Professional Documents

Culture Documents

Temperature of Freshly Mixed Hydraulic-Cement Concrete

Temperature of Freshly Mixed Hydraulic-Cement Concrete

Uploaded by

Hasan al MahmudOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Temperature of Freshly Mixed Hydraulic-Cement Concrete

Temperature of Freshly Mixed Hydraulic-Cement Concrete

Uploaded by

Hasan al MahmudCopyright:

Available Formats

Designation: C1064/C1064M − 12

Standard Test Method for

Temperature of Freshly Mixed Hydraulic-Cement Concrete1

This standard is issue

issued

d under the fixed designation

designation C1064

C1064/C106

/C1064M;

4M; the number immediately

immediately following the desig

designatio

nation

n indicates

indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon ( ´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

-

1. Sco

Scope*

pe* ture represents the temperature at the time of testing and may -

-

`

,

,

`

,

1.1 This test method covers the determination

determination of tempera- not be an indication of the temperature of the freshly mixed `

,

,

`

,

,

concrete at a later time. It may be used to verify conformance

`

-

ture of freshly mixed hydraulic-cement concrete. `

-

`

`

`

to a specified requirement for temperature of concrete. `

,

,

,

1.2 The values stated

stated in either SI or inch-pound

inch-pound units are to ,

`

`

`

,

,

be regarded separately as standard. The values stated in each 3.2 Concre

Concretete containing aggregate

aggregate of a nomin

nominal

al maximum `

-

-

system may not be exact equivalents; therefore, each system size greater than 75 mm [3 in.] may require up to 20 min for the

shall be used independently

independently of the other. Combining

Combining values transfer

transfer of heat from aggregate

aggregate to mortar

mortar.. (See ACI Committee

4

from the two systems may result in non-conformance with the 207.1R Report. )

standard.

1.3 The text of this standard

standard references

references notes and footnotes 4. Appar

Apparatus

atus

that provide explanatory

explanatory infor

information

mation.. These notes and foot-

4.1 Container, shall be large enough to provide at least 75

notess (e

note (exc

xclu

ludi

ding

ng th

thos

osee in tab

table

less an

and

d fig

figur

ures

es)) sh

shal

alll no

nott be mm [3 in.] of concrete in all directions around the sensor of the

considered as requirements of this standard.

temperature measuring device; concrete cover must also be at

1.4 This standar

standard d doe

doess not purport

purport to add

addre

ress

ss all of the leastt thr

leas three

ee time

timess the nominal

nominal max

maximu

imumm siz

sizee of the coa

coarse

rse

safetyy co

safet conc

ncer

erns

ns,, if an

anyy, as

asso

socia

ciate

ted

d wi

with

th its ususe.

e. It is th

thee aggregate.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 4.2 Tempera

Temperatur

turee Measu ring Device, shal

Measuring shalll be ca capa

pabl

blee of

bility of regulatory limitations prior to use. ( Warning—Fresh

(Warning —Fresh accurate

accu rately

ly meas

measuri

uring

ng the temp

tempera

eratur

turee of the fre

freshl

shly

y mix

mixed

ed

hydrau

hyd raulic

lic ceme

cementi

ntitiou

tiouss mix

mixtur

tures

es are cau

causti

sticc and may cau

cause

se concrete to 6 0.5 °C [61 °F] throughout a range of 0° to 50 °C

chemical burns to skin and tissue upon prolonged exposure. 2) [30°° to 120 °F]. The design of the temp

[30 tempera

eratur

turee mea

measur

suring

ing

device shall be such that it allows 75 mm [3 in.] or more

2. Referenc

Referenced

ed Documents

Documents immersion during operation.

2.1 ASTM Standards:3

4.3 Partial

Partial imm

immers

ersion

ion liq

liquid

uid-in

-in-gl

-glass

ass the

thermo

rmomete

meters

rs (an

(andd

C172 Practice

C172 Practice for Sampling Freshly Mixed Concrete

possibly other types) shall have a permanent mark to which the

C670 Practice

C670 Practice for Preparing Precision and Bias Statements

device must be immersed without applying a correction factor.

for Test Methods for Construction Materials

4.4 Refer

Reference

ence Tempera

emperatur

turee Measu ring Device, shall

Measuring shall be

3. Sign

Significan

ificance

ce and Use readable and accurate to 6 0.2 °C [0.5 °F] at the verification

3.1 Thi

Thiss tes

testt meth

method

od pro

provid

vides

es a mea

means

ns for measurin

measuring

g the in 5.1

points in 5.1.. A certificate or report that verifies the accuracy

temperature of freshly mixed concrete. The measured tempera- shall

sha ll be ava

availab

ilable

le in the lab

labora

orator

tory

y for review.

review. Acc

Accura

uracy

cy of

liquid-in-glass reference temperature measuring devices shall

be verified once. Verification of direct-reading resistance ref-

1

Thiss tes

Thi testt met

method

hod is und

under

er the jur

jurisd

isdict

iction

ion of ASTM Com

Commit

mittee

tee C09 on erence

ere nce temp

tempera eratur

turee meas

measuri

uring

ng devdevices

ices sha

shall

ll be per

perfor

formed

med

Concrete and Concrete Aggregatesand is the direct responsibility of Subcommittee

C09.60 on Testing Fresh Concrete.

C09.60 every

eve ry twe

twelve

lve mon

months

ths.. The cert

certifica

ificate

te or rep

report

ort sha

shall

ll pro

provid

videe

Current

Curre nt editio

edition

n appro

approved

ved Dec. 1, 2012. Published

Published Janua

January

ry 2013. Originally

Originally documentation that the reference standard used in the verifi-

approved

approv ed in 1986. Last previous edition approved

approved in 2011 as C1064–11.

C1064–11. DOI: cation is traceable to the National Institute of Standards and

10.1520/C1064_C1064M-12.

2

Section

Secti on on Safe

Safety

ty Preca

Precautions

utions,, Manua

Manuall of Aggregate and Concr

Concrete

ete Testing,

Testing, Technology (NIST).

Annual Book of ASTM Standards, Vol 04.02.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Available from American Concrete Institute (ACI), P.O. Box 9094, Farmington

the ASTM website. Hills, MI 48333-9094, http://www.concrete.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright ASTM International

Provided by IHS under license with ASTM

1

No reproduction or networking permitted without license from IHS Not for Resale

C1064/C1064M − 12

5. Verification of the Accuracy of Temperatur

emperaturee 6.2.3 Place the freshly mixed concrete into the container.

container.

Measuring Devices

7. Pro

Procedu

cedure

re

5.1 The accu

accuracy

racy of each temp

tempera

eratur

turee mea

measur

suring

ing dev

device

ice

used for determining the temperature of freshly mixed concrete 7.1 Positio

Positionn the temper

temperature

ature measuring

measuring device so that the

shall be verified annually, or whenever there is a question of end of the temperature sensing portion is submerged a mini-

accuracy

accurac y. Verify the accura

accuracy

cy of the temper

temperature

ature measuring mum of 75 mm [3 in.] into the freshly mixed concrete. Close

device by comparing the readings of the reference temperature the void left by the placement by gently pressing the concrete

measuring device to the temperature measuring device at two around the temperature measuring device at the surface of the

temperatures at least 15 °C [30 °F] apart. concrete

concrete to prevent ambient air temper

temperature

ature from affecting

affecting the

5.2 Verifica

erification

tion of the accuracy of the temper

temperature

ature measur-

measur- reading.

ing devices may be made in oil or other suitable bath liquids 7.2 Leave the temperature

temperature measuring device in the fresh

freshly

ly

having uniform density if provision is made to: mixed concrete

concrete for at least 2 min but not more than 5 min, then

5.2.1 Maintai

Maintainn the bath temperature

temperature constant

constant within 0.2 °C read and record the temperature to the nearest 0.5 °C [1 °F]. Do

[0.5 °F] during the verification process. not remove

remove the device from the con concre

crete

te whe

whenn rea

readin

dingg the

5.2.2

5.2 .2 Con

Contin

tinuou

uously

sly cir

circula

culate

te the bat

bath

h liqu

liquid

id to pro

provid

videe a temperature.

uniform temperature throughout the bath.

8. Repor

Reportt

5.2.3 Suspen

Suspend d the temperature measuring

measuring devices

devices in such a

manner that the devices are not contacting the sides or bottom 8.1 Report the measured temperature

temperature of the fresh

freshly

ly mixed

of the bath container during verification. concrete to the nearest 0.5 °C [1 °F].

5.3 Place both the temper

temperature

ature and reference temperature

temperature 9. Pre

Precisi

cision

on and Bias

measuring devices in the bath for at least 5 min before reading

9.1 The data used to develop the precision

precision statement were

temperatures at the test points specified in

in 5.1

5.1..

obtained using the inch-pound version of this test method. The

5.4 Prior to reading the temperature

temperature measuring devices,

devices, if precisi

precision

on ind

indices

ices shown in SI uni

units

ts are con

conver

versio

sions

ns of the

the temperatur

temperaturee in the bath has been red

reduce

uced,

d, slig

slightl

htly

y tap values in brackets.

thermometers

thermo meters containing

containing liquid to avoid adhesion

adhesion of the liquid

9.2 The single operator standard

standard deviation for measurement

measurement

to the glass.

of concrete temperature has been found to be 0.3 °C [0.5 °F]. 5

5.5 Read and record the temperature

temperature of both the refer

reference

ence Therefore, results of two properly conducted tests by the same

temperature measuring device and the temperature measuring operator on the same sample of material should not differ by

device. Reject the temperature measuring device if the differ- more than 0.7 °C [1.3 °F]. 5

ence in readings exceeds 0.5 °C [1 °F] at either test point. If the

9.3 The multi-operator

multi-operator standard

standard deviation for the measure-

indicat

ind icator

or of the rej

rejecte

ected

d temp

temperat

erature

ure mea

measur

suring

ing dev

device

ice is

ment of concrete temperature on the same sample has been

adjustab

adju stable,

le, rev

reveri

erificat

fication

ion is per

permitt

mitted

ed aft

after

er adj

adjust

ustmen

ment.t. In

found to be 0.4 °C [0.7 °F]. 5 Therefore, two tests properly

addition to the temperature readings, record the identification

conduc

conducted

ted by dif

differ

ferent

ent ope

operat

rators

ors but on the sam

samee mate

materia

riall

numbers of both devices used, the date verified, and the name

should not differ by more than 1.1 °C [1.9 °F]. 5

of individual performing the verification.

9.4 The precision

precision values given were derived

derived from an inter-

6. Samp

Sampling

ling Concrete

Concrete

laboratory study using 11 operators on two concrete batches at

6.1 It is acce

acceptab

ptable

le to meas

measure

ure the tem

temper

peratu

ature

re of fre

freshl

shly

y around 24 °C [75 °F]. 6

mixed con

mixed concre

crete

te in eith

either

er the tran

transpo

sportin

rting

g equ

equipm

ipment

ent or the 9.5 Sin

Since

ce there is no accepted

accepted referenc

referencee mate

material

rial suitable

suitable

-

-

-

`

forms after discharge provided the sensor of the temperature

,

,

`

for determining the bias of this test method, no statement on ,

`

,

,

measuring device has at least 75 mm [3 in.] of concrete cover `

,

bias is being made.

,

`

-

`

in all directions. -

`

`

`

`

,

,

10. Keyw

Keywords

ords

,

,

6.2 If the transporting

transporting equipment or placement forms are not

not `

`

`

,

,

`

used as the container, a sample shall be prepared as follows: 10.1 freshly mixed concrete; temperature; temperature mea-

-

-

6.2.1

6.2.1 Immediate

Immediatelyly,, pri

prior

or to sam

samplin

pling

g the fre

freshl

shly

y mix

mixed

ed suring device

concrete, dampen (with water) the sample container.

6.2.2 Sample the freshly

freshly mixed concrete

concrete in accordance with

5

These numbers represent, respectively, the (1s) and (d2s) limits as described in

Practice C172

Practice C172,, except that composite samples are not required

Practice C670..

Practice C670

if the only purpose for obtaining the sample is to determine 6

Supporting data have been filed at ASTM International Headquarters and may

temperature. be obtained by requesting Research Report RR:C09-1028.

Copyright ASTM International

Provided by IHS under license with ASTM

2

No reproduction or networking permitted without license from IHS Not for Resale

C1064/C1064M − 12

SUMMARY OF CHANGES

Committ

Com mittee

ee C09 has identified

identified the location

location of sele

selected

cted changes

changes to thi

thiss spe

specific

cificatio

ation

n sin

since

ce the las

lastt issu

issue,

e,

C1064/C1064M–11, that may impact the use of this specification. (Approved December 1, 2012)

(1) Ad

Adde

ded

d ne

new

w 9.1 to ind

indicat

icatee tha

thatt pre

precisi

cision

on valu

values

es wer

weree

obtained using the inch-pound version of the test method and

renumbered subsequent subsections.

Committ

Com mittee

ee C09 has identified

identified the location

location of sele

selected

cted changes

changes to thi

thiss spe

specific

cificatio

ation

n sin

since

ce the las

lastt issu

issue,

e,

C1064/C1064M–08, that may impact the use of this specification. (Approved December 1, 2011)

(1) Revised

Revised 1.2

1.2 to co

conf

nfo

orm to th

thee AS

ASTM

TM Fo

Form

rm an

and

d St

Sty

yle

le.. (2) Revised Section 5

Section 5 to

to require documentation of verification,

list the tole

toleran

rance

ce for rej

rejecti

ecting

ng the

thermo

rmomete

meters,

rs, clar

clarify

ify the re-

quirements for a liquid bath, and change the term used from

“calibration”

“calibration” to “verifi

“verification.

cation.””

ASTM International

International takes no positi

position

on respecting the validi

validity

ty of any patent rights assert

asserted

ed in connec

connection

tion with any item mentio

mentioned

ned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible

respon sible technical

technical committee, which you may attend. If you feel that your comments have not receiv

received

ed a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address

address or at 610-

610-832-

832-9585

9585 (pho

(phone),

ne), 610-

610-832-

832-9555

9555 (fax

(fax),

), or serv

service@

ice@astm

astm.org

.org (e-m

(e-mail)

ail);; or thro

through

ugh the ASTM webs

website

ite

(www.astm.

(www .astm.org).

org). Permission

Permission rights to photocopy the standa

standard

rd may also be secure

secured

d from the ASTM website (www.astm.or

(www.astm.org/

g/

COPYRIGHT/).

-

-

-

`

,

,

`

,

`

,

,

`

,

,

`

-

`

-

`

`

`

`

,

,

,

,

`

`

`

,

,

`

-

-

Copyright ASTM International

Provided by IHS under license with ASTM

3

No reproduction or networking permitted without license from IHS Not for Resale

You might also like

- Aws c2.25 2002 Thermal Spray Feedstock PDFDocument27 pagesAws c2.25 2002 Thermal Spray Feedstock PDFneyzaNo ratings yet

- ASHRAE Procedures For Commercial Building Energy AuditsDocument140 pagesASHRAE Procedures For Commercial Building Energy Auditsm_immaculate67% (3)

- Equipotential MappingDocument6 pagesEquipotential MappingSaritech100% (4)

- Jis B 1196Document19 pagesJis B 1196indeceNo ratings yet

- Aws B2.1-001 PDFDocument10 pagesAws B2.1-001 PDFAli SASSINo ratings yet

- Ansi z5354pdfDocument52 pagesAnsi z5354pdfBaraa AtwanNo ratings yet

- AGMA6011 I03 Specification For High Speed Helical Gear UnitsDocument59 pagesAGMA6011 I03 Specification For High Speed Helical Gear UnitsSusmita SivasankaranNo ratings yet

- PDF Iso Iec 27001 2022Document26 pagesPDF Iso Iec 27001 2022Kî Fëh84% (74)

- Houlding Ptolemy Terms (Rus)Document44 pagesHoulding Ptolemy Terms (Rus)Геннадий ЗениковNo ratings yet

- Acceleration and Vibration SensorDocument28 pagesAcceleration and Vibration Sensoramirul lexNo ratings yet

- Iso 7919 1 Mechanical Vibration Standard Measurements On Rotating PartspdfDocument24 pagesIso 7919 1 Mechanical Vibration Standard Measurements On Rotating PartspdfspeNo ratings yet

- Experiment 1Document4 pagesExperiment 1Kim Joy CoronelNo ratings yet

- Common Core First Grade 4 Today: Daily Skill PracticeFrom EverandCommon Core First Grade 4 Today: Daily Skill PracticeNo ratings yet

- CFM56Document378 pagesCFM56yasanuNo ratings yet

- PDF Asme PTC 18 2011 Hydraulic Turbines and Pump Turbines Performance Test Codes - CompressDocument39 pagesPDF Asme PTC 18 2011 Hydraulic Turbines and Pump Turbines Performance Test Codes - CompressZuli HarismanNo ratings yet

- Din 1946 4Document68 pagesDin 1946 4trifiloNo ratings yet

- 0415621488Document166 pages0415621488aliouecheNo ratings yet

- Managerial Economics, Allen, Test Bank, CH 7Document10 pagesManagerial Economics, Allen, Test Bank, CH 7SBNo ratings yet

- Literaturhinweise Literaturhinweise: E DIN EN 61703:2013-11 E DIN EN 61703:2013-11Document57 pagesLiteraturhinweise Literaturhinweise: E DIN EN 61703:2013-11 E DIN EN 61703:2013-11Arian NjNo ratings yet

- Controller Tuning and Control Loop PerformanceDocument92 pagesController Tuning and Control Loop PerformanceLuis100% (2)

- ASME B30.04-2015 IngDocument46 pagesASME B30.04-2015 IngEmmanuel NahasNo ratings yet

- 4 - Frequency Response AnalysisDocument30 pages4 - Frequency Response Analysisahmed4665No ratings yet

- Iec 60229pdfDocument7 pagesIec 60229pdfPKSNo ratings yet

- Aspen PlusDocument214 pagesAspen PlusCatherine LiNo ratings yet

- ASTM C 642 90 (Adsoprsi)Document3 pagesASTM C 642 90 (Adsoprsi)Rahmat KurniawanNo ratings yet

- Astm D 1298-12b SG HidrometerDocument8 pagesAstm D 1298-12b SG HidrometerYunizar PutriNo ratings yet

- Chapter 5 Honors Notes PDFDocument13 pagesChapter 5 Honors Notes PDFBobNo ratings yet

- AASHTO T 191-02 - Density of Soil in Place by The Sand Cone MethodDocument6 pagesAASHTO T 191-02 - Density of Soil in Place by The Sand Cone MethodBambang DwihargonoNo ratings yet

- DIN 1946 - 4 - December - 2008Document68 pagesDIN 1946 - 4 - December - 2008Yakdhan YaseenNo ratings yet

- Astm e 1417pdfDocument12 pagesAstm e 1417pdfShabbir aliNo ratings yet

- Telangana State Public Service Commission: Prathibha Bhavan, M.J.Road, Nampally, HyderabadDocument1 pageTelangana State Public Service Commission: Prathibha Bhavan, M.J.Road, Nampally, HyderabadMartha Shashank VarmaNo ratings yet

- Pages From Dorman Longs - Handbook For Constructional Engineers - 1895-42Document1 pagePages From Dorman Longs - Handbook For Constructional Engineers - 1895-42Fornvald TamasNo ratings yet

- en 12668 1 2010pdfDocument48 pagesen 12668 1 2010pdfYang YangNo ratings yet

- PDF Psicologia en El Futbol Videos Motivacionales - CompressDocument21 pagesPDF Psicologia en El Futbol Videos Motivacionales - CompressEduardo RojasNo ratings yet

- PDF Psicologia en El Futbol Videos Motivacionales CompressDocument21 pagesPDF Psicologia en El Futbol Videos Motivacionales CompressEduardo RojasNo ratings yet

- Asme b1648 2010 Line BlanksDocument56 pagesAsme b1648 2010 Line BlanksDaryna KupriianovaNo ratings yet

- Acrylonitrile-Acrylonitrile - Butadiene-Styrene Butadiene-Styrene (ABS) Pressure Pipe - (ABS) Pressure PipeDocument14 pagesAcrylonitrile-Acrylonitrile - Butadiene-Styrene Butadiene-Styrene (ABS) Pressure Pipe - (ABS) Pressure Pipenoodlehead675No ratings yet

- Pages From Dorman Longs - Handbook For Constructional Engineers - 1895-36Document1 pagePages From Dorman Longs - Handbook For Constructional Engineers - 1895-36Fornvald TamasNo ratings yet

- en 12680 32011ok PDFDocument6 pagesen 12680 32011ok PDFUtkarsh GautamNo ratings yet

- PDF Aa Adm 2015 Aluminium Desig Manual CompressDocument20 pagesPDF Aa Adm 2015 Aluminium Desig Manual Compressmehdi mouhibNo ratings yet

- Bsen 1008812014Document40 pagesBsen 1008812014Bayu ShafarNo ratings yet

- BS 7562 5 IrrigationDocument32 pagesBS 7562 5 IrrigationSana UllahNo ratings yet

- ISO 27001.2022 Info Security MGMT Systems - RequirementsDocument26 pagesISO 27001.2022 Info Security MGMT Systems - RequirementsmariyanaNo ratings yet

- Cartesian Coordinate SystemDocument2 pagesCartesian Coordinate SystemSabria SantosNo ratings yet

- Proforma For Self Certification by The Government Employee For LTC Bilingual 20211202125357Document2 pagesProforma For Self Certification by The Government Employee For LTC Bilingual 20211202125357hanipay tinamisanNo ratings yet

- International International Standard Standard: ISO ISO 6506-1 6506-1Document1 pageInternational International Standard Standard: ISO ISO 6506-1 6506-1CarlosNo ratings yet

- SINDICATODocument1 pageSINDICATORuddy CamachoNo ratings yet

- Cobotta eDocument6 pagesCobotta eThắng HoàngNo ratings yet

- AWWA 121-12 W-Add 2014 GRP BOLTED Water Storage TanksDocument89 pagesAWWA 121-12 W-Add 2014 GRP BOLTED Water Storage TanksGabriel Natal GonzálezNo ratings yet

- Ne'Trc:On Tents : GallonsDocument1 pageNe'Trc:On Tents : GallonsfcordNo ratings yet

- Aniruddha CharitraDocument81 pagesAniruddha CharitraNaren G SuryaNo ratings yet

- Astm-A 530Document8 pagesAstm-A 530ganapathymuruganantham24No ratings yet

- საერთაშორისო ორგანიზაციებიDocument14 pagesსაერთაშორისო ორგანიზაციებიnatiaNo ratings yet

- Dawning of The DayDocument1 pageDawning of The DayDiego CalvoNo ratings yet

- Duswasn Bindu o AmalkumarDocument6 pagesDuswasn Bindu o AmalkumargoluputiNo ratings yet

- பனித்துளிகள்Document7 pagesபனித்துளிகள்Praveen Dasan DNo ratings yet

- PDF Cti Atc 105 Acceptance Test Code For Water Cooling Towers Supplement - CompressDocument22 pagesPDF Cti Atc 105 Acceptance Test Code For Water Cooling Towers Supplement - CompressMas BagusNo ratings yet

- Jis B 1196 2010 Dimention Standard Weld NutDocument19 pagesJis B 1196 2010 Dimention Standard Weld Nutjunes pujiNo ratings yet

- 450-Article Text-724-1-10-20210203Document8 pages450-Article Text-724-1-10-20210203maksim.verpaNo ratings yet

- Wireless World 1990 11Document100 pagesWireless World 1990 11Milton NastNo ratings yet

- Physics TestDocument3 pagesPhysics TesthappytohelpNo ratings yet

- Press Brake FBD Series Parts ListDocument146 pagesPress Brake FBD Series Parts Listnorin1373No ratings yet

- Supersonic,': (Turbulencei, in .. /), GAMMA-,R'AY .'.Document39 pagesSupersonic,': (Turbulencei, in .. /), GAMMA-,R'AY .'.janiklp1337No ratings yet

- Ebook PDF Understanding Learning and Learners Custom Edition 2e PDFDocument41 pagesEbook PDF Understanding Learning and Learners Custom Edition 2e PDFferne.bass217100% (35)

- Termohigrometro 2017 ULTIMO PDFDocument1 pageTermohigrometro 2017 ULTIMO PDFChirley Jazmin Bayona BautistaNo ratings yet

- Termohigrometro 2017 ULTIMODocument1 pageTermohigrometro 2017 ULTIMOChirley Jazmin Bayona BautistaNo ratings yet

- BS 8110 Design and DetailedDocument31 pagesBS 8110 Design and DetailedChikumbuso LunguNo ratings yet

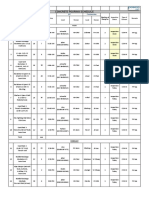

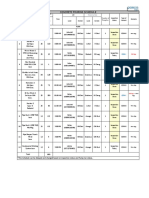

- Daily Concrete Pouring Schedule (02-08-22)Document2 pagesDaily Concrete Pouring Schedule (02-08-22)Hasan al MahmudNo ratings yet

- Daily Concrete Pouring Schedule (07!08!22)Document2 pagesDaily Concrete Pouring Schedule (07!08!22)Hasan al MahmudNo ratings yet

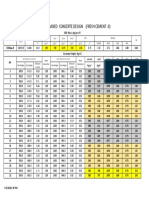

- Combined Gradation of Coarse Aggregate - Astm C33-Size 67-1Document106 pagesCombined Gradation of Coarse Aggregate - Astm C33-Size 67-1Hasan al MahmudNo ratings yet

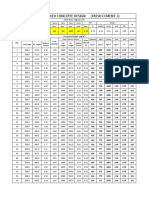

- Grade/Class Production Day Age Date of TestingDocument9 pagesGrade/Class Production Day Age Date of TestingHasan al MahmudNo ratings yet

- Daily Concrete Pouring Schedule (01-05-22) - 1Document1 pageDaily Concrete Pouring Schedule (01-05-22) - 1Hasan al MahmudNo ratings yet

- 25mpa Case-C Mixed Concerte Design (Fresh Cement - Ii)Document1 page25mpa Case-C Mixed Concerte Design (Fresh Cement - Ii)Hasan al MahmudNo ratings yet

- Grade/Class Project Name Requirem Ent Compressi Production Day Age Date of TestingDocument3 pagesGrade/Class Project Name Requirem Ent Compressi Production Day Age Date of TestingHasan al MahmudNo ratings yet

- Grade/Class Project Name Requirem Ent Compressi Production Day Age Date of TestingDocument3 pagesGrade/Class Project Name Requirem Ent Compressi Production Day Age Date of TestingHasan al MahmudNo ratings yet

- C30Mpa-B Mixed Concerte Design (Fresh Cement - Ii)Document1 pageC30Mpa-B Mixed Concerte Design (Fresh Cement - Ii)Hasan al MahmudNo ratings yet

- Marine Concrete UFGS 03-31-29Document67 pagesMarine Concrete UFGS 03-31-29Hasan al MahmudNo ratings yet

- C35Mpa-C Mixed Concerte Design (Fresh Cement - I)Document1 pageC35Mpa-C Mixed Concerte Design (Fresh Cement - I)Hasan al MahmudNo ratings yet

- Electrical Resistivity of Sandy Soil: Géotechnique Letters September 2015Document9 pagesElectrical Resistivity of Sandy Soil: Géotechnique Letters September 2015Hasan al MahmudNo ratings yet

- 329.1T-18 Minimum Cementitious MaterialsDocument4 pages329.1T-18 Minimum Cementitious MaterialsHasan al MahmudNo ratings yet

- ASTM (G57) and AASHTO (T 288-91) Standards: Be Necessary To Determine The Correct Multiplier". This Statement ImpliesDocument2 pagesASTM (G57) and AASHTO (T 288-91) Standards: Be Necessary To Determine The Correct Multiplier". This Statement ImpliesHasan al MahmudNo ratings yet

- PT. Fadnov Airtech Indonesia Profile.Document18 pagesPT. Fadnov Airtech Indonesia Profile.abdur rohmanNo ratings yet

- Industrial Visit PlannerDocument86 pagesIndustrial Visit PlannerAkshay K PradeepNo ratings yet

- B2 Nyelvvizsga Tételek (2305843009213904139) (2305843009213904936) (2305843009213905179)Document11 pagesB2 Nyelvvizsga Tételek (2305843009213904139) (2305843009213904936) (2305843009213905179)Anna JósvaiNo ratings yet

- LightSYS2 Brochure EN-LR PDFDocument4 pagesLightSYS2 Brochure EN-LR PDFSOPORTE TECNICONo ratings yet

- United States v. Jeffrey McCoy, 4th Cir. (2013)Document7 pagesUnited States v. Jeffrey McCoy, 4th Cir. (2013)Scribd Government DocsNo ratings yet

- 542 Performance - FREE Week - 60HYBRID I'mDocument21 pages542 Performance - FREE Week - 60HYBRID I'mankitgurung194No ratings yet

- Retail Outlet Inspection Report: A. Sales & Stock 1. Totalizer ReadingsDocument6 pagesRetail Outlet Inspection Report: A. Sales & Stock 1. Totalizer ReadingsRajneesh JhoradNo ratings yet

- 1a2. - Design Principles Ce134p-2 - EscruzDocument12 pages1a2. - Design Principles Ce134p-2 - EscruzAireesha GozeNo ratings yet

- "Scenarios For Mongolia: Building A Positive Future" GuidebookDocument13 pages"Scenarios For Mongolia: Building A Positive Future" GuidebookEconomic Policy and Competitiveness Research CenterNo ratings yet

- Physics Project: Poster Making On Safety Measures On LightiningDocument5 pagesPhysics Project: Poster Making On Safety Measures On LightiningRavichandran SekarNo ratings yet

- SJWCS-DRRM MagazineDocument6 pagesSJWCS-DRRM MagazineIrish Capili LaquiNo ratings yet

- Distribution in A Services ContextDocument45 pagesDistribution in A Services ContextKirti GiyamalaniNo ratings yet

- A Study of Technological Pedagogical Content Knowledge of Science Teachers at The Higher Secondary StageDocument8 pagesA Study of Technological Pedagogical Content Knowledge of Science Teachers at The Higher Secondary StageAnonymous CwJeBCAXpNo ratings yet

- Strategic ManagementDocument13 pagesStrategic ManagementJanice KawiraNo ratings yet

- A Review of Phytconstituents For UrolithiasisDocument5 pagesA Review of Phytconstituents For UrolithiasisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- H105RBDocument12 pagesH105RBironwilukuNo ratings yet

- Currency ConverterDocument16 pagesCurrency ConverterRohan BhadvankarNo ratings yet

- 3 Types of Muscle TissueDocument11 pages3 Types of Muscle TissueJohnMichaelFabellaRuizNo ratings yet

- Shrinky Dink MoleculaDocument42 pagesShrinky Dink Moleculaisrael43No ratings yet

- Shriya Maini Statement of Purpose Oxford University PDFDocument2 pagesShriya Maini Statement of Purpose Oxford University PDFaditya parihar100% (1)

- This Study Resource Was: InstructionsDocument3 pagesThis Study Resource Was: InstructionsRama fauziNo ratings yet

- Music Keys and BPM Copy 4Document466 pagesMusic Keys and BPM Copy 4gabidjNo ratings yet