Professional Documents

Culture Documents

Test Report - Ss Tubings: Doc No: E&P 205 Rev No: 00 Eff Date:11/11/2020

Uploaded by

Shaikh sohil0 ratings0% found this document useful (0 votes)

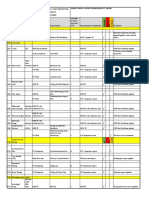

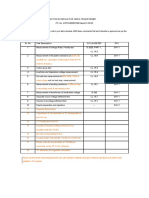

14 views2 pagesThis document summarizes the hydrostatic and pneumatic testing of stainless steel tubing. It provides details of the test such as the client, tubing size and location. Both tests were performed by pressurizing the tubing and checking for leaks. The tubing passed both the hydrotest at 380 bar for 1 hour and the pneumatic test at 7 bar with no leaks found. Upon completion, the tubing was connected to the compressor/dispenser system.

Original Description:

Original Title

Untitled

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes the hydrostatic and pneumatic testing of stainless steel tubing. It provides details of the test such as the client, tubing size and location. Both tests were performed by pressurizing the tubing and checking for leaks. The tubing passed both the hydrotest at 380 bar for 1 hour and the pneumatic test at 7 bar with no leaks found. Upon completion, the tubing was connected to the compressor/dispenser system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views2 pagesTest Report - Ss Tubings: Doc No: E&P 205 Rev No: 00 Eff Date:11/11/2020

Uploaded by

Shaikh sohilThis document summarizes the hydrostatic and pneumatic testing of stainless steel tubing. It provides details of the test such as the client, tubing size and location. Both tests were performed by pressurizing the tubing and checking for leaks. The tubing passed both the hydrotest at 380 bar for 1 hour and the pneumatic test at 7 bar with no leaks found. Upon completion, the tubing was connected to the compressor/dispenser system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

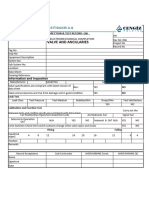

Doc No : E&P 205

TEST REPORT – SS TUBINGS Rev No : 00

Eff Date :11/11/2020

Client

TPIA

Contractor

Tube Size & Length

Location

HYDRO TEST DETAILS :

TEST INFORMATION TEST 'ON' INTERMEDIATE READINGS TEST OFF

Date & time

Recorded Pressure

(bar or Kg/Cm2)

Test Period :

Calibrated Bourdon test Gauge - Type

Serial Number

Calibration Date Calibration Expiry Date

PNEUMATIC TEST DETAILS :

TEST INFORMATION TEST 'ON' INTERMEDIATE READING TEST OFF

Date & time

Recorded Pressure

(bar or Kg/Cm2)

Test Period :

Calibrated Bourdon test Gauge Type

Serial Number

Calibration Date Calibration Expiry Date

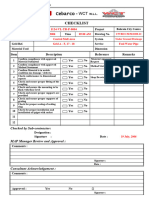

Visual Inspection of SS tubing and fittings Y/N

Proper clamping of SS tubing Y/N

Pressurization of SS tubing at 380 bar pressure for Hydro test. Y/N

Pressure gauge calibrated Y/N

Holding period for the Installation 1 hour, at the raised pressure. Y/N

Checking of fitting joints for tracing any leakage. Y/N

If leakage found Y/N

Depressurized the system and rectify leakage/s Y/N

Hydrotest repeated Y/N

If no leakage found

Y/N

Hydro test accepted Y/N

Flushing of SS tubing with Nitrogen/Air Y/N

Pneumatic Test at 7 bar pressure with nitrogen Y/N

Checking of all fittings with soap solution Y/N

If leakage found Y/N

Depressurized the system and rectify leakage/s Y/N

Y/N

Hydrotest repeated

If no leakage found Y/N

Pneumatic test accepted Y/N

Depressurized of the system and connectivity with Y/N

compressor/dispenser

REMARKS

Contractor TPIA IOAGPL-Projects

Name :

Depressurized of the system and connectivity with compressor/dispenser

Sign

Date :

You might also like

- Instrument Technology: Measurement of Pressure, Level, Flow and TemperatureFrom EverandInstrument Technology: Measurement of Pressure, Level, Flow and TemperatureRating: 4 out of 5 stars4/5 (1)

- CHW & HW Piping Pressure Test Report FormatDocument1 pageCHW & HW Piping Pressure Test Report FormatSandhyaRamakrishnaNo ratings yet

- Material Receiving ReportDocument15 pagesMaterial Receiving ReportGomathyselvi100% (1)

- NFPA 14 Underground Piping - Fire Hose ReelDocument2 pagesNFPA 14 Underground Piping - Fire Hose Reelahmed fouadNo ratings yet

- Spool HT EPCMD 2 QM00 FMT PP 028 - 01Document1 pageSpool HT EPCMD 2 QM00 FMT PP 028 - 01Muthu AlaguRajNo ratings yet

- Pressure Test Report For Water Supply PipingDocument1 pagePressure Test Report For Water Supply PipingBelal Alrwadieh100% (1)

- Form Test PacketDocument24 pagesForm Test PacketYudha Andrie Sasi ZenNo ratings yet

- 11-Hydrostatic Test Leakage Main Chilled Water Pipe ReportDocument1 page11-Hydrostatic Test Leakage Main Chilled Water Pipe Reportchinith75% (4)

- NFPA 13 - Aboveground Piping Test Certificate Zona 1 PDFDocument3 pagesNFPA 13 - Aboveground Piping Test Certificate Zona 1 PDFsamantha guerreroNo ratings yet

- FIR Magnesium Anode Test QCDocument1 pageFIR Magnesium Anode Test QCFafa seyzaNo ratings yet

- Contractor's Material and Test Certificate For Underground PipingDocument4 pagesContractor's Material and Test Certificate For Underground PipingSurya EngineeringNo ratings yet

- ElectroMechanical Completion VALVE and ANCILLARIESDocument1 pageElectroMechanical Completion VALVE and ANCILLARIEShuseyinyuksel1903No ratings yet

- ITP FORMAT - PSV Modified FormateDocument1 pageITP FORMAT - PSV Modified Formatemurthy challapalliNo ratings yet

- Sprinkler Report NFPA 25 03.27.13Document8 pagesSprinkler Report NFPA 25 03.27.13redbire100% (1)

- Checklist2210 - Laying New Pipeline - Pressure TestDocument1 pageChecklist2210 - Laying New Pipeline - Pressure TestRojin FrancisNo ratings yet

- NFPA 24-2013 Standpipe Test AttachmentDocument2 pagesNFPA 24-2013 Standpipe Test AttachmentPatrick John PaguioNo ratings yet

- Pressure Test ReportDocument9 pagesPressure Test Reportjaysonquitelgonzales06No ratings yet

- C0M-14 Hydrostatic Test of Pressure VesselDocument3 pagesC0M-14 Hydrostatic Test of Pressure VesselHong Trung DuongNo ratings yet

- Lube Flushing Unit FAT Inhouse Report (12233)Document2 pagesLube Flushing Unit FAT Inhouse Report (12233)Idung ChristopherNo ratings yet

- Water Based Fire Protection System Test Report: Date: TimeDocument2 pagesWater Based Fire Protection System Test Report: Date: TimeViệt Đặng XuânNo ratings yet

- Agp 22050 TP Pip E01 1297.00 - UpdatedDocument18 pagesAgp 22050 TP Pip E01 1297.00 - Updatedangelito bernalNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Gb-Gas Servicing ChecklistDocument1 pageGb-Gas Servicing ChecklistQco MyNo ratings yet

- Inspection and Test Plan: Fabrication / In-Process InspectionDocument1 pageInspection and Test Plan: Fabrication / In-Process InspectionGLEDSONNo ratings yet

- Magnesium Anode Test Quality Control and Inspection Report FormDocument1 pageMagnesium Anode Test Quality Control and Inspection Report Formsindalisindi0% (1)

- Standpipe System Inspection Check ListDocument3 pagesStandpipe System Inspection Check ListMd. Sujaur RahmanNo ratings yet

- Inspection and Test Program: Fabrication / In-Process InspectionDocument4 pagesInspection and Test Program: Fabrication / In-Process InspectionGLEDSONNo ratings yet

- Accord Check ListDocument12 pagesAccord Check ListHasan100% (1)

- Pressure Test Report - SampleDocument1 pagePressure Test Report - SamplemomoitachiNo ratings yet

- GE Healthcare Carestation 600 SeriesDocument9 pagesGE Healthcare Carestation 600 SerieshailongwangNo ratings yet

- 11 5K 5K Annular BOPDocument4 pages11 5K 5K Annular BOPEdwin MP0% (1)

- Overhead Crane - FunctionTestProcedureDocument15 pagesOverhead Crane - FunctionTestProcedurepetazNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Hydrostatic Testing of Pipelines: The City of GalvestonDocument4 pagesHydrostatic Testing of Pipelines: The City of GalvestonMoezNo ratings yet

- Fire Infra Commissionning and Acceptance ReportDocument2 pagesFire Infra Commissionning and Acceptance ReportNathaniel IFEANYINo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- HYDRO Test ReportDocument3 pagesHYDRO Test ReportHanuman RaoNo ratings yet

- Transformer Vector GroupDocument11 pagesTransformer Vector GroupjohnNo ratings yet

- Sample Transformer Life Assessment SheetDocument10 pagesSample Transformer Life Assessment SheetMuhammed Zubair NNo ratings yet

- Technical Specification - 2023 01 16 18 50 06Document10 pagesTechnical Specification - 2023 01 16 18 50 06abhishekgupta9990No ratings yet

- Item Inspected: CBLT-TPI-00F-186-12623Document16 pagesItem Inspected: CBLT-TPI-00F-186-12623Zulfadli RaniNo ratings yet

- HVAC Systems List of Tests - LCETEDDocument4 pagesHVAC Systems List of Tests - LCETEDjon aquinoNo ratings yet

- Annexure To Start-Up & Commissioning of Fire Water PumpsDocument5 pagesAnnexure To Start-Up & Commissioning of Fire Water PumpsMina KhalilNo ratings yet

- Tank Certificate SampleDocument1 pageTank Certificate SampleYajaira Hernández GómezNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Third Party Certificates - Electrical ConduitsDocument30 pagesThird Party Certificates - Electrical ConduitsArun UdayabhanuNo ratings yet

- SATRDocument1 pageSATRAhmed BoraeyNo ratings yet

- - Monthly Report of Inspection - نسخةDocument3 pages- Monthly Report of Inspection - نسخةWaleed AwanNo ratings yet

- Test Report 2Document14 pagesTest Report 2Rogelio PabuayaNo ratings yet

- Inspection Checklist For: Control ValvesDocument2 pagesInspection Checklist For: Control Valvesabdelkader benabdallahNo ratings yet

- Inspection Checklist For: Control ValvesDocument2 pagesInspection Checklist For: Control Valvesabdelkader benabdallahNo ratings yet

- Property - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-08 - Valves FORM - 2pDocument2 pagesProperty - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-08 - Valves FORM - 2pHarumNo ratings yet

- Inspection Checklist For: Control ValvesDocument2 pagesInspection Checklist For: Control Valvesabdelkader benabdallahNo ratings yet

- O. Appendix O: Pressure Testing References: O.1. Hydrostatic Test ProcedureDocument13 pagesO. Appendix O: Pressure Testing References: O.1. Hydrostatic Test ProcedureCharlie Dela RosaNo ratings yet

- 80MVAR Reactor Test ReportDocument28 pages80MVAR Reactor Test ReportSARAVANAN ANo ratings yet

- C0M-11 Hydrostatic Pressure Test (Piping)Document3 pagesC0M-11 Hydrostatic Pressure Test (Piping)Hong Trung DuongNo ratings yet

- 1 Trazabilidad de Los Medidores Coriolis en Aplicaciones de Hidrocarburos Fase GasDocument32 pages1 Trazabilidad de Los Medidores Coriolis en Aplicaciones de Hidrocarburos Fase GasChemicalProgrammerNo ratings yet

- Air Handling Unit QC Checklist: AHU InformationDocument5 pagesAir Handling Unit QC Checklist: AHU InformationRaheel AhmedNo ratings yet

- 12-09-2023 Final Test Plidco Rak0011Document1 page12-09-2023 Final Test Plidco Rak0011dhani projectoNo ratings yet

- Pressure Vessel InspectionDocument3 pagesPressure Vessel InspectionSpectex dubaiNo ratings yet

- Eqt RecordDocument41 pagesEqt RecordShaikh sohilNo ratings yet

- Dbs Station Kiwad, Petroleum: Megha City Gas Distribution PVT - Ltd. Kiwad Petroleum Chikodi Jitendra ThakurDocument1 pageDbs Station Kiwad, Petroleum: Megha City Gas Distribution PVT - Ltd. Kiwad Petroleum Chikodi Jitendra ThakurShaikh sohilNo ratings yet

- Industrial SkidsDocument2 pagesIndustrial SkidsShaikh sohilNo ratings yet

- Oil BathDocument1 pageOil BathShaikh sohilNo ratings yet

- Heat and Mass Transfer in A Clay-Pot Refrigerator: Analysis RevisitedDocument15 pagesHeat and Mass Transfer in A Clay-Pot Refrigerator: Analysis RevisitedSanaan AhmadiNo ratings yet

- Magnetic Field Due To Electric Current by Ajju SirDocument42 pagesMagnetic Field Due To Electric Current by Ajju Sirnitesh02006No ratings yet

- Gravity MethodDocument38 pagesGravity Methodzain828No ratings yet

- Astm D4053Document3 pagesAstm D4053AndygarciaNo ratings yet

- Chapter 3 - Force and MotionDocument4 pagesChapter 3 - Force and MotionJerico LlovidoNo ratings yet

- MATLAB Problem Set 4Document12 pagesMATLAB Problem Set 4xman4243No ratings yet

- Inductance, Inductive Reactance, and Inductive Circuits Inductance, Inductive Reactance, and Inductive CircuitsDocument51 pagesInductance, Inductive Reactance, and Inductive Circuits Inductance, Inductive Reactance, and Inductive CircuitsKareen Chua0% (1)

- Ac Part 2Document10 pagesAc Part 2Lester James SaingNo ratings yet

- Solution To Manometer Problem PDFDocument5 pagesSolution To Manometer Problem PDFMark Augusto V. AgusNo ratings yet

- Guide 80: Guidance For The In-House Preparation of Quality Control Materials (QCMS)Document11 pagesGuide 80: Guidance For The In-House Preparation of Quality Control Materials (QCMS)NOURNo ratings yet

- Experiment NodalDocument8 pagesExperiment NodalWyndellRioNo ratings yet

- Mech 343 Lab Report 1Document22 pagesMech 343 Lab Report 1Yousef MeguidNo ratings yet

- Structural Dynamics 1.1-090921Document34 pagesStructural Dynamics 1.1-090921santoshNo ratings yet

- Assignment No. 1 - Basics of Quantity Surveying: Metric SystemDocument11 pagesAssignment No. 1 - Basics of Quantity Surveying: Metric SystemVince JecielNo ratings yet

- 1PQ8315-4PB40-Z A23+A72+C14+H70 Datasheet enDocument1 page1PQ8315-4PB40-Z A23+A72+C14+H70 Datasheet enyon naNo ratings yet

- 1cm To 6kmDocument5 pages1cm To 6kmFekir ZelekeNo ratings yet

- Otero2002 QSEDocument6 pagesOtero2002 QSEaissadia80No ratings yet

- Bottom Hole PressureDocument30 pagesBottom Hole PressuredinoNo ratings yet

- Kejenuhan Parsial Dan KelembapanDocument44 pagesKejenuhan Parsial Dan KelembapanMaritsya Dita Kurnia PutriNo ratings yet

- Verification of Norton TheoremDocument3 pagesVerification of Norton TheoremImam Mehedi HasanNo ratings yet

- "راجع معانا".. المراجعة النهائية في مادة "الفيزياء لغات" لطلاب الصف الأول الثانويDocument10 pages"راجع معانا".. المراجعة النهائية في مادة "الفيزياء لغات" لطلاب الصف الأول الثانويHassan MosadNo ratings yet

- Medidor StarDocument4 pagesMedidor StarFredy De Jesús SaloméNo ratings yet

- Steady-State Flow of Gas Through Pipes: Du+ DV G G DZ +D (PV) +DQ D WDocument16 pagesSteady-State Flow of Gas Through Pipes: Du+ DV G G DZ +D (PV) +DQ D WAkshat TarateNo ratings yet

- Spektra Se-09 Data Sheet enDocument2 pagesSpektra Se-09 Data Sheet enjairNo ratings yet

- 2024 UHS Mock Fma SolutionsDocument16 pages2024 UHS Mock Fma SolutionsLuke HuangNo ratings yet

- 16MVA Transformer Test Schedule CommentsDocument1 page16MVA Transformer Test Schedule CommentsAmany HamdyNo ratings yet

- Physics For Scientists and Engineers 9th Edition Serway Test BankDocument23 pagesPhysics For Scientists and Engineers 9th Edition Serway Test Bankninhletitiaqt3100% (29)

- SUMMARY of HEAT ENERGY Grade 7Document2 pagesSUMMARY of HEAT ENERGY Grade 7yopy metzNo ratings yet

- For SteamDocument17 pagesFor Steammehmet hassanNo ratings yet

- SI Prefixes: Prefix Symbol Factor Prefix Symbol Factor Y Z E P T G M k h da d c m μ n p f a z yDocument2 pagesSI Prefixes: Prefix Symbol Factor Prefix Symbol Factor Y Z E P T G M k h da d c m μ n p f a z yDerick PeraltaNo ratings yet