearly marked empty.

Always use cylinder carrier/trolley when moving cylinders. The cylinders must be capped and

secured inside carrier before transport.

Protect cylinders from heat, chemicals, flammable liquids or fumes, or corrosive materials.

Care shall be taken during handling of cylinders.

Never lift a cylinder by its protective safety cap.

3.7 WELDING/CUTTING

The following steps shall be completed before commencement of work:

Issuance of the Permit to Work certificates.

The initial cut on the gas/chemical and other flammable lines shall be done in the presence of

the APR.

Work area is cleaned from all combustible materials.

Page 7 of 14 RFP Collective No. YNB-PR5221

Work area is screened with fire blanket to prevent sparks from flying outside the welding area.

Fire extinguisher is available at the work site and shall be in good condition.

Personnel executing the work are wearing PPE according to job requirement.

Fire watch must be in attendance while welding or cutting is in progress.

Welding equipment is properly earthed.

Welding machines must be inspected, and shall be in good working condition.

Gas cylinders are equipped with flash back arrestor between regulator and hoses and between

torch & hose.

Ensure that regulators are used properly and gauges are checked and calibrated.

Make sure that regulators, hoses and fittings are inspected and are in good condition.

Keep hoses clear from traffic lanes.

Open the valve slowly and check for leaks before commencement of work.

Never leave pressurized hoses unattended in confined spaces; cylinders shall be switched off.

3.8 ELECTRICAL HAND TOOLS

All items which are placed in tool containers shall be properly stored to avoid accidents.

Inspect and ensure that tools are in good condition before use.

All electrical tools and equipment must be properly maintained in good working condition.

Always carry tools in bags/boxes when ascending or descending ladders.

Ensure cable plug sockets and/or connectors are in good condition before use.

Do not try to repair tools if not authorized.

Equipment power switch must be in off position before plugging into power source.

Before using any electric tool, make sure that you are using the correct power supply.

Never stand on wet surface when using electrical equipment.

Keep electrical equipment dry and clean.

Disconnect power from equipment when it is not in use.

Electric power tools should be regularly inspected and maintained by competent electrician.

Electrical equipment that are to be used in the wet area should be compatible and intrinsically

safe.

3.9 LADDERS

A temporary or permanent working platform or stage, where practical, is recommended.

Inspect ladders before use and report all defects. Do not use defective ladders.

Make sure that ladders are tied near the top or arrangement must be made to prevent the

ladder from slipping outwards or sideways.

The foot of the ladder should be supported on a firm level surface and should not rest on a

drum or a box or any unsteady base to get extra height.

Place the ladder at a suitable angle (75°) to minimize the risk of it slipping outwards (one

meter out for every four (4) meters in height).

Rest the top of the ladder against a solid surface.

Do not use the last two steps from the top of the ladder; the ladders should extend at least

1.05 meters above the platform.

Use both hands when ascending on or descending from a ladder; use tool bags for lifting tools.

Do not overreach from a ladder, always move it.

Ensure firm grip of hands and feet before moving on to the next step to avoid slipping.

Area around top and base of the ladder must be free from tripping hazard.

Page 8 of 14 RFP Collective No. YNB-PR5221

The ladder is of suitable quality for industrial use.

3.10 CONFINED SPACE ENTRY

No one is allowed to enter a confined space, unless Permit to Work certificates are issued and

all safety requirements mentioned in the Permit to Work have been met.

Only appointed workers are allowed to enter confined space.

Ensure all personnel protective equipment are inspected and in good working condition.

Ensure the standby attendant is fully aware of his responsibilities.

Ensure that Permit to Work certificate is valid and displayed at job location.

If work is stopped for any reason and the confined space is vacated, “NO ENTRY” sign must be

displayed on the entrance of the confined space, i.e., column, vessel, tank, etc.

Standby attendant should be trained and certified by MARAFIQ.

Gas cylinders are not allowed inside the confined space.

For welding activities inside the confined space, local or forced-air ventilation should be used.

3.11 LIFTING OPERATION/EQUIPMENT

All lifting equipment (cranes, forklifts, chains, man-basket, lifting belts, tackles, etc.) must be

inspected prior to use and are in compliance with all regulations and guidelines and certified by

a third party.

Make sure that the safe working load is indicated clearly on the lifting equipment. Do not

exceed the maximum lifting capacity of the equipment.

Use the right lifting equipment for the job.

A guide rope (tag line) must be used to control objects while lifting.

Working/lifting area should be barricaded.

Supervisor, lifting operator and rigger is aware of the scope.

Lifting operators should be certified by 3rd party Inspectorate recognized by Saudi

Government and copies of certificates should be submitted to MARAFIQ Safety section prior to

bringing them on site as per MARAFIQ safety manual.

Permit to Work certificate must be obtained prior to start of the job.

3.12 SCAFFOLDING

Scaffold structure shall be erected by certified scaffolder.

Inspect scaffolding prior to use. Use only scaffolding that is certified for use with a green tag.

Make sure scaffold is firmly supported.

Do not overload scaffold; distribute the load.

Do not leave material on scaffold.

Mobile scaffold should be used on flat level surface and shall have four (4) wheels locked to

ensure stability. No persons or materials may remain on the tower while it is being moved.

The frequency of inspection shall be seven (7) days as per MARAFIQ safety manual.

Scaffolding shall be modified only by qualified scaffolders.

Scaffolders should wear full body harness during erection/dismantling or alteration and

stand/work on platform with minimum two (2) boards.

Steel boards shall be used if the erected scaffold is in contact with hot surface.

Scaffold fittings (i.e., joints, pipes....etc) should be lowered by hands or rope safely.

Page 9 of 14 RFP Collective No. YNB-PR5221

3.13 FIRE PREVENTION

Smoking is permitted only in designated smoking areas.

Smokers should ensure that cigarette butts are extinguished properly before leaving their

designated smoking areas.

Burning of rubbish or any other material, at site is strictly prohibited.

Do not obstruct access to fire extinguishers or other firefighting equipment.

Ensure a safe access to all work areas is maintained.

Do not allow paper, oily rags or any other rubbish to accumulate at your working area.

Do not use fire hydrants or fire hoses/equipment except for firefighting purposes.

3.14 HOUSEKEEPING

High standards of housekeeping should be maintained during & after completion of the work.

Site (both ground floor & elevated platforms/levels) must be kept clean and in a tidy condition,

with cables and hoses coiled up and stored in a safe place.

Waste material should be collected and removed from the work area and placed in waste

drums or trash skips on a regular basis to arrange required level of housekeeping.

Housekeeping inspection shall be carried out on regular basis.

Wastes shall be dropped in the designated bins.

Waste bins shall be emptied regularly to avoid overfilling.

3.15 PREVENTION OF FALLING OBJECTS

The hand tools should be tied with a cord and attached to the belt of the technician.

Bins or bags should be provided for storage of nuts, bolts and other small items.

A sheet should be laid to cover all gaps and openings, if working above on a platform having

grating on it.

Tools. materials, etc., should not be thrown from the heights but shall be brought down by a

rope, bucket or crane.

The area should be cordoned off and no one should be allowed to cross under during lifting.

Ropes/slings should be inspected each time before use.

Suitable arrangement shall be made for the people above and below elevations, in one

location.

3.16 MEDICAL & WELFARE FACILITES

The contractor shall ensure and maintain compliance with Ministerial Decision 404 and Saudi

Arabian Labor Regulation Article 134 regarding work site requirements from the Minister of

Health

All eating and sanitation facilities (either shared or contractor-controlled) shall be maintained

in a clean and sanitary condition at all times.

Food shall not be consumed in any area “onsite” that is not designated as an approved eating

area.

Contractor shall provide clean, potable cooled drinking water in sufficient quantity for its

employees in a safe and hygienic manner at all sites.

Page 10 of 14 RFP Collective No. YNB-PR5221

Toilets, bathrooms, washing facilities & rest room should be provided with enough supply of

water and other required necessities.

The number of chemical toilets shall be at least 1 per 15 personnel on site with regular daily

cleaning.

Prayer rooms shall be arranged either within the office, separate cabin, etc., depending on the

site requirements.

Shelters for heat/cold stress, smoking, bus stop, etc., shall be provided as needed throughout

the project.

3.17 LAYDOWN AREAS

Contractor shall coordinate with project owner for allotment of laydown area(s) prior to

mobilization to site.

Contractor shall prepare clear layout sketch of laydown area and get approved by coordinating

department’s responsible engineer prior to commencement of the contract work.

Layout should indicate clearly contract work area, boundary fence, lighting, access points,

internal routes and laydown area for offices, temporary workshops, parking, storage,

warehouse, toilets, first aid clinic, etc.

Consideration for drainage & protection from rain ad sand storms shall be made.

All required welfare facilities, rest, eating, praying area, shelters, etc., should be provided on

site and should be maintained in tidy, clean and good hygienic condition.

An assembly point shall be established in each laydown area for emergency purposes.

3.18 DISCIPLINARY ACTION

MARAFIQ safety rules and regulations will always supersede contractor’s disciplinary guidelines.

At MARAFIQ’s discretion, employees may be removed from the project when committing unsafe

acts, depending on the extent and severity of the violation.

The employees committing HSE violation will be dealt with in accordance with the respective

company’s rules and regulations.

4.0 TRAINING

4.1 SAFETY INDUCTION

All persons working on MARAFIQ facilities shall have completed the MARAFIQ safety induction

course and have passed the competency test.

4.2 PERMIT TO WORK (PTW)

It is a requirement that all supervisors who are required to receive Permit to Work Certificate

(PTWC) for performing intended contract works in MARAFIQ areas must have successfully

completed the MARAFIQ PTW course; passed the written and oral test and possess authorization

card issued by MARAFIQ PTW authorization committee as Authorized Permit Receiver (APR).

Page 11 of 14 RFP Collective No. YNB-PR5221

4.3 BREATHING APPARATUS & EQUIPMENT CERTIFICATION

All personnel utilizing breathing apparatus for activities at MARAFIQ must be trained and certified.

Certifications will vary depending upon the type and/or manufacturer of the equipment.

4.4 SUPERVISOR BRIEFING

Each supervisor will endorse and accept the responsibility to comply with the requirements of

MARAFIQ safety manual.

4.5 STANDBY ATTENDANT (FOR CONFINED SPACE ENTRY)

Trained personnel will assume the role of standby attendant for activities involving confined

space entry. The only approved training course is offered by MARAFIQ Loss Prevention (Loss

Prevention (LP))/Safety section. Candidates who have successfully completed the course will

be authorized to carry out standby attendant activities. Authorization card will be arranged for

successful individual, which is valid for three (3) years.

Record will be maintained by MARAFIQ Loss Prevention (LP)/Safety section in case a check is

carried out by MARAFIQ.

4.6 SCHEDULE OF TRAINING & NUMBER OF MANPOWER

The following safety training courses will be conducted by MARAFIQ Loss Prevention (LP)/Safety

section. Prior coordination shall take place by contractor safety representatives.

Safety Induction

Permit to Work

Standby Attendant for Confined Space

Safety Procedures Awareness

Authorized Gas Testers

5.0 SAFETY INFORMATION, GUIDELINES AND COMMUNICATION

The following tools of communication will be used at site and shall be kept as a record:

Safety Audit Forms

Tool Box Talk

Safety Letters

Safety Meetings

Safety Posters

5.1 TOOL BOX TALK

Tool box talk will be conducted weekly by supervisors prior to the start of work. These will be

audited by MARAFIQ Safety section. The toolbox talk will include, and not limited to, the monthly

Page 12 of 14 RFP Collective No. YNB-PR5221

safety topic, safety advice, safety observation, and incidents which occurred along with learning

points.

5.2 TEAM TALKS

Team talks will be conducted by supervisors prior to starting each task. These will be audited

by MARAFIQ Safety section.

There will be a short discussion with the team about the tasks to be carried out and should

include the following:

Details of the task and hazards that may arise.

Details of risk assessment where applicable.

Permit conditions.

Work methodology.

Personal protective equipment requirements.

Equipment and tools shall be used.

Feedback from the working crew about the method of work.

Feedback from any safety learning points.

5.3 HEALTH, SAFETY & ENVIRONMENT LETTERS

HSE letters will be circulated to all employees reporting/highlighting any health or safety topic

for educational purposes. The HSE letter will be issued by the contractor Safety Officer on

weekly basis.

5.4 HEALTH, SAFETY & ENVIRONMENT POSTERS

HSE posters will be designed, produced by the contractor & displayed regularly around the work

site in an attempt to increase safety awareness.

6.0 HEALTH, SAFETY & ENVIRONMENT REPORTING

6.1 HSE SUGGESTIONS

All employees are encouraged to make HSE suggestions. A form should be made available for

this purpose.

HSE incentive programs should be designed & organized by the contractor to reward the

employees/departments who contribute in the HSE suggestions and/or comply with safety

requirements. Details of the HSE suggestion and incentive programs will be distributed to all

employees prior to the start of the program.

6.2 NEAR-MISS / INJURY REPORTING

Near-miss Incident: it is an incident that could have caused property damage or personal

injury. Near- miss incidents, when not corrected, will contribute to accidents.

All near-miss and/or injuries must be reported immediately to the first line supervisor/foreman

and contractor HSE Officer. The MARAFIQ accident/incident report form is shall be completed

within 24 hours.

Page 13 of 14 RFP Collective No. YNB-PR5221

Contractor HSE Officer shall report all incidents, including near-misses, to MARAFIQ Safety

section immediately.

Copy of the near-miss/incident report will be kept available with the contractor HSE Officer.

7.0 HEALTH, SAFETY & ENVIRONMENT MONITORING

All line supervisors shall be involved in health, safety and environment site inspections. The

inspections will be in line with MARAFIQ site inspections procedure & forms.

The contractor HSE Officers will jointly develop a schedule and provide copy of the forms for

the monitoring, to all concerned line managements. They will also co-ordinate the actions

arising from the returned forms.

HSE Officer will utilize learning’s from these inspections for safety letters & posters.

Contractor’s HSE Officer shall conduct HSE inspections on a daily basis, report findings & follow

up the implementation of corrective actions.

Page 14 of 14 RFP Collective No. YNB-PR5221

You might also like

- NAG1 ManualDocument199 pagesNAG1 ManualJorge RuzNo ratings yet

- Jubail Management Procedure: 090102 Subject Pipeline Corridor Work Permit PurposeDocument6 pagesJubail Management Procedure: 090102 Subject Pipeline Corridor Work Permit PurposeAbdalrahman AntariNo ratings yet

- JHADocument6 pagesJHABishop Ojonuguwa AmehNo ratings yet

- Soil InvestigationDocument6 pagesSoil InvestigationglenNo ratings yet

- TRAFFIC MANAGEMENT PLAN Daft 1Document10 pagesTRAFFIC MANAGEMENT PLAN Daft 1RajeshNo ratings yet

- Marine Safety Management Plan: Kendall Bay Sediment Remediation ProjectDocument37 pagesMarine Safety Management Plan: Kendall Bay Sediment Remediation Projectkhabiran100% (1)

- Internal PTW Training Slide For Construction WorkersDocument44 pagesInternal PTW Training Slide For Construction WorkersLion DayNo ratings yet

- Accident Notification Form - Ec Safe RF 009Document6 pagesAccident Notification Form - Ec Safe RF 009Mohamad Hidayat Zainul MasriNo ratings yet

- MFMF-1-PC-057 Att D Scope of WorkDocument18 pagesMFMF-1-PC-057 Att D Scope of WorkThomas JohnNo ratings yet

- Afritech-Health and Safety PlanDocument17 pagesAfritech-Health and Safety PlanBouba Bttnyn SeneNo ratings yet

- CHS Application FormDocument5 pagesCHS Application FormCuevas GridNo ratings yet

- HSE Requirements For SubctrDocument11 pagesHSE Requirements For SubctrjoellontopNo ratings yet

- D7 Emergency Response PlanDocument31 pagesD7 Emergency Response PlanHSE GrantecNo ratings yet

- Implementing OSHA in The Construction Industry - A ReviewDocument24 pagesImplementing OSHA in The Construction Industry - A Reviewz969862100% (4)

- Company Health and SafetyDocument15 pagesCompany Health and Safetymel cruzNo ratings yet

- 2003 Dredging MergedDocument100 pages2003 Dredging MergedWarlock P.No ratings yet

- Construction Safety and Health ProgramDocument13 pagesConstruction Safety and Health ProgramDeosrock SalvadorNo ratings yet

- Construction Safety Policy 022020Document20 pagesConstruction Safety Policy 022020leo100% (2)

- Over View of The Industrial Fabrication YardDocument6 pagesOver View of The Industrial Fabrication Yardzam110100% (1)

- 2022.11 Eshs MPR Ifrdp Nrr-Nampula N-14.NovemberDocument74 pages2022.11 Eshs MPR Ifrdp Nrr-Nampula N-14.NovemberMarcelino Adelino NivallNo ratings yet

- PPE ProgramDocument8 pagesPPE ProgramAldrin BanaayNo ratings yet

- Construction Traffic Management PlanDocument24 pagesConstruction Traffic Management PlanGLa DysNo ratings yet

- New Guid To Safety Final Nov 2017Document28 pagesNew Guid To Safety Final Nov 2017ck19654840No ratings yet

- Volime II - Cathodic ProtectionDocument69 pagesVolime II - Cathodic Protectionjose yoyNo ratings yet

- IRC Draft Specification For Cold Milling 14 April 2011Document3 pagesIRC Draft Specification For Cold Milling 14 April 2011Sunil BoseNo ratings yet

- PTW SystemDocument21 pagesPTW SystemJaouad IDBOUBKERNo ratings yet

- Project and Construction Management Indicators - ReportDocument3 pagesProject and Construction Management Indicators - ReportJatinder SinghNo ratings yet

- NL Traffic Control Manual 2010Document95 pagesNL Traffic Control Manual 2010Chewfy1No ratings yet

- Responsibilities Summary: Department of LaborDocument2 pagesResponsibilities Summary: Department of LaborBonaventure NzeyimanaNo ratings yet

- Temporary Work ProcedureDocument16 pagesTemporary Work ProcedureAlbert JopsonNo ratings yet

- MDC EHS Progress Report Presentation 21 Nov 09Document37 pagesMDC EHS Progress Report Presentation 21 Nov 09Eze FoncardasNo ratings yet

- CDM Health and Safety File ContentsDocument1 pageCDM Health and Safety File ContentsParashuram PatilNo ratings yet

- Based On The UK Construction Industry Key Performance IndicatorsDocument30 pagesBased On The UK Construction Industry Key Performance Indicatorsahtin618No ratings yet

- ESMPDocument21 pagesESMPdavid chisambaNo ratings yet

- Mfmf-1-Pc-054 Rev 7 Att A Epc ContractsDocument42 pagesMfmf-1-Pc-054 Rev 7 Att A Epc ContractsThomas JohnNo ratings yet

- Saudi Aramco General StandardDocument4 pagesSaudi Aramco General StandardThomas JohnNo ratings yet

- METHOD STATEMENT Conduits For Power OutletsDocument12 pagesMETHOD STATEMENT Conduits For Power OutletsVenkatKakarlaNo ratings yet

- Fact Tel Plan-Final - 1Document77 pagesFact Tel Plan-Final - 1sudhakarNo ratings yet

- 0418MC 04.17.19 Form 25 CPM Flagging Checklist 28th STDocument3 pages0418MC 04.17.19 Form 25 CPM Flagging Checklist 28th STMohammed Jahanzeb ChoudaryNo ratings yet

- Optical Cross ConnectDocument39 pagesOptical Cross ConnectgptsivaNo ratings yet

- Site-Specific Health and Safety Plan1 PDFDocument24 pagesSite-Specific Health and Safety Plan1 PDFCarl WilliamsNo ratings yet

- Mobilization Plan GeneralTechnicalRequirementsDocument29 pagesMobilization Plan GeneralTechnicalRequirementsvwoke oyibogareNo ratings yet

- Project Management AssignmentDocument14 pagesProject Management AssignmentKIRUB100% (1)

- 2018 - sh210 6 sh210lc 5 t3Document14 pages2018 - sh210 6 sh210lc 5 t3Ralf MaurerNo ratings yet

- Normazione 07223: Fiat Standard Diagnostic Protocol On K Line KWP 2000Document61 pagesNormazione 07223: Fiat Standard Diagnostic Protocol On K Line KWP 2000kufemusik50% (2)

- JAFZA Construction Regulation - Third Edition 2003Document73 pagesJAFZA Construction Regulation - Third Edition 2003Abdul JabbarNo ratings yet

- EMSP 7 Construction Traffic Management Sub-PlanDocument147 pagesEMSP 7 Construction Traffic Management Sub-Planmyn maliQueNo ratings yet

- Environmental Management PlanDocument14 pagesEnvironmental Management Plansafak ışıkNo ratings yet

- Safety Bulletin 2007-1 - Rev 8 Sept 30 2014Document3 pagesSafety Bulletin 2007-1 - Rev 8 Sept 30 2014Mohammed Jahanzeb ChoudaryNo ratings yet

- Grating Decking and Floor Removal FormDocument2 pagesGrating Decking and Floor Removal FormMohamed Abd ElhaleemNo ratings yet

- Form K - Item 1 - Nigerian Content Execution PlanDocument8 pagesForm K - Item 1 - Nigerian Content Execution PlanBALARISI ENGINEERNo ratings yet

- ESH&S Plan Semi - Mobile Coal WashingDocument76 pagesESH&S Plan Semi - Mobile Coal WashingWahyu NugrahaNo ratings yet

- Emerging Technologies A Suggested Design Method For Curved Jacked Steel PipeDocument11 pagesEmerging Technologies A Suggested Design Method For Curved Jacked Steel PipefalokunNo ratings yet

- Hs-Hoo-Tp-120017-Hse-Pl-03 Environment Management PlanDocument32 pagesHs-Hoo-Tp-120017-Hse-Pl-03 Environment Management PlanMoaatazz NouisriNo ratings yet

- Environment Impact Assessment ReportDocument259 pagesEnvironment Impact Assessment ReportPranav WalkhadeNo ratings yet

- Project Health Safety and Environmental HSE Plan With All Forms - Method Statement HQDocument3 pagesProject Health Safety and Environmental HSE Plan With All Forms - Method Statement HQsvsrnbNo ratings yet

- Stevan Damjanovic - Master of Civil Engineering. Licence 412Document3 pagesStevan Damjanovic - Master of Civil Engineering. Licence 412Lazar AndonovNo ratings yet

- Environmental & Social Monitoring PlanDocument49 pagesEnvironmental & Social Monitoring Planmoses kyambadeNo ratings yet

- ESMP Revised Road No 7Document144 pagesESMP Revised Road No 7Nisanth ThulasidasNo ratings yet

- Method Statement of Road Sub Base Amd BaseDocument7 pagesMethod Statement of Road Sub Base Amd BaseBrian Colon50% (2)

- Safe Work Method StatementDocument6 pagesSafe Work Method StatementStansilous Tatenda NyagomoNo ratings yet

- NJQS Renewal Form v13Document1 pageNJQS Renewal Form v13AF Dowell MirinNo ratings yet

- 54 - Method Statements For Erection of Steel PDFDocument1 page54 - Method Statements For Erection of Steel PDFAbdul RahmanNo ratings yet

- Final - Commercial & SOR-Vol IDocument86 pagesFinal - Commercial & SOR-Vol IengharshNo ratings yet

- Job Hazard Analysis Engineering Site Inspection 2Document5 pagesJob Hazard Analysis Engineering Site Inspection 2Nonsoufo ezeNo ratings yet

- Risk Assessment in RoadworksDocument14 pagesRisk Assessment in RoadworksJared Makori100% (1)

- Driving Policy Signed ApprovedDocument1 pageDriving Policy Signed ApprovedSantos RexNo ratings yet

- General Provisions SOPDocument15 pagesGeneral Provisions SOPMohd Zubaidi Bin OthmanNo ratings yet

- Work Zone Traffic Management Guide Version 1.1 - Release NoteDocument2 pagesWork Zone Traffic Management Guide Version 1.1 - Release Notefreanne_0527100% (2)

- PR-CIV-005 - Ornametal Wire Mesh & Gate With All Accessories & SupportDocument8 pagesPR-CIV-005 - Ornametal Wire Mesh & Gate With All Accessories & SupportThomas JohnNo ratings yet

- PR CIV 010 Sign BoardsDocument6 pagesPR CIV 010 Sign BoardsThomas JohnNo ratings yet

- Saudi Arabian Oil Company: 12.0 Electrical 12.1 GeneralDocument3 pagesSaudi Arabian Oil Company: 12.0 Electrical 12.1 GeneralThomas JohnNo ratings yet

- Dillep KodothDocument5 pagesDillep KodothThomas JohnNo ratings yet

- Quotation: Customer InformationDocument2 pagesQuotation: Customer InformationThomas JohnNo ratings yet

- Murali CVDocument4 pagesMurali CVThomas JohnNo ratings yet

- PR-CIV-006 - Decorative Steel Motorized Sliding GatesDocument7 pagesPR-CIV-006 - Decorative Steel Motorized Sliding GatesThomas JohnNo ratings yet

- N.I.C. N.I.C. N.I.CDocument1 pageN.I.C. N.I.C. N.I.CThomas JohnNo ratings yet

- Concrete Curbs DatasheetDocument3 pagesConcrete Curbs DatasheetThomas JohnNo ratings yet

- Scope of WorkDocument19 pagesScope of WorkThomas JohnNo ratings yet

- 05 - Safco Piping MtoDocument12 pages05 - Safco Piping MtoThomas JohnNo ratings yet

- MFMF 1 PC 026 Instructions To BiddersDocument8 pagesMFMF 1 PC 026 Instructions To BiddersThomas JohnNo ratings yet

- Quotation: M/s From Dhafer M AL Zlaiq Cont Co Attn Tel Fax E-Mail Mob. SubDocument2 pagesQuotation: M/s From Dhafer M AL Zlaiq Cont Co Attn Tel Fax E-Mail Mob. SubThomas JohnNo ratings yet

- Waterproofing Works: Eastern Province - Dammam Area, Northern Area and Al-Hassa Area. North East Area - Al-Jouf AreaDocument1 pageWaterproofing Works: Eastern Province - Dammam Area, Northern Area and Al-Hassa Area. North East Area - Al-Jouf AreaThomas JohnNo ratings yet

- Summary of Document Revisions: 0 New Initial IssueDocument19 pagesSummary of Document Revisions: 0 New Initial IssueThomas JohnNo ratings yet

- Contractor Prequalification Summary CD 009B: REFERENCE NO.Document13 pagesContractor Prequalification Summary CD 009B: REFERENCE NO.Thomas JohnNo ratings yet

- Attachment - 4 Dimension Table For Steel Structural SectionDocument1 pageAttachment - 4 Dimension Table For Steel Structural SectionThomas JohnNo ratings yet

- 0 25-Jan-2013 New Initial Issue: Page 2 of 18Document20 pages0 25-Jan-2013 New Initial Issue: Page 2 of 18Thomas JohnNo ratings yet

- 5.4 Sample DrawingDocument4 pages5.4 Sample DrawingThomas JohnNo ratings yet

- 5.5 Dimension Table For Steel Structural Section 2013.01.25Document1 page5.5 Dimension Table For Steel Structural Section 2013.01.25Thomas JohnNo ratings yet

- Air Compressor ManualDocument11 pagesAir Compressor Manualkb2productionsNo ratings yet

- 1SBL351001R8000 A50 30 00 220 230v 50hz 230 240v 60hz ContactorDocument4 pages1SBL351001R8000 A50 30 00 220 230v 50hz 230 240v 60hz ContactorRobin ChiluisaNo ratings yet

- Radius Gauges Letter of ConformanceDocument1 pageRadius Gauges Letter of ConformanceSumair Ahsan SheikhNo ratings yet

- Surface Vehicle Recommended Practice: (R) Vehicle Acceleration MeasurementDocument8 pagesSurface Vehicle Recommended Practice: (R) Vehicle Acceleration MeasurementJose Gabriel DiazNo ratings yet

- ProjectDocument9 pagesProjectChandan KumarNo ratings yet

- Content Security Policy: Directives of CSPDocument10 pagesContent Security Policy: Directives of CSPМr. X GamingNo ratings yet

- TFR1 Precast RCDocument19 pagesTFR1 Precast RCvaibhavsensesNo ratings yet

- MD 2021-19 enDocument10 pagesMD 2021-19 enquality4720 GOLNITNo ratings yet

- Lotus Domino Mock Test - AdministrationDocument10 pagesLotus Domino Mock Test - AdministrationLotusLearnsNo ratings yet

- GC 2024 04 09Document9 pagesGC 2024 04 09quentasillallyNo ratings yet

- TR - Rac Servicing (Pacu-Cre) NC IIIDocument108 pagesTR - Rac Servicing (Pacu-Cre) NC IIIIch KhayNo ratings yet

- 08-1462 Siemens SICAM PAS CertificateDocument2 pages08-1462 Siemens SICAM PAS CertificatevishadkapadiaNo ratings yet

- Repeat After Me User's GuideDocument5 pagesRepeat After Me User's GuideBanditsRTGSJSKALNo ratings yet

- B - 02 - Speech Signaling Analysis - 609500Document17 pagesB - 02 - Speech Signaling Analysis - 609500hasan doganNo ratings yet

- Analysis of MtcarsDocument3 pagesAnalysis of Mtcarsarnulfo.perez.p100% (1)

- KDACI New V1 PDFDocument30 pagesKDACI New V1 PDFVasaNo ratings yet

- Datasheet MAG322-323Document2 pagesDatasheet MAG322-323BarnayNo ratings yet

- File - AGR Field Operations TD Handy-Scan Data Sheet - 051210Document2 pagesFile - AGR Field Operations TD Handy-Scan Data Sheet - 051210Dhanasekaran RNo ratings yet

- 3 Architectural StylesbjhbbhDocument35 pages3 Architectural Stylesbjhbbhcuongtv_abcNo ratings yet

- HRB Hydrostatic Regenerative Braking System TheDocument7 pagesHRB Hydrostatic Regenerative Braking System ThexxshNo ratings yet

- CSE 6203 - Lecture 01Document18 pagesCSE 6203 - Lecture 01Sumit PramanikNo ratings yet

- HSUPA 2ms Optimization-TTI Optimize - Phase 4 Day 7 Report V1.0Document20 pagesHSUPA 2ms Optimization-TTI Optimize - Phase 4 Day 7 Report V1.0Gagandeep Singh Jassal50% (2)

- SecureDrive EX2 PDFDocument42 pagesSecureDrive EX2 PDFLuis BañuelosNo ratings yet