Professional Documents

Culture Documents

Lube Flushing Unit FAT Inhouse Report (12233)

Uploaded by

Idung ChristopherOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lube Flushing Unit FAT Inhouse Report (12233)

Uploaded by

Idung ChristopherCopyright:

Available Formats

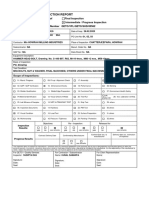

VENDOR: DEEPAK VACUUM TECHNOLOGIES PVT. LIMITED.

LUBE OIL FLUSHING UNIT INSPECTION

CHECKLIST

- XOFL1000

Avialablity

for Client

Accepted

Available

Rejected

Sr.no Material and Grade / visual test

Not

. operation Brand Testing by Type of check (Y/N) Documentation of inpsection Comments

1.00 RAW MATERIAL

Sheets used for Hydrotest reports for housings

storage tanks sighted together with materials

1.01 and housings SS 304 Material Test Certificate Y OEM / Supplier TC √ report

2.00 Accessories

2.01 Valves L&T OEM Test Certificate Y OEM TC √ OEM Test Certificate sighted.

All Valves were confirmed

surface inspection visual fault Y DVT - Inspection report √ functional.

Filpro /

Pune

2.03 Float switch TechTrol OEM TC Electronic test Y OEM TC √ OEM Test Certificate sighted.

DVT Test Continuity test Y DVT - Inspection report √ This test was not witnessed

Actuation test was successful and

DVT Test Actuation tests Y DVT - Inspection report √ interlocked to anunciator panel

Pressure relief

2.04 valve OEM TC Testing & OEM Calibration Y OEM TC √ OEM Test Certificate sighted.

Std. OEM testing & Calib.

2.05 Flow meter OEM TC Cert. Y OEM TC √ OEM Test Certificate sighted.

Calibrated measuring Jar

DVT Test Test N DVT - Inspection report √

Differential Monitors OEM TC with

2.06 pressure guage India Ltd. calibration Cert Y OEM TC with calibration Cert √ OEM Test Certificate sighted.

OEM TC with

2.07 Pressure Gauges Baumer calibration Cert Y OEM TC with calibration cert. √ OEM Test Certificate sighted.

Dial Temp. OEM TC with

2.08 Gauge National calibration Cert Y OEM TC with calibration Cert √ OEM Test Certificate sighted.

Contamination Testing & Calibration

2.09 Monitor HYDAC OEM TC Certificate Y OEM -TC √ OEM Test Certificate sighted.

Filtered oil testing using

Patch test kit &

DVT Test Microscope Y DVT Inspection report. √ This test was not witnessed

Rejecte

Availab

Accept

Fabrication and

Not

ed

3.00 Testing

d

Dye Penetration

3.01 Test DVT inspection Dye Penetration test kit N DVT - Inspection report √

X-ray testing

3.02 (10%) Third Party test Porosity & contamination Y Third part test report √ Radiography report sighted.

Pneumatic

3.03 Testing DVT Inspection 10 Kg/cm2 N DVT Inspection Report √

3.04 Hydro Testing DVT Inspection 12 Kg/cm2 Hydro Test N DVT inspection report √ Hydrotest report sightest

5.00 Centrifugal pump, Motor

Manufac

tured -

Centrifugal KSB ,

5.01 pump India OEM TC OEM TC Y OEM TC √ Pump performance Curve sighted.

Motor

manufac

tured by

:

5.02 60 HP Motor Siemens OEM TC OEM TC Y OEM TC √ Motor Test Report Sighted.

Manufac

tured by -

Rotodel

5.03 Oil Filling pump Pumps OEM TC OEM TC Y OEM TC √

Motor

manufac

tured by

:

5.04 Oil Filling motor Siemens OEM TC OEM TC Y OEM TC √

Variable

5.03 Frequncy Drive OEM TC OEM TC Y OEM TC √

6.00 Internal Testing at DVT

Test results were satiffactory at

6.1 Flow Test 1000 LPM Y DVT Inspection report √ 10,20,30,40 & 50Hz.

6.3 Heating 75 Deg C. Y DVT Inspection report √

Low level float switch was

Safety Low level float switch confirmed to be interlocked with

6.4 Y the anunciator panel and flushing

Interlocking - 1 with Oil Flushing pump

DVT Inspection report √ pump.

The high level switch was

Safety High level float switch intelocked with the anunciator

6.5 Y panel but not with the filling

Interlocking - 2 with oil filling pump

DVT Inspection report √ pump.

Safety Interlock - Safety Pressure sensor

6.6

3 interlocked with oil

Y DVT Inspection report √

Temperature controller was

Safety Interlock - Safety Temperature confirmed to switch off heating

6.7 Y at the desired set point

4 Controller with Heaters

DVT Inspection report √ temperature.

6.8

Continuous

6.9

operation

48 hours N DVT Inspection report √

7 NAS value NAS Achievable 6 Y DVT Inspection report √

Motor Current

below range specified by Maximum current draw was

7.1 Consumption at Y

max load.

OEM DVT Inspection report √ 37.1A at 50Hz of VFD reading

Heater current consumption was

Heater Current 50A which is within OEM

7.2 Within OEM range Y DVT Inspection report

Consumption

√ specification

Not Available

Manual and

Accepted

Rejected

8

Calculations

Instruction Step wise process Y Client Acceptance report

8.01 manual explained √ Instruction Manual Received.

Flushing Pump Y DVT Instruction Manual

Instruction manual with

Instruction

8.02 manual

Performance curve √

Safety How to operate system Y DVT Instruction Manual

8.06 Explaination safely √

Y DVT Instruction Manual

How to identify issues and

8.07 Troubleshooting solve them correctly √

Safety Sticker information Y DVT Instruction Manual

8.09 Safety Stickers and their identification √

Witnessed

Witnessedby:

By: Accepted

Accepted By:by: AffiliatedAffilliated

By: by: Final Acceptance & Seal

Final Acceptance and Seal:

OramaboB.

Oramabo B.Hope

Hope Ezikpe Chima

Ezikpe Chima EhiobuUvaivi

DaviesOkwaraeke: Uvaivi Okwaraeke Emmanuel Okon

E&I Engr. Snr. Project

Snr. Manager

Project Manager QHSE Coordinator GM, QHSE/Training

E&I Engr. GM, QHSE/Training MD/CEO

You might also like

- Essay 1 Weight and BalanceDocument4 pagesEssay 1 Weight and BalanceHamdan Merchant83% (6)

- Quality Assurance Protocol: Raw MaterialDocument2 pagesQuality Assurance Protocol: Raw MaterialShah Newaz KabirNo ratings yet

- Inspeksi Trafo - Sabtu SiangDocument24 pagesInspeksi Trafo - Sabtu SiangJAN OJANNo ratings yet

- LT Panel SOP For Test ProcedureDocument5 pagesLT Panel SOP For Test ProcedureShrikanth Sola100% (2)

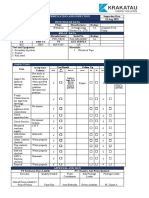

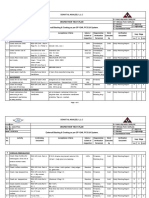

- Inspection and Test Plan: Fabrication / In-Process InspectionDocument1 pageInspection and Test Plan: Fabrication / In-Process InspectionGLEDSONNo ratings yet

- Control Plan: 3 1/4" Bore A-Series Side-Lug CapsDocument4 pagesControl Plan: 3 1/4" Bore A-Series Side-Lug CapsRavichandran D100% (1)

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Document2 pagesVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- ITP Low Tempt Test - RevDocument6 pagesITP Low Tempt Test - RevAgus GunawanNo ratings yet

- YzcvfDocument2 pagesYzcvfCheeragNo ratings yet

- Quantum of Check of Material&WorkmanshipDocument35 pagesQuantum of Check of Material&Workmanshipsanjay vidhateNo ratings yet

- QAP New Customer Nov23Document1 pageQAP New Customer Nov23RND DRAWNo ratings yet

- 20170315151791679167Document6 pages20170315151791679167AndRiy A S GoeLtomNo ratings yet

- Spool HT EPCMD 2 QM00 FMT PP 028 - 01Document1 pageSpool HT EPCMD 2 QM00 FMT PP 028 - 01Muthu AlaguRajNo ratings yet

- SL Engineering Works: External Provider Audit ReportDocument2 pagesSL Engineering Works: External Provider Audit Reportdeepak guptaNo ratings yet

- Ir562 Hmi 28.02.23Document2 pagesIr562 Hmi 28.02.23Pinki Mitra DasNo ratings yet

- Inspection and Test Plan: Fabrication / In-Process InspectionDocument17 pagesInspection and Test Plan: Fabrication / In-Process InspectionGLEDSON100% (1)

- Inspection & Test Plan (Itp) - Iso 5167 - Fittings (SC / DC)Document1 pageInspection & Test Plan (Itp) - Iso 5167 - Fittings (SC / DC)Guru DevaNo ratings yet

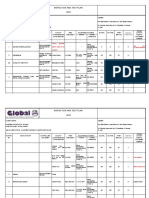

- Inspection and Test Plan: DOC: GBL/QC/2015/ITP-001/REV 01 Dtd.04/01/2017Document4 pagesInspection and Test Plan: DOC: GBL/QC/2015/ITP-001/REV 01 Dtd.04/01/2017Ubed KudachiNo ratings yet

- LT Panel PDI SOPDocument4 pagesLT Panel PDI SOPShrikanth Sola100% (2)

- Et 0000 97 Toc 001bDocument5 pagesEt 0000 97 Toc 001bGLEDSONNo ratings yet

- ITP Turbine Cooler Air System, Rotor Air Cooler, RAC PipeDocument2 pagesITP Turbine Cooler Air System, Rotor Air Cooler, RAC PipeIbadurrahman KahfiNo ratings yet

- Factory Acceptance Test Document 20000075: Machine InformationDocument4 pagesFactory Acceptance Test Document 20000075: Machine Informationastojadin1873No ratings yet

- ITP IGV, CT, Inlet Air & Starting SystemDocument3 pagesITP IGV, CT, Inlet Air & Starting SystemIbadurrahman KahfiNo ratings yet

- ITP - (Pressure Testing Piping) PDFDocument3 pagesITP - (Pressure Testing Piping) PDFSUNNY BOSS100% (1)

- Protection Relay Verification and Inspection Switchgear DataDocument11 pagesProtection Relay Verification and Inspection Switchgear DatamomoNo ratings yet

- QC.02.FAT.01-equipment Completeness Checklist R1Document4 pagesQC.02.FAT.01-equipment Completeness Checklist R1FENGJUNNo ratings yet

- Proposed QAP For Adani Internal CTR JobDocument2 pagesProposed QAP For Adani Internal CTR JobSasanka SekharNo ratings yet

- Quenching and Tempering Check Sheet - Issue 1Document8 pagesQuenching and Tempering Check Sheet - Issue 1Sakthi VelNo ratings yet

- IR204 - Siddheswari Evaluation - SUD 06.08.21Document2 pagesIR204 - Siddheswari Evaluation - SUD 06.08.21sudipta dasNo ratings yet

- Itp 116Document4 pagesItp 116muralidmurthyNo ratings yet

- Inspection and Test Plan For External Blasting & Coating As SP-1246 PCS-2A SystemDocument6 pagesInspection and Test Plan For External Blasting & Coating As SP-1246 PCS-2A SystemVinayaga MoorthiNo ratings yet

- QAP FormatsDocument13 pagesQAP Formatsavvari sureshNo ratings yet

- Eil FormatDocument1 pageEil Formatsales.aquavalvesNo ratings yet

- BSIBV ITP 04-1 ITP For Anode Installation Rev. 0Document4 pagesBSIBV ITP 04-1 ITP For Anode Installation Rev. 0AMALENDU PAULNo ratings yet

- 01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Document29 pages01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Eljo AndsNo ratings yet

- Exhibit D3 Inspection and Test Plan (ITP)Document12 pagesExhibit D3 Inspection and Test Plan (ITP)Muhammad Ali AkbarNo ratings yet

- ElectroMechanical Completion VALVE and ANCILLARIESDocument1 pageElectroMechanical Completion VALVE and ANCILLARIEShuseyinyuksel1903No ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument4 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- ITP For Non-Fire Resistant CI CableDocument1 pageITP For Non-Fire Resistant CI CableMeng PamplonaNo ratings yet

- Receipt Inspection Report: Checked As Per PO and Found SatisfactoryDocument14 pagesReceipt Inspection Report: Checked As Per PO and Found Satisfactorysanjayprakash1979No ratings yet

- Inspection Test Plan (Itp) at Shop: Remark No DescriptionDocument2 pagesInspection Test Plan (Itp) at Shop: Remark No Descriptionanang_pri100% (1)

- QAP For MS PipelineDocument32 pagesQAP For MS PipelineArup karanNo ratings yet

- Inspection & Test Plan (Itp) : Earth FillingDocument1 pageInspection & Test Plan (Itp) : Earth FillingLOPA THANDARNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Valve Service Report For GNPK 2022 Outage Valve Services For Unit 3 & 4Document166 pagesValve Service Report For GNPK 2022 Outage Valve Services For Unit 3 & 4JonasNo ratings yet

- CERTIFICADO PLASSON PORTABRIDA 90 MMDocument1 pageCERTIFICADO PLASSON PORTABRIDA 90 MMangel rojasNo ratings yet

- Calibration Certificate: Page 1 / 1Document1 pageCalibration Certificate: Page 1 / 1Eduard GadzhievNo ratings yet

- What Is The Measuring Instruments Directive (MID) ?Document4 pagesWhat Is The Measuring Instruments Directive (MID) ?ZbigNo ratings yet

- Inspection Testing Plan (ITP)Document1 pageInspection Testing Plan (ITP)Kdown 99100% (1)

- Test Report - Ss Tubings: Doc No: E&P 205 Rev No: 00 Eff Date:11/11/2020Document2 pagesTest Report - Ss Tubings: Doc No: E&P 205 Rev No: 00 Eff Date:11/11/2020Shaikh sohilNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00194Document2 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00194sudipta dasNo ratings yet

- System Leak Test: Calibration RecordsDocument1 pageSystem Leak Test: Calibration Recordsarun kumarNo ratings yet

- TATA Painting Specification 40Document1 pageTATA Painting Specification 40Suleman KhanNo ratings yet

- Qap For Steam TurbineDocument3 pagesQap For Steam TurbinedgmprabhakarNo ratings yet

- Calibration Certificate: Page 1 / 1Document1 pageCalibration Certificate: Page 1 / 1EduardNo ratings yet

- Attach-2 ITP For Building WaterDocument29 pagesAttach-2 ITP For Building WaterSukalyan BasuNo ratings yet

- H79IQ001EN-A ServiceReportAbbemat Eco 3000 3100 3200 FieldsDocument6 pagesH79IQ001EN-A ServiceReportAbbemat Eco 3000 3100 3200 FieldsDiego BouNo ratings yet

- SFDSF PDFDocument3 pagesSFDSF PDFbishnu sahNo ratings yet

- Sample Report-Handphone-电子电器-耳机Document19 pagesSample Report-Handphone-电子电器-耳机raulNo ratings yet

- Hazardous Gas Monitoring, Fifth Edition: A Guide for Semiconductor and Other Hazardous OccupanciesFrom EverandHazardous Gas Monitoring, Fifth Edition: A Guide for Semiconductor and Other Hazardous OccupanciesNo ratings yet

- Img 0003Document1 pageImg 0003Idung ChristopherNo ratings yet

- Repair Questionnaire v5 0 - EATDocument2 pagesRepair Questionnaire v5 0 - EATIdung ChristopherNo ratings yet

- Mpnu-Idioho Designed For: Project Info: Project ID:: June 26, 2020Document6 pagesMpnu-Idioho Designed For: Project Info: Project ID:: June 26, 2020Idung ChristopherNo ratings yet

- Technical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoDocument27 pagesTechnical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoIdung ChristopherNo ratings yet

- Christophe Idung Corrosion EngineerDocument4 pagesChristophe Idung Corrosion EngineerIdung ChristopherNo ratings yet

- A Study of Frequency and Temperature Effects On Fatigue Crack Growth Resistance of CPVCDocument11 pagesA Study of Frequency and Temperature Effects On Fatigue Crack Growth Resistance of CPVCIdung ChristopherNo ratings yet

- Project Schedule For Construction of 8 X 300km Egbema Nag WellDocument16 pagesProject Schedule For Construction of 8 X 300km Egbema Nag WellIdung ChristopherNo ratings yet

- Christophe Idung Reservoir EngineerDocument3 pagesChristophe Idung Reservoir EngineerIdung ChristopherNo ratings yet

- Otaway Schedule. 01pdfDocument3 pagesOtaway Schedule. 01pdfIdung ChristopherNo ratings yet

- Psychometric Development and Validation of GaslightingDocument15 pagesPsychometric Development and Validation of GaslightingYang ZhangNo ratings yet

- Apl 220014Document2 pagesApl 220014Elprince MidoNo ratings yet

- Fluid Mechanics EXERCHAP08Document3 pagesFluid Mechanics EXERCHAP08scribdgggNo ratings yet

- The Power of Human Connection Review 2Document81 pagesThe Power of Human Connection Review 2Tajam SoftNo ratings yet

- Bruh I Hate File Handling - CPPDocument3 pagesBruh I Hate File Handling - CPPJayson AmodiaNo ratings yet

- Microgrid Modeling and Grid Interconnection StudiesDocument71 pagesMicrogrid Modeling and Grid Interconnection StudiesVeeravasantharao BattulaNo ratings yet

- PLX7100A Digital Mobile C-Arm X-Ray Machine: 1. Technical SpecificationDocument3 pagesPLX7100A Digital Mobile C-Arm X-Ray Machine: 1. Technical SpecificationAbdalhakeem AlturkyNo ratings yet

- Quantities Survey MethodsDocument73 pagesQuantities Survey MethodsparvezNo ratings yet

- Astm A394 2008 PDFDocument6 pagesAstm A394 2008 PDFJavier Ricardo Romero BohorquezNo ratings yet

- Customer DemandDocument42 pagesCustomer Demandtulika_ajwaniNo ratings yet

- C.KESAVAN - Diploma EEE: Phone No Mail IdDocument3 pagesC.KESAVAN - Diploma EEE: Phone No Mail IdKesavan ChinaswmiNo ratings yet

- 1 s2.0 0304386X9190055Q MainDocument32 pages1 s2.0 0304386X9190055Q MainJordan Ulloa Bello100% (1)

- Photo Luminescence of Surfaces and InterfacesDocument25 pagesPhoto Luminescence of Surfaces and InterfacesNick KellerNo ratings yet

- Permability & Seepage-Dr Siddharth G Shah PDFDocument8 pagesPermability & Seepage-Dr Siddharth G Shah PDFSG ShahNo ratings yet

- en Product OverviewDocument81 pagesen Product OverviewShakeel AhmedNo ratings yet

- Form 1 ExercisesDocument160 pagesForm 1 Exerciseskays MNo ratings yet

- AtomDocument15 pagesAtomdewi murtasimaNo ratings yet

- Binary PDFDocument13 pagesBinary PDFbyprasadNo ratings yet

- OcrDocument16 pagesOcrBeena JaiswalNo ratings yet

- Ball Charge ManagementDocument14 pagesBall Charge ManagementSalud Y SucesosNo ratings yet

- Examples of Balancing Method - Four-Run and Least-Squares Influence CoefficientsDocument44 pagesExamples of Balancing Method - Four-Run and Least-Squares Influence CoefficientsNguyen Anh TuNo ratings yet

- Bodybuilder Guidelines: Update: 2011-22Document438 pagesBodybuilder Guidelines: Update: 2011-22thkimzone73100% (12)

- LTE Rach ProcedureDocument4 pagesLTE Rach ProcedureDeepak JammyNo ratings yet

- Chapter - Four Soil Permeability and SeepageDocument19 pagesChapter - Four Soil Permeability and SeepageBefkadu KurtaileNo ratings yet

- Agilis AAV680 FullC PDFDocument2 pagesAgilis AAV680 FullC PDFhendpraz88No ratings yet

- TOFD Dead Zone CalculatorDocument4 pagesTOFD Dead Zone CalculatorWill SmithNo ratings yet

- All Graphs and Charts Available in Show MeDocument16 pagesAll Graphs and Charts Available in Show MeGANGA TAGRANo ratings yet

- Momus Design CNC Router Manual Version 2.1Document178 pagesMomus Design CNC Router Manual Version 2.1Francisco Teruel100% (8)

- Presentation: Isa Test Sets Training Course - 2014Document5 pagesPresentation: Isa Test Sets Training Course - 2014Sultan Uddin KhanNo ratings yet