Professional Documents

Culture Documents

Hydraulic Pump - Test and Adjust

Uploaded by

Diego CatariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Pump - Test and Adjust

Uploaded by

Diego CatariCopyright:

Available Formats

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(S...

Página 1 de 20

Shutdown SIS

Previous Screen

Product: BACKHOE LOADER

Model: 432D BACKHOE LOADER WEP

Configuration: 432D Backhoe Loader WEP00001-UP (MACHINE) POWERED

BY 3054C Engine

Testing and Adjusting

416D, 420D, 424D, 428D, 432D and 442D Backhoe Loaders Hydraulic and Steering System

Media Number -RENR7779-00 Publication Date -01/01/2004 Date Updated -21/01/2004

i02662934

Hydraulic Pump - Test and Adjust

SMCS - 5070-025; 5070-081

Sudden movement of the machine or release of oil under pressure can

cause serious injury to persons on or near the machine.

To prevent possible injury, perform the procedure that follows before

testing and adjusting the hydraulic system.

Personal injury or death can result from escaping fluid under pressure.

Escaping fluid under pressure, even a very small pin-hole size leak, can

penetrate body tissue and cause serious injury and possible death. If

fluid is injected into your skin, it must be treated immediately by a

doctor familiar with this type of injury.

Always use a board or cardboard when checking for a leak.

Table 1

Required Tools

Part Number Description Quantity

6V-4143 Couplers 4

177-7860 Hose Assemblies 2

8T-0856 Pressure Gauges 2

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(S... Página 2 de 20

8T-0860 Pressure Gauge 2

8C-3417 Elbows 2

4C-9910 Flow Meter 1

6V-8946 Reducer Assemblies 2

6V-9831 Cap Assembly 1

123-3893 Cap Assembly 1

6V-3989 Fittings 4

8T-0857 Pressure gauge 1

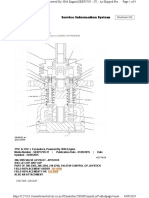

Illustration 1 g01048789

(1) Hydraulic pump

(2) Flow compensator valve

(3) Pressure compensator valve

(4) Signal pressure tap

Signal pressure tap (4) is located on hydraulic pump (1) . Flow compensator valve (2) and pressure

compensator valve (3) are also located on hydraulic pump (1) . Access is gained from the bottom of the

machine or access is gained by removing the floorplate.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(S... Página 3 de 20

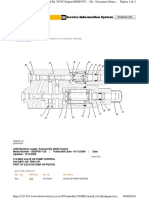

Illustration 2 g01048732

(5) System pressure tap

The system pressure tap (5) is located on the block for the pump discharge pressure. Access is gained from

the bottom of the machine.

Pump discharge pressures are known values. The pump discharge pressures can be tested during two specific

conditions.

low pressure standby

high pressure stall

Prior to making any pump adjustments, perform "Low Pressure Standby Test", "Margin Pressure Test" and

"High Pressure Stall Test".

Increase the hydraulic oil temperature to the operating temperature by installing the boom lock and stalling

the boom down for 60 seconds. Check for leaks.

Assembly of the Hose Assemblies

1. Install one 6V-4143 Coupler to each end of the 177-7860 Hose Assemblies .

2. Install one 6V-3989 Fitting to each pressure gauge.

Low Pressure Standby Test

1. Start the engine.

2. Lower the work tool on the front of the machine and the stabilizers to the ground. Engage the parking

brake. Stop the engine.

3. Turn the engine start switch key to the ON position.

4. Move the hydraulic hand controls to all the positions in order to release system pressure.

5. Turn the engine start switch key to the OFF position.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(S... Página 4 de 20

6. Remove the floorplate and the floor mat.

Illustration 3 g00869466

a. Remove two bolts (6) and plate (7) .

Illustration 4 g00869467

b. Remove two bolts (8) and plate (9) . Remove floor mat (10) .

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(S... Página 5 de 20

Illustration 5 g00869469

c. Remove four bolts (11) and set the floorplate (12) aside.

7. Install the 8T-0856 Pressure Gauges with a range of 0 to 6000 kPa (0 to 870 psi) to each hose

assembly. Install one hose assembly to the pressure tap (5) for system pressure. Install one hose

assembly to the signal pressure tap (4) .

Note: Do not move any hydraulic hand controls or the steering wheel while the 8T-0856 Pressure

Gauges are installed. The higher pressure that is created by upstroking the pump will damage the

gauges.

8. Start the engine. Run the engine at HIGH idle. Check for leaks.

9. Do not move any hydraulic hand controls nor move the steering wheel. The pressure reading on the

gauge that is attached to the pressure tap (5) for the system pressure should be 2850 ± 750 kPa (415 ±

110 psi). This pressure is the low pressure standby pressure. For best results, the low standby pressure

should be set at approximately 3100 kPa (450 psi).

10. The pressure reading on the gauge that is attached to the signal pressure tap (4) should be

approximately 650 kPa (95 psi). This pressure is the steering signal pressure. The steering signal

pressure is not adjustable.

Note: The steering signal pressure will vary with each machine. The steering signal pressure of each

machine should remain consistent with the previous readings on that machine.

11. Stop the engine.

12. Before continuing to the next test, remove the two 8T-0856 Pressure Gauges from both hose

assemblies. Install a 8T-0860 Pressure Gauge with a range of 0 to 40000 kPa (0 to 5800 psi) to the

hose assembly that is attached to the pressure tap (5) and to the pressure tap (4) .

Note: Failure to remove the 8T-0856 Pressure Gauges prior to performing the following tests will

cause the gauges to be destroyed, when the pump is upstroked.

Margin Pressure Test

1. Start the engine.

2. Engage the boom lock. Stall the boom circuit with a one-third lever movement in the DOWN position.

3. Subtract the pressure at signal pressure tap (4) from the pressure and system pressure tap (5) . This is

the margin pressure. The margin pressure should be 2200 ± 100 kPa (320 ± 15 psi).

4. Stop the engine.

5. If margin pressure or standby pressure is not correct, the flow compensator valve must be adjusted.

6. Do not make adjustments to the flow compensator spool based on the results of this test. Perform the

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(S... Página 6 de 20

"High Pressure Stall Test" before you make adjustments to the flow compensator spool.

High Pressure Stall Test

1. Install the swing lock pin and install the boom lock.

2. Start the engine. Run the engine at LOW idle.

3. Ensure that the work tool on the front of the machine and the stabilizers are on the ground. Engage the

parking brake.

4. Move the hydraulic hand controls one at a time in order to initiate a stall condition for the circuits in

Table 3. Note the pressure reading at pressure tap (4) for each circuit.

5. See Table 3 for the proper pressure readings at pressure port (4) .

Table 2

420D, 428D, 432D and

Hydraulic Circuit 416D and 424D

442D

STICK OUT

STICK IN

STICK EXTEND (if equipped)

STICK RETRACT (if equipped)

Auxiliary (if equipped) 22800 ± 700 kPa (3300 20700 ± 700 kPa (3000

± 100 psi) ± 100 psi)

SWING

Backhoe BUCKET DUMP

Backhoe BUCKET CLOSE

BOOM RAISE

BUCKET DUMP (parallel lift machines)

16200 ± 700 kPa (2350

± 100 psi)

N/A

RACK BACK (parallel lift machines) 22800 ± 700 kPa (3300

± 100 psi)

BUCKET DUMP and RACK BACK

(single tilt machines) 22800 ± 700 kPa (3300 20700 ± 700 kPa (3000

LIFT ± 100 psi) ± 100 psi)

Note: There may be air in the signal network, if there is a hesitation before reaching the relief

pressure. Purge the signal lines of the air.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(S... Página 7 de 20

6. In order to check the BOOM LOWER circuit, perform the following procedure.

a. Engage the boom lock.

For 416D, 420D, 424D and 430D machines, run the engine at 1100 rpm. Activate the

BOOM LOWER by pushing the boom control lever fully forward.

For 428D, 432D, 438D and 442D machines, run the engine at 1250 rpm. Activate the

BOOM LOWER by pushing the boom control lever fully forward.

b. Note the pressure reading at pressure tap (4) .

c. See Table 4 for the proper pressure readings at pressure port (4) .

Table 3

Hydraulic Circuit

420D, 428D, 432D and 442D 416D and 424D

BOOM LOWER 15200 ± 700 kPa (2200 ± 100 psi) 15500 ± 700 kPa (2250 ± 100 psi)

7. If the machine is equipped with All Wheel Steer, perform the following procedure.

Illustration 6 g00869579

(13) All Wheel Steer switch

a. Check the circuit for the All Wheel Steer by moving the All Wheel Steer switch (13) to the

right.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(S... Página 8 de 20

Illustration 7 g01049077

The Independent Rear Maneuvering switches are located on the pilot operated controls.

(14) Switch for the clam bucket

(15) Left Independent Rear Maneuvering switch

(16) Right Independent Rear Maneuvering switch

(17) Pilot operated loader control

b. Stall the rear axle by pressing the left Independent Rear Maneuvering switch (15) or the right

Independent Rear Maneuvering switch (16) .

c. Note the pressure reading at pressure tap (4) .

d. See Table 5 for the proper pressure readings at pressure port (4) .

Table 4

416D, 424D, 428D and

Hydraulic Circuit 420D and 442D

432D

Independent Rear

22800 ± 700 kPa (3300 ± 100 N/A

Maneuvering

psi)

8. Turn off the engine. Engage the parking brake and remove the test equipment.

9. If the BOOM LOWER, RACK BACK or DUMP pressures are not within the specification, check the

line relief valve of the suspected function.

10. If the RACK BACK or DUMP pressure is not with the specification for these machines (S/N:

FDP7199-UP, BNK2502-UP), check the relief valve for the signal pressure on the tilt control valve.

11. If the pressure for any other circuit is not within the specification, the pressure compensator valve

needs to be adjusted.

12. If the engine stalls, the torque limiter needs to be adjusted.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(S... Página 9 de 20

13. Stop the engine and remove the gauges.

Adjustments for the Pump Controller

NOTICE

When the compensator valve is rebuilt, ensure that the pressure

compensator adjustment and the flow compensator adjustment are

backed out to a low pressure setting before the engine is started. Severe

pump damage and system damage could be the result, or the engine

may not start.

Illustration 8 g01338081

Pump control valve

(1) Flow compensator

(2) Orifice

(3) O-ring

(4) Locknut

(5) Adjustment screw

(6) Cap

(7) Adjustment screw

(8) Cap

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(... Página 10 de 20

(9) Locknut

(10) O-ring

(11) Pressure compensator spool

(12) Seal

(13) Seal

Note: If an adjustment is necessary, replace the Seals (12) and (13) . Replacing the Seals will reduce the

possibility of oil leakage after an adjustment to the compensator valve is made.

Flow compensator valve (1) and pressure compensator valve (11) have been tested by running the pump

discharge tests.

Adjustment For The Pressure Compensator Spool

Adjustments to the pressure compensator spool can be made on the machine. If the "High Pressure Stall

Test" is within the specification, then go to the Flow Compensator Spool Adjustment. If the "High Pressure

Stall Test" is not within the specification, then do the following procedure.

1. Ensure that the work tool on the front of the machine and the stabilizers are on the ground. Engage the

parking brake.

2. Stop the engine.

3. Turn the engine start switch key to the ON position.

4. Move all of the hydraulic hand controls to all of the positions. This releases the system pressure.

5. Turn the engine start switch key to the OFF position.

6. Remove cap (8) and loosen locknut (9) . Turn adjusting screw (7) clockwise in order to increase the

pressure setting. Turn adjusting screw (7) counterclockwise in order to decrease the setting.

7. Install a 8T-0860 Pressure Gauge with a range of 0 to 40000 kPa (0 to 5800 psi) to system pressure tap

(4) .

8. Repeat the "High Pressure Stall Test" until the system pressure is within the specification.

9. When the pressure compensator is adjusted correctly, stop the engine. Tighten locknut (9) . Replace

cap (8) and remove the gauges.

Flow Compensator Spool Adjustment

Adjustments to the flow compensator spool can be made on the machine. If the Margin Pressure and Low

Pressure Standby pressures are within the specifications, then go to the Test and Adjustment for the Torque

Limiter. If the Margin Pressure or Low Pressure Standby pressures are not within the specification, then do

the following procedure.

1. Lower the work tool on the front of the machine and the stabilizers to the ground. Engage the parking

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(... Página 11 de 20

brake.

2. Stop the engine.

3. Turn the engine start switch key to the ON position.

4. Move all the hydraulic hand controls through all of the positions in order to release pressure in the

hydraulic system.

5. Turn the engine start switch key to the OFF position.

6. Install two 8T-0856 Pressure Gauges with a range of 0 to 6000 kPa (0 to 870 psi) to the pressure tap

(5) for the system pressure and to signal pressure tap (4) .

Note: Do not move any hydraulic hand controls nor move the steering wheel while the 8T-0856

Pressure Gauge is installed. The higher pressure that is created by upstroking the pump will damage

the gauge.

7. Repeat the "Low Pressure Standby Pressure Test".

8. If the low pressure standby pressure is within the specifications, then go to Step 11. If the low pressure

standby pressure is not within the specifications, then remove cap (6) and loosen locknut (4) . Turn

adjusting screw (5) clockwise in order to increase the pressure setting. Turn adjusting screw (5)

counterclockwise in order to decrease the pressure setting.

9. Repeat the "Low Pressure Standby Pressure Test" until the low pressure standby pressure is within the

specification.

10. Tighten locknut (4) and replace cap (6) .

11. Lower the implements to the ground. Stop the engine and engage the parking brake.

12. Remove all test equipment.

13. Repeat the "Margin Pressure Test" in order to check that the margin pressure is still within the

specification.

Test for the Torque Limiter

Note: The following procedure can be used in most cases when the torque limiter may be the cause of a

performance problem.

Note: Install a 9U-7400 Multitach to the engine. Check the low idle. The low idle must be 975 ± 25 rpm. If

the engine low idle rpm is not within the specification, then refer to Systems Operation, Testing and

Adjusting, SENR5816, "3054 Engine for Caterpillar Built Machines". Perform the low idle adjustment. The

engine idle must be within the specification before continuing to the next procedure.

Note: Perform "Low Pressure Standby Pressure Test", "Margin Pressure Test" and "High Pressure Stall

Test" prior to performing the Test for the Torque Limiter. Make the necessary adjustments in order to meet

the specifications.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(... Página 12 de 20

NOTICE

Care must be taken to ensure that fluids are contained during

performance of inspection, maintenance, testing, adjusting and repair

of the product. Be prepared to collect the fluid with suitable containers

before opening any compartment or disassembling any component

containing fluids.

Refer to Special Publication, NENG2500, "Caterpillar Dealer Service

Tool Catalog" for tools and supplies suitable to collect and contain

fluids on Caterpillar products.

Dispose of all fluids according to local regulations and mandates.

Perform the following tests before you adjust the torque limiter.

Perform the test for the torque limiter on single tilt machines and parallel lift loaders.

1. Ensure that the work tool on the front of the machine and the stabilizers are on the ground. Engage the

parking brake.

2. Start the engine. Run the engine at LOW idle.

3. Place the transmission in SECOND gear. Activate the front running lights. Activate the air conditioner

(if equipped).

4. Engage the service brakes.

5. Perform the appropriate test.

a. For single tilt machines, rack back the bucket fully and lower the bucket to the ground. Activate

the LIFT circuit slowly. Note the pressure while the lift arms are moving. Do not stall the LIFT

circuit.

b. For parallel lift machines, dump the bucket fully and lower the bucket to the ground. Stall the

DUMP circuit and activate the LIFT circuit slowly. Note the pressure while the lift arms are

moving. Do not stall the LIFT circuit.

6. Stop the engine.

7. If the engine does not stall, no adjustment to the torque limiter is necessary.

8. If the engine stalls, the torque limiter on the hydraulic pump is set too high or the engine has low

power. Lower the work tool to the ground. Stop the engine and engage the parking brake. Adjust the

torque limiter by performing Step 16 through Step 21 of the "Test and Adjust the Torque Limiter with

a Flow Meter" procedure. Then, repeat the test procedure. If the engine stalls, adjust the fuel pump for

the engine.

Optional Test for the Torque Limiter

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(... Página 13 de 20

Perform the BOOM DOWN circuit test for the torque limiter on backhoe loaders.

1. Ensure that the work tool on the front of the machine and the stabilizers are on the ground. Engage the

boom lock. Engage the parking brake.

2. Start the engine. Run the engine at 1100 rpm.

3. Activate the BOOM DOWN circuit. Stall the circuit.

4. If the engine does not stall, no adjustment to the torque limiter is necessary. Stop the engine and

engage the parking brake.

5. If the engine stalls, the torque limiter on the hydraulic pump is set too high or the engine has low

power. Lower the work tool to the ground. Stop the engine and engage the parking brake. Adjust the

torque limiter by performing Step 16 through Step 21 of the "Test and Adjust the Torque Limiter with

a Flow Meter" procedure. Then, repeat the test procedure. If the engine stalls, adjust the fuel pump for

the engine.

Test and Adjust the Torque Limiter with a Flow Meter

Table 5

Required Tools

Part Number Description Quantity

FT-2812 Modified Wrench for Adjusting the Torque Limiter 1

Note: This test should not be performed unless the "Test for the Torque Limiter" does not resolve the

performance problem with the torque limiter.

Illustration 9 g01048389

(1) Pump pressure tap

(2) Hydraulic pump

Pump pressure tap (1) is located on hydraulic pump (2) .

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(... Página 14 de 20

1. Start the engine. Engage the parking brake.

2. Move the stick OUT. Lower all the work tools and the stabilizers to the ground.

3. Stop the engine. Move all the control levers to all positions. This releases system pressure.

4. Install one 8T-0860 Pressure Gauge with a range of 0 to 40000 kPa (0 to 5800 psi) to one end of the

177-7860 Hose Assembly . Attach the second end of the hose assembly to pump pressure tap (1) .

5. Install one 8C-3417 Elbow into each port in 4C-9910 Flow Meter . Attach one 6V-8946 Reducer

Assembly onto each 8C-3417 Elbow . Attach one 6V-8943 Reducer Assembly onto one of the 6V-

8946 Reducer Assemblies .

Illustration 10 g00747372

(5) Retainers

6. There are two retainers (5) on the boom. Remove the two bolts from each retainer. Remove the

retainers.

Illustration 11 g00747389

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(... Página 15 de 20

(6) Hose to the head end of the boom cylinder

(7) Connector to the head end of the boom cylinder

7. Remove the hose (6) from the connector from the head end of the boom cylinder (7) . Install one 123-

3893 Cap Assembly to connector (7) .

8. Install the hose to the head end of the boom cylinder (6) onto the 6V-8943 Reducer Assembly that was

installed in Step 5.

Illustration 12 g00747400

(8) Hose to the rod end of the boom cylinder

(9) Tube to the rod end of the boom cylinder

9. Remove hose (8) from the tube to the rod end of the boom cylinder (9) . Install a 6V-9831 Cap

Assembly to tube (9) .

10. Install the end of hose (8) onto the 6V-8946 Reducer Assembly that was installed in Step 5.

11. Start the engine. Cycle the work tools until the hydraulic oil temperature on the 4C-9910 Flow Meter

rises to 60 °C (140 °F).

12. When the hydraulic oil temperature is at 60 °C (140 °F), increase the engine speed to 2200 rpm. Move

the boom control lever to the boom RAISE position. Hold the boom control lever in the RAISE

position. Flow will decrease as rpm decreases.

13. Rotate the control knob for the pressure on the 4C-9910 Flow Meter until the pump pressure is 17,900

kPa (2600 psi) at pump pressure tap (1) . Record the flow and the oil pressure.

Note: If the engine cannot maintain 2200 rpm, refer to Systems Operation, Testing and Adjusting,

SENR5815, "3054 Engine for Caterpillar Built Machines". Perform the torque converter stall test and

check the high idle. The engine high idle must be within the specification before continuing to the next

procedure.

14. Table 7 shows the correct pump pressure and the correct flow rate for 416D and 424D machines.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(... Página 16 de 20

Table 6

PUMP PRESSURE FLOW

17900 ± 300 kPa (2600 ± 40 psi) 102 ± 6 L/min (27 ± 2 US gpm)

Table 8 shows the correct pressure and the correct flow rate for all other machines.

Table 7

PUMP PRESSURE FLOW

17900 ± 300 kPa (2600 ± 40 psi) 112 ± 4 L/min (30 ± 1 US gpm)

15. If the flow is not within the specification, then the torque limiter needs to be adjusted. Lower all work

tools to the ground and stop the engine.

16. Turn the engine start switch key to the ON position.

17. Move all the hydraulic hand controls through all of the positions in order to release pressure in the

hydraulic system.

18. Turn the engine start switch key to the OFF position.

Illustration 13 g01048509

(10) Cap on the torque limiter

19. Remove cap (10) .

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(... Página 17 de 20

Illustration 14 g01048683

(11) Locknut on the torque limiter

(12) Plug on the torque limiter

20. Loosen locknut (11) . Turn plug (12) clockwise in order to increase the flow. Turn plug (12)

counterclockwise in order to decrease the flow.

Note: Use FT-2812 Modified Wrench for Adjusting the Torque Limiter .

Note: Take care to loosen the locknut so that the sleeve will not bind. If the bolt dislodges from the

sleeve, the sleeve does not rotate. If the sleeve does not rotate, no adjustment is made.

Note: Turning the plug (12) to the next flat side of the plug will change the flow approximately 7.6

L/min (2 US gpm). Never, adjust plug (12) more than three and a half of a turn. Adjusting the plug

(12) more may damage the internal spring. If the spring fails, the pump performance will be poor.

21. After the adjustment is made, tighten locknut (10) .

22. Repeat Steps 11, 12, 13 and 14.

23. If the flow is not within the specification, then repeat Steps 20 and 21. If the torque limiter is not

within the specification after several attempts, then rework the torque limiter. Go to the next test in

order to Rework the Torque Limiter. Repeat the test and adjust for the torque limiter after you rework

the torque limiter.

24. When the flow is within the specification in Steps 14, then proceed with the next Step.

25. Turn the engine start switch key to the ON position.

26. Move all the hydraulic hand controls through all of the positions in order to release pressure in the

hydraulic system.

27. Turn the engine start switch key to the OFF position.

28. Remove the test equipment.

29. Remove hose (6) from the 6V-8946 Reducer Assembly . Remove 6V-9831 Cap Assembly from tube

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(... Página 18 de 20

(5) . Place a new O-ring onto the fitting and reinstall hose (6) to tube (5) .

30. Remove hose (4) from the 6V-8946 Reducer Assembly . Remove 6V-9832 Cap Assembly from elbow

(3) . Place a new O-ring onto the fitting and reinstall hose (4) to elbow (3) .

31. Replace hoses (4) and (6) into the two retainers (8) on the boom for the two hoses. Reinstall the four

bolts (7) . There are two bolts on each retainer (8) . Reinstall the retainers (8) on the boom for the

hoses.

32. Replace the floorplate. Reinstall the four screws that hold the floorplate in place.

33. Reinstall the four screws that hold the two plates for the floor mat. There are two screws on each plate.

The plates are located at the edge of each door in the cab.

Rework the torque limiter

Table 8

Required Tools

Part Number Description Quantity

FT-2812 Modified Wrench for Adjusting the Torque Limiter 1

Note: If the torque limiter cannot be set within the specification, then replace the torque limiter.

Note: This procedure will not increase the lifting capacity of the machine.

Personal injury can result from hydraulic oil pressure and hot oil.

Hydraulic oil pressure can remain in the hydraulic system after the

engine has been stopped. Serious injury can be caused if this pressure is

not released before any service is done on the hydraulic system.

Make sure all of the work tools have been lowered to the ground, and

the oil is cool before removing any components or lines. Remove the oil

filler cap only when the engine is stopped, and the filler cap is cool

enough to touch with your bare hand.

NOTICE

Care must be taken to ensure that fluids are contained during

performance of inspection, maintenance, testing, adjusting and repair

of the product. Be prepared to collect the fluid with suitable containers

before opening any compartment or disassembling any component

containing fluids.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(... Página 19 de 20

Refer to Special Publication, NENG2500, "Caterpillar Dealer Service

Tool Catalog" for tools and supplies suitable to collect and contain

fluids on Caterpillar products.

Dispose of all fluids according to local regulations and mandates.

1. Move the machine to a level surface.

2. Lower all of the work tools to the ground.

3. Turn the engine OFF. Engage the parking brake.

4. Turn the engine start switch key to the ON position.

5. Move all the hydraulic hand controls through all of the positions in order to release pressure in the

hydraulic system.

6. Turn the engine start switch key to the OFF position.

Illustration 15 g00747791

(1) Piston pump

(2) Torque limiter

(3) Bolts

(4) Tube

7. Clean the area around torque limiter (2) .

8. Disconnect tube (4) from torque limiter (2) .

9. Remove the two bolts (3) .

Note: Use FT-2812 Modified Wrench for Adjusting the Torque Limiter .

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C Engine(... Página 20 de 20

10. Remove torque limiter (2) from pump (1) .

Illustration 16 g00850777

(5) Springs

11. Replace the springs (5) for the torque limiter and the O-rings for the torque limiter.

12. Clean all of the parts prior to assembly. Assemble the torque limiter.

13. Install the torque limiter (2) .

14. Install two bolts (3) .

15. Connect tube (4) to torque limiter (2) .

16. Repeat the Test for the Torque Limiter.

17. Check the hydraulic oil level. Refer to the Operation and Maintenance Manual for the proper capacity.

Copyright 1993 - 2016 Caterpillar Inc. Wed Aug 17 09:33:11 UTC-0400 2016

All Rights Reserved.

Private Network For SIS Licensees.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb ... 17/08/2016

You might also like

- Valvulas de AlivioDocument4 pagesValvulas de AlivioEdgar Martinez CarmonaNo ratings yet

- Pressure Limiter Valve - Test: Essai Et RéglageDocument6 pagesPressure Limiter Valve - Test: Essai Et RéglagechakrouneNo ratings yet

- Relief Valves (Implement) - Test and Adjust: Pruebas y AjustesDocument3 pagesRelief Valves (Implement) - Test and Adjust: Pruebas y AjustesLENIN JHAIR VALDERRAMA SEGURANo ratings yet

- Main Hydraulic Pump PDFDocument12 pagesMain Hydraulic Pump PDFalsief1951No ratings yet

- Pruebas y Ajustes 330d Sistema HidarulicoDocument4 pagesPruebas y Ajustes 330d Sistema HidarulicoVictorDjChiqueCastillo100% (1)

- Cat 120H, 12H, 140H, 143H, 160H, 163H TransmisiónDocument8 pagesCat 120H, 12H, 140H, 143H, 160H, 163H TransmisiónJefferson Maldonado.No ratings yet

- Main Pump (Flow) - Test - Constant Horsepower Flow Control: Cerrar SIS Pantalla AnteriorDocument38 pagesMain Pump (Flow) - Test - Constant Horsepower Flow Control: Cerrar SIS Pantalla AnteriorClemente Flores100% (1)

- Relief Valve (Line) - Test and Adjust: Shutdown SISDocument10 pagesRelief Valve (Line) - Test and Adjust: Shutdown SISMbahdiro KolenxNo ratings yet

- Stick Hydraulic SystemDocument11 pagesStick Hydraulic SystemAllan LariosaNo ratings yet

- Solenoid Valve (Proportional Reducing) - Power Shift System: Operación de SistemasDocument5 pagesSolenoid Valve (Proportional Reducing) - Power Shift System: Operación de Sistemasgalvis1020No ratings yet

- Relief Valve (Load Sensing Signal) 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónDocument6 pagesRelief Valve (Load Sensing Signal) 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónPablo Cesar Poma ArrateaNo ratings yet

- Crankshaft - InstallDocument7 pagesCrankshaft - InstallLeonardo PerezNo ratings yet

- Excavadora Hidraulica 345b (Relief Valve Pruebas - y - Ajustes)Document17 pagesExcavadora Hidraulica 345b (Relief Valve Pruebas - y - Ajustes)Maquinaria Pesada ServisNo ratings yet

- Pump Control - OutputDocument4 pagesPump Control - OutputSam Sung100% (1)

- 318B PumpDocument15 pages318B Pumpsamir kadriNo ratings yet

- Hydraulic Schematic of Main Control ValveDocument8 pagesHydraulic Schematic of Main Control ValveWaridi RidiNo ratings yet

- Calibration ModeDocument16 pagesCalibration ModeDANIEL VARGAS RODRIGUEZNo ratings yet

- Pruebas y Ajustes Hidraulicos Cat 325lDocument57 pagesPruebas y Ajustes Hidraulicos Cat 325lJoze 23No ratings yet

- Engine Performance - Test - Engine Speed: 320D and 323D Excavators Hydraulic SystemDocument3 pagesEngine Performance - Test - Engine Speed: 320D and 323D Excavators Hydraulic SystemEm sulistio100% (1)

- Main Relief 302.5Document11 pagesMain Relief 302.5Yudi setiawanNo ratings yet

- Relief Valve (Line) - Test and Adjust: Shutdown SIS Previous ScreenDocument5 pagesRelief Valve (Line) - Test and Adjust: Shutdown SIS Previous Screenchanlin0% (1)

- 320, 320 L and 320 N Operation Hydraulic SystemDocument162 pages320, 320 L and 320 N Operation Hydraulic SystemF Labio AlexNo ratings yet

- Pruebas y Ajustes 14G HidraulicaDocument25 pagesPruebas y Ajustes 14G HidraulicayeisonNo ratings yet

- Boom Drift Reduction ValveDocument4 pagesBoom Drift Reduction ValveJuan Daniel Martinez MontoyaNo ratings yet

- SwivelDocument2 pagesSwivelHusika HusikaaNo ratings yet

- 330bl NFC AdjustDocument10 pages330bl NFC AdjustDaniel Rhasty-ghee AhmanorNo ratings yet

- Performance Test D8R (9EM)Document6 pagesPerformance Test D8R (9EM)ahmad ruyaniNo ratings yet

- Testing and Adjusting Hydraulic PressureDocument6 pagesTesting and Adjusting Hydraulic Pressuremink4u100% (2)

- Hydraulic Pump (8J6730) (Part of 8J6731 Pump Group) : SpecificationsDocument7 pagesHydraulic Pump (8J6730) (Part of 8J6731 Pump Group) : SpecificationsJohn Fredy Palacio G.No ratings yet

- Pistoes c7Document6 pagesPistoes c7Alaina SousaNo ratings yet

- Engine Performance - Test - Engine Speed: Testing and AdjustingDocument2 pagesEngine Performance - Test - Engine Speed: Testing and AdjustingDANIEL VARGAS RODRIGUEZ100% (1)

- E Piston Pump (Main)Document4 pagesE Piston Pump (Main)wong apian100% (1)

- Status Mode: Systems OperationDocument12 pagesStatus Mode: Systems OperationDANIEL VARGAS RODRIGUEZNo ratings yet

- Bypass Check ValveDocument2 pagesBypass Check Valvealsief1951No ratings yet

- Groupon Vale CatDocument4 pagesGroupon Vale CatLuis Carlos RamosNo ratings yet

- Relief Valve (Line) - Test and Adjust - Boom Lowering Control ValveDocument9 pagesRelief Valve (Line) - Test and Adjust - Boom Lowering Control ValveR I Santoso100% (1)

- Systems Operation: Shutdown SIS Previous ScreenDocument163 pagesSystems Operation: Shutdown SIS Previous ScreenAngelica VergaraNo ratings yet

- Roto KSCDocument4 pagesRoto KSCdaniel ortegaNo ratings yet

- CrossoverDocument6 pagesCrossoverRendy Pratama100% (3)

- Test Sistema DirecciónDocument29 pagesTest Sistema DirecciónDenisNo ratings yet

- Pressure SpecificationsDocument6 pagesPressure SpecificationsHamid EssarboutiNo ratings yet

- Transmission - Valve, Regulator and Oil PumpDocument2 pagesTransmission - Valve, Regulator and Oil PumpSilvio Roman100% (1)

- Cylinder (Boom Stick Bucket)Document3 pagesCylinder (Boom Stick Bucket)Energy Sun Biocar100% (1)

- Important Information: Testing and AdjustingDocument16 pagesImportant Information: Testing and AdjustingDeyvi Cconocuyca Huallparimachi100% (1)

- Testing and Adjusting Hydraulic System: Shutdown SIS Previous ScreenDocument55 pagesTesting and Adjusting Hydraulic System: Shutdown SIS Previous Screenluis eduardo corzo enriquezNo ratings yet

- Specification 320CDocument7 pagesSpecification 320CSteven ManuputtyNo ratings yet

- Renr3646renr3646-03 - Sis 320c Akh Hidraulic PumpDocument8 pagesRenr3646renr3646-03 - Sis 320c Akh Hidraulic PumpGabriely MuriloNo ratings yet

- PC200 Series Excavator Installation Manual Component Code 6ADocument48 pagesPC200 Series Excavator Installation Manual Component Code 6ARouni AñazcoNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document17 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768lull434100% (2)

- 120H 5FM CircleDocument3 pages120H 5FM CircleCasandra Lizet100% (1)

- Mecanismo de ValvulasDocument7 pagesMecanismo de ValvulasAlaina SousaNo ratings yet

- Ajuste Válvula de Alivio PilotoDocument2 pagesAjuste Válvula de Alivio PilotoLuis Carlos Vera100% (1)

- Atachment System 3.sis PDFDocument2 pagesAtachment System 3.sis PDFJuan GarciaNo ratings yet

- 320 B Diagrama HidraulicoDocument11 pages320 B Diagrama HidraulicoJimmyJavierTorresSalas100% (3)

- Fluid Power Graphic Symbols User's Guide: General Service InformationDocument17 pagesFluid Power Graphic Symbols User's Guide: General Service Informationjorge william ramirezNo ratings yet

- 950F Frenos OperacionDocument19 pages950F Frenos OperacionChrissz Noxd50% (2)

- Pruebas y Ajustes Servo 14GDocument15 pagesPruebas y Ajustes Servo 14Gyeison100% (1)

- Transmission Forward Low and RDocument2 pagesTransmission Forward Low and Rvalterrip100% (1)

- Hydraulic Pump Test and Adjust PDFDocument22 pagesHydraulic Pump Test and Adjust PDFservhiperu100% (1)

- 432d Signal Resolver Network - CheckDocument6 pages432d Signal Resolver Network - CheckDiego CatariNo ratings yet

- Service Manual: 1 2 3 A B C D E F G KDocument6 pagesService Manual: 1 2 3 A B C D E F G KDiego CatariNo ratings yet

- 966C-PEDIDO2Document1 page966C-PEDIDO2Diego CatariNo ratings yet

- 323D-MAIN RELIEFDocument7 pages323D-MAIN RELIEFDiego CatariNo ratings yet

- 966C-PEDIDO2Document1 page966C-PEDIDO2Diego CatariNo ratings yet

- Cotizacion: IT. U-M. Codigo Ubic. Cant. P.Unit Imp-Br % DES Total TipoDocument2 pagesCotizacion: IT. U-M. Codigo Ubic. Cant. P.Unit Imp-Br % DES Total TipoDiego CatariNo ratings yet

- Valvulas de Presion DesarmadoDocument7 pagesValvulas de Presion DesarmadoDiego CatariNo ratings yet

- CotizacionDocument3 pagesCotizacionDiego CatariNo ratings yet

- 4.4L - 6.7L Tier 3Document6 pages4.4L - 6.7L Tier 3Diego CatariNo ratings yet

- Planos Carrito 1Document14 pagesPlanos Carrito 1Diego CatariNo ratings yet

- Fuel Injection Nozzle - Test: Testing and AdjustingDocument10 pagesFuel Injection Nozzle - Test: Testing and AdjustingDiego CatariNo ratings yet

- Desensamble de Tan Hidra. 966Document25 pagesDesensamble de Tan Hidra. 966Diego CatariNo ratings yet

- Desamado de Valvular Reguladoras de PresionDocument11 pagesDesamado de Valvular Reguladoras de PresionDiego CatariNo ratings yet

- Front Track Roller Frame - Remove: Desarmado y ArmadoDocument5 pagesFront Track Roller Frame - Remove: Desarmado y ArmadoDiego CatariNo ratings yet

- Manual ViewerDocument24 pagesManual ViewerDiego CatariNo ratings yet

- Fuel System - Prime: Testing and AdjustingDocument2 pagesFuel System - Prime: Testing and AdjustingDiego CatariNo ratings yet

- Low Idle RPM - Adjust: Testing and AdjustingDocument3 pagesLow Idle RPM - Adjust: Testing and AdjustingDiego CatariNo ratings yet

- Fuel Injection Timing - Check: Testing and AdjustingDocument5 pagesFuel Injection Timing - Check: Testing and AdjustingDiego Catari100% (3)

- Shutdown SIS: Backhoe Loader 432D Backhoe Loader Wep 432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C EngineDocument2 pagesShutdown SIS: Backhoe Loader 432D Backhoe Loader Wep 432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C EngineDiego CatariNo ratings yet

- Finding Top Center Position For No. 1 Piston: Testing and AdjustingDocument3 pagesFinding Top Center Position For No. 1 Piston: Testing and AdjustingDiego CatariNo ratings yet

- Valvula Compoensadora de TorqueDocument2 pagesValvula Compoensadora de TorqueDiego CatariNo ratings yet

- Valvula de Control de PresionDocument2 pagesValvula de Control de PresionDiego CatariNo ratings yet

- 432d Signal Resolver Network - CheckDocument6 pages432d Signal Resolver Network - CheckDiego CatariNo ratings yet

- 432d Signal Resolver Network - CheckDocument6 pages432d Signal Resolver Network - CheckDiego CatariNo ratings yet

- Especificaciones de Valvula ReguladoraDocument3 pagesEspecificaciones de Valvula ReguladoraDiego CatariNo ratings yet

- Shutdown SIS: Backhoe Loader 432D Backhoe Loader Wep 432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C EngineDocument4 pagesShutdown SIS: Backhoe Loader 432D Backhoe Loader Wep 432D Backhoe Loader WEP00001-UP (MACHINE) POWERED BY 3054C EngineDiego CatariNo ratings yet

- 432d Signal Resolver Network - CheckDocument6 pages432d Signal Resolver Network - CheckDiego CatariNo ratings yet

- Calibracion Del GovernadorDocument10 pagesCalibracion Del GovernadorDiego CatariNo ratings yet

- Calibracion de VelocidadesDocument21 pagesCalibracion de VelocidadesDiego CatariNo ratings yet

- Manual Service Bobcat 753 Skid Steer Loader Safety Identificacion Systems Components Engine Specifications PDFDocument348 pagesManual Service Bobcat 753 Skid Steer Loader Safety Identificacion Systems Components Engine Specifications PDFIngeniero Proyectos100% (4)

- Module 4.Document16 pagesModule 4.Sania MaqsoodNo ratings yet

- Data Table CarbonDocument2 pagesData Table Carbonyodaswarrior33% (15)

- Six Sigma Statistical Methods Using Minitab 13 Manual4754Document95 pagesSix Sigma Statistical Methods Using Minitab 13 Manual4754vinaytoshchoudharyNo ratings yet

- RK271007 AN RXSF 1Document2 pagesRK271007 AN RXSF 1Ahmed FaragNo ratings yet

- Daily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFDocument6 pagesDaily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFAEO Begowala100% (2)

- LPDocument5 pagesLPHeizyl ann VelascoNo ratings yet

- Automobiles Seat ComfortDocument10 pagesAutomobiles Seat ComfortAnushree DeshingeNo ratings yet

- Skills For A High Performing Civil Service PDFDocument140 pagesSkills For A High Performing Civil Service PDFSam ONiNo ratings yet

- COT English 3rd PrepositionDocument14 pagesCOT English 3rd PrepositionGanie Mae Talde Casuncad100% (1)

- CV Template DixieDocument3 pagesCV Template DixieDarybelle BusacayNo ratings yet

- For Construction and Industry: Liebherr Diesel EnginesDocument8 pagesFor Construction and Industry: Liebherr Diesel EnginesGoran MatovicNo ratings yet

- Expansion Joint PSDocument2 pagesExpansion Joint PSYoga SaputraNo ratings yet

- TMDI Lesson Plan in Storing and Reconstituting StocksDocument5 pagesTMDI Lesson Plan in Storing and Reconstituting StocksDiane VillNo ratings yet

- Products For Enhanced Oil RecoveryDocument4 pagesProducts For Enhanced Oil RecoverypmarteeneNo ratings yet

- RV RVR en 0714 Edit PDFDocument6 pagesRV RVR en 0714 Edit PDFJacques FerreiraNo ratings yet

- 5S ManualDocument60 pages5S ManualMun Hein ZawNo ratings yet

- Partlist Sym Vf3i 185Document83 pagesPartlist Sym Vf3i 185Jack Wilder100% (1)

- Well Plan Release NotesDocument28 pagesWell Plan Release Notesahmed_497959294No ratings yet

- BIGuidebook Templates - BI Logical Data Model - Data Integration DesignDocument12 pagesBIGuidebook Templates - BI Logical Data Model - Data Integration DesignShahina H CrowneNo ratings yet

- Mcgill Thesis GuidelinesDocument5 pagesMcgill Thesis Guidelinesisabelleonorpaterson100% (2)

- Operations Management (Zheng) SU2016 PDFDocument9 pagesOperations Management (Zheng) SU2016 PDFdarwin12No ratings yet

- SpinView Getting StartedDocument16 pagesSpinView Getting StartedRicardo SequeiraNo ratings yet

- Physics ProjectDocument12 pagesPhysics ProjectRita SharmaNo ratings yet

- Brochure PILA Lamps and LuminairesDocument42 pagesBrochure PILA Lamps and Luminairesaldtol21No ratings yet

- Economics Not An Evolutionary ScienceDocument17 pagesEconomics Not An Evolutionary SciencemariorossiNo ratings yet

- EPFO Declaration FormDocument4 pagesEPFO Declaration FormSiddharth PednekarNo ratings yet

- MA 7 TranscriptDocument82 pagesMA 7 TranscriptBob AndrepontNo ratings yet

- Challan FormDocument2 pagesChallan FormSingh KaramvirNo ratings yet

- Review of Guyana's Social Education ProgramDocument6 pagesReview of Guyana's Social Education ProgramTineka Jagan CharlesNo ratings yet

- Guia Instalacion ENTECDocument15 pagesGuia Instalacion ENTECHislim SaidNo ratings yet