Professional Documents

Culture Documents

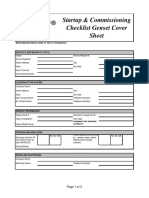

CK-E61 H - Generator Set Onan-Cummins Generic2

Uploaded by

Edward SchenkOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CK-E61 H - Generator Set Onan-Cummins Generic2

Uploaded by

Edward SchenkCopyright:

Available Formats

U.S.

DEPARTMENT OF STATE

OVERSEAS BUILDINGS OPERATIONS

FACILITIES MAINTENANCE DIVISION

PREVENTIVE MAINTENANCE CHECKLIST

E61H - Generator, Onan/Cummins (or other)

SAFETY & SPECIAL INSTRUCTIONS:

1. Have approved type fire extinguisher readily available.

2. Allow no open flame or smoking in area.

3. Use safety type fuel cans only.

4. Follow instructions in manufacturer's operation & maintenance manuals.

5. Turn engine switch off and tag out.

6. Wear eye protection when testing and filling batteries.

7. If the answer to a PM task is NO, briefly explain WHY NOT.

Notes: This checklist is intended as a Reminder and a Record. Some tasks may not apply to the unit you are maintaining.

Replaceable or refillable items were not replaced or refilled unless noted in the Comment Column.

Data Entry: Tab to the next field. Shift Tab to the previous field. Enter or Space to check a box. Use semicolon, not comma.

1. IMAP Equipment Identifier Number: 2. Checklist Completed By: 3. Date (m/d/yy):

4. Post: 5. Manufacturer: 6. Leave Blank

7. Model Number: 8. Serial Number:

9. Location Installed CAA or (Building/Area/Room 10. Area Served CAA or (Building/Area/Room Number):

Number):

11. Date Manufactured: 12. Leave Blank

unknown date known date estimated

13. General Assessment of Condition listing anything out of the

ordinary including broken, worn, missing, or newly replaced

components): Excellent Good Fair Poor Failed / Broken

14. DOCUMENTATION: Manufacturer’s operation and maintenance manuals available at Post: YES. NO.

15. Total Run Time (hours): 16. Estimated Annual Run Time (hours):

THE ENGINE

17. The Engine Manufacturer: 18. Governor Type:

19. The Engine Model Number: 20. The Engine Serial Number: 21. The Engine Arrangement

Number:

22. Governor Manufacturer: 23. Starting Battery Voltage:

12 Volt 24 Volt 32 Volt

24. Fuel Type: 25. Fuel Tank Construction:

Gasoline Diesel Steel Fiberglass Other

26. Day Tank Size: 27. Fuel Tank Size:

Gallons Liters Gallons Liters

Updated on 001/02/07 Page 1 of 5

E61H Updated from version F

THE GENERATOR

28. Generator Manufacturer: 29. Generator Model Number:

30. Generator Serial Number: 31. Generator Arrangement Number:

32. Number of Phases: 33. Frequency (50 / 60 Hz):

34. Prime Continuous Rating:

KVa

KW

35. Standby Rating:

KVa

KW

36. Output Voltage:

Phase – Phase Phase – Neutral

TRANSFER SWITCH

37. Transfer Switch Type: 38. IMAP Equipment Identifier Number for Transfer

Automatic Manual Switch:

Preventive Maintenance Procedures: Onan/Allis Chalmers Checked Record Readings/ Comments

or Done?

Y/N/NA

A. Check battery specific gravity and water level, add distilled water

as required.

B. Inspect engine and generator wiring harness for wear and damage.

C. Inspect engine and generator wiring and terminals for loose and

broken connection.

D. Clean battery terminals and lugs. (Apply grease on

terminal/connections.

E. Inspect starter motor and alternator. Clean and lubricate as

required

F. Check and tighten circuit breaker lugs and connections with

torque wrench.

G . Clean generator interior, starter, rotor, and exciter windings with

compressed air or vacuum cleaner.

H. Automatically start unit and run under load for 1 hour. (add load

test data to Box #40[below])

I. Observe auto-start Delay and transfer time and record *#.

J. Read and record all gauges/meters (adjust/calibrate as required).

K. Inspect trickle-charger voltage/amps.

Updated on 001/02/07 Page 2 of 5

E61H Updated from version F

39. Preventive Maintenance Procedures: Onan/Allis Chalmers CHECK RECORD READINGS/

(continued) Y/N COMMENTS

L. Reset test switch. Observe and record retransfer/cool down time.*#

(Use Additonal Comments block if more space is needed.)

M. Test start unit. Read and record all gauges/meters(5 Minutes No

Load).

NOTE: *#. Time delay engine start (TDES) 10-12 seconds. 2.Time delay transfer to emergency (TDNE) 2-3 seconds.

3.Time delay emergency to normal (TDEN) 3-5 minutes. 4. Time delay engine cooldown (TDEC) 5 minutes.

N. Inspect all fuel, oil water piping for secure mounting.

O. Check fuel level in storage and day tank. Add as required

P. Open fuel day tank drain valve, Drain off water and sediment

Q. Drain water and sediment from fuel line and filters. Reprime

R. Drain water and sediment from water separator.

S. Check exhaust for excessive black or white smoke. (See

manufacturer’s manual)

T. Check all hoses for wear, leaks and flexibility, change if necessary.

U. Check fuel pressure gauge. If green, OK. If Red, Change fuel

filter. Green

Red Red Green Red Check air filter service

indicator. If Green it is OK. If Red, replace the air filter. Green

Red Check air filter service indicator. If Green it is OK. If

Red, replace the air filter. Green Red

V. Lubricate fan shaft bearings. (Non shielded bearing only)

W If applicable, check operation of engine block water heater.

X. Clean radiator air Passages and duct work with pressure washer.

Y. Check cooling system anti-freeze mixture freeze-protection level.

Record the reading in o F.

Z. Inspect tension and condition of Vee-belts. Replace if cracked.

(adjust tension to 1/2” movement when pressed inward).

AA. Check water level in radiator tank. Add antifreeze as required.

AB. Add 0.5 liters of Caterpillar coolant conditioner. See manufacturer

's operation and maintenance manual.

AC. If applicable, check operation of oil heater.

AD. Check engine, lube oil level with dip stick. Add as required.

Change engine oil. (if over200 hrs since last oil change or 1 year)

AE. Replace engine oil filter ( if over 200 hrs. or 1 year since last filter

change. Note eng hrs on filter).

AG. While Engine is operating, check for water, fuel, and oil leaks.

AH. Clean air filter element. Replace after three cleaning or 200 hrs. or

1 year (note eng hrs on filter)

Updated on 001/02/07 Page 3 of 5

E61H Updated from version F

AI. Inspect exhaust muffler and piping insulation.

AJ. Inspect unit thoroughly for loose fasteners.

AK. Check turbocharge for vibration, check for any abnormal noise

during operation.

AL. Check exhaust manifold, muffler, and piping for leaks and secure

mountings.

AM. Check air filter service indicator. If Green it is OK. If Red,

replace the air filter. Green Red

AN. Inspect unit for corrosion. Remove any corrosion, prime and paint.

AO. Shut down engine. (Non-Emergency)

AP. Clean mechanical room and remove unnecessary materials and

parts.

AQ. Test engine auto-shutdown components. *

AR. Additional Comments

NOTE * AUTO SHUTDOWN COMPONENTS:

1. Test not applicable for transducer type shutdown system.

2.With engine running (in manual mode) and generator circuit breaker open and no load on the generator perform the

following:

A. Jumper water temperature switch.(engine should stop and temp failure light should light) reset the control panel.

B. Jumper oil pressure switch. (engine should stop and oil press. failure light should light). reset the control panel.

C. Press test button on the overspeed module.(engine should stop and overspeed failure light should light). Reset the

control panel.

TOOLS & MATERIALS: 1. Standard mechanic's tool set. 2. Distilled water. 3. Grease gun. 4. Hydrometer. 5.

engine oil. 6. air & fuel filters. 7. Antifreeze/coolant inhibitor. 8. Oiler can. 9. Cleaning Rags. 10. Oil filters. 11.

Vacuum cleaner. 12. Compressed air. 13. Radiator hoses. 14. torque wrench, 1/2" drive x 250 lbs. 15.Pressure sprayer.

Updated on 001/02/07 Page 4 of 5

E61H Updated from version F

E40H - Load Test Data: Date of Test

Time A phase amp reading B phase amp reading C phase amp reading

A to B phase volts B to C phase volts C to A phase volts

A phase to neutral B phase to neutral C phase to neutral volts

volts volts

Time delay to start

Time delay to emergency power

Time delay to normal power

Engine cool down time

41. ADDITIONAL FINDINGS OR COMMENTS:

Updated on 001/02/07 Page 5 of 5

E61H Updated from version F

You might also like

- Instruction Manual For AC Compressors English Engine John Deere 6135 Engine Caterpillar C15Document82 pagesInstruction Manual For AC Compressors English Engine John Deere 6135 Engine Caterpillar C15powermanagerNo ratings yet

- Test Report Iso 8528-5 Reciprocating Internal Combustion Engine Driven Alternating Current Generating SetsDocument17 pagesTest Report Iso 8528-5 Reciprocating Internal Combustion Engine Driven Alternating Current Generating SetsDaniela SincaNo ratings yet

- TRG-TRC002-En Cooling and Heating Load EstimationDocument95 pagesTRG-TRC002-En Cooling and Heating Load Estimationhonisme50% (2)

- 1-Drilling Rig EquipmentDocument194 pages1-Drilling Rig EquipmentBashir Ali100% (1)

- Pre-Engineered Building Design and Its Design ChartsDocument9 pagesPre-Engineered Building Design and Its Design ChartsPavan RajNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestDocument24 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestabderrahmaneNo ratings yet

- Power Pack 760d PDFDocument524 pagesPower Pack 760d PDFjesus manuel morales alvidrez100% (1)

- Cummins QSB 6.7 Parts Book AbbyDocument97 pagesCummins QSB 6.7 Parts Book Abbyhafiz100% (2)

- Standard Operating Procedure: Operation and Preventive Maintenance of TransformersDocument5 pagesStandard Operating Procedure: Operation and Preventive Maintenance of TransformersMaryanthony NamyaloNo ratings yet

- Genset Startup and Commissioning Checklist C 175Document3 pagesGenset Startup and Commissioning Checklist C 175Dwi Mulyanti Dwimulyantishop100% (1)

- Safe Work Method of Statement For Testing and Commissioning of Diesel GeneratorsDocument9 pagesSafe Work Method of Statement For Testing and Commissioning of Diesel GeneratorsHumaid ShaikhNo ratings yet

- 3.1 Oil Filled Power TransformersDocument32 pages3.1 Oil Filled Power TransformersThameemul BuhariNo ratings yet

- 19.station - Service TransformerDocument9 pages19.station - Service TransformerThameemul BuhariNo ratings yet

- Job Scope For Over Hauling of Power Transformers - FinalDocument7 pagesJob Scope For Over Hauling of Power Transformers - FinalrambihariNo ratings yet

- The PIC Microcontroller: Your Personal Introductory CourseFrom EverandThe PIC Microcontroller: Your Personal Introductory CourseRating: 1 out of 5 stars1/5 (2)

- Boilers RLADocument60 pagesBoilers RLAGanesh100% (1)

- Checklist For Shunt ReactorDocument4 pagesChecklist For Shunt ReactorSanthosh Kumar VinayagamNo ratings yet

- TM9 2320 212 10Document161 pagesTM9 2320 212 10rick.mccort2766100% (1)

- Checklist For Shunt Reactor Rev01Document4 pagesChecklist For Shunt Reactor Rev01Santhosh Kumar VinayagamNo ratings yet

- Check ListDocument6 pagesCheck ListSikandar Khan0% (1)

- Cumming Parts Catalog PM Qsb6 7 GBDocument9 pagesCumming Parts Catalog PM Qsb6 7 GBsteven100% (59)

- Standard Commissioning Procedure For Evaporative Cooling SystemsDocument10 pagesStandard Commissioning Procedure For Evaporative Cooling Systemsbedilu77No ratings yet

- Student Exploration: Air Track: Name: Akshat Date:12/15/20Document9 pagesStudent Exploration: Air Track: Name: Akshat Date:12/15/20Akshat Pant100% (8)

- Checklist For Auxiliary Transformer Rev00Document4 pagesChecklist For Auxiliary Transformer Rev00Santhosh Kumar VinayagamNo ratings yet

- 10 Under Balance DrillingDocument13 pages10 Under Balance DrillingZiad AouichatNo ratings yet

- Installation Guide & Operators ManualDocument132 pagesInstallation Guide & Operators ManualMauricio OlayaNo ratings yet

- Pocket Book Material - HKI 2020Document43 pagesPocket Book Material - HKI 2020Yuan PermanaNo ratings yet

- CK-E55 H - Generator Set Caterpillar2Document6 pagesCK-E55 H - Generator Set Caterpillar2Edward SchenkNo ratings yet

- CK-E73 H - Generator Set Detroit Diesel - Series 71 In-Line2Document5 pagesCK-E73 H - Generator Set Detroit Diesel - Series 71 In-Line2Edward SchenkNo ratings yet

- Inventory Checklist E33H - Medium Voltage Regulator Safety& Special InstructionsDocument1 pageInventory Checklist E33H - Medium Voltage Regulator Safety& Special InstructionsEdward SchenkNo ratings yet

- Project Provisional Acceptance HamusitDocument8 pagesProject Provisional Acceptance HamusitAbrham KeNo ratings yet

- Reactor - For SwitchayrdDocument10 pagesReactor - For SwitchayrdSindhuKumarNo ratings yet

- PressureReliefValves SpecsDocument11 pagesPressureReliefValves SpecsnmosilvaNo ratings yet

- Annexure To Start-Up & Commissioning of Fire Water PumpsDocument5 pagesAnnexure To Start-Up & Commissioning of Fire Water PumpsMina KhalilNo ratings yet

- 6.FM-JEC - Chilled Water Fan Coil Unit (F)Document4 pages6.FM-JEC - Chilled Water Fan Coil Unit (F)Thi Ha NaingNo ratings yet

- Idabb PSSS: Inspection and Test Record Diesel Generators 1 Katolight Corporation 2Document2 pagesIdabb PSSS: Inspection and Test Record Diesel Generators 1 Katolight Corporation 2nana arya sumardjaNo ratings yet

- Safety & Special Instructions:: Preventive Maintenance Checklist E09H - Automatic Transfer SwitchDocument2 pagesSafety & Special Instructions:: Preventive Maintenance Checklist E09H - Automatic Transfer SwitchEdward SchenkNo ratings yet

- Work - Instruction 66-33KV TRANSFORMERDocument5 pagesWork - Instruction 66-33KV TRANSFORMERTAHIR HUSAINNo ratings yet

- Standart Prosedur TestDocument3 pagesStandart Prosedur TestAlwinNo ratings yet

- MPM 813 01 04Document2 pagesMPM 813 01 04Mousa PetrolNo ratings yet

- Transformer TestingDocument4 pagesTransformer Testingengr.ayaz7772No ratings yet

- I & C Check Sheet 717 F 14 2 Rev 02Document2 pagesI & C Check Sheet 717 F 14 2 Rev 02winkyaw igtlNo ratings yet

- Manufacturer: Model: Serial No:: SECTION 26 08 30 Generator Testing Procedures FormDocument12 pagesManufacturer: Model: Serial No:: SECTION 26 08 30 Generator Testing Procedures FormarieznavalNo ratings yet

- Coskovic Branimir Etfos 2017 Zavrs SveucDocument2 pagesCoskovic Branimir Etfos 2017 Zavrs SveucsffvghjNo ratings yet

- Diesel TankDocument1 pageDiesel TankRejo AbrahamNo ratings yet

- 26 32 13 Engine Generators M7Document37 pages26 32 13 Engine Generators M7Chess Servin PerezNo ratings yet

- Power Transformer - For SwitchayrdDocument20 pagesPower Transformer - For SwitchayrdSindhuKumarNo ratings yet

- Service Manual: DPS-V55/V55MDocument32 pagesService Manual: DPS-V55/V55MQuiruNo ratings yet

- Datasheet For MotorDocument6 pagesDatasheet For Motorjack jalaNo ratings yet

- MPM 316 04 09Document2 pagesMPM 316 04 09Mousa PetrolNo ratings yet

- Ee-Gen Emerg InglesDocument15 pagesEe-Gen Emerg InglesginursamadNo ratings yet

- Vertical, Multistage Centrifugal Pumps: Grundfos Data BookletDocument44 pagesVertical, Multistage Centrifugal Pumps: Grundfos Data BookletDina Moh El HadedyNo ratings yet

- Manufacturer: Model: Serial No:: SECTION 26 08 30 Generator Testing Procedures FormDocument12 pagesManufacturer: Model: Serial No:: SECTION 26 08 30 Generator Testing Procedures FormzainNo ratings yet

- DISCONNECT&GROUNDING SWITCHEsDocument5 pagesDISCONNECT&GROUNDING SWITCHEsShady NasrNo ratings yet

- Engineering Systems LTD.: PROJECT: 90 KLPD Distillery Plant Section: Air Cooled Condenser ClientDocument5 pagesEngineering Systems LTD.: PROJECT: 90 KLPD Distillery Plant Section: Air Cooled Condenser ClientS B DubalNo ratings yet

- O&M Shuaibah Final Rev02 PDFDocument810 pagesO&M Shuaibah Final Rev02 PDFgustavo aguilarNo ratings yet

- R0 - 11-08-08 DG BoqDocument20 pagesR0 - 11-08-08 DG BoqmuthazirNo ratings yet

- Air Conditioning: Self-Contained HeaterDocument27 pagesAir Conditioning: Self-Contained HeaterhaasNo ratings yet

- Annexure D-Yearly Maintenance ChecklistDocument2 pagesAnnexure D-Yearly Maintenance Checklistrabia akramNo ratings yet

- Toaz - Info Cat Compact Start Up and Commissioning Checklist PRDocument19 pagesToaz - Info Cat Compact Start Up and Commissioning Checklist PRKhaled Naseem Abu-SabhaNo ratings yet

- MPM 324 05 24Document2 pagesMPM 324 05 24Mousa PetrolNo ratings yet

- Cupiagua CPF: A. C. Motor HV / LV Function Test CertificateDocument3 pagesCupiagua CPF: A. C. Motor HV / LV Function Test CertificateKhaled FatnassiNo ratings yet

- MPM 332 01 33Document2 pagesMPM 332 01 33Mousa PetrolNo ratings yet

- MPM 573 01 52Document4 pagesMPM 573 01 52Mousa PetrolNo ratings yet

- HT Motor PMDocument2 pagesHT Motor PMdevraj.singh133No ratings yet

- Ims-Om-Cl-001-R00 AcdbDocument1 pageIms-Om-Cl-001-R00 AcdbVeerendra YduvanshiNo ratings yet

- BPCL Technical-DataSheet-a8a979Document13 pagesBPCL Technical-DataSheet-a8a979cnrk777inNo ratings yet

- MPM 312 09 08Document2 pagesMPM 312 09 08Mousa PetrolNo ratings yet

- Corona 250 KVADocument2 pagesCorona 250 KVAArif TalukderNo ratings yet

- Tutorial Stress and StrainDocument4 pagesTutorial Stress and StrainSujay BalakrishnanNo ratings yet

- REYQ-T REMQ-T 4PEN353997-1B Installer and User Reference Guides EnglishDocument84 pagesREYQ-T REMQ-T 4PEN353997-1B Installer and User Reference Guides EnglishMaxmore KarumamupiyoNo ratings yet

- Safety in Pressure TestingDocument12 pagesSafety in Pressure TestingrodofgodNo ratings yet

- Poveda Pachon Marlon Yesid Tarea #1Document12 pagesPoveda Pachon Marlon Yesid Tarea #1Marlon Yesid PovedaNo ratings yet

- Fiat Alfa Lancia AbarthDocument2,102 pagesFiat Alfa Lancia Abarthabdo zainNo ratings yet

- Motion Add Stress Intensity of Grinding Beads in A Stirred Media Mill. Part 1: Energy Density Distribution and Motion of Single Grinding BeadsDocument10 pagesMotion Add Stress Intensity of Grinding Beads in A Stirred Media Mill. Part 1: Energy Density Distribution and Motion of Single Grinding BeadsVictor Manuel Morales de la Fuente100% (1)

- EMR70HLR_513400004Document4 pagesEMR70HLR_513400004WERLAN SILVANo ratings yet

- Rotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaDocument3 pagesRotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaKirit IndustriesNo ratings yet

- BVD2034GBDocument4 pagesBVD2034GBSamehibrahemNo ratings yet

- Bretec L20C Parts ManualDocument24 pagesBretec L20C Parts ManualJayantha parakrama ThennakoonNo ratings yet

- MasteringPhysics - Assignments10 - 9 - 11Document12 pagesMasteringPhysics - Assignments10 - 9 - 11Dylan StefanskiNo ratings yet

- XLR3 ConnectorsDocument10 pagesXLR3 ConnectorsAbel FSNo ratings yet

- 04 Work Energy and PowerDocument6 pages04 Work Energy and PowerJerico LlovidoNo ratings yet

- StegoDocument1 pageStegoSlm WidNo ratings yet

- Lever Hoist - Tiger LiftingDocument9 pagesLever Hoist - Tiger LiftingYADAGIRI REDDYNo ratings yet

- Beef Brisket Saw: Tool DataDocument22 pagesBeef Brisket Saw: Tool DatajavierNo ratings yet

- Theory Manual ENGLISH PDFDocument111 pagesTheory Manual ENGLISH PDFpoojaNo ratings yet

- Gearless MGI17Document2 pagesGearless MGI17Savinder Singh GulairNo ratings yet

- Design Codes & Standarts & Specifications: Plan ViewDocument1 pageDesign Codes & Standarts & Specifications: Plan ViewIonut FloricaNo ratings yet

- 140H Cambios de MarchasDocument12 pages140H Cambios de MarchasJose Jaramillo100% (2)

- CE 212 Mechanics of Solids Sessional: Department of Civil EngineeringDocument54 pagesCE 212 Mechanics of Solids Sessional: Department of Civil EngineeringjulesNo ratings yet