Professional Documents

Culture Documents

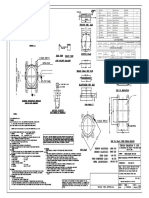

2850-1992 KN S (Type - A1) Span P 51 Anti Uplift Arrangement

Uploaded by

Gaurav PatilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2850-1992 KN S (Type - A1) Span P 51 Anti Uplift Arrangement

Uploaded by

Gaurav PatilCopyright:

Available Formats

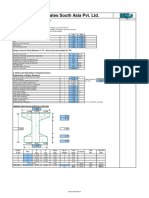

DESIGN OF 2850 KN (ULS) & 1992 KN (SLS) CAPACITY Free SLIDDING POT BEARINGS

Type (A1 ) P51 CONSTRUCTION OF MULTI -MODEL TRANSIT HUB AT THANE RAILWAY STATION EAST

REFERANCE CODE:- IRC:83 (Part III) - 2018

DESIGN PARAMETERS : DT: 07-06-2021

1) Grade of Concrete

a) Pedestal : 45 Mpa Min Size 900 X 900

b) Superstructure : 45 Mpa

Modulus of elasticity 34312.98368 Mpa

2) Permissible Stress in Concrete

Normal Case Seismic Case

a) Bottom sb : 22.50 N/mm2 28.13 N/mm2

b) Top st : 22.50 N/mm2 28.13 N/mm2

fcd : 20.10 N/mm2

3) Permissible Bearing Stress in Concrete

Normal Case Seismic Case

a) Bottom sbc : 14.85 N/mm2 18.56 N/mm2

b) Top stc : 14.85 N/mm2 18.56 N/mm2

4) Grade of Cast Steel : 340 -570W of IS:1030

Permissible stress in Cast Steel (Cl. 926.2.2) where fy = 340.0 N/mm2

sst : 204 N/mm2

sp : 255 N/mm2

5) Vertical Load For ULS case For SLS case

a) Vmax : 2850 KN 1992 KN

b) Vmin : 60.12 KN 140 KN

c) Vmax-ses : 2200 KN 1620 KN

d) Vmin-ses : 220 KN 360 KN

6) Horizontal Force under Normal Condition

a) Longitudinal Hbf : 0 KN 0 KN

b) Transverse Hbt : 0 KN 0 KN

c) Resultant HRn : 0.00 KN 0.00 KN

Since HRn < 10% of Vmax

HRn 285.00 KN 199.20 KN (Cl. 926.1.4)

7) Since Horizontal Force in Longitudinal Seismic is more than Transverse Seismic and Wind Condition

\ Horizontal Force under Seismic Condition

a) Longitudinal Hsl : 0 KN 0 KN

b) Transverse Hst : 0 KN 0 KN

c) Resultant HRs : 0.00 KN 0.00 KN

d) Wind:- Yes Yes

Since Hsl > HRs

HRs 220.00 KN 162.00 KN

8) Rotation (Normal, Seismic)

a) Resultant Rotation, q : 0.01 radians

b) Resultant rotation due to variable action positive rotation , qv : 0.0002 radians

c) Resultant rotation due to permanent action and long term effects , qp : 0.0098 radians

d) Resultant rotation due to variable action negative rotation , qv : 0.0020 radians

Assumed qp = 2 % of q & qv = 98 % of q

Since D5 / Tn = 13.64 As per table 5.1 of IRC:83 (Part III)-2018 Cl. 5.1.5.1.)

k1 = 1.981818182

k2 = 77.98181818

9) Longitudinal Movement

elng : + 50 mm - 50 mm

10) Transverse Movement

etran : + 20 mm - 20 mm

11) Vertical Movement

evrt : + 0 mm - 0 mm

upward downward

Confidential Tefcon Bearings P. Ltd. 1 of 9

Design of POT PTFE Bearing

Ref. Code:-IRC 83-Part III-2018

Minimum grade of steel = 350 MPa

fu = 570 MPa

fy = 340 MPa

ϒm Cast Steel = 1.1

ϒc For concrete = 1.5

Pedestal height h = 300.00 mm

width b = 600.00 mm

length d = 600.00 mm

BEARING PARAMETERS 2850 KN FREE TYPE BEARING. QTY :- 1 NOS.

I) POT :

Effective diameter of bottom plate A1 = D5 + (2XA2) = 363 mm

Diameter of Pot at Bottom A = A1 = 425 mm Do

Thickness of Pot at Base A2 = 31.5 mm kb

Depth of Pot A6 = A3-A2 = 36 mm hc=A3-kb

Total Ht. of Pot A3 = A2+Tn+w+2 = 67.5 mm

Outer Diameter of Pot A7 = 390 mm do

Inner Diameter of Pot D5 = 300 mm di

Horizontal Lever Arm A5 = A2+Tn+(w/2) = 59.5 mm

Pot Thickness (A7-D5)/2 = 45 mm

II) ELASTOMERIC PAD : (Cl-5.2.3.5)

Diameter of Elastomeric Pad D5 = 300 mm OK

Thickness of Elastomeric Pad he Tn = 22 mm OK

Effective Thickness of Elastomeric Pad Nt-eff = Tn-4 = 18 mm

III) PISTON / CENTRE PLATE :

Size of Centre Plate (C3 x C3) = 330 mm

Piston Diameter Dp = 299 mm

Overall Thicknes of Centre Plate C2 = 40 mm

Contact width of Piston w = 12 mm

Piston recess hn = 12 mm

IV) P.T.F.E. :

Length & Width L = 310 mm

Thickness t = 4.5 mm

V) S.S. Plate :

Length SSPl = 410 mm

Width SSPw = 370 mm

Thickness SSPt = 3 mm

VI) TOP PLATE :

Effective Length & Width B1 = 356 mm Dp

Diameter of Piston Dp = 299 mm

Length BL = 450 mm

Width BW = 410 mm

Thickness B2 = 23 mm

Distance of line of Horz. force from top B5 = 23 mm

X) GUIDE / END CONSTRAINT :

Length El = 0 mm

Width Eb = 0 mm

Height Eh = 0 mm

VII) ANCHOR BOLT :

Diameter of Bolt Bf = 20 mm

Total Number of Bolts N = 4 nos.

Grade of Bolt = Grade 8.8

Confidential Tefcon Bearings P. Ltd. 2 of 9

VIII)LUGS :

Length Ll = 75 mm

Width LW = 75 mm

Thickness Lt = 25 mm

IX) ANCHOR SLEEVES :

Diameter of Sleeve D = 50 mm

Sleeve length for Bottom Lb = 200 mm

Sleeve length for Top Ls = 200 mm

BEARING THICKNESS THK = 121.5 mm

b1 354

DESIGN CHECK :

I) ELASTOMERIC PAD :

1) Diameter to Thickness Ratio (Cl. 5.2.3.5)

D5/Tn = 13.64 </= 16 OK

2) Strain in Elastomer (Cl. 5.2.3.4)

tneo = 0.5 x D5 x q

Nt-eff

= 0.08 </= 0.15 OK

3) Design value of resistance of the elastoneric pad normal case - NRd (Cl. 5.2.3.2) ULS

Fek is the charasteristic contact strength of the elastomer = 60.00 Mpa

ϒm partial factor 1.30

Characteristic value of resistance of the elastomeric pad - NRK

NRK = π/4 di2 fe,k

= 4241.15 kN

Design value NRd = NRK

ϒm

NRd = 3262.42 kN

Nsd < NRd____OK

4) Design value of resistance of the elastoneric pad seismic case - NRd (Cl. 5.2.3.2) ULS

Fek is the charasteristic contact strength of the elastomer = 60.00 Mpa

ϒm partial factor 1.30

Characteristic value of resistance of the elastomeric pad - NRK

NRK = π/4 di2 fe,k

= 4241.15 kN

Design value NRd = NRK

ϒm

NRd = 3262.42 kN

Nsd < NRd____OK

5) Minimum Average Stress (Cl. 5.2.3.3) SLS

sneo-min = Vmin x 1000

p/4 x D52

= 1.98 < 2 N/mm2 `

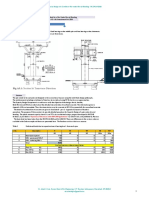

ANTI-UPLIFT ARRANGMENT IS MADE AND CALCULATION ARE ADDING ACCORDINGLLY

5) Moment due to resistance to rotation due to tilting stiffness of elastomeric pad (Cl. 5.1.5.1) ULS-SLS

Me-d = D53 x [(k1 x qp) +(k2 x qv)]

= 9.45E+05 N-mm

6) Moment due to friction at the piston-cylinder contact surface under normal condition (Cl. 5.1.5.2)

Confidential Tefcon Bearings P. Ltd. 3 of 9

MR-d(n) = 0.2 x C x Vd C=D5/2 ULS

= 8.55E+06 N-mm

7) Moment due to friction at the piston-cylinder contact surface under Seismic condition (Cl. 5.1.5.2)

MR-d(s) = 0.2 x C x Vd ULS

= 6.60E+06 N-mm

8) Moment due to friction at the piston-cylinder contact surface under normal condition (Cl. 5.1.5.2)

MR-d(n) = 0.2 x C x Vd C=D5/2 SLS

= 5.88E+06 N-mm

9) Moment due to friction at the piston-cylinder contact surface under Seismic condition (Cl. 5.1.5.2)

MR-d(s) = 0.2 x C x Vd SLS

= 4.78E+06 N-mm

10) Total induce Moment under normal condition (Cl. 5.1.6) ULS

MT-d(n) = Me-d + MR-d(n)

= 9.50E+06 N-mm

11) Total induce Moment under Seismic condition (Cl. 5.1.6) ULS

MT-d(s) = Me-d + MR-d(s)

= 7.55E+06 N-mm

12) Total induce Moment under normal condition (Cl. 5.1.6) SLS

MT-d(n) = Me-d + MR-d(n)

= 6.82E+06 N-mm

13) Total induce Moment under Seismic condition (Cl. 5.1.6) SLS

MT-d(s) = Me-d + MR-d(s)

= 5.72E+06 N-mm

II) POT :

Particular recommendations for design of POT bearings

Pot Wall Subjected to tensile forces for normal condition Clause 5.3.1.2.3 ULS

AR = (do-di) * hc = 3240 mm

Vesd = 4*Nsd*he/(pi*di) = 266.11 kN

Vfxysd = sqrt(Vfxsd^2+Vfysd^2) = 0.00 kN

Vsd = Vesd + Vfxysd = 266.11 kN

Vrd = fy*AR/ϒm = 1001.454545 kN

Vsd < Vrd ------ OK

Pot Wall Subjected to tensile forces for seismic condition Clause 5.3.1.2.3 ULS

AR = (do-di) * hc = 3240 mm

Vesd = 4*Nsd*he/(pi*di) = 205.42 kN

Vfxysd = sqrt(Vfxsd^2+Vfysd^2) = 0.00 kN

Vsd = Vesd + Vfxysd = 205.42 kN

Vrd = fy*AR/ϒm = 1001.454545 kN

Vsd < Vrd ------ OK

POT Wall Subjected to Shear forces for normal condition Clause 5.3.1.2.4 ULS

V'sd = (Vesd+1.5 Vfxysd)/di = 887.02 1/m kN

V'rd = (fy (do-di))/(2 ϒm sqrt(3)) = 8030.417 1/m kN

V'sd < V'rd ------ OK

POT Wall Subjected to Shear forces for seismic condition Clause 5.3.1.2.4 ULS

V'sd = (Vesd+1.5 Vfxysd)/di = 684.72 1/m kN

V'rd = (fy (do-di))/(2 ϒm sqrt(3)) = 8030.417 1/m kN

V'sd < V'rd ------ OK

POT base Subjected to Tensile forces for normal condition Clause 5.3.1.2.5 ULS

Ap = do kb = 0.0123 m2

Vsd = 266.11 kN

TVrd = (fy Ap)/ϒm = 3797.18 kN

Vsd < TVrd------ OK

POT base Subjected to Tensile forces for seismic condition Clause 5.3.1.2.5 ULS

Ap = do kb = 0.0123 m2

Vsd = 205.42 kN

TVrd = (fy Ap)/ϒm = 3797.18 kN

Vsd < TVrd------ OK

Confidential Tefcon Bearings P. Ltd. 4 of 9

Minimum Thickness of POT base shall not be less than 2.5% of inner diameter of the POT cylinder

Clause 5.3.1.3

T2 min = 2.5% di = 7.5 mm

T2 = provided thickness of the POT base = 31.5 mm

T2min < T2------ OK

Flat contact surface under normal condition(NOT REQUIRED) Clause 5.3.1.4.1 ULS

𝑉_𝑅𝑑= (𝑓𝑦 𝑑_𝑖 𝑤)/(1.5 𝛾_𝑚 ) VRd = 741.818182 kN

𝑉_𝑅𝑑= (15 〖𝑓𝑢〗^2 𝑅 𝑑𝑖)/(𝐸𝑠 〖𝛾𝑚〗^2 )

Vsd < VRd_____OK

Flat contact surface under seismic condition(NOT REQUIRED) Clause 5.3.1.4.1 ULS

𝑉_𝑅𝑑= (𝑓𝑦 𝑑_𝑖 𝑤)/(1.5 𝛾_𝑚 ) VRd = 741.818182 kN

Vsd < VRd_____OK

𝑉_𝑅𝑑= (15 〖𝑓𝑢〗^2 𝑅 𝑑𝑖)/(𝐸𝑠 〖𝛾𝑚〗^2 )

Curved contact surface under normal condition Clause 5.3.1.4.2 ULS

Radius of contact surface R = 150 mm

𝑉_𝑅𝑑= (15 〖𝑓𝑢〗^2 𝑅 𝑑𝑖)/(𝐸𝑠 〖𝛾𝑚〗^2 )

VRd = 906.23 kN

Vsd < VRd_____OK

Curved contact surface under seismic condition Clause 5.3.1.4.2 SLS

Radius of contact surface R = 150 mm

𝑉_𝑅𝑑= (15 〖𝑓𝑢〗^2 𝑅 𝑑𝑖)/(𝐸𝑠 〖𝛾𝑚〗^2 )

𝑤_𝑒=3.04 √((1.5 × 𝑉_(𝐹𝑥𝑦,𝑠𝑑) VRd = 906.23 kN

× 𝑅)/(𝐸𝑠 × 𝑑𝑖))

Vsd < VRd_____OK

Design rotation ϴ Clause 5.1.7

ϴavg. = ϴv + ϴv' ϴavg. = 0.0118

ϴmax = ϴp + ϴv ϴmax = 0.0100

ϴ = ϴmass + 0.005 ϴ = 0.0150

< 0.03___OK

Effective contact width 𝑤_𝑒=3.04 √((1.5 × 𝑉_(𝐹𝑥𝑦,𝑠𝑑) Clause 5.3.1.4.2 ULS

× 𝑅)/(𝐸𝑠 × 𝑑𝑖)) we = 0.00 mm

we + ϴ di < w we + ϴ di = 4.500 mm

w = 12 mm

we + ϴ di < w____OK

Reduced area for eccentric loading Annexure B ULS

Lever arm for horizontal force = 59.5 mm

Horizontal force H = 285.00 kN

Moment M = 16.9575 kNm

Vertical force V = 2850 kN

Ar = Aco (1- 0.75 π e/L) e = 5.950 mm

e < L/8 - OK

Aco = 70685.8 mm2

Ar = 67382.6 mm2

III) Sliding Check

Slid path SA,d Cl. 5.1.8

SA,d = nv x ϴv,range x di/2 < 5 x ST

nv = 1.00E+06 nos.

POM seal and carbon filled PTFE seal ST = 2000 m

ϴv,range = 0.0050 rad

SA,d = 750 m < 5 x ST

5 x ST = 10000 m

Confidential Tefcon Bearings P. Ltd. 5 of 9

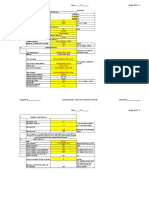

Sliding Surface for Guides (PTFE) 'S' Cl.5.2.4.3

Protrusion 'h' h = 1.75+ L/1200 >2.2 h = 2.2000 mm >= 2.2 OK

Thickness 'tp' 2.2h < tp±8.0 tp = 4.84 mm

tp±8.0 = 12.5 mm

2.2h < tp±8.0 ---- OK

s = Ap/(uxh) x (tp-h)/h

Coefficient of friction for PTFE 'µmax'

o

minimum effective temperature = 40 C

average pressure for normal condition σp = 29.7 Mpa

average pressure for seismic condition σp = 22.9 Mpa

µmax for Normal condition µmax = 0.0303

𝐹_𝑅𝑑𝑢= 𝐴_𝑐0×𝑓_𝑐𝑑×√(𝐴_𝑐1/𝐴_𝑐0 ) ≤3×𝑓_𝑐𝑑×𝐴_𝑐0 0.03 < µmax < 0.08

µmax for Seismic condition µmax = 0.0365

0.03 < µmax < 0.08

IV) TOP PLATE :

Design resistance of the adjacent concrete structure. (Cl. 5.2.1.1) ULS

fcd = 20.10 Mpa

b1 = 425.000 mm

𝐹_𝑅𝑑𝑢= 𝐴_𝑐0×𝑓_𝑐𝑑×√(𝐴_𝑐1/𝐴_𝑐0 ) ≤3×𝑓_𝑐𝑑×𝐴_𝑐0 d1 = 425.000 mm

b2 = 600.000 mm < 3b1

d2 = 600.000 mm < 3d1

h > (b2-b1) OK

h > (d2-d1) OK

Ac0 = 180625.00 mm2

Ac1 = 360000.00 mm2

FRdu = 5125.50 kN

3 fcd Ac0 = 10891.6875 kN

Frdu < 3 fcd Ac0 OK

Maximum strain in bedding grout/concrete Cl 5.2.1.3 ULS

Limiting strain in concrete = 0.0035

Stress for normal condition = 46.72 Mpa

Strain for normal condition = 0.001361 OK

Stress for seismic condition = 33.59 Mpa

Strain for seismic condition = 0.000979 OK

Steel bearing component Cl 5.2.2

Limiting strain steel = 0.0035

Stress for normal condition = 43.52 Mpa

Strain for normal condition = 0.000218 OK

Stress for seismic condition = 33.59 Mpa

Strain for seismic condition = 0.000168 OK

Confidential Tefcon Bearings P. Ltd. 6 of 9

Additional geometrical conditions for required rotation capacity (Cl. 5.3.1.5)

hc-he-(w-we)x0.5 - (ϴx0.5xdi) > δ

hp-(hc-he) - (ϴx0.5xDp) > δ

Flat contact surface w = 12 mm

we = 12.00 mm

δ = 3.00 mm

hc-he-(w-we)x0.5 - (ϴx0.5xdi) = 11.75 > δ OK

hp-(hc-he) - (ϴx0.5xDp) = 7.76 > δ OK

V) ANCHOR BOLTS :

Resistance in shear (Cl.5.3.6.2) ULS

Steel on concrete Seismic Zone III µk = 0.6

Ƴµ = 1.2

Edge distance = 30 mm

c/c distance = 60 mm

Minimum fastening thread length = 24 mm

Nsd,min = 60.12 kN

n = 4 nos.

A=As = 244.95 mm2

Fub = 800 Mpa

αv = 0.6

Ƴm2 = 1.25

Design shear resistance of single anchor

Fvrd = αv x fub x A / Ƴm2 Fvrd = 94.06 kN

Design value of anchorage resistance in shear

Vpd = n X Fvrd Vpd = 376.24 kN

Anchorage strength/frictional resistance

Vrd = µk/Ƴµ X Nsd,min + Vpd Vrd = 406.30 kN

Vxy,sd = 285.00 kN

Vxy,sd < Vrd OK

VI) ANCHOR SLEEVES : ULS

(Cl.5.3.6.4)

Diameter of sleeve = 50 mm

Sleeve length for Bottom = 200 mm

Sleeve length for Top = 200 mm

Resistance offered by concrete Frdu = D X L X fcd/(3)^1/2 Frdu = 116.05 KN

Design shear resistance of single anchor Fvrd = 94.06 KN

Frdu > Fvrd OK

VII) LUGS ULS

Thickness of Lug Lt = 25 mm

Length of Lug Ll = 75 mm

Area of Bolt Hole Ab = 600.00 mm2

Area of Lugs Al = 1875.00 mm2

Effective area of lug Ae = 1275.00 mm2

Horizontal force on each lug under normal condition

Hln = HRn

n

= 285.00

4

= 71.25 kN

Stress on lug due to horizontal force under normal condition

Sln = Hln x 1000

Ae

= 71250

1275.00

= 55.88 < 153 N/mm2

Confidential Tefcon Bearings P. Ltd. 7 of 9

Horizontal force on each lug under Seismic condition

Hls = HRs

n

= 220.00

4

= 55.00 kN

Stress on lug due to horizontal force under Seismic condition

Sls = Hls x 1000

Ae

= 55000

1275.00

= 43.14 < 153 N/mm2

Check for Thickness of POT in Bending : Top

Maximum vertical load Vmax = 2850.00 kN

Effective Length / Width of Topplate Ble = 356 mm

Size of Loaded Area (PTFE) L = 310 mm

Projection of the Topplate = Ble - L

2

= 23 mm

Stress to concrete at Topplate = Vmax x 1000

Ble2

sct = 22.488 N/mm2

Bending Moment at the Top = sct x Projection2

2

BM = 5947.994 N.mm

Thickness of Topplate required to cater the Bending Moment

= BM Where sbt = 0.66 x fy

1/6 x sbt

12.611 mm < 23 mm Hence OK

Check for Thickness of POT in Bending : Bottom

Maximum vertical load Vmax = 2850.00 kN

Effective Dia. Of POT A = 363 mm

Dia. of Loaded Area (Pad) D5 = 300 mm

Projection of the Piston = A - D5

2

= 31.5 mm

Stress to concrete at POT = Vmax x 1000

p/4 x A2

scb = 27.553 N/mm2

Bending Moment at the Top = scb x Projection 2

2

BM = 13669.514 N

Thickness of Topplate required to cater the Bending Moment

= BM Where sbt = 0.66 x fy

1/6 x sbt

19.118 mm < 31.5 mm Hence OK

A) Design of bracket for pre-compression arrangement for Sliding

bearings (Free in Both. Direction) :-

The minimum load req. to satisfy the condition of 2 Mpa.

( of IRC 83:2018 (Part III) )

D5

Diameter of Elastomeric300

Padmm mm

Vmin = 2 X 0.785 X mm X mm / 1000

Vmin = 142 KN

The minimum load60 available

KN. =

The difference for which the bracket is to be designed.

= 142 - 60 KN

= 82 KN.

(The bearing will be compresed by 82 KN force in the compression machine in our factory. After compression the bearing top

and bottom will be welded with the help of assembly patti of size 50 mm X 20 mm X 100 mm. to retain the compression load.)

Design of anti-uplift arrangement :-

= 41 KN. (Given in the load data.)

Confidential Tefcon Bearings P. Ltd. 8 of 9

= 41 X 1.25 (Add 25 % extra as safety factor.)

= 51 KN.

So each bracket is to be designed for 51 KN load uplift.

1) Design of Projection : (Bracket)

Bending Moment, M = force x Dist.

= 51 KN x 25 N-mm

= 1279375

= 125 KN N-mm

x 10 mm = 1250 E+3 N-mm

Bending stress, s = M / Z

= 1E+06 /(1/6) x 60 x 25 x 25

= 205 N/mm2 < 224.4 N/mm2

Shear stress , ss = F / A

= 51 KN / ( 60 x 25 )

= 34 N/mm2 < 153 N/mm2

Combined stress Cs = 2

(s + (3 x σs 2))1/2

= 213.059 N/mm2 < 306 N/mm2

1) Design of Projection : (Lower Bracket)

Bending Moment, M = force x Dist.

= 51 KN x 25 N-mm

= 1279375 N-mm

Bending stress, s = M / Z

= 1E+06 /(1/6) x 60 x 25 x 25

= 205 N/mm2 < 224.4 N/mm2

Shear stress , ss = F / A

= 51 KN / ( 60 x 25 )

= 34 N/mm2 < 153 N/mm2

Combined stress Cs =

(s2 + (3 x σs 2))1/2

= 213.059 N/mm2 <306 N/mm2

Confidential Tefcon Bearings P. Ltd. 9 of 9

You might also like

- Elastomercic Bearing DN (14+872 MNB)Document19 pagesElastomercic Bearing DN (14+872 MNB)Ankur ChauhanNo ratings yet

- FB. 60M - Free Bearing DesignDocument10 pagesFB. 60M - Free Bearing DesignBasava SowmyaNo ratings yet

- Bearing Pot Cum 27-08-2020Document48 pagesBearing Pot Cum 27-08-2020Hymavathi MNo ratings yet

- Type FRB1. 333 Ton Free Sliding Bearing DesignDocument8 pagesType FRB1. 333 Ton Free Sliding Bearing DesignAnkush SharmaNo ratings yet

- Calculation of loads and stresses for a 16.5m steel girder bridge spanDocument1 pageCalculation of loads and stresses for a 16.5m steel girder bridge spansups madiNo ratings yet

- Detailed Design of Free Pot BearingDocument7 pagesDetailed Design of Free Pot BearingDevesh SinghNo ratings yet

- Design of Laminated Elastomeric Bearing for 20m SpanDocument8 pagesDesign of Laminated Elastomeric Bearing for 20m Spannaresh KUMARNo ratings yet

- Design of Elastomeric Bearing: (For Effective Span of 20.95M)Document8 pagesDesign of Elastomeric Bearing: (For Effective Span of 20.95M)vivekNo ratings yet

- I. Partial Safety Factors: II. Section PropertiesDocument150 pagesI. Partial Safety Factors: II. Section Propertiespinakin nikash100% (1)

- 29+635 - (32 Deg Skew)Document27 pages29+635 - (32 Deg Skew)Praveen CyssanNo ratings yet

- Br. No. 326 ABTDocument134 pagesBr. No. 326 ABTAnish ThakurNo ratings yet

- Design of Elastomeric BearingsDocument6 pagesDesign of Elastomeric BearingsHarshitha GaneshNo ratings yet

- Free POT/PTFE BearingDocument25 pagesFree POT/PTFE BearingZakee MohamedNo ratings yet

- Bearing 1 PDFDocument1 pageBearing 1 PDFAnkit SuriNo ratings yet

- (300 X 400 X 64) Elastomeric Bearing-15m For 0deg 8 CWDocument12 pages(300 X 400 X 64) Elastomeric Bearing-15m For 0deg 8 CWaniketNo ratings yet

- Neutral AxisDocument2 pagesNeutral AxispandianNo ratings yet

- POT Design R0Document9 pagesPOT Design R0VB665No ratings yet

- Design of Substructure and Foundations of Abutment - Ch. 420+400Document126 pagesDesign of Substructure and Foundations of Abutment - Ch. 420+400Ankush SharmaNo ratings yet

- Calculate spherical bearing loadsDocument5 pagesCalculate spherical bearing loadsSHARATH VASUPRADA100% (1)

- Elastomeric Bearing Design for Solid Slab Decking SpanDocument8 pagesElastomeric Bearing Design for Solid Slab Decking SpanCivil MexNo ratings yet

- Longitudinal BearingDocument6 pagesLongitudinal BearingDPJAIN INFRASTRUCTURENo ratings yet

- Tan PierwellDocument64 pagesTan Pierwellamit_saxena_10No ratings yet

- Design of Abutment - 31+010Document26 pagesDesign of Abutment - 31+010ajayNo ratings yet

- Calculation of Seismic Coefficient: ProjectDocument1 pageCalculation of Seismic Coefficient: Projectnandu523No ratings yet

- Design File Type RUBDocument116 pagesDesign File Type RUBAbilaash VNo ratings yet

- Bearing Design For ROB at Chainage 145+368 (47m CC of E.J.)Document11 pagesBearing Design For ROB at Chainage 145+368 (47m CC of E.J.)amitkuknaNo ratings yet

- Combined Footing Design: ASDIP Foundation 3.2.2Document4 pagesCombined Footing Design: ASDIP Foundation 3.2.2Rodain NajjarNo ratings yet

- Box Culvert 20mDocument68 pagesBox Culvert 20mV P GUPTANo ratings yet

- Superstructure Sketch: Fig. Superstructure Dimensions (All Dimensions Are in MM)Document14 pagesSuperstructure Sketch: Fig. Superstructure Dimensions (All Dimensions Are in MM)Himal KafleNo ratings yet

- Pier Design 2x20.84Document52 pagesPier Design 2x20.84shashi rajhansNo ratings yet

- Paradip Port Connectivity Project Temperature Gradient CalculationsDocument79 pagesParadip Port Connectivity Project Temperature Gradient CalculationsSM ConsultantsNo ratings yet

- Bridge Design Data Span DetailsDocument76 pagesBridge Design Data Span Detailspraloy dasNo ratings yet

- p4 & P6-Pier Well & Well CapDocument74 pagesp4 & P6-Pier Well & Well Capamit_saxena_10No ratings yet

- (Min. of 0.33qc or 30kg/cm ) : Calculation of Rock Socketing LengthDocument1 page(Min. of 0.33qc or 30kg/cm ) : Calculation of Rock Socketing LengthvivekNo ratings yet

- A Bridge RuleDocument120 pagesA Bridge RulemanishNo ratings yet

- DESIGN OF ABUTMENT 30m COMPOSITE GIRDER IN N F RAILWAY PDFDocument33 pagesDESIGN OF ABUTMENT 30m COMPOSITE GIRDER IN N F RAILWAY PDFShashibhushan SinghNo ratings yet

- Design of Substructure & Foundation For Pier: (Table:8, Cl.219.5.1.1, IRC:6-2014)Document3 pagesDesign of Substructure & Foundation For Pier: (Table:8, Cl.219.5.1.1, IRC:6-2014)Muhammad HasanNo ratings yet

- Design of Pier For Major Bridge at KM 4+547 PDFDocument129 pagesDesign of Pier For Major Bridge at KM 4+547 PDFmrinal kayalNo ratings yet

- Beam Design and Vibration AnalysisDocument9 pagesBeam Design and Vibration AnalysisjatinNo ratings yet

- IRC Class A and 70R Bending Moment CalculationDocument15 pagesIRC Class A and 70R Bending Moment CalculationTashi TamangNo ratings yet

- r0 - Design - Nncs Del Deh Lvup CH 105+450 1x12x4Document47 pagesr0 - Design - Nncs Del Deh Lvup CH 105+450 1x12x4Muzzammil ShaikhNo ratings yet

- Analysis and Design of Abutment.Document18 pagesAnalysis and Design of Abutment.rakesh yadavNo ratings yet

- Design of Retaining WallDocument5 pagesDesign of Retaining WallRektorUnitelNo ratings yet

- IS 1343 Bursting and bearing reinforcement calculationsDocument2 pagesIS 1343 Bursting and bearing reinforcement calculationsArun KumarNo ratings yet

- Modified RCL Design InputDocument21 pagesModified RCL Design Inputyasaswini veeramalluNo ratings yet

- OHT DesignDocument55 pagesOHT Designdheeraj tiwariNo ratings yet

- Well Cap Design at Pier LocationDocument4 pagesWell Cap Design at Pier LocationkailashaharNo ratings yet

- Calculation of Reactions & Horizontal Loads For Pot-Ptfe BearingsDocument12 pagesCalculation of Reactions & Horizontal Loads For Pot-Ptfe BearingsVenkat PalliNo ratings yet

- Bolted ConnectionsDocument1 pageBolted ConnectionsManju BirjeNo ratings yet

- Mass CC Return 2m0.500Document120 pagesMass CC Return 2m0.500Amit SinghNo ratings yet

- Part 3 Abut - Well Foundation DesignDocument46 pagesPart 3 Abut - Well Foundation Designshashi rajhansNo ratings yet

- Prof Ashok Jain - Example On Bi-Axial Bending IRC SP 114-App A3Document10 pagesProf Ashok Jain - Example On Bi-Axial Bending IRC SP 114-App A3Ankit GuptaNo ratings yet

- Load calculation and section properties for ROB designDocument121 pagesLoad calculation and section properties for ROB designEr Navneet JassiNo ratings yet

- IsDocument2 pagesIsvishnumani3011No ratings yet

- Solid Slab - 10m.Document8 pagesSolid Slab - 10m.Aditya JoshiNo ratings yet

- Comment - Draft - Comp Girder-26.34-R6Document61 pagesComment - Draft - Comp Girder-26.34-R6Nilay GandhiNo ratings yet

- Design of Square Footing For A Recta Sloped Footing: Check For Development LengthDocument44 pagesDesign of Square Footing For A Recta Sloped Footing: Check For Development LengthSwarna LathaNo ratings yet

- Design of POT-PTFE (Fixed)Document8 pagesDesign of POT-PTFE (Fixed)NONGTHONNo ratings yet

- Bracket DesignDocument4 pagesBracket DesignAnonymous JUn5jis0No ratings yet

- Kışladağ Silo Hesap RaporuDocument14 pagesKışladağ Silo Hesap RaporuBllbyk BykNo ratings yet

- Time Sheet Format AprilDocument16 pagesTime Sheet Format AprilGaurav PatilNo ratings yet

- 1992-2850KN S (TYPE - A1) ANTI UPLIFT ARRANGEMENT1-ModelDocument1 page1992-2850KN S (TYPE - A1) ANTI UPLIFT ARRANGEMENT1-ModelGaurav PatilNo ratings yet

- 2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementDocument9 pages2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementGaurav PatilNo ratings yet

- 2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementDocument9 pages2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementGaurav PatilNo ratings yet

- Structural Calculations For Timber Canopy With Gable RoofDocument18 pagesStructural Calculations For Timber Canopy With Gable RoofConrad Harrison100% (1)

- Transient Dynamics of Laminated Beams, An Evaluation With A Higher-Order Refined TheoryDocument11 pagesTransient Dynamics of Laminated Beams, An Evaluation With A Higher-Order Refined TheoryFAIZNo ratings yet

- Chapter 6 Applied StabilityDocument59 pagesChapter 6 Applied StabilitytimsykiNo ratings yet

- Design of Movable BridgesDocument22 pagesDesign of Movable BridgesNandeesha RameshNo ratings yet

- SAGE Profile V6.3.2 User Manual - Volume 3Document55 pagesSAGE Profile V6.3.2 User Manual - Volume 3GodwinNo ratings yet

- Applyingcodes BDocument99 pagesApplyingcodes BsppatilNo ratings yet

- Steel and Timber Structures Part Two:: Design of Structural Steel MembersDocument51 pagesSteel and Timber Structures Part Two:: Design of Structural Steel MembersDhinesh KalaimaranNo ratings yet

- Course Plan Steel StructureDocument7 pagesCourse Plan Steel StructureNabin Chandra SharmaNo ratings yet

- SPE Paper References for Torque, Drag, Buckling, BendingDocument4 pagesSPE Paper References for Torque, Drag, Buckling, BendingjamartiNo ratings yet

- NAPD 051 Exercises EditedDocument9 pagesNAPD 051 Exercises Editedlwinmoethu18No ratings yet

- Dcs 2 PutDocument2 pagesDcs 2 Putmaniram7No ratings yet

- Steel Design Flowcharts: Read Chapter 2 of Aisc For General InformationDocument70 pagesSteel Design Flowcharts: Read Chapter 2 of Aisc For General InformationNathaniela LoretoNo ratings yet

- Lehigh University Library Fritz Laboratory Reports - Shear Strength of Plate GirdersDocument62 pagesLehigh University Library Fritz Laboratory Reports - Shear Strength of Plate GirdersMaria FabianaNo ratings yet

- Developments of Morden Timber Structures - Timber in ConstructionDocument22 pagesDevelopments of Morden Timber Structures - Timber in ConstructionPapa ConfiNo ratings yet

- 19ME411Document17 pages19ME411Aravind KumarNo ratings yet

- VB AaDocument17 pagesVB AaIsmahene SmahenoNo ratings yet

- Design of Steel Structures BS 5950: Eng. Chamara Yapa Arachchi Civil EngineerDocument60 pagesDesign of Steel Structures BS 5950: Eng. Chamara Yapa Arachchi Civil Engineerpareen9No ratings yet

- Design of CEP Pit Rev CDocument27 pagesDesign of CEP Pit Rev Cnajam ansariNo ratings yet

- Simple beam spreadsheetDocument65 pagesSimple beam spreadsheetKrishn DevNo ratings yet

- Finite Element Analysis of Frame With Soil Structure InteractionDocument5 pagesFinite Element Analysis of Frame With Soil Structure InteractionJaga ChNo ratings yet

- Quick-Connect Moment Connection: Technical Design Guide Issued by Forest and Wood Products AustraliaDocument28 pagesQuick-Connect Moment Connection: Technical Design Guide Issued by Forest and Wood Products AustraliaJoseph BookerNo ratings yet

- ERF 2016 37 H160 Thermoplastic RotorhubDocument9 pagesERF 2016 37 H160 Thermoplastic RotorhubHelimanualNo ratings yet

- Laminated Strip Under Three-Point BendingDocument6 pagesLaminated Strip Under Three-Point BendingDan WolfNo ratings yet

- RahemiDocument113 pagesRahemiDani SantosNo ratings yet

- GTG Beam Formwork DesignDocument32 pagesGTG Beam Formwork DesignshihabNo ratings yet

- Behavior of Members Subjected To Axial LoadsDocument21 pagesBehavior of Members Subjected To Axial LoadsAhmad Faraz JuttNo ratings yet

- 07 Design of Guideways (Cont.) and Machine Tool FrameDocument37 pages07 Design of Guideways (Cont.) and Machine Tool FrameKareem MahdyNo ratings yet

- ConcreteCodeCheck15 EN1992 EnuDocument644 pagesConcreteCodeCheck15 EN1992 EnuSean CassarNo ratings yet

- Structural Analysis-II - WWW - Rgpvnotes.inDocument11 pagesStructural Analysis-II - WWW - Rgpvnotes.inDenish GondudeNo ratings yet

- DNV RP C104Document86 pagesDNV RP C104Maremagnum3No ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Waves and Beaches: The Powerful Dynamics of Sea and CoastFrom EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastRating: 4 out of 5 stars4/5 (1)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- Three Laws of Nature: A Little Book on ThermodynamicsFrom EverandThree Laws of Nature: A Little Book on ThermodynamicsRating: 4.5 out of 5 stars4.5/5 (10)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet