Professional Documents

Culture Documents

Maxon EC Motor: An Introduction To Brushless DC Motors

Uploaded by

mohammedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maxon EC Motor: An Introduction To Brushless DC Motors

Uploaded by

mohammedCopyright:

Available Formats

maxon EC motor

An introduction to brushless DC motors

maxon EC motor

An introduction to

brushless DC motors

Design variants: maxon EC motor families

Common features

– operating principle

– winding connections, iron losses

Electronic commutation systems

– block commutation with and without Hall sensors

– sinusoidal commutation

Comparison to DC motors with brushes

© 2010, maxon motor ag, Sachseln, Schweiz

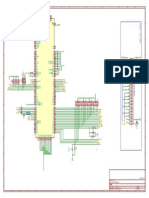

Components of an EC drive system

load

power

supply

Hall

3 motor

mechanical sensors

phases

range line

electrical

2, © 2010, maxon motor ag, www.maxonmotor.com/academy

range

commutation

and controller

electronic

encoder range

line command

EC motors - overview

© 2012, maxon motor ag, www.maxonmotor.com/academy Page 1

maxon EC motor

An introduction to brushless DC motors

Brushless DC motor

names: EC motor, BLDC motor

motor behavior similar to DC motor

– design similar to synchronous motor (3 phase stator winding,

rotating magnet)

– the powering of the 3 phases according to rotor position

main advantages: higher life, higher speeds

3, © 2010, maxon motor ag, www.maxonmotor.com/academy

slotless windings

– similar advantages as coreless DC motors

– no magnetic detent, less vibrations

becomes more attractive: costs, size, magnets

Part 1: maxon EC motor design variants

slotless

slotted

external rotor

features in common

4, © 2010, maxon motor ag, www.maxonmotor.com/academy

– 3 phase winding in the

stator (3 winding

connections)

– rotating permanent magnet

made of NdFeB

– preloaded ball bearings

slotted

– electronic commutation internal rotor

© 2012, maxon motor ag, www.maxonmotor.com/academy Page 2

maxon EC motor

An introduction to brushless DC motors

maxon EC motor: Coreless design

design with coreless maxon winding

– internal rotor with 1 or 2 pole pair

maxon EC motor

– many types: e.g. short – long,

sterilisable, integrated electronics, …

– typically for high speeds

5, © 2010, maxon motor ag, www.maxonmotor.com/academy

maxon EC-max

– Philosophy: reliable EC motor at

reasonable price

maxon EC-4pole

– Philosophy: the strongest possible motor

maxon EC motor

magn. return:

preloaded laminated iron stack

PCB with ball bearings

Hall sensors

control

magnet

6, © 2010, maxon motor ag, www.maxonmotor.com/academy

housing

3 phase knitted balancing rings

maxon winding rotor

el. connections winding

and Hall sensors (permanent magnet)

© 2012, maxon motor ag, www.maxonmotor.com/academy Page 3

maxon EC motor

An introduction to brushless DC motors

EC-max 30 vs. EC-4pole 30

standard maxon knitted hexagonal

winding magnetic return winding

- different thickness

- FeSi vs. FeNi

7, © 2010, maxon motor ag, www.maxonmotor.com/academy

ball bearings

- different size rotor

rotor - different preload: 6N, 8N - 5mm shaft

- 4mm shaft - 4 pole magnet

- 2 pole magnet - balancing rings

EC-max: design characteristics

Philosophy: reliable EC motor at reasonable price

standard maxon winding

– only star circuit possible

– not optimized with respect to performance (power)

Hall sensors monitor directly the power magnet

8, © 2010, maxon motor ag, www.maxonmotor.com/academy

– no control magnet

– special orientation process of Hall sensors to winding

no balancing rings

– very high speeds are not possible (up to 12 - 20'000 rpm)

preloaded ball bearings

long and short versions per diameter

© 2012, maxon motor ag, www.maxonmotor.com/academy Page 4

maxon EC motor

An introduction to brushless DC motors

EC-4pole: design characteristics

Philosophy: the strongest possible EC motor

very high torque and acceleration

– knitted maxon winding

– hexagonal winding on long versions

– 4-pole permanent magnet

9, © 2010, maxon motor ag, www.maxonmotor.com/academy

moderate speeds up to 25'000 rpm

– higher commutation frequency

– higher iron losses

special orientation process of Hall sensors to winding

preloaded ball bearings

maxon EC motor: Slotted design

maxon EC-i

– Philosophy: strong EC Motor at an

attractive price

– dynamic motor, cogging torque

– slotted winding, internal rotor

– several magnetic pole pairs

10, © 2010, maxon motor ag, www.maxonmotor.com/academy

flat maxon EC motor

– Philosophy: flat EC Motor at an

attractive price

– slotted winding, external rotor

– more than 4 magnetic pole pairs

– relatively high torque but limited speed

and dynamics

© 2012, maxon motor ag, www.maxonmotor.com/academy Page 5

maxon EC motor

An introduction to brushless DC motors

EC flat motor: design characteristics

Philosophy: flat design with attractive price

rotor:

external rotor => high torque 1

multi-pole magnetic ring of NdFeB

2 3

=> higher commutation frequency,

=> not very high speeds

11, © 2010, maxon motor ag, www.maxonmotor.com/academy

stator: 3 2

3 phases, several teeth per phase 1

further characteristics:

Hall sensors detect magnetic ring e.g. EC 32 flat:

but also often sensorless - 8 magnetic poles

preloaded ball bearings - 2 teeth per winding phase

Part 2: Interaction of rotor and stator

current distribution in phases

– 3 phases: 6 possible current distributions

– 6 winding magnetic field directions rotated by 60°

– 60° commutation

Iout

commutation

12, © 2010, maxon motor ag, www.maxonmotor.com/academy

Iin Iin

winding

magnetic field

Iout of winding

© 2012, maxon motor ag, www.maxonmotor.com/academy Page 6

maxon EC motor

An introduction to brushless DC motors

Winding connections

13, © 2010, maxon motor ag, www.maxonmotor.com/academy

RY 3 R

high resistance low resistance

low currents k M,Y 3 k M, low voltages

higher torque higher speed constant

1

constant k n,Y k n, possibility of induced circular

3

winding currents

internal connection of the 3 phases: no practical consequences

Iron losses

origin: rotating magnet

hysteresis losses

– changing the direction of

magnetization needs energy

eddy current losses

14, © 2010, maxon motor ag, www.maxonmotor.com/academy

– rotating magnetic field causes

eddy currents effect of

effects: additional motor iron losses

heating

– at high speeds less current for

torque generation is allowed

– see operation range diagram

© 2012, maxon motor ag, www.maxonmotor.com/academy Page 7

maxon EC motor

An introduction to brushless DC motors

Part 3: Electronic commutations systems

common goal: applying the current to get the maximum torque

perpendicular magnetic field orientation of

- rotor (permanent magnet)

- and stator (winding)

knowledge of rotor position with respect to winding

commutation

15, © 2010, maxon motor ag, www.maxonmotor.com/academy

block type sine

sensorless Hall sensors rotor position encoder (+ HS)

feedback

maxon

DECS controller DES

DEC family

families EPOS

Block commutation

rotor position from Hall

sensor signals

north

control magnet south

16, © 2010, maxon motor ag, www.maxonmotor.com/academy

Hall sensor

1 1 0 0 0 1 1

0 1 1 1 0 0 0

0 0 0 1 1 1 0

0° 60° 120° 180° 240° 300° 360°

EC-max and EC flat:

rotation angle

Power magnet is probed directly

© 2012, maxon motor ag, www.maxonmotor.com/academy Page 8

maxon EC motor

An introduction to brushless DC motors

Block commutation

power stage EC motor

controller + (MOSFET) (magnet, winding, sensor)

phase 1 HS1

commutation

logics

17, © 2010, maxon motor ag, www.maxonmotor.com/academy

phase 3

HS3

HS2

_ phase 2

rotor position feedback

Multi-pole EC motor: commutation

2 1

15 30 45 60 75 90°

2 3

18, © 2010, maxon motor ag, www.maxonmotor.com/academy

3 2

1 1

© 2012, maxon motor ag, www.maxonmotor.com/academy Page 9

maxon EC motor

An introduction to brushless DC motors

Sensorless block commutation

rotor position detection without

(Hall) sensors EMF

measuring the back EMF

star point

zero crossing of back EMF

time delay 30°

19, © 2010, maxon motor ag, www.maxonmotor.com/academy

difficult at low speeds

special starting procedure sensorless commutation

only for continuous

similar to stepper motor

operation at high speeds

Sensorless block commutation

virtual star point

virtual star point in the electronics

star or delta configuration

controller for

sensorless operation

EMF

20, © 2010, maxon motor ag, www.maxonmotor.com/academy

~1kW R R

Y

© 2012, maxon motor ag, www.maxonmotor.com/academy Page 10

maxon EC motor

An introduction to brushless DC motors

Block commutation

1 1 0 0 0 1 1

motor with 1 pole pair 0 1 1 1 0 0 0

0 0 0 1 1 1 0

– position known within 60°

– commutation every 60° 0° 60° 120° 180° 240° 300° 360°

rotation angle

motor with P pole pairs

– position known within 60°/ P

21, © 2010, maxon motor ag, www.maxonmotor.com/academy

– commutation every 60°/ P

block shaped phase

currents

– torque ripple

– vibrations, humming

Sinusoidal commutation

rotor position

must be known very accurately

typical 2'000 points per rev.

500 pulse encoder

(Hall sensors for start: absolute

rotor position)

22, © 2010, maxon motor ag, www.maxonmotor.com/academy

resolver as an alternative

0° 60° 120° 180° 240° 300° 360°

phase currents rotation angle

sinusoidal

120° phase shift Sinusoidal commutation for

similar to synchronous motor with smooth running even at the

variable frequency lowest speeds

© 2012, maxon motor ag, www.maxonmotor.com/academy Page 11

maxon EC motor

An introduction to brushless DC motors

Part 4: DC and EC motor: Comparison

DC motor EC motor

simple operation and long life, high speeds

control, even without – preloaded ball bearings

electronics no brush fire

no electronic parts in the

iron losses in the magnetic

23, © 2010, maxon motor ag, www.maxonmotor.com/academy

motor

return

brush commutation system needs electronics to run

limits motor life – more cables

– more expensive

max. speed limited by

commutation system electronic parts in the

motor (Hall Sensor)

DC and EC motor: Comparison

maxon motor family RE (DC) EC EC-max

(20 … 100 Watt) EC-4pole EC-flat EC-i

50 000 min-1 10 W/cm3 2 mNm/cm3 10 ms

24, © 2010, maxon motor ag, www.maxonmotor.com/academy

25 000 min-1 5 W/cm3 1 mNm/cm3 5 ms

max. speed power density torque density mech. time

(min-1) (W/cm3) (mNm/cm3) const. (ms)

Comparison DC and EC

© 2012, maxon motor ag, www.maxonmotor.com/academy Page 12

You might also like

- IEEE Guide: Test Procedures for Synchronous Machines - ParametersDocument108 pagesIEEE Guide: Test Procedures for Synchronous Machines - Parametersflywheel2006100% (2)

- Permanent Magnet Synchronous MachineDocument8 pagesPermanent Magnet Synchronous MachineWilli Apupalo NaranjoNo ratings yet

- Bts 310Document3 pagesBts 310oscarleandro690% (1)

- Linear Synchronous Motors PDFDocument56 pagesLinear Synchronous Motors PDFJorge Peralta0% (1)

- Maxon DC MotorDocument16 pagesMaxon DC MotorteguhNo ratings yet

- Maxon Coreless DCmotorDocument34 pagesMaxon Coreless DCmotorteguhNo ratings yet

- DC and BLDC Motors With Permanent MagnetsDocument13 pagesDC and BLDC Motors With Permanent MagnetsMahalingam DuraisamyNo ratings yet

- Analysis and Comparison of Two Brushless DC Generators With Doubly Salient Structure and Stator Field WindingDocument4 pagesAnalysis and Comparison of Two Brushless DC Generators With Doubly Salient Structure and Stator Field WindingmohammadNo ratings yet

- Design of High Performance Linear Brushless DC Motor With Ironless CoreDocument6 pagesDesign of High Performance Linear Brushless DC Motor With Ironless CoreShubhzsNo ratings yet

- Optimization Design of The Permanent Magnent Synchronous Motor For Electric ActuatorDocument5 pagesOptimization Design of The Permanent Magnent Synchronous Motor For Electric ActuatorMano DanoNo ratings yet

- Analysis of Power and Torque For The IPM Motors With High Flux Density in StatorDocument8 pagesAnalysis of Power and Torque For The IPM Motors With High Flux Density in Statorphan hoai nam PhanNo ratings yet

- Design of Axial Flux Permanent Magnet Brushless DC Motor For Direct Drive of Electric VehicleDocument6 pagesDesign of Axial Flux Permanent Magnet Brushless DC Motor For Direct Drive of Electric Vehiclegrun.jpgNo ratings yet

- Over-excited synchronous motor explainedDocument2 pagesOver-excited synchronous motor explainedmaneeshkNo ratings yet

- Maxon- Mars Exploration ProgrammeDocument618 pagesMaxon- Mars Exploration ProgrammeRoger SheddenNo ratings yet

- Project AbbtractDocument8 pagesProject Abbtractchannel ThingsNo ratings yet

- Analysis of Copper Loss of Permanent Magnet Synchronous Motor With Formed Transposition WindingDocument10 pagesAnalysis of Copper Loss of Permanent Magnet Synchronous Motor With Formed Transposition WindingAndre NasrNo ratings yet

- Permanent Magnet DC Criteria: Motors Design and Operation AdvantagesDocument7 pagesPermanent Magnet DC Criteria: Motors Design and Operation Advantagesdjole07No ratings yet

- A Novel Torque Quality Improvement of An Asymemetric Windings Permanent MagnetDocument6 pagesA Novel Torque Quality Improvement of An Asymemetric Windings Permanent MagnetLEONEL JORDY PEREZ SOLORZANONo ratings yet

- Design of Wound Rotor Low-Voltage Synchronous Generator: M. Osovi, S. Smaka, Š. Maši I. Salihbegovi H. SteinhartDocument5 pagesDesign of Wound Rotor Low-Voltage Synchronous Generator: M. Osovi, S. Smaka, Š. Maši I. Salihbegovi H. SteinhartMurat Erhan BalciNo ratings yet

- Principles of DC MotorsDocument14 pagesPrinciples of DC MotorsAravind Raj PandianNo ratings yet

- 20201019-AC MachinesDocument99 pages20201019-AC Machinesvaraprasad93No ratings yet

- Optimal Design and Control of Axial-Flux Brushless DC Wheel Motor For Electrical VehiclesDocument10 pagesOptimal Design and Control of Axial-Flux Brushless DC Wheel Motor For Electrical Vehiclesfre12345No ratings yet

- Variable-Flux Outer-Rotor Permanent Magnet Synchronous Motor For In-Wheel Direct-Drive ApplicationsDocument8 pagesVariable-Flux Outer-Rotor Permanent Magnet Synchronous Motor For In-Wheel Direct-Drive Applicationsdeepakmahto.eeNo ratings yet

- Axial FluxDocument5 pagesAxial Flux123456No ratings yet

- Axial Flux Motors Radial Flux MotorsDocument5 pagesAxial Flux Motors Radial Flux Motors123456No ratings yet

- Design and Simulation of A Servo-Drive Motor Using ANSYS ElectromagneticsDocument13 pagesDesign and Simulation of A Servo-Drive Motor Using ANSYS ElectromagneticsMustafa AlhumayreNo ratings yet

- Electrical Technology: Difference Between Synchronous and Asynchronous MotorDocument6 pagesElectrical Technology: Difference Between Synchronous and Asynchronous MotorNAVEEN KUMAR SUMANNo ratings yet

- Rotor-Shape Optimization of Interior-Permanent-Magnet Motors To Reduce Harmonic Iron LossesDocument9 pagesRotor-Shape Optimization of Interior-Permanent-Magnet Motors To Reduce Harmonic Iron LossesVahid KarimiNo ratings yet

- Calculation of Eddy Current Losses in Permanent Magnets of Servo MotorDocument5 pagesCalculation of Eddy Current Losses in Permanent Magnets of Servo Motorسورنا سوریاناNo ratings yet

- Jansons Institute of Technology: Special Electrical MachinesDocument98 pagesJansons Institute of Technology: Special Electrical Machineselangoprt1No ratings yet

- Rare-Earth Free Motor Research at 2013 Renewable Energy ConferenceDocument6 pagesRare-Earth Free Motor Research at 2013 Renewable Energy ConferenceHuong ThaoNo ratings yet

- Wrobel2003 Article ANewApproachToReductionOfTheCoDocument11 pagesWrobel2003 Article ANewApproachToReductionOfTheCoJohn XaviNo ratings yet

- Design and Modelling of Internal Permanent Magnet Motor (#764846) - 1189475Document25 pagesDesign and Modelling of Internal Permanent Magnet Motor (#764846) - 1189475Tejas PanchalNo ratings yet

- Permanent Magnet Synchronous MotorDocument9 pagesPermanent Magnet Synchronous MotorHAMID SULIAMANNo ratings yet

- IET Electric Power Appl - 2020 - Ahmad - Design of A High Thrust Density Moving Magnet Linear Actuator With Magnetic FluxDocument7 pagesIET Electric Power Appl - 2020 - Ahmad - Design of A High Thrust Density Moving Magnet Linear Actuator With Magnetic FluxDONE AND DUSTEDNo ratings yet

- Ali Soomro 2020 IOP Conf. Ser. - Mater. Sci. Eng. 917 012005Document10 pagesAli Soomro 2020 IOP Conf. Ser. - Mater. Sci. Eng. 917 012005DJALOUL KARBOUANo ratings yet

- Magnetic Braking System ExplainedDocument32 pagesMagnetic Braking System ExplainedTajinder SinghNo ratings yet

- PMSM Vs Induction MotorDocument4 pagesPMSM Vs Induction MotorGarry GeorgeNo ratings yet

- Wevj 05 00546 PDFDocument4 pagesWevj 05 00546 PDFHenryHutabaratNo ratings yet

- Stepper MotorsDocument9 pagesStepper MotorsAnonymous mRBbdopMKfNo ratings yet

- AN1164 BLDC MotorsDocument9 pagesAN1164 BLDC Motorsbabulcp07No ratings yet

- A New 9-Phase Permanent Magnet Synchronous Motor With Consequent Pole Rotor For High Power Traction ApplicationsDocument6 pagesA New 9-Phase Permanent Magnet Synchronous Motor With Consequent Pole Rotor For High Power Traction ApplicationskkarthiksNo ratings yet

- A Novel Dual Three-Phase Permanent Magnet Synchronous Motor With Asymmetric Stator WindingDocument4 pagesA Novel Dual Three-Phase Permanent Magnet Synchronous Motor With Asymmetric Stator WindingmohammadNo ratings yet

- Massachusetts Institute of Technology: 2.1 Surface Magnet MachinesDocument32 pagesMassachusetts Institute of Technology: 2.1 Surface Magnet MachinesEgyptman JanNo ratings yet

- Assignment 2 Ac DCDocument15 pagesAssignment 2 Ac DCVincoy JohnlloydNo ratings yet

- Permanent Magnet Motor GuideDocument36 pagesPermanent Magnet Motor GuidekkarthiksNo ratings yet

- Design of Axial-Flux Motor For Traction ApplicatioDocument13 pagesDesign of Axial-Flux Motor For Traction Applicatioantriksh mahajanNo ratings yet

- Efficiency Improvement Analysis of A SiC MOSFET-based PMSM Drive System With Variable Switching FrequencyDocument9 pagesEfficiency Improvement Analysis of A SiC MOSFET-based PMSM Drive System With Variable Switching Frequencymdht1556No ratings yet

- Design of electric motor using coupled electromagnetic and structural analysis and optimizationDocument7 pagesDesign of electric motor using coupled electromagnetic and structural analysis and optimizationCầu CaoNo ratings yet

- Iet-Epa 2020 0126Document6 pagesIet-Epa 2020 0126Mehdi AminiNo ratings yet

- Sae2023 01 1074Document8 pagesSae2023 01 1074Joanne WNo ratings yet

- A Novel Magnetic Gear For High Speed Motor System: Kohei Aiso, Kan Akatsu, Yasuaki AoyamaDocument7 pagesA Novel Magnetic Gear For High Speed Motor System: Kohei Aiso, Kan Akatsu, Yasuaki AoyamabnbaNo ratings yet

- IEEE review of techniques for minimizing pulsating torque in PMAC motor drivesDocument10 pagesIEEE review of techniques for minimizing pulsating torque in PMAC motor drivesIan SilveiraNo ratings yet

- Unit I Synchronous Reluctance MotorsDocument78 pagesUnit I Synchronous Reluctance MotorsshilpaNo ratings yet

- XS-2321 Peak Performance DC MotorDocument64 pagesXS-2321 Peak Performance DC MotorromachNo ratings yet

- Icem 2020Document8 pagesIcem 2020rasoolNo ratings yet

- IEEE-TOM - Journal ArticleDocument4 pagesIEEE-TOM - Journal ArticleedumacerenNo ratings yet

- Created by Rick Munz, Edited by Steve Stretz (8/10/2011)Document7 pagesCreated by Rick Munz, Edited by Steve Stretz (8/10/2011)Ashutosh TrivediNo ratings yet

- Simulation of A Double-Sided Axial Flux Brushless DC Two-Phase Motor DynamicsDocument7 pagesSimulation of A Double-Sided Axial Flux Brushless DC Two-Phase Motor Dynamicsrupalchopade5163No ratings yet

- Prodotti 7 01703710Document9 pagesProdotti 7 01703710Julius RojoNo ratings yet

- ToM47 10 - 3602 3605Document5 pagesToM47 10 - 3602 3605AimmadNo ratings yet

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsFrom EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNo ratings yet

- 10125623a00 1-CpuDocument1 page10125623a00 1-CpumohammedNo ratings yet

- GPFC250 Commercial/GPFM250 Medical: 250 Watt Global Performance SwitchersDocument2 pagesGPFC250 Commercial/GPFM250 Medical: 250 Watt Global Performance SwitchersmohammedNo ratings yet

- Mindray CLIA Dilution Sheet: 6×8 ML 2×30 MLDocument1 pageMindray CLIA Dilution Sheet: 6×8 ML 2×30 MLmohammedNo ratings yet

- Ten Simple Rules For Creating A Good Data Management Plan: William K. MichenerDocument9 pagesTen Simple Rules For Creating A Good Data Management Plan: William K. MichenermohammedNo ratings yet

- Lecture Notes in Foundations of MathematicsDocument35 pagesLecture Notes in Foundations of MathematicsmohammedNo ratings yet

- IC17 IC15: +10VREF +10VREF 0vana +10VREFDocument1 pageIC17 IC15: +10VREF +10VREF 0vana +10VREFmohammedNo ratings yet

- IV Infusion SolutionDocument8 pagesIV Infusion SolutionmohammedNo ratings yet

- Dual Notes-IDocument3 pagesDual Notes-ImohammedNo ratings yet

- 03 Measurements-System2-Waleed-AltalabiDocument36 pages03 Measurements-System2-Waleed-AltalabimohammedNo ratings yet

- PDFDocument55 pagesPDFاحمد ابراهيمNo ratings yet

- 02 Measurements-System1-Waleed-AltalabiDocument19 pages02 Measurements-System1-Waleed-AltalabimohammedNo ratings yet

- 00 Introducing-Instrumentation-Waleed-AltalabiDocument7 pages00 Introducing-Instrumentation-Waleed-AltalabimohammedNo ratings yet

- Peripheral Simulation: PEC Channels DialogDocument1 pagePeripheral Simulation: PEC Channels DialogmohammedNo ratings yet

- Top Arteries of the Human BodyDocument9 pagesTop Arteries of the Human BodymohammedNo ratings yet

- 2002Document64 pages2002mohammedNo ratings yet

- Ua 66 - 1531 66Document1 pageUa 66 - 1531 66mohammedNo ratings yet

- Power Supplies Module 02Document20 pagesPower Supplies Module 02Genes Mancio AcenasNo ratings yet

- السلامة المهنيةDocument166 pagesالسلامة المهنيةtibNo ratings yet

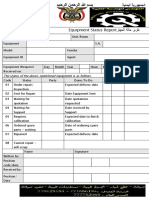

- PM MEDICAL EQUIPMENTDocument1 pagePM MEDICAL EQUIPMENTmohammedNo ratings yet

- 2.6 Training of Technicians For Medical Equipment MaintenanceDocument4 pages2.6 Training of Technicians For Medical Equipment MaintenanceWolaé Mathurin Edmond AmegandjinNo ratings yet

- chap 17.pptصيانة وادارةDocument35 pageschap 17.pptصيانة وادارةmohammedNo ratings yet

- Switching Power Supply Circuit Diagram With Explanation: CatalogDocument22 pagesSwitching Power Supply Circuit Diagram With Explanation: CatalogmohammedNo ratings yet

- 11المهندس للهندسة الطبية اجمالي تقارير الصيانةDocument13 pages11المهندس للهندسة الطبية اجمالي تقارير الصيانةmohammedNo ratings yet

- A BIST Scheme For Testing and Repair of Multi-Mode Power SwitchesDocument6 pagesA BIST Scheme For Testing and Repair of Multi-Mode Power SwitchesmohammedNo ratings yet

- GPFC250 Commercial/GPFM250 Medical: 250 Watt Global Performance SwitchersDocument2 pagesGPFC250 Commercial/GPFM250 Medical: 250 Watt Global Performance Switchersmohammed0% (1)

- Training COURSE2020-1Document4 pagesTraining COURSE2020-1mohammedNo ratings yet

- Fresenius Optima PT, VS, ST - Service ManualDocument106 pagesFresenius Optima PT, VS, ST - Service ManualJoey Chavez Bagatela100% (1)

- SMPS DesignDocument30 pagesSMPS Designshihabnitt100% (1)

- Preview To "Troubleshooting and Repairing Switch Mode Power Supply"Document9 pagesPreview To "Troubleshooting and Repairing Switch Mode Power Supply"b0bwhite80% (5)

- Fall 2014 HW 7 Solns PDFDocument22 pagesFall 2014 HW 7 Solns PDFJenniferNataliaCoyNo ratings yet

- Magnetic Properties of SolidsDocument2 pagesMagnetic Properties of Solidsblerb795No ratings yet

- M.Tech Nanotechnology Syllabus in PSGDocument11 pagesM.Tech Nanotechnology Syllabus in PSGumapathi_nanoNo ratings yet

- Avo CT-38 Service Manual OcrDocument35 pagesAvo CT-38 Service Manual Ocr240GL guyNo ratings yet

- Light Sensitive Trigger Automatically Controls Street LightsDocument21 pagesLight Sensitive Trigger Automatically Controls Street LightsAtharvaNo ratings yet

- 3Document8 pages3K@mR@N D@uD P@nHw@RNo ratings yet

- RRP Singh, M. Rigol and D. Huse - Kagome Lattice AntiferromagnetsDocument48 pagesRRP Singh, M. Rigol and D. Huse - Kagome Lattice AntiferromagnetsBanshees_GleeNo ratings yet

- Post Workshop Assignment 12 - EMI - VKNDocument7 pagesPost Workshop Assignment 12 - EMI - VKNmapuclouddigitalworldNo ratings yet

- Multiphase Brushless DC MotorDocument36 pagesMultiphase Brushless DC MotorMohammed IrfanNo ratings yet

- BTL 4th Sem Power Electronics Lab ManualDocument88 pagesBTL 4th Sem Power Electronics Lab ManualGopinath B L NaiduNo ratings yet

- COMPASS ERROR Copy5Document3 pagesCOMPASS ERROR Copy5Francis ParisNo ratings yet

- Ch-04 Moving Charges and Magnetism: Lect-10Document32 pagesCh-04 Moving Charges and Magnetism: Lect-10Kishan KumarNo ratings yet

- Design of Permanent Magnet Systems Using Finite Element AnalysisDocument5 pagesDesign of Permanent Magnet Systems Using Finite Element AnalysiselectronenergyNo ratings yet

- Rewinding of Single Phase Induction MotorsDocument2 pagesRewinding of Single Phase Induction Motors2023seee004No ratings yet

- Alternator 25a Sandy and DusDocument2 pagesAlternator 25a Sandy and DusGita Pradani Putri ApriyonoNo ratings yet

- ETE 1112 Electrical Lab ManualDocument27 pagesETE 1112 Electrical Lab ManualSabuj Ahmed100% (1)

- Esc201A: Introduction To Electronics: Circuit FundamentalsDocument57 pagesEsc201A: Introduction To Electronics: Circuit Fundamentalsash jayNo ratings yet

- Circuit Analysis Final Exam Paper UNITENDocument7 pagesCircuit Analysis Final Exam Paper UNITENwandjawadNo ratings yet

- Magnetic Particle Examination Procedure PorDocument7 pagesMagnetic Particle Examination Procedure PorFasil ParuvanathNo ratings yet

- 8.4 Transformer 2017Document17 pages8.4 Transformer 2017fillyana01No ratings yet

- EE2403 - Special Electrical MachinesDocument5 pagesEE2403 - Special Electrical Machinesshiva shakthyNo ratings yet

- Basic Electrical Engineering Multiple Choice Questions: Unit I ElectromagnetismDocument13 pagesBasic Electrical Engineering Multiple Choice Questions: Unit I ElectromagnetismDhananjayNo ratings yet

- Per Unit System SolvedDocument15 pagesPer Unit System SolvedsaiNo ratings yet

- Unit 6 Alternator (Synchronous Generator) : StructureDocument29 pagesUnit 6 Alternator (Synchronous Generator) : Structureshubhammahajan26No ratings yet

- Simple DIY Induction Heater - RMCyberneticsDocument44 pagesSimple DIY Induction Heater - RMCyberneticsjay_milkNo ratings yet

- Construction and Working of Brushless DC PDFDocument12 pagesConstruction and Working of Brushless DC PDFaswardi8756No ratings yet

- Diffusion in Iron, Iron Solid Solutions and SteelsDocument38 pagesDiffusion in Iron, Iron Solid Solutions and SteelsJuliana FortunatoNo ratings yet

- Speed Control of Induction MotorDocument4 pagesSpeed Control of Induction Motormahato741No ratings yet