Professional Documents

Culture Documents

Polishing Procedure For Pipes

Uploaded by

ReduddboyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polishing Procedure For Pipes

Uploaded by

ReduddboyCopyright:

Available Formats

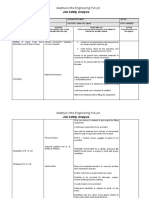

Polishing Procedure for Pipes

1. General Description

1.1 The dimension of pipes for polishing shall be 8B SCH.80 (O.D219.1 x 12.7t) with the material

SA312-TP 304.

1.2 The inside surface of straight pipe shall be polished to 400#

1.3 The inside surface of bend pipe shall be polished to 600# before bending.

2. Inspect prior to polish

Inspect the surface of pipe, it shall be free of mottling, rut and other defects.

3. Polishing tools

3.1 Polishing wheel, used for rough polish and finishing polishing, is made of cotton cloth, soft cloth,

canvas and some grinding material

3.2 Grinding material shall be aluminium oxide, chrome oxide and shall be iron-free.

4. Polishing procedure

4.1 Polishing procedure (Straight pipe)

4.1.1 Rough polish and the inside surface of pipe shall be cleaned of oxide.

4.1.2 Semi-finishing polish and inside surface of pipe shall be polished to 180#

4.1.3 Finishing polish and inside surface of pipe shall be polished to 320#

4.1.4 Lustering with glazer and inside surface of pipe shall be polished to 400#

4.2 For bend pipe, the procedure is the same as straight pipe before lustering. Prior to lustering, the

inside surface of pipe shall be polished to 600# by MES

5. Inspect the polishing roughness

After polishing, the inspector check whether the rough satisfy the requirements of drawing by

rough measuring apparatus(model: Surtronic 10), and compare with the polishing sample. It shall

be re-polished for sub-quality parts.

Three ample pieces shall be submitted for approval and one piece will be returned to the Vendor after

approval or review with comments. Sample piece size: 100mm x 100mm x 3mm thick.

You might also like

- 1 New Job Pack Slot CleanerDocument10 pages1 New Job Pack Slot Cleaneryandere dollie100% (1)

- Job Safety Analysis (Jsa)Document9 pagesJob Safety Analysis (Jsa)MohdHuzairiRusliNo ratings yet

- Work Procedure of Reverse Osmosis Plant: FN/WI/MT/004/R00 Authorized By: Asst. Manager MechanicalDocument1 pageWork Procedure of Reverse Osmosis Plant: FN/WI/MT/004/R00 Authorized By: Asst. Manager MechanicalFahad SarwarNo ratings yet

- !drilling Machine Geared Head InstructionDocument5 pages!drilling Machine Geared Head InstructionTiago PaivaNo ratings yet

- OCP Confined Space ShahiDocument4 pagesOCP Confined Space ShahiVishal SrivastavaNo ratings yet

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationVishnu VijayanNo ratings yet

- Window CleaningDocument1 pageWindow CleaningSanthoshKumarNo ratings yet

- Electric Arc Weldin SafetyDocument5 pagesElectric Arc Weldin SafetynickurfriendNo ratings yet

- The University of Faisalabad: Commercial Electrical Inspection Checklists (2008 Nec)Document1 pageThe University of Faisalabad: Commercial Electrical Inspection Checklists (2008 Nec)Rao UmarNo ratings yet

- Welding, Cutting and Hot WorkDocument6 pagesWelding, Cutting and Hot WorkyahiyaNo ratings yet

- Emal Contractor Red BookDocument75 pagesEmal Contractor Red BookVenkadesh PeriathambiNo ratings yet

- Tool Box Talk Form: Date - Location - SupervisorDocument2 pagesTool Box Talk Form: Date - Location - SupervisorNeeraj SinghNo ratings yet

- Luxathane 5160Document2 pagesLuxathane 5160shameelNo ratings yet

- Biomass Boiler Risk Assessment NPDocument7 pagesBiomass Boiler Risk Assessment NPknabpshoNo ratings yet

- Bench Cutting MachineDocument2 pagesBench Cutting MachinemurthyNo ratings yet

- Pipe Color Code PDFDocument1 pagePipe Color Code PDFAllen EspeletaNo ratings yet

- Hot Works: Job Safety AnalysisDocument8 pagesHot Works: Job Safety AnalysisUğur BilenNo ratings yet

- SRB-02-2011 - (Welding of Pipes) For Thrust BoringDocument4 pagesSRB-02-2011 - (Welding of Pipes) For Thrust BoringkkalviNo ratings yet

- Oxy Acetylene Cutting TorchDocument2 pagesOxy Acetylene Cutting TorchChristian Makande100% (1)

- Milling MachineDocument1 pageMilling MachineFikri MaulanaNo ratings yet

- 39-98 - Safe Use of Lifting Machines and Lifting Tackle - 0Document59 pages39-98 - Safe Use of Lifting Machines and Lifting Tackle - 0JakesNo ratings yet

- Hazard Identification and Risk AssesmentDocument4 pagesHazard Identification and Risk AssesmentSkipper SkyNo ratings yet

- SOP of Angle GrindingDocument6 pagesSOP of Angle GrindingINFNo ratings yet

- Welding Procedure - Arc Welding Machine - Method Statement HQDocument8 pagesWelding Procedure - Arc Welding Machine - Method Statement HQSaaed EllalaNo ratings yet

- WMS For Fire Fighting Line and SupportsDocument4 pagesWMS For Fire Fighting Line and SupportsAbdul Rehman Sheikh100% (1)

- Utico FZC Work Instruction Manual Drilling MachineDocument2 pagesUtico FZC Work Instruction Manual Drilling MachineNAVANEETHNo ratings yet

- Caretaker Risk Assessment - Working at HeightDocument8 pagesCaretaker Risk Assessment - Working at HeightLina MarcelaNo ratings yet

- Accident Investigation FormDocument8 pagesAccident Investigation FormagusnurcahyoNo ratings yet

- Hand Tools Inspection ChecklistDocument2 pagesHand Tools Inspection ChecklistSaravana KumarNo ratings yet

- Sop Hydraulic Punch and ShearDocument1 pageSop Hydraulic Punch and ShearBorislav VulićNo ratings yet

- Emergency Drill Fall From HeightDocument5 pagesEmergency Drill Fall From HeightBinay100% (1)

- Eil Permit For Energy Isolation & De-IsolationDocument1 pageEil Permit For Energy Isolation & De-IsolationAvesh ChauahanNo ratings yet

- 01.hse Instruction - Shop FloorDocument3 pages01.hse Instruction - Shop Floormuthuswamy77No ratings yet

- Safety and Security Committe Meeting Presentation 12Document32 pagesSafety and Security Committe Meeting Presentation 12R Sahadeo Reddy100% (1)

- Welding Gas Cutting ChecklistDocument13 pagesWelding Gas Cutting ChecklistSAmyNo ratings yet

- Confined Spaces Standard Operating Procedure and Permit CombinedDocument8 pagesConfined Spaces Standard Operating Procedure and Permit CombinedRaza Muhammad SoomroNo ratings yet

- Risk Assessment For Welding JobsDocument16 pagesRisk Assessment For Welding Jobsمحمد عمر حسينNo ratings yet

- SWP Welder Oxy-Fuel Gas AS563Document2 pagesSWP Welder Oxy-Fuel Gas AS563anon_106345234100% (1)

- 45 Job Specific Attendance SheetDocument3 pages45 Job Specific Attendance SheetJunard Lu HapNo ratings yet

- Oxy-Acetylene Inspection Checklist: # Criteria Yes No N/A RemarksDocument1 pageOxy-Acetylene Inspection Checklist: # Criteria Yes No N/A RemarksFelcisNo ratings yet

- SOP - LatheDocument2 pagesSOP - LatheQuality PFPLNo ratings yet

- 015 CH 10 Tool InspectionDocument3 pages015 CH 10 Tool InspectionLinda BooysenNo ratings yet

- EXCAVATION BY HAND (Live Electrical) (Known & Unknown) : Job Safety AnalysisDocument2 pagesEXCAVATION BY HAND (Live Electrical) (Known & Unknown) : Job Safety Analysisfrancis100% (1)

- JOB Description: Position Title Department Position Reports To Job Class Job SummaryDocument2 pagesJOB Description: Position Title Department Position Reports To Job Class Job SummaryVijay RajaindranNo ratings yet

- 6.2 Sample Risk Assessment 2Document3 pages6.2 Sample Risk Assessment 2Luwalhati TomilasNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- Jsa GRIT BLASTINGDocument3 pagesJsa GRIT BLASTINGPrajnay ShettyNo ratings yet

- Welding ChecklistDocument1 pageWelding Checklistsafety86No ratings yet

- Bearing Housing Assembly Procedure EXTERNALDocument10 pagesBearing Housing Assembly Procedure EXTERNALAlejandroZegarraNo ratings yet

- Punch Press Safety and Operating ProceduresDocument2 pagesPunch Press Safety and Operating ProceduresRAMESH100% (1)

- Method Statement Fisher PlugDocument5 pagesMethod Statement Fisher PlugChezy629No ratings yet

- Job: Assembling of Internal Floating Roof.: Job Safety Analysis FormDocument3 pagesJob: Assembling of Internal Floating Roof.: Job Safety Analysis FormDilshad ali100% (1)

- December-22 (Week-1)Document11 pagesDecember-22 (Week-1)pabitra pandaNo ratings yet

- Jsa D. G. INSTALLATIONDocument5 pagesJsa D. G. INSTALLATIONRavi thokalNo ratings yet

- Fire Policy 1Document2 pagesFire Policy 1caleb99No ratings yet

- Safety Engineer PDFDocument3 pagesSafety Engineer PDFخلف الله التوم0% (1)

- Bench GrinderDocument6 pagesBench GrinderGaurav KhamkarNo ratings yet

- Above Ground Piping ProcedureDocument4 pagesAbove Ground Piping Proceduremusthafa_11No ratings yet

- ISO 2063-Thermal Spray Coating PDFDocument5 pagesISO 2063-Thermal Spray Coating PDFabhibmaneNo ratings yet

- Polishing Procedure For PipesDocument4 pagesPolishing Procedure For Pipesคุณพ่อน้อง บิ๊กบอส0% (1)

- ITP For Pressure Vessel - Static EquipmentDocument8 pagesITP For Pressure Vessel - Static EquipmentReduddboyNo ratings yet

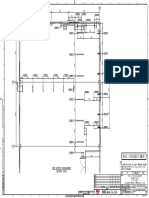

- 1.typical DrawingDocument31 pages1.typical DrawingReduddboyNo ratings yet

- Material Receiving Inspection SENDING ULN3 TO LPGU3Document30 pagesMaterial Receiving Inspection SENDING ULN3 TO LPGU3ReduddboyNo ratings yet

- Piping Support Arrangement Drawing List - 1-MAR-21Document1 pagePiping Support Arrangement Drawing List - 1-MAR-21ReduddboyNo ratings yet

- Pipe Support Arrangement - Etching Room - Rev.0Document1 pagePipe Support Arrangement - Etching Room - Rev.0ReduddboyNo ratings yet

- Method Statement For Rotating Equipment InstallationDocument10 pagesMethod Statement For Rotating Equipment Installationคุณพ่อน้อง บิ๊กบอส100% (3)

- Inspection and Test PlanDocument6 pagesInspection and Test PlanReduddboy100% (1)