Professional Documents

Culture Documents

Driving Session Plan

Uploaded by

Erickson Songcal0 ratings0% found this document useful (0 votes)

52 views14 pagesOriginal Title

driving session plan

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

52 views14 pagesDriving Session Plan

Uploaded by

Erickson SongcalCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 14

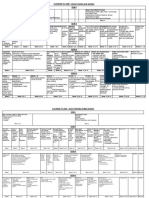

TRAINING PLAN

SHIELDED METAL ARC WELDING NC II

Unit of Competency: WELD CARBON STEEL PLATES

MODULE TITLE : PERFORMING GROOVE WELDING ON CARBON STEEL PLATES

MODALITY : FACE TO FACE LEARNING

Learning Outcome Assessment Criteria Learning Content

ASSESSMENT

CORE CONTENT CONDITIONS METHODOLOGY

METHOD

LO 1 Weld carbon 1. Root penetration Essential The student/trainee Face-to-Face:

steel plates in not exceeding s of welding must be provided with Lecture Written/oral

flat position (1G) allowable the following:

tolerances Internati 1. Equipment Demonstration Interview

specified by onal welding -Welding machine

welding codes/ codes and (AC or AC/DC) Dualized Direct

standards on standards -Welding table or jig observation

conc -Portable grinder Self-paced

avity Accepta -Welding booth learning

conv ble weld profiles -Portable oven

exity

unde Weld 2.Tools/Accessories

rcut defects, causes -Welding mask

exce and remedies -Steel brush

ss penetration -Clear glass

LO 2. Weld carbon

lack Welding -Chipping hammer

steel plates in

of fusion Procedure -Dark glass

horizontal

burn- Specifications

position (2G)

through (WPS) 3. Supplies/ Materials

crack -Electrodes

s -Carbon steel plates

2. Weld capping/ -Cutting grinding

final pass not disk

exceeding

allowable

tolerances

specified by

welding codes/

standards on:

Learning Outcome Assessment Criteria Learning Content

ASSESSEMENT

CORE CONTENT CONDITIONS METHODOLOGY

METHOD

LO3. Weld carbon heigh Welding 4. Personal protective

steel plates in t of techniques and equipment

vertical position reinforcement procedures - Safety shoes

(3G) unde - Apron

rfill Safe - Leggings

poro welding practices - Safety goggles

sities - Gloves

unde

rcut 5. Training Materials

crack - Arc welding

s manuals

LO4. Weld carbon cold -Welding procedures

steel plates in laps specifications (WPS)

overhead 3. Uniformity of bead -Welding standards

position (4G) ripples must be in

accordance with

welding standards

4. Stringer or layered

beads deposited

in accordance with

welding standards

5. Finish weldment

visually

acceptable in

accordance with

welding standards

for:

spatt

ers

arc

strikes

slag

unifo

rmity of beads

Learning Outcome Assessment Criteria Learning Content

TECHNOLOGY SCIENCE MATH COMM

Familiarization on

work

equipment

function

Familiarization on

operator’s

compartment

Familiarization on

controls, levers

and pedals

LO5. Check safety 1. Backhoe Loader General Identify health-

devices and Safety devices precaution and related problems,

accessories are checked for safety procedures which may result

functionality Familiarization from exposure

according safety on safety levers to work related

regulation and controls chemicals and

2. Personal safety hazardous

devices are materials, and

checked in know the

accordance with proper precautions

OHS procedure, required for

handling such

materials.

Learning Outcome Assessment Criteria Learning Content

TECHNOLOGY SCIENCE MATH COMM

LO6. Perform post- 1. Perfor Proper Shutdown Prepare daily

operation med post Procedures equipment time

procedures. operation check Safe Parking record report

based on Procedures

standard Vandalism

procedures. Prevention

2. Accom

plished Daily

Equipment Time

Record/Report

(DETR) in line

with company

rules and policy.

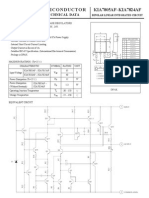

Units Of Competency : WELD CARBON STEEL PIPE

Module Title : PERFORMING GROOVE WELDING ON CARBON STEEL PIPES

MODALITY : FACE TO FACE LEARNING

Learning Outcome Assessment Criteria Learning Content

ASSESSMENT

CORE CONTENT CONDITIONS METHODOLOGY

METHODS

LO1. Weld carbon 1. Root Essenti The student/trainee Face-to-Face: Written/oral

steel pipes in penetration not als of welding must be provided with Lecture

horizontal exceeding the following: Interview

position (2G) allowable Internati 1. Equipment Demonstration

tolerances onal welding -Welding machine Direct

specified by codes and (AC or AC/DC) Dualized observation

welding codes/ standards -Welding table or jig

standards on: -Portable grinder Self-paced

conc Accepta -Welding booth learning

avity ble weld profiles -Portable oven

conv

exity Weld 2.Tools/Accessories

unde defects, causes -Welding mask

rcut and remedies -Steel brush

exce -Clear glass

ss penetration Welding -Chipping hammer

lack Procedure -Dark glass

LO 2. Weld carbon of fusion Specifications

steel pipes in burn- (WPS) 3. Supplies/ Materials

Fixed pipe through -Electrodes

horizontal crac -Carbon steel plates

position (5G) ks -Cutting grinding

disk

2. Weld

capping/ final pass

not exceeding

allowable

tolerances specified

by welding codes/

standards on:

Learning Outcome Assessment Criteria Learning Content

ASSESSMENT

CORE CONTENT CONDITIONS METHODOLOGY

METHODS

heig 4. Personal protective

LO 3. Weld carbon ht of equipment

steel pipes in reinforcement - Safety shoes

fixed pipe, unde - Apron

inclined at 45 rfill - Leggings

position (6G) poro - Safety goggles

sities - Gloves

unde

rcut 5. Training Materials

crac - Arc welding

ks manuals

cold -Welding procedures

laps specifications (WPS)

6. Uniformity of bead -Welding standards

ripples must be in

accordance with

welding standards

7. Stringer or layered

beads deposited

in accordance

with welding

standards

8. Finish weldment

visually

acceptable in

accordance with

welding standards

for:

spatt

ers

arc

strikes

slag

unifo

rmity of beads

UNITS OF COMPETENCY : PERFORM BACKHOE LOADER OPERATION

MODULE TITLE : Performing Backhoe Loader Operation

Learning Outcome Assessment Criteria Learning Content

TECHNOLOGY SCIENCE MATH COMM

LO 1. Perform 1. Low bed trailer for Safety Jobsite

loading and transporting the practices on conditions

unloading of Backhoe Loader are loading and

Backhoe considered according unloading

Loader to to equipment procedures

and from specification. Proper tie-

truck/trailer 2. Coordination and down

(low bed). communication are procedures of

maintained with the

authorized signalman equipment

while Observation

loading/unloading. of company

3. Backhoe Loader is rules and

loaded/unloaded regulations

using adequate ramp General

based on safe Precautions

operating procedures. and safety

4. All safety locks and Traveling

controls are secured procedures

based on operations Productive

and maintenance operation

manual. procedures

5. Rested bucket

properly based on

safe work procedure

(Loaded).

6. Tracks (UC) or

wheels are secured

with stopper blocks

and binders (loaded).

Learning Outcome Assessment Criteria Learning Content

TECHNOLOGY SCIENCE MATH COMM

7. Control and brakes

are checked in line

with safety

procedures prior to

starting,

loading/unloading

the machine from

the low bed trailer.

8. Stopper blocks and

binder are removed

prior to unloading of

the machine.

9. Bucket is raised

based on safe

unloading

procedures.

10. Responded to

unexpected

situations in line with

company rules and

regulation in a

manner that

minimizes risks to

personnel and

equipment.

Learning Outcome Assessment Criteria Learning Content

TECHNOLOGY SCIENCE MATH COMM

LO2. Travel the 1. Work area for Jobsite

Backhoe Loader. accessibility is inspection

surveyed for potential General

hazards in accordance Precautions

with safe operating Traveling

procedures. procedures

2. Boom/arm angle

position is maintained

in accordance with

traveling procedures.

3. Sprocket wheels are

positioned according to

correct traveling

posture.

4. Maintained bucket to

ground clearance in

accordance with safety

standards.

5. Travel speed is

observed with or

without load according

to safety standards.

6. Responded to

unexpected situations

in line with company

rules and regulation in

a manner that

minimizes risks to

personnel and

equipment.

Learning Outcome Assessment Criteria Learning Content

TECHNOLOGY SCIENCE MATH COMM

LO3. Perform 1. Bucket clearance is Solve problems Company rules

Backhoe maintained based on General for volume, and regulations

Loader recommended height Precautions weight, area,

operations above ground during and safety circumference

transport of materials Jobsite and

according to safe conditions perimeter

operating Productive measurements

procedures. operation for rectangles,

2. Load is carried out techniques squares, and

within bucket and cylinders.

capacity according to procedures :

manufacturer’s o stockpiling

performance o bench clearing

specifications. o Load and carry

3. Machine travel and o Spreading

engine speed is

o Loading

controlled during

travel with load in o Lifting

accordance with work

area condition.

4. Loading operation to

dump truck is

performed according

to safe operating

procedure

5. Ground is checked

and cleared of

obstructions as per

standard operating

procedures

Learning Outcome Assessment Criteria Learning Content

TECHNOLOGY SCIENCE MATH COMM

6. Materials are scoped in

accordance to safe

operating procedure.

7. Struck, penetrated and

lifted materials are in

accordance with

recommended bucket

application/positioning

procedures.

8. Materials are loaded

into dump truck in

accordance with the

recommended dump

truck loading

procedures.

9. Stockpiling operation is

performed according to

safe operating

procedure

10. Unexpected situations

are responded to in line

with company rules

and regulations.

You might also like

- MODULES OF INSTRUCTION Coresmawnc1Document16 pagesMODULES OF INSTRUCTION Coresmawnc1KaJong JaclaNo ratings yet

- CBC Smaw PipeDocument10 pagesCBC Smaw PipeYuriiNo ratings yet

- CBC - GmawDocument22 pagesCBC - GmawPrances PelobelloNo ratings yet

- CBLM SmawDocument71 pagesCBLM SmawJoven Roque100% (2)

- CBLM Core Smaw nc1Document57 pagesCBLM Core Smaw nc1MANPOWER ORMOC100% (5)

- CBLMDocument11 pagesCBLMfred gallardoNo ratings yet

- CBLM For SMAW DondonDocument148 pagesCBLM For SMAW DondonRomeo Espinosa Carmona Jr100% (3)

- CBLMDocument32 pagesCBLMYamgnod Mariuz Jr.No ratings yet

- fnlSESSION PLAN 2-GDocument3 pagesfnlSESSION PLAN 2-GButz GhanulNo ratings yet

- SMAW NC I CBLM CoreDocument146 pagesSMAW NC I CBLM CoreSeniorito Louiesito100% (2)

- Tle - Iaaw11Fw-Ia-Iij-3: K To 12 TVL Track Industrial Arts - Shielded Metal Arc Welding Curriculum Guide December 2013Document9 pagesTle - Iaaw11Fw-Ia-Iij-3: K To 12 TVL Track Industrial Arts - Shielded Metal Arc Welding Curriculum Guide December 2013Jymaer GeromoNo ratings yet

- K to 12 SMAW CurriculumDocument9 pagesK to 12 SMAW Curriculumcath borja0% (1)

- UNIT OF COMPETENCY: Weld Carbon Steel Plates MODULE TITLE: Performing Groove Welding On Carbon Steel PlatesDocument152 pagesUNIT OF COMPETENCY: Weld Carbon Steel Plates MODULE TITLE: Performing Groove Welding On Carbon Steel PlatesNaive Eilevor100% (2)

- Corse Flow - 1Document2 pagesCorse Flow - 1ASHVIN YADAVNo ratings yet

- Shield Metal Arc Welding Training MatrixDocument4 pagesShield Metal Arc Welding Training MatrixNell Sabas AdolfoNo ratings yet

- Cblm-Smaw-Nc IiDocument80 pagesCblm-Smaw-Nc IiERIC NARAGANo ratings yet

- CBLM SMAW NC II GMTDocument68 pagesCBLM SMAW NC II GMTmikel SeritoNo ratings yet

- Course of Study Shielded Metal Arc Welder (H-024-1) Module 14: 1G Plate Smaw ProcessDocument5 pagesCourse of Study Shielded Metal Arc Welder (H-024-1) Module 14: 1G Plate Smaw Processmuhammad qasimNo ratings yet

- Basic Welding Training (Weldability of Steels) PDFDocument18 pagesBasic Welding Training (Weldability of Steels) PDFPhu PhuocNo ratings yet

- SiC Special Inspections GuideDocument28 pagesSiC Special Inspections GuideReinaldo Andrei SalazarNo ratings yet

- Saep 1105 PDFDocument7 pagesSaep 1105 PDFbalajiNo ratings yet

- CBLM Smaw - NC IiDocument68 pagesCBLM Smaw - NC IiGissele Abolucion100% (2)

- SMAW Welding ModuleDocument44 pagesSMAW Welding ModuleAko Lang Poh100% (5)

- Session PlanDocument4 pagesSession PlanElmezar D. VelascoNo ratings yet

- Welding Principles and PracticesDocument141 pagesWelding Principles and PracticesEvan Jared L. GalvezNo ratings yet

- CBLM Smaw NC Ii PipeDocument40 pagesCBLM Smaw NC Ii PipeRyanM.PradelNo ratings yet

- CBLM Smaw NciiDocument44 pagesCBLM Smaw NciiJacaskills Jstac50% (2)

- Competency Based Learining MaterialDocument11 pagesCompetency Based Learining MaterialPradel FamilyNo ratings yet

- DATA SHEET - WD-Co6 RodDocument1 pageDATA SHEET - WD-Co6 RodriadhNo ratings yet

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Document21 pagesTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- Saep 744Document7 pagesSaep 744Anonymous 4IpmN7OnNo ratings yet

- AWS A5.4 Specification for Stainless Steel Welding ElectrodesDocument5 pagesAWS A5.4 Specification for Stainless Steel Welding ElectrodesLuis RR OficialNo ratings yet

- Astm F1941M 2005Document11 pagesAstm F1941M 2005Jesse ChenNo ratings yet

- Competency - Based Learning Materials: Metals and Engineering (Sector)Document44 pagesCompetency - Based Learning Materials: Metals and Engineering (Sector)Gissele AbolucionNo ratings yet

- SMAW welding procedure parameters guideDocument3 pagesSMAW welding procedure parameters guideCrauxz de TraxNo ratings yet

- Updated WMS - Welding of Duplex Stainless SteelDocument5 pagesUpdated WMS - Welding of Duplex Stainless Steelcameron toolseeNo ratings yet

- C EngNotebook LaBoube Aug17 1Document2 pagesC EngNotebook LaBoube Aug17 1Gero FacultadNo ratings yet

- ANSI/AWS A5.6-84R Specification for Covered Copper ElectrodesDocument4 pagesANSI/AWS A5.6-84R Specification for Covered Copper Electrodesalok987No ratings yet

- Weld Acceptance Criteria and Repair Procedures Arc Welds and Arc Brazes - SteelDocument32 pagesWeld Acceptance Criteria and Repair Procedures Arc Welds and Arc Brazes - SteelLuis zamora100% (2)

- Welding Defects - Classification, Causes and Remedies - Welding & NDTDocument11 pagesWelding Defects - Classification, Causes and Remedies - Welding & NDTadel100% (1)

- CBLM - SMAW NC II - CORE PIPES NewDocument207 pagesCBLM - SMAW NC II - CORE PIPES NewCharity GarrateNo ratings yet

- Hot Tin and Hot Tin/Lead Dip On Ferrous and Non-Ferrous MetalsDocument5 pagesHot Tin and Hot Tin/Lead Dip On Ferrous and Non-Ferrous MetalsDanZel DanNo ratings yet

- 2020-CBLM Smaw HandoutsDocument93 pages2020-CBLM Smaw HandoutsRoddx PalosNo ratings yet

- Calamba Manpower Development Center Training Plan: Shielded Metal Arc Welding NC IiDocument2 pagesCalamba Manpower Development Center Training Plan: Shielded Metal Arc Welding NC IiFrinces Marvida0% (1)

- Code Welding - Welds That Pass InspectionDocument5 pagesCode Welding - Welds That Pass InspectionVeer GangjiNo ratings yet

- Part III ISO and ASME DevelopmentsDocument7 pagesPart III ISO and ASME Developmentsروشان فاطمة روشانNo ratings yet

- Final Tle - Ia - Smaw Grades 11-12 01.09.2014Document9 pagesFinal Tle - Ia - Smaw Grades 11-12 01.09.2014Renante Deseo60% (5)

- Learning Activity Sheets (LAS) For SMAW NC II: Weld Carbon Steel Plates in Flat Position (1G) andDocument4 pagesLearning Activity Sheets (LAS) For SMAW NC II: Weld Carbon Steel Plates in Flat Position (1G) andKler Daradar100% (2)

- Silicon Nitride Bearing Balls: Standard Specification ForDocument8 pagesSilicon Nitride Bearing Balls: Standard Specification ForkrutikNo ratings yet

- 1 - IPP - API 1104 Handout - Jun 10 PDFDocument43 pages1 - IPP - API 1104 Handout - Jun 10 PDFMuhammad Yunus NurdinNo ratings yet

- Flux Cored Arc Welding PDFDocument147 pagesFlux Cored Arc Welding PDFCedric MercadoNo ratings yet

- F 2282 - 03 - RjiyodiDocument15 pagesF 2282 - 03 - RjiyodikrutikNo ratings yet

- Astm B695 - 2021Document6 pagesAstm B695 - 2021Danny TriwibowoNo ratings yet

- HBS-Brochure Stud Welding Fasteners-Engl 100920 01Document12 pagesHBS-Brochure Stud Welding Fasteners-Engl 100920 01Luis SabinoNo ratings yet

- Irs Welded Bridge CodeDocument32 pagesIrs Welded Bridge Codeamawauce67% (3)

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Automation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingFrom EverandAutomation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingP D BoydNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Grade11 Statistics and Probabilty - Module 2Document6 pagesGrade11 Statistics and Probabilty - Module 2Erickson SongcalNo ratings yet

- Philippine Literature during American and Japanese PeriodsDocument5 pagesPhilippine Literature during American and Japanese PeriodsErickson SongcalNo ratings yet

- M2. Understanding Culture, Society and PoliticsDocument4 pagesM2. Understanding Culture, Society and PoliticsErickson SongcalNo ratings yet

- M3. Understanding Culture, Society and PoliticsDocument4 pagesM3. Understanding Culture, Society and PoliticsErickson Songcal100% (1)

- M2. 21st Century Lit Phil and WorldDocument6 pagesM2. 21st Century Lit Phil and WorldErickson SongcalNo ratings yet

- Statistics and Probability DistributionsDocument4 pagesStatistics and Probability DistributionsErickson SongcalNo ratings yet

- Grade11 Statistics and Probabilty - Module 3Document5 pagesGrade11 Statistics and Probabilty - Module 3Erickson SongcalNo ratings yet

- Grade11 Statistics and Probabilty - Module 4Document7 pagesGrade11 Statistics and Probabilty - Module 4Erickson SongcalNo ratings yet

- Polarity of Molecules ExperimentDocument5 pagesPolarity of Molecules ExperimentErickson SongcalNo ratings yet

- HI M2 Introduction To Computer ConceptsDocument12 pagesHI M2 Introduction To Computer ConceptsErickson SongcalNo ratings yet

- Atomic Theory DevelopmentDocument4 pagesAtomic Theory DevelopmentErickson SongcalNo ratings yet

- Grade11 Physical Science - Module 1Document3 pagesGrade11 Physical Science - Module 1Erickson SongcalNo ratings yet

- Explore Pre-Colonial Philippine LiteratureDocument7 pagesExplore Pre-Colonial Philippine LiteratureErickson SongcalNo ratings yet

- Grade11 Business Math - Module 1Document9 pagesGrade11 Business Math - Module 1Erickson SongcalNo ratings yet

- Grade11 Business Math - Module 4Document6 pagesGrade11 Business Math - Module 4Erickson SongcalNo ratings yet

- Grade11 Business Math - Module 2Document5 pagesGrade11 Business Math - Module 2Erickson Songcal100% (1)

- Waste Disposal Area Designated WasteDocument9 pagesWaste Disposal Area Designated WasteErickson SongcalNo ratings yet

- Competency Based Curriculum DrivingDocument73 pagesCompetency Based Curriculum DrivingElonah Jean ConstantinoNo ratings yet

- Forms Program Registration 2018Document25 pagesForms Program Registration 2018Tahani Awar GurarNo ratings yet

- Basic Microbiology and Infection Control For Midwives-4Document207 pagesBasic Microbiology and Infection Control For Midwives-4rehanaNo ratings yet

- Carrying Out Vehicle Maintenance and Repair Operations L1 300911Document7 pagesCarrying Out Vehicle Maintenance and Repair Operations L1 300911Calligraphie D'un Cicatrice100% (1)

- Teaching Test Taking Strategies REVISEDDocument68 pagesTeaching Test Taking Strategies REVISEDdsNo ratings yet

- TR - Driving NC IIDocument61 pagesTR - Driving NC IIClintNo ratings yet

- Micro para - Essential Modules For Summer FocusDocument1 pageMicro para - Essential Modules For Summer FocusErickson SongcalNo ratings yet

- TR - Driving NC IiDocument61 pagesTR - Driving NC IiErickson SongcalNo ratings yet

- SMAW Welding ModuleDocument44 pagesSMAW Welding ModuleAko Lang Poh100% (5)

- Mate Selection p2Document13 pagesMate Selection p2Erickson SongcalNo ratings yet

- GAD Made Easy Climate changeRIRDocument26 pagesGAD Made Easy Climate changeRIRErickson SongcalNo ratings yet

- Strategies For Reducing Math Anxiety PDFDocument8 pagesStrategies For Reducing Math Anxiety PDFErickson SongcalNo ratings yet

- IntR 09 2012 0199Document23 pagesIntR 09 2012 0199Hazel Bianca GabalesNo ratings yet

- Linear IC Voltage RegulatorsDocument11 pagesLinear IC Voltage RegulatorsJavier Avalos GallosNo ratings yet

- Manual T240Document80 pagesManual T240Juan GarciaNo ratings yet

- KIA7805Document17 pagesKIA7805Thomas1JessieNo ratings yet

- EN14181 Asig Calitatii CEMSDocument45 pagesEN14181 Asig Calitatii CEMSbrctlnNo ratings yet

- Candle Power Stirling Engine PDFDocument4 pagesCandle Power Stirling Engine PDFFodor EmericNo ratings yet

- Eee421: Power Electronics: Power Semiconductor Devices: MOSFETDocument9 pagesEee421: Power Electronics: Power Semiconductor Devices: MOSFETRafat ShamsNo ratings yet

- Bike TN02 BK 4721 RC Book Honda UnicornDocument1 pageBike TN02 BK 4721 RC Book Honda UnicornvinothNo ratings yet

- XNX Universal TransmitterDocument12 pagesXNX Universal TransmitterDiego Costella100% (1)

- Sonnax HP 4L60E Catalog v1Document12 pagesSonnax HP 4L60E Catalog v1Brad Franc100% (2)

- The Ultimate Guide To WaterjetDocument9 pagesThe Ultimate Guide To WaterjetNsidibe Michael EtimNo ratings yet

- DCMotorsDocument19 pagesDCMotorsAndrew BuckleyNo ratings yet

- Digital Forensics On Facebook Messenger Application in An Android Smartphone Based On NIST SP 800-101 R1 To Reveal Digital Crime CasesDocument7 pagesDigital Forensics On Facebook Messenger Application in An Android Smartphone Based On NIST SP 800-101 R1 To Reveal Digital Crime CasesTeguh RijanandiNo ratings yet

- SYNCHRONIZE 3 Student Book U5Document12 pagesSYNCHRONIZE 3 Student Book U5hmarmolvilNo ratings yet

- Research Paper - Allison PorterDocument13 pagesResearch Paper - Allison Porterapi-609389611No ratings yet

- Toshiba LCD TV-DVD 17HLV85 - SVMDocument134 pagesToshiba LCD TV-DVD 17HLV85 - SVMJose Angel Coronel SanchezNo ratings yet

- Daa Mini ProjectDocument18 pagesDaa Mini ProjectSai Rohit PaturiNo ratings yet

- Firestop Product ApplicationsDocument18 pagesFirestop Product Applicationsc1565No ratings yet

- Cricket Research PaperDocument7 pagesCricket Research Paperuylijwznd100% (1)

- Buddy Memory AllocationDocument3 pagesBuddy Memory AllocationBibek GuptaNo ratings yet

- RatioandRegressionMethodofEstimation Lecture7 10Document30 pagesRatioandRegressionMethodofEstimation Lecture7 10mrpakistan444No ratings yet

- Urban Transit For Livable Cities: ReferencesDocument3 pagesUrban Transit For Livable Cities: ReferencesVismitha RamaiahNo ratings yet

- User Manual: Digital-Control and Programmable DC Power SupplyDocument10 pagesUser Manual: Digital-Control and Programmable DC Power SupplyElib SekeeveNo ratings yet

- Control System Configuration PDFDocument2 pagesControl System Configuration PDFjuliunNo ratings yet

- CIS SM DemoDocument6 pagesCIS SM Democgupta9990No ratings yet

- Standardised Effect Size in Mixed ML ModelsDocument9 pagesStandardised Effect Size in Mixed ML ModelsSergio Enrique Mora MojicaNo ratings yet

- Qualis VHDL-QuickReferenceCard V2.1 PDFDocument2 pagesQualis VHDL-QuickReferenceCard V2.1 PDFlakithaNo ratings yet

- Power System Protection Lab: Department of Electrical EngineeringDocument33 pagesPower System Protection Lab: Department of Electrical EngineeringBharat Kumar PrajapatiNo ratings yet

- ODJMS Project ReportDocument40 pagesODJMS Project ReportBALACHANDAR R (RA2031005010056)No ratings yet

- Notes:: Brisbane City Council Standard DrawingDocument1 pageNotes:: Brisbane City Council Standard DrawingShaunitchi El GrecoNo ratings yet