Professional Documents

Culture Documents

CRS For 200063-PMC-SJV-00720 - Lube Oil Flushing Procedure - Rev.B - 30 of July '19

Uploaded by

Yusuf0 ratings0% found this document useful (0 votes)

7 views4 pagesOriginal Title

CRS for 200063-PMC-SJV-00720_Lube Oil Flushing Procedure_Rev.B_30 of July '19

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views4 pagesCRS For 200063-PMC-SJV-00720 - Lube Oil Flushing Procedure - Rev.B - 30 of July '19

Uploaded by

YusufCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 4

14th Floor, GRAN SEOUL Tower 1, 33, Jong-ro, Jongno-gu, Seoul, 110-130, Korea

Tel. +82-2-2158-6900

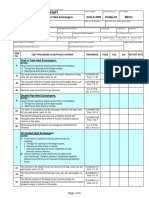

KARBALA REFINERY PROJECT

COMMENTS RESOLUTION SHEET

EMPLOYER Letter Ref. No. & Date 200063-PMC-SJV-00720 HDGSK Transmittal No. & Date KRP-T-CS-EH-1225-CM

2019-07-30 2019-07-22

Document No. & Rev. No. IONE-AA00-PE-CM-0031 & Rev. B Document Class Class 2

Document Description LUBE OIL PROCEDURE Discipline Code JV-CM

Reference/Page EMPLOYER / PMC

No. EMPLOYER / PMC COMMENTS HDGSK RESPONSES STATUS

no. RESPONSES

Contractor shall follow Manufacture’s AGREED CLOSED

requirement and Standars for Cleanliness of

Prior to flushing, Contractor to ensure

Lube/Seal Oil and Fuild Power Systems such

flushing procedure includes all the

1 as ISO 4406, NAS 1638, ISO 10438-1 and

Cleanliness Standard for Lube/Seal Oil and

SAE AS 4059 E. The cleaness standard will

Fluid Power Systems

be indicated in the individual method

statement.

14th Floor, GRAN SEOUL Tower 1, 33, Jong-ro, Jongno-gu, Seoul, 110-130, Korea

Tel. +82-2-2158-6900

Reference/Page EMPLOYER / PMC

No. EMPLOYER / PMC COMMENTS HDGSK RESPONSES STATUS

no. RESPONSES

Contractor to provide details of the methods Contractor will clean and dry the lube oil AGREED CLOSED

of it is necessary to clean a new lube/seal system by air blowing because there is no

oil or fluid power system initially by fouling in new equipmets. High velocity oil

mechanical cleaning; flushing, steam flushing is effective cleaning method to meet

cleaning, hot alkaline treatment, acid/EDTA Manufacture’s requirement.

cleaning, neutralization and passivation.

2 For some systems it may not be necessary

to use all of the above steps since the

degree of contamination will vary from unit

to unit. The exact procedure used for

cleaning to be determined by Contractor

and reviewed by Employer

Contractor has not included the responsible Contractor suggest that the degree fo

laboratory for verification degree of cleaniness of oil sample can be vefified by

cleanliness of oil sample certified particle counter.

13th Aug. 2019 Noted, the folling statement will be included in

3 NOT AGREED next revision.

INCLUDES LAB REFERENCE “The degree of cleanliness oil sample can be

verified by certified particle counter. For

reference purpose, one (1) bottle of sample might

be kept for Lab analysis in case of

Manufacturer’s requirement.”

Contractor to verify that Lube Oil Flushing Noted, This statement will be included in next AGREED CLOSED

is after cleaning and drying the system, revision

remove any temporary bypass connections

4 other than those bypassing bearings, seals

and gearboxes, and leave them in place

until flushing is completed

14th Floor, GRAN SEOUL Tower 1, 33, Jong-ro, Jongno-gu, Seoul, 110-130, Korea

Tel. +82-2-2158-6900

Reference/Page EMPLOYER / PMC

No. EMPLOYER / PMC COMMENTS HDGSK RESPONSES STATUS

no. RESPONSES

Contractor to provide specification of the Contractor will install the fine mesh (100 INCLUDE IN NEXT REVISION

inspection screens, including removal and mesh) on the return line to reservoir as

5 install new inspection screens in the lube described in 7.1.(h) and inspect it every 8

and seal oil return piping at the reservoir hours. Depend on cleanliness of systems the

flanges every 8 hours interval of inspection can be varied.

Contractor has not included the details of Flushing velocity will be 3 m/s as minimum. INCLUDE IN NEXT REVISION

6 the flushing velocity

Contractor to include the manufacturers Noted. This rquirement will be described in AGREED CLOSED

7 requirements / guidelines WMS for each lube oil flushing package.

Contractor to include actions to be taken if Contractor will check the dryness of system INCLUDE IN NEXT REVISION

8 water is detected due to incomplete drying prior to start lube oil flushing.

Contractor to include how the dislodge of Contractor will describe the metholodge to AGREED CLOSED

foreign bodies maybe achieved by thermal dislodge of foreign material in next revision.

9 shock, mechanical shock or hydraulic

shock

Contractor to include time period of flushing Contractor will inspect the mesh screen INCLUDE IN NEXT REVISION

and acceptance criteria as typically after every 8 hours. If visual inspection is satisfied,

10 approximately two days of flushing, perform Contractor will circulate the oil for 1 hour

an acceptance check to verify whether it before taking sample for acceptance check

meets the cleanliness requirements as per API 614

Preparation for serice is described in 7.4. AGREED CLOSED

The detailed information will be described in

Contractor to include full preparation for

WMS

11 service details and in event of delay the

If there is no planned activity, Contractor will

necessary lay up details

circulate the system bi-weekly for 1 hour for

preservation.

14th Floor, GRAN SEOUL Tower 1, 33, Jong-ro, Jongno-gu, Seoul, 110-130, Korea

Tel. +82-2-2158-6900

Reference/Page EMPLOYER / PMC

No. EMPLOYER / PMC COMMENTS HDGSK RESPONSES STATUS

no. RESPONSES

Contractor will prepare the spillage kit near INCLUDE IN NEXT REVISION

Contractor to include contingency plans for the working area and stop the activity until

12 andling leaks system is safe condition after rectifying the

problem.

Contractor will collect the used oil to waste INCLUDE IN NEXT REVISION

13 Contractor to include waste disposal plans collection drum and it will be disposed

according to waste disposal regulation.

Lube oil System details to be submitted for Contractor will submit the package for review AGREED CLOSE

review to include; location, fill volume, as described in 6.1 and the detailed

materials of construction, components information and procedure will be sumbmitted

14 isolated, blinded, plugged, or removed, by WMS.

instruments, filters, tanks. Contaminant

composition and solubility in the proposed

acid solution

You might also like

- 72.00.00 Engine - Inspection - CheckDocument83 pages72.00.00 Engine - Inspection - CheckTimoteo Molina RomeroNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Misting Properties of Lubricating Fluids: Standard Test Method ForDocument7 pagesMisting Properties of Lubricating Fluids: Standard Test Method ForBlack MambaNo ratings yet

- Kuwait National Petroleum Company (K.S.C) Clean Fuels Project (CFP) KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025Document4 pagesKuwait National Petroleum Company (K.S.C) Clean Fuels Project (CFP) KNPC Contract No. CFP/EPC/0054-MAB1 PSCJ Job No. JI-2025arun kumarNo ratings yet

- In-Service Monitoring of Mineral Turbine Oils For Steam, Gas, and Combined Cycle TurbinesDocument19 pagesIn-Service Monitoring of Mineral Turbine Oils For Steam, Gas, and Combined Cycle TurbinesEhsan ZiaeiNo ratings yet

- Rev 01 Mud Gas Separator of Oil ServiceDocument3 pagesRev 01 Mud Gas Separator of Oil ServiceKanti LakhankarNo ratings yet

- Air Release Properties of Hydrocarbon Based Oils: Standard Test Method ForDocument6 pagesAir Release Properties of Hydrocarbon Based Oils: Standard Test Method ForTarlan AllahverdiyevNo ratings yet

- Air Leak TestingDocument5 pagesAir Leak TestingsarikaNo ratings yet

- Specification For Smoke Bomb Test PDFDocument4 pagesSpecification For Smoke Bomb Test PDFganis supriadiNo ratings yet

- D 3427 - 02 - Rdm0mjctmdiDocument5 pagesD 3427 - 02 - Rdm0mjctmdiLea CoriaNo ratings yet

- Engine - Inspection - CheckDocument2 pagesEngine - Inspection - CheckSECCION TECNICANo ratings yet

- Oil Leak Test ProcedureDocument5 pagesOil Leak Test ProcedurekumaraguruNo ratings yet

- Draft OGN-OPS-CHEM-021 Rev. 0 On Examination and Maintenance of Lub Oils of Turbine and Boiler Feed PumpDocument17 pagesDraft OGN-OPS-CHEM-021 Rev. 0 On Examination and Maintenance of Lub Oils of Turbine and Boiler Feed Pumppraveen singhNo ratings yet

- Astm D4378-22Document19 pagesAstm D4378-22Hani YilmazNo ratings yet

- Engine, Turboprop - InspectionDocument5 pagesEngine, Turboprop - InspectionSECCION TECNICANo ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- Attachment A - Scope of WorkDocument7 pagesAttachment A - Scope of WorkMazhar MahadzirNo ratings yet

- Functional Specifications FOR Test Separation Module: Onshore Engg Services, N Delhi Document No.: OESG/ARP/TSP/M002 REVDocument18 pagesFunctional Specifications FOR Test Separation Module: Onshore Engg Services, N Delhi Document No.: OESG/ARP/TSP/M002 REVAnonymous O0lyGOShYGNo ratings yet

- Astm D6439 11Document18 pagesAstm D6439 11RoobinRZamir100% (4)

- Norma D4378-03 Monitoreo AceitesDocument11 pagesNorma D4378-03 Monitoreo AceitesSebastian DimianNo ratings yet

- Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument19 pagesSaudi Arabian Oil Company (Saudi Aramco) General Instruction ManualEagle SpiritNo ratings yet

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument17 pagesContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualAldrien CabinteNo ratings yet

- Prueba de Dilucion de CombustibleDocument10 pagesPrueba de Dilucion de CombustibleGalo OrralaNo ratings yet

- Saic e 2010Document3 pagesSaic e 2010sureshNo ratings yet

- EU-GMP Guideline Particle CoutingDocument7 pagesEU-GMP Guideline Particle Coutingabhishek bhowmikNo ratings yet

- ASTM D3427-03 - Air Release ValueDocument5 pagesASTM D3427-03 - Air Release ValueDr. Minhaj Uddin MonirNo ratings yet

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechDocument3 pagesSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominNo ratings yet

- Technical Information Letter: Evaporative Cooler Commissioning ProcedureDocument2 pagesTechnical Information Letter: Evaporative Cooler Commissioning ProcedureChidiebere Samuel OkogwuNo ratings yet

- Rotork Manual Operacion Actuador GO PDFDocument13 pagesRotork Manual Operacion Actuador GO PDFmilecsa100% (1)

- 26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air SystemDocument5 pages26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air Systemankarao69No ratings yet

- Ms For Hyrdo Pneumatic Testing of Spherical TANKS (730-TK-03 A/B & C) A-CON-PRO-730-38939Document15 pagesMs For Hyrdo Pneumatic Testing of Spherical TANKS (730-TK-03 A/B & C) A-CON-PRO-730-38939Ramzi ZoghlamiNo ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 Mechkarthi51289No ratings yet

- SAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesDocument6 pagesSAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesAhdal NoushadNo ratings yet

- MRS MaintenanceDocument15 pagesMRS MaintenanceDevang PatelNo ratings yet

- P-005 Liquid Penetant Testing ProcedureDocument13 pagesP-005 Liquid Penetant Testing ProcedureSaheb YadavNo ratings yet

- Seal Oil SystemDocument22 pagesSeal Oil SystemRaja VigneshNo ratings yet

- AC7114-1S Rev L 3Document34 pagesAC7114-1S Rev L 3Przemyslaw100% (1)

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282Document11 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282benchinounNo ratings yet

- PRES-E-03 Electrical Equipment - Motor & GeneratorDocument2 pagesPRES-E-03 Electrical Equipment - Motor & GeneratorsalamlinNo ratings yet

- SAIC-A-2023 Rev 6 Prssure Test Air GasDocument5 pagesSAIC-A-2023 Rev 6 Prssure Test Air Gaspookkoya thangalNo ratings yet

- ASTM D-6224-9 Aux Oil Analysis Power PlantDocument15 pagesASTM D-6224-9 Aux Oil Analysis Power Plantridhal fauzanNo ratings yet

- Oil Flushing of Rotating EquipmentDocument9 pagesOil Flushing of Rotating Equipmentsrigirisetty208No ratings yet

- In-Service Monitoring of Lubricating Oil For Auxiliary Power Plant EquipmentDocument20 pagesIn-Service Monitoring of Lubricating Oil For Auxiliary Power Plant Equipmentمحمد نصیریNo ratings yet

- SAIC-E-2009 Intrnal Cleanliness Insp of HEDocument2 pagesSAIC-E-2009 Intrnal Cleanliness Insp of HEAnonymous S9qBDVkyNo ratings yet

- Repair Standards For Aero and Industrial Turbine BladesDocument6 pagesRepair Standards For Aero and Industrial Turbine BladesStanislav Work accountNo ratings yet

- MDBFP Oil FlushingDocument13 pagesMDBFP Oil Flushingsrigirisetty208No ratings yet

- SCTPL Q SP 002 A1 Vaccum Box Testing ProcedureDocument6 pagesSCTPL Q SP 002 A1 Vaccum Box Testing ProcedureKandula Raju100% (1)

- SAIC-L-2095 Rev 7Document6 pagesSAIC-L-2095 Rev 7Jaseel KanhirathingalNo ratings yet

- BMCR CommentDocument2 pagesBMCR CommentAkhmad SyukrieNo ratings yet

- Caltex Regal Ro 46Document3 pagesCaltex Regal Ro 46HyungTae JangNo ratings yet

- Maintenance Manual - Actuator PDFDocument9 pagesMaintenance Manual - Actuator PDFParag PadoleNo ratings yet

- Evaluating and Qualifying Oil Field and Refinery Corrosion Inhibitors Using Rotating CageDocument6 pagesEvaluating and Qualifying Oil Field and Refinery Corrosion Inhibitors Using Rotating CageNav Talukdar100% (1)

- Ahu Operation Qualification DocumentDocument21 pagesAhu Operation Qualification DocumentRamakrishna Agumbe100% (9)

- Leakage Test Procedure For Crude Oil Storage Tank: (Arial 12)Document6 pagesLeakage Test Procedure For Crude Oil Storage Tank: (Arial 12)Ahmad MohammadNo ratings yet

- Procedure - 3lpe - Msl-Rev.00Document15 pagesProcedure - 3lpe - Msl-Rev.00Suresh KrishnanNo ratings yet

- Repair Manual Cummins ISX QSX15Document16 pagesRepair Manual Cummins ISX QSX15angel017100% (2)

- 3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommDocument10 pages3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommNishit KhuntNo ratings yet

- Norgren - Guide To Clean Compressed AirDocument24 pagesNorgren - Guide To Clean Compressed AirYongWei-Jin100% (1)

- T 375R3Document3 pagesT 375R3조준장No ratings yet

- 2 - Underground Sewers and PipingDocument7 pages2 - Underground Sewers and PipingYusufNo ratings yet

- 2 - Pipe Priming, Coating & WrappingDocument2 pages2 - Pipe Priming, Coating & WrappingYusufNo ratings yet

- f202 - Field Engineering Duties and ResponsibilitiesDocument6 pagesf202 - Field Engineering Duties and ResponsibilitiesYusufNo ratings yet

- Smooth Bore Cargo and Submarine Hose, 275 Psi MWP-MSDocument18 pagesSmooth Bore Cargo and Submarine Hose, 275 Psi MWP-MSYusufNo ratings yet

- 1 - Underground Piping InstallationDocument6 pages1 - Underground Piping InstallationYusufNo ratings yet

- Field Hydrostatic Testing of Piping Systems-EGDocument9 pagesField Hydrostatic Testing of Piping Systems-EGYusufNo ratings yet

- Pneumatic Test CalculationDocument23 pagesPneumatic Test CalculationYusufNo ratings yet

- 211-04a - CONTROL OF INSPECTION, MEASURINGDocument7 pages211-04a - CONTROL OF INSPECTION, MEASURINGYusufNo ratings yet

- 216-05 - Control of Quality RecordsDocument8 pages216-05 - Control of Quality RecordsYusufNo ratings yet

- Smooth Bore Cargo and Submarine Hose, 275 Psi MWP-EGDocument19 pagesSmooth Bore Cargo and Submarine Hose, 275 Psi MWP-EGYusufNo ratings yet

- Stainless Steel Piping Fabrication-EGDocument8 pagesStainless Steel Piping Fabrication-EGYusufNo ratings yet

- 212-04a - INSPECTION AND TEST STATUSDocument5 pages212-04a - INSPECTION AND TEST STATUSYusufNo ratings yet

- 207-04a - Control of Customer Supplied MaterialsDocument7 pages207-04a - Control of Customer Supplied MaterialsYusufNo ratings yet

- 203-04a - PROJECT COST CONTROL AND PLANNINGDocument12 pages203-04a - PROJECT COST CONTROL AND PLANNINGYusufNo ratings yet

- 220-04a - STATISTICAL TECHNIQUESDocument6 pages220-04a - STATISTICAL TECHNIQUESYusufNo ratings yet

- 210-05 - Inspection and TestingDocument13 pages210-05 - Inspection and TestingYusufNo ratings yet

- 221-03a - HANDLING CUSTOMER COMPLAINTSDocument5 pages221-03a - HANDLING CUSTOMER COMPLAINTSYusufNo ratings yet

- 306-1 - Internal Quality AuditsDocument17 pages306-1 - Internal Quality AuditsYusufNo ratings yet

- Document and Data ControlDocument8 pagesDocument and Data ControlYusufNo ratings yet

- Design ControlDocument16 pagesDesign ControlYusufNo ratings yet

- 204-05 - Design ControlDocument18 pages204-05 - Design ControlYusufNo ratings yet

- 202-05 - Response To EnquiriesDocument9 pages202-05 - Response To EnquiriesYusufNo ratings yet

- 206-05 - ProcurementDocument10 pages206-05 - ProcurementYusufNo ratings yet

- CP - 107 - Reporting-Investigating Near Miss IncidentsDocument7 pagesCP - 107 - Reporting-Investigating Near Miss IncidentsYusufNo ratings yet

- 205-04a - DOCUMENT AND DATA CONTROLDocument14 pages205-04a - DOCUMENT AND DATA CONTROLYusufNo ratings yet

- CP - 110 - Back Injury PreventionDocument8 pagesCP - 110 - Back Injury PreventionYusufNo ratings yet

- CP - 109 - Safe Work Obsevation ProcessDocument8 pagesCP - 109 - Safe Work Obsevation ProcessYusufNo ratings yet

- CP - 105 - Safety Task Analysis-Job Hazard AnalysisDocument10 pagesCP - 105 - Safety Task Analysis-Job Hazard AnalysisYusufNo ratings yet

- CP - 108 - Incident Investigation and NotificationDocument15 pagesCP - 108 - Incident Investigation and NotificationYusufNo ratings yet

- CP - 111 - Environmental, Safety and Health AssessmentsDocument10 pagesCP - 111 - Environmental, Safety and Health AssessmentsYusufNo ratings yet

- SFNHS - Extension's School Learning Continuity PlanDocument5 pagesSFNHS - Extension's School Learning Continuity PlanClaudie MabiniNo ratings yet

- Full Download Book Breastfeeding A Guide For The Medical Professional PDFDocument41 pagesFull Download Book Breastfeeding A Guide For The Medical Professional PDFgeorge.pittman905100% (14)

- Different Perspectives in PsychologyDocument23 pagesDifferent Perspectives in PsychologyChicki ChandwaniNo ratings yet

- Respiratory Module 4 8Document11 pagesRespiratory Module 4 8David Dwane Art SilorioNo ratings yet

- Prevalence of Maxillary Sinus Septa: Systematic Review and Meta-AnalysisDocument9 pagesPrevalence of Maxillary Sinus Septa: Systematic Review and Meta-AnalysisDennis DinellyNo ratings yet

- Akkermansia Wikipedia Page Safari - Sep 18 2022Document1 pageAkkermansia Wikipedia Page Safari - Sep 18 2022Rodrigo FerreiraNo ratings yet

- Successes and Lessons of Be LCP ImplementationDocument5 pagesSuccesses and Lessons of Be LCP ImplementationMariaemmacaridad Abu TenorioNo ratings yet

- Scientific Method BeriberiDocument4 pagesScientific Method BeriberiadelavazNo ratings yet

- New Mexico MPJE Study Guide (Master Exam)Document30 pagesNew Mexico MPJE Study Guide (Master Exam)Chinhui Dang100% (12)

- What Is XBX?: Same Order, and in The Same Maximum Time LimitDocument2 pagesWhat Is XBX?: Same Order, and in The Same Maximum Time LimitMohammad IslamNo ratings yet

- Department of Radiology: Ultrasound - Whole AbdomenDocument2 pagesDepartment of Radiology: Ultrasound - Whole AbdomenLeoThomasNo ratings yet

- Scope of Endodontics: Regenerative Endodontics: AAE Position StatementDocument3 pagesScope of Endodontics: Regenerative Endodontics: AAE Position StatementPuneet ChahalNo ratings yet

- Metabolic Dysregulation: America's Got Side EffectsDocument28 pagesMetabolic Dysregulation: America's Got Side EffectsNaiana PaulaNo ratings yet

- Introduction To Survey Methods: Prof. Dr. John T. ArokiasamyDocument41 pagesIntroduction To Survey Methods: Prof. Dr. John T. ArokiasamyThulasi tootsieNo ratings yet

- Outcome of Crown and Root Resection: A Systematic Review and Meta-Analysis of The LiteratureDocument14 pagesOutcome of Crown and Root Resection: A Systematic Review and Meta-Analysis of The LiteratureLorenaCastanoGarzonNo ratings yet

- Southern Samar National Comprehensive High SchoolDocument2 pagesSouthern Samar National Comprehensive High SchoolGerlie E. BaselidesNo ratings yet

- Wiring A Web For Global GoodDocument2 pagesWiring A Web For Global GoodRessie Joy Catherine FelicesNo ratings yet

- Rule V - Operations and Structure of BucorDocument52 pagesRule V - Operations and Structure of BucorAlper PugoyNo ratings yet

- Hpe Unit Plan Year 8 NetballDocument11 pagesHpe Unit Plan Year 8 Netballapi-518408081No ratings yet

- Abortion - A Philosophical Perspective: OpsommingDocument7 pagesAbortion - A Philosophical Perspective: OpsommingGeorge RaresNo ratings yet

- Kindergarten Communication of Learning - OntarioDocument4 pagesKindergarten Communication of Learning - OntarioAngela JainNo ratings yet

- My Personal Stress Plan: Part 1: Tackling The ProblemDocument4 pagesMy Personal Stress Plan: Part 1: Tackling The ProblemLark SantiagoNo ratings yet

- LGBTQIA+ Rights Are Human RightsDocument13 pagesLGBTQIA+ Rights Are Human RightsI'm World Wide Handsome u know??No ratings yet

- Common Errors-1Document12 pagesCommon Errors-1Sama N SamirNo ratings yet

- Welding and Gas CuttingDocument9 pagesWelding and Gas CuttingSandeep KumarNo ratings yet

- P-17C, Hagkol, Valencia City, Bukidnon SCHOOL ID NO: 405069 MB NO. 09972661592Document33 pagesP-17C, Hagkol, Valencia City, Bukidnon SCHOOL ID NO: 405069 MB NO. 09972661592Regina Minguez SabanalNo ratings yet

- Y2 Iw ZJ M2 MTHH NTUw Mjgy MJ Y0 ZJ VH NDG 2 OTFi MWVi NWMX MGE4 NDDH NQDocument4 pagesY2 Iw ZJ M2 MTHH NTUw Mjgy MJ Y0 ZJ VH NDG 2 OTFi MWVi NWMX MGE4 NDDH NQLouis HutahaeanNo ratings yet

- Health: Quarter 1 - Module 4 Consumer HealthDocument18 pagesHealth: Quarter 1 - Module 4 Consumer HealthKen FerdinandNo ratings yet

- LESSON PLAN Health Lesson PlanDocument2 pagesLESSON PLAN Health Lesson PlanSusie Hauchab ChalitaNo ratings yet

- Atenolol Oral Suspension 2mg/mLDocument1 pageAtenolol Oral Suspension 2mg/mLChemistixNo ratings yet