Professional Documents

Culture Documents

Commissioning Definition and Activities: Technical Data Base

Uploaded by

InfoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Commissioning Definition and Activities: Technical Data Base

Uploaded by

InfoCopyright:

Available Formats

COMMISSIONING DEFINITION and ACTIVITIES

COMMISSIONING SEQUENCES

COMMISSIONING PREPARATIONS

All Basic Functions, grouped by subsystem, discipline and type of Basic Function, are listed in a

Technical Data Base, which is therefore the exhaustive description of the physical content of all

Technical Data subsystems. It is the equivalent of the Status Index used for Precommissioning.

Base The Data Base indicates, for each Basic Function, the type of Commissioning operation required, by

reference to the task report form of this operation, and it also gives other relevant information (set

points, drawings No., etc.).

The Preliminary Checks are the cross verification by the Commissionning Team that is effectively "Ready for

Commissioning". They take place when a subsystem nears or reaches the Ready For Commissioning status, and

consist of:

A physical check on site of the installation.

A thorough review of the Precommissioning Dossier.

Preliminary

The Preliminary Checks are carried out by each discipline and formalised by a specific report form

Checks & In order to avoid rework or recheck (once by Precommissioning team, once by Commissioning team), the witnessing

Pre Com of the Precommissioning by the commissioning shall be carried out as a part of the Preliminary Checks (PRC)

Witnessing process.

At this stage, a number of new punch list items, discovered by the Commissioning team during their cross-checking of

the plant are incorporated in the subsystem Punch list (agreed between CONTRATOR and COMPANY).

Once Preliminary Checks have been done, the RFC certificate is countersigned by the commissioning representatives,

and the PRC sheet can be issued (signed by each discipline commissioning representative) after Pre commissioning

dossier check.

These are the live tests performed on each instrument, telecommunication, and electrical, elementary function. For

commodity, an item or group of items of equipment that performs an elementary function of the plant is named a Basic

Function. It is the smallest equipment that can be subject to a commissioning operation. the main types of Basic

Functional Functions of a plant: switchboards, process control loops, ESDV's, etc./.

Tests The functional tests are carried out in accordance with technical specifications, the results being recorded on

Functional Test Sheets.

One Test Sheet form is available for every type of functional test one form being filled in for each test performed.

Once all Basic Functions have been functionally tested, major equipment, system, subsystem or group of

subsystems, is subject to an Operational Test, wherever applicable.

It consists of bringing the system into operation under conditions as close as possible to normal with inert fluids, not

only to live test the automated devices, controls, normal and shutdown sequences, but also to reveal possible

mechanical or electrical faults (water tightness, vibrations, overheating, overloading, etc.) which may occur during

prolonged normal use. Every operational test is a multi-discipline activity, conducted in accordance with an Operational

Test Procedure (OTP), which has been established during the Commissioning preparation phase and approved by the

Operational COMPANY.

Tests Typical subsystems subject to an operational test are (but not limited to):

, power generation, ESD system, export pumps in recycle, process compressors in recycle (with air or nitrogen if

possible, under gas after Start-up if not), loop, etc.

Prior to the preparation of Operational Test Procedures the Operational Tests procedure, acceptance criteria principle

shall be defined if there is no contractual requirement (duration of test, number of cycles, etc.) and approved by

COMPANY.

The operational test is the key commissioning activity. In any case, it shall be witnessed, followed, assisted and

checked by COMPANY and shall be subject to an Operational Test Certificate.

This certificate shall state that the subsystem and/or equipment listed on the certificate have been brought into

operational condition, and that all related VENDOR equipment has been satisfactorily tested.

These are all the specific Commissioning activities required to prepare the piping network before the introduction the

gas in the Pipeline:

Leak test

Drying-out

Pre Start Up Inerting

Activities

These are covered by specific procedures and reports.

It may happen that some of these activities are not related to a single system or subsystem . A Task report may

therefore be created to report the results, which are then referred to in all concerned subsystems commissioning

dossiers.

Commissioning Dossier

First Start-Up sequence and procedure with all notes taken during the start-up for further update of

the procedure

Marked-up P&IDs showing the status for blinds and spades at time of transfer to the

OPERATOR.

Ready for Operation Certificate

Updated Punch List

Operational Test Procedure, reports, and Operational Test Certificate carried out during the

start-up phase

Routine Start-up procedures, Emergency and routine shutdown procedures

Ready For START-UP(RFSUC) M.R.KHALDI

OIL and GAS Process trainer

You might also like

- Durat Is Well Experienced in Pre-Commissioning and Commissioning Activities and Can Provide The inDocument13 pagesDurat Is Well Experienced in Pre-Commissioning and Commissioning Activities and Can Provide The inEduardo Papupita NúñezNo ratings yet

- Basics of Equipment Qualification - 2Document4 pagesBasics of Equipment Qualification - 2RainMan75No ratings yet

- Basics of Equipment Qualification - Pharma Pathway PDFDocument6 pagesBasics of Equipment Qualification - Pharma Pathway PDFJ VENKATESHNo ratings yet

- Basics of Equipment Qualification - Pharma PathwayDocument7 pagesBasics of Equipment Qualification - Pharma PathwayMSL India100% (1)

- SPD0054ERN - 2 HEMP Procedure Att.6.6Document4 pagesSPD0054ERN - 2 HEMP Procedure Att.6.6chuntao fengNo ratings yet

- Testing and Commissioning Plan TemplateDocument68 pagesTesting and Commissioning Plan Templatemd_rehan_2100% (19)

- Competency Code ELE IAC5 07 0511: Initial Verification ProceduresDocument15 pagesCompetency Code ELE IAC5 07 0511: Initial Verification Proceduresfrezer mesfinNo ratings yet

- Pre CommDocument1 pagePre CommInfoNo ratings yet

- 5.3.2 Test ProcedureDocument6 pages5.3.2 Test ProcedureRija MobinNo ratings yet

- CommissioningStartUp PDFDocument22 pagesCommissioningStartUp PDFM.Jamil SyahputraNo ratings yet

- 欧盟:计算机化系统的验证 核心文件 (中英文) PDFDocument11 pages欧盟:计算机化系统的验证 核心文件 (中英文) PDFJasonNo ratings yet

- Test Protocols and Test Plans: Need Validation Help?Document6 pagesTest Protocols and Test Plans: Need Validation Help?NandgulabDeshmukhNo ratings yet

- Commissioning and Start-Up: EM 1110-1-4001 3 Jun 02Document24 pagesCommissioning and Start-Up: EM 1110-1-4001 3 Jun 02Reda ElgohariNo ratings yet

- The Role of OpercomDocument7 pagesThe Role of OpercomAnonymous 3Y5SgP7100% (5)

- Qualification - Validation CPOB 2018 PDFDocument145 pagesQualification - Validation CPOB 2018 PDFmela milaniNo ratings yet

- Installation QualificationDocument14 pagesInstallation QualificationTuan Nguyen100% (1)

- Building Management System (BMS) - Validation OverviewDocument6 pagesBuilding Management System (BMS) - Validation OverviewlastrajNo ratings yet

- Commissioning PlanDocument25 pagesCommissioning Plananjum128100% (2)

- Renewed Performance Qualification After Replacing Device ComponentsDocument8 pagesRenewed Performance Qualification After Replacing Device ComponentsМаксим ШульгаNo ratings yet

- The Commissioning Approach 2012 Chemical and Process Plant Commissioning HandbookDocument3 pagesThe Commissioning Approach 2012 Chemical and Process Plant Commissioning Handbookgimmyhead_69No ratings yet

- Schletter-Brochure-Service Ground Mounted SystemsDocument3 pagesSchletter-Brochure-Service Ground Mounted Systemsf789sgacanonNo ratings yet

- Val 045Document7 pagesVal 045drs_mdu48No ratings yet

- Steering Gear Control System: Standard For CertificationDocument7 pagesSteering Gear Control System: Standard For CertificationsimonNo ratings yet

- Commissioning Documents For Instrumentation EngineersDocument7 pagesCommissioning Documents For Instrumentation EngineersVraja Kisori100% (1)

- BMS ValidationDocument4 pagesBMS Validationk.p.No ratings yet

- QP-ENG-PRC-008 - QP Procedure For Site Acceptance Test - Rev 00Document13 pagesQP-ENG-PRC-008 - QP Procedure For Site Acceptance Test - Rev 00salem elhajNo ratings yet

- Commissioning NotesDocument17 pagesCommissioning NotesAhmed Elhady100% (1)

- Factory Acceptance Test Procedure For DCS - Page 1Document2 pagesFactory Acceptance Test Procedure For DCS - Page 1kapsarcNo ratings yet

- Manual Servicio - Controler - SM - Yke - Yke-N - FRX - LVX - Uxc - Uxc - N PDFDocument186 pagesManual Servicio - Controler - SM - Yke - Yke-N - FRX - LVX - Uxc - Uxc - N PDFData PrintNo ratings yet

- Loop Check PresentationDocument39 pagesLoop Check Presentationsaqib javaid100% (5)

- Service General Specification: Applicable SystemsDocument2 pagesService General Specification: Applicable SystemsRizky MuhammadNo ratings yet

- Pharm Validation - Fat & Sat - JSK NagarajanDocument31 pagesPharm Validation - Fat & Sat - JSK Nagarajannagasaki2001100% (1)

- Revalidation SOPDocument12 pagesRevalidation SOPIlayaraja Boopathy100% (2)

- Steam Turbine Maintenance Inspections or Repairs: Turbine Restart After MajorDocument3 pagesSteam Turbine Maintenance Inspections or Repairs: Turbine Restart After Majordreamboy87No ratings yet

- Acceptance Testing - ELT - 201!2!2Document6 pagesAcceptance Testing - ELT - 201!2!2castrojpNo ratings yet

- Mss-15 Fahu Controls LemDocument17 pagesMss-15 Fahu Controls LemsamNo ratings yet

- Commissioning Procedure of Northern Gas Compression FacilitiesDocument18 pagesCommissioning Procedure of Northern Gas Compression FacilitiesMohamed Sayed Abdo100% (3)

- Factory Acceptance TestDocument8 pagesFactory Acceptance Testpsn_kylm100% (2)

- Quality Control & Tests Plan: BAZ-KSA-QAC-034Document12 pagesQuality Control & Tests Plan: BAZ-KSA-QAC-034Raghad GNo ratings yet

- Why Is Testing ImportantDocument5 pagesWhy Is Testing ImportantmoosixNo ratings yet

- RAC System Test Plan Outline 11gr2 v2 4Document39 pagesRAC System Test Plan Outline 11gr2 v2 4xwNo ratings yet

- Schneider Startup Test ProcedureDocument45 pagesSchneider Startup Test ProcedureJonathan Feruelo100% (1)

- Calibration and Validation of HPLC, GC and UV-VIS SpectrosDocument8 pagesCalibration and Validation of HPLC, GC and UV-VIS SpectrosDrAtiq Ur-RahmanNo ratings yet

- System Testing TemplateDocument12 pagesSystem Testing TemplateSE ProjectNo ratings yet

- Commissioning Start UpDocument22 pagesCommissioning Start Upmostafa_1000No ratings yet

- Guide 15997Document29 pagesGuide 15997djukalNo ratings yet

- Equipment QualificationDocument64 pagesEquipment QualificationbuuNo ratings yet

- Electrical Equipments Testing ProceduresDocument45 pagesElectrical Equipments Testing ProceduresMohamed Salah100% (3)

- Testing Direct Digital Controls (DDC)Document11 pagesTesting Direct Digital Controls (DDC)efasaravananNo ratings yet

- SP HseDocument157 pagesSP HseDie HArdNo ratings yet

- Semi-Markov Models: Control of Restorable Systems with Latent FailuresFrom EverandSemi-Markov Models: Control of Restorable Systems with Latent FailuresNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- LP Flare System: M.R.K Spie Oil & Gas ServicesDocument1 pageLP Flare System: M.R.K Spie Oil & Gas ServicesInfoNo ratings yet

- Check List Pre-StartupDocument3 pagesCheck List Pre-StartupInfoNo ratings yet

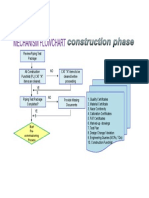

- Constuction PhaseDocument1 pageConstuction PhaseInfoNo ratings yet

- Commissioning HandbookDocument8 pagesCommissioning HandbookPanji Mulyana Martha100% (1)

- COMMISSIONING2Document1 pageCOMMISSIONING2InfoNo ratings yet

- Presentation Transition From Construction To CommissioningDocument47 pagesPresentation Transition From Construction To CommissioningInfoNo ratings yet

- Presentation Transition From Construction To CommissioningDocument47 pagesPresentation Transition From Construction To CommissioningInfoNo ratings yet

- An Overview of The Pre-Commissioning and Commissioning Plan: Prepared By: Mohamed Ridha KHALDIDocument16 pagesAn Overview of The Pre-Commissioning and Commissioning Plan: Prepared By: Mohamed Ridha KHALDIInfoNo ratings yet

- Plants Commissioning in One Page: Pre Commissioning Activities SummaryDocument1 pagePlants Commissioning in One Page: Pre Commissioning Activities SummaryInfoNo ratings yet

- MODEL OF Commissioning Procedures ListDocument1 pageMODEL OF Commissioning Procedures ListInfoNo ratings yet

- Clean Agent Calculation - V2Document3 pagesClean Agent Calculation - V2InfoNo ratings yet

- Clean Agent Calculation - V2Document3 pagesClean Agent Calculation - V2InfoNo ratings yet

- CO2 CalculDocument3 pagesCO2 CalculInfoNo ratings yet

- Clean Agent Calculation-Novec 1230Document4 pagesClean Agent Calculation-Novec 1230InfoNo ratings yet

- ISSA2013Ed CabinStores v100 Часть10Document2 pagesISSA2013Ed CabinStores v100 Часть10AlexanderNo ratings yet

- 6 - European Cluster Partnership For Excellence - European Cluster Collaboration PlatformDocument5 pages6 - European Cluster Partnership For Excellence - European Cluster Collaboration PlatformDaniela DurducNo ratings yet

- Family Factors: Its Effect On The Academic Performance of The Grade 6 Pupils of East Bayugan Central Elementary SchoolDocument11 pagesFamily Factors: Its Effect On The Academic Performance of The Grade 6 Pupils of East Bayugan Central Elementary SchoolGrace Joy AsorNo ratings yet

- MikoritkDocument6 pagesMikoritkChris Jonathan Showip RouteNo ratings yet

- Chemistry II EM Basic Learning MaterialDocument40 pagesChemistry II EM Basic Learning MaterialMAHINDRA BALLANo ratings yet

- Microbiological Quality Ice CreamDocument9 pagesMicrobiological Quality Ice CreamocortezlariosNo ratings yet

- Thompson, Damon - Create A Servitor - How To Create A Servitor and Use The Power of Thought FormsDocument49 pagesThompson, Damon - Create A Servitor - How To Create A Servitor and Use The Power of Thought FormsMike Cedersköld100% (5)

- Preblending of Raw Materia1Document26 pagesPreblending of Raw Materia1Mohammed Abdo100% (1)

- Pepperberg Notes On The Learning ApproachDocument3 pagesPepperberg Notes On The Learning ApproachCristina GherardiNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- Necromunda CatalogDocument35 pagesNecromunda Catalogzafnequin8494100% (1)

- Science Grade 10 (Exam Prep)Document6 pagesScience Grade 10 (Exam Prep)Venice Solver100% (3)

- PRINCIPLES OF TEACHING NotesDocument24 pagesPRINCIPLES OF TEACHING NotesHOLLY MARIE PALANGAN100% (2)

- NCPDocument6 pagesNCPJoni Lyn Ba-as BayengNo ratings yet

- Jar Doc 06 Jjarus Sora Executive SummaryDocument3 pagesJar Doc 06 Jjarus Sora Executive Summaryprasenjitdey786No ratings yet

- Jordan CVDocument2 pagesJordan CVJordan Ryan SomnerNo ratings yet

- RADMASTE CAPS Grade 11 Chemistry Learner GuideDocument66 pagesRADMASTE CAPS Grade 11 Chemistry Learner Guideamajobe34No ratings yet

- Java Edition Data Values - Official Minecraft WikiDocument140 pagesJava Edition Data Values - Official Minecraft WikiCristian Rene SuárezNo ratings yet

- NHL DB Rulebook ENGLISHDocument6 pagesNHL DB Rulebook ENGLISHAdhika WidyaparagaNo ratings yet

- Hatayoga 1Document11 pagesHatayoga 1SACHIDANANDA SNo ratings yet

- Heat Pyqs NsejsDocument3 pagesHeat Pyqs NsejsPocketMonTuberNo ratings yet

- OnTime Courier Software System Requirements PDFDocument1 pageOnTime Courier Software System Requirements PDFbilalNo ratings yet

- Star Wars Galactic Connexionstm Galactic Beckett Star Wars Story Connexions CallingDocument4 pagesStar Wars Galactic Connexionstm Galactic Beckett Star Wars Story Connexions CallingJuan TorresNo ratings yet

- Steve JobsDocument18 pagesSteve JobsVibhor AggarwalNo ratings yet

- School Clinic Action PlanDocument2 pagesSchool Clinic Action PlanAlera Kim100% (7)

- Context in TranslationDocument23 pagesContext in TranslationRaluca FloreaNo ratings yet

- Nuttall Gear CatalogDocument275 pagesNuttall Gear Catalogjose huertasNo ratings yet

- SQLDocument13 pagesSQLRadhakrishnan__7263No ratings yet

- Offshore Training Matriz Matriz de Treinamentos OffshoreDocument2 pagesOffshore Training Matriz Matriz de Treinamentos OffshorecamiladiasmanoelNo ratings yet

- MBA-7002-20169108-68 MarksDocument17 pagesMBA-7002-20169108-68 MarksN GNo ratings yet