Professional Documents

Culture Documents

8D Report 中英文对照模板

8D Report 中英文对照模板

Uploaded by

cong da0 ratings0% found this document useful (0 votes)

944 views4 pagesOriginal Title

8D-Report-中英文对照模板

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

944 views4 pages8D Report 中英文对照模板

8D Report 中英文对照模板

Uploaded by

cong daCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 4

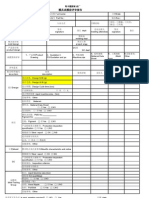

8D-Report/8D报告

Reference No.: Intermediate report date:

8D编号: 中间报告:

Concession No.: Final report date:

回用/让步放行编号: 最终报告:

Header data/ 表头信息

Complaint Date: Product:

投诉日期: 4/20/2011 产品型号: 前橡胶减震

8D-Title:

8D主题: 橡胶部分出现裂口

Warranty Decision: Manufacturing plant:

质保决定: 制造工厂: 河北旭龙公司

Customer: Customer Material No.:

客户: 北方凌云 客户物料编号:

Complaint type/mode: Serial No.:

投诉类型/方式 电子邮件 系列号:

Supplier No.:

供应商编号:

Supplier name: Issuer:

供应商名称: 发布者:

Contact Person at Customer: Telephone:

客户联系人: 电话:

Business Address: Telefax:

通讯地址: 传真:

Email:

电子邮件:

Telephone:

电话:

Business Address: Telefax:

通讯地址: 传真:

Email:

电子邮件:

Contact Person at Supplier: Telephone:

供应商联系人: 电话:

Business Address: Telefax:

通讯地址: 传真:

Email:

电子邮件:

D1 Problem Solving Team/ 解决问题工作组

Sponsor:

监管人: 张健

Surname/ 姓 Lastname/ 名 Teamleader/ 组长 E-Mail - Address/电子邮件地址:

Team: xulongjsb@163.com

组员:

Externals:

外部人员:

D2 Problem Description/ 问题描述

Customer Complaint:

客户投诉内容: 前橡胶减震橡胶部分出现裂口

Manufacturer Descr:

生产者描述:

Failure Type:

故障类型: 生产型故障

Failure Location:

故障位置: 橡胶与骨架连接部分

Manufacturing Date: Quantity of complaint products: End date of D2:

生产日期: 客户投诉的产品数量: D2结束日期:

D3 Containment action(s)/ 临时措施(围堵行动)

检查现有库存产品

Responsible: introduced on: effective from:

负责人: 张健 引进日期: 生效日期:

Agreement of the customer with process or product-changing immediate measures at: Responsible:

客户同意有关过程改变或产品改变的临时措施的日期: 负责人:

Editor: BR/QMM1 FR 08958-1 Page 1 / 4

8D-Report/8D报告

Reference No.: Intermediate report date:

8D编号: 中间报告:

Concession No.: Final report date:

回用/让步放行编号: 最终报告:

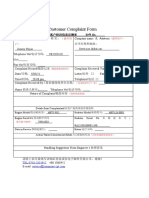

D4 Root Cause Analysis/ 根本原因分析:

Failure Cause / Causing Process:

故障原因/原因分析过程:

在硫化过程中由于模具底部温度过高,用胶量过大,使部分产品出现橡胶与骨架粘接部分烧边现象,

Root cause(s) (RC) and verification of effectiveness: why could the failure occur?

根本原因(RC)及其有效性验证:为什么故障会发生?

在硫化过程中由于模具底部温度过高,用胶量过大。

Responsible: completed on:

负责人: 张健 完成日期: 4/21/2011

Root cause(s) (RC) and verification of effectiveness: why has the failure not been detected?

根本原因(RC)及其有效性验证:为什么故障没有被发现?

没有设置此处的检验点

Responsible: completed on:

负责人 田连海 完成日期: 4/21/2011

Expected effects/Risk assessment (Probability)/ 风险评估:

Production period affected from: to: Responsible: completed on:

受到影响的生产周期: 直到: 负责人: 完成日期:

Expected quantity of further failure at produced parts: Pot. failure qty: intern: 0 km: Field:

估计此后生产出的该种故障产品/零件数量: 0 潜在故障数量: 内部: 0 现场:0

D5 Potential corrective actions and proof of effectiveness/ 潜在的纠正措施和有效性的证实:

将厂内现有产品逐一检验,避免再有此类现象发生,增加此种检验点

Responsible: completed on:

负责人: 田连海 完成日期: 4/21/2011

D6 Introduction of corrective actions and tracking of effectiveness/ 实施纠正措施并追踪其有效性:

Introduced corrective action(s)/ 实施的纠正措施:

已经将现有的库存产品进行了逐一检验。在检验规程中已经增加相应检验项目

Responsible: planned introduction on: introduced on: effective from:

负责人: 张健 计划引进日期: 4/21/2011 引进日期: 4/21/2011 生效日期: 4/21/2011

Customer agreement at: by:

客户认可: 通过:

Tracking of effectiveness of the introduced corrective action(s)/ 实施的纠正措施的有效性跟踪:

已经将现有的库存产品进行了逐一检验。在检验规程中已经增加相应检验项目

Responsible: completed on:

负责人: 张健 完成日期: 4/21/2011

Removal of containment action(s)/ 取消围临时措施:

Responsible: removed at:

负责人: 取消日期:

D7 Preventive action(s) of recurrence of the failure/ 避免故障再次发生的预防措施:

Update for QM-System (FMEA, Procedure-Instructions, PQP ...)

优化质量管理体系(FMEA,程序指导,PQP...)

Responsible: due date: completed on:

负责人: 要求完成日期: 实际完成日期:

Adoption of Poss. Corrective Action(s) for other Processes, Products, Sites:

可以应用到其他过程、其他产品、其他场所的纠正措施:

Could the failure concern other processes, products or sites?

此故障跟其他过程、产品或场所有关吗?

If yes: Which departments do you inform (e.g. FMEA, Lessons-Learned Coordinators)?

Editor: BR/QMM1 FR 08958-1 Page 2 / 4

8D-Report/8D报告

Reference No.: Intermediate report date:

8D编号: 中间报告:

Concession No.: Final report date:

回用/让步放行编号: 最终报告:

如果是:要通知哪些部门(例如:FMEA和学习教训的协调员)?

If no: Why don't you expect other processes, products or sites to be concerned?

如果不是:为什么你认为与其他过程、产品或场所无关?

Responsible: due date: completed on:

负责人: 要求完成日期: 实际完成日期:

Editor: BR/QMM1 FR 08958-1 Page 3 / 4

8D-Report/8D报告

Reference No.: Intermediate report date:

8D编号: 中间报告:

Concession No.: Final report date:

回用/让步放行编号: 最终报告:

D8 Final Meeting/ 最终会议

Surname/姓 Lastname/名 E-Mail - Address/ 电子邮件:

Participant:

参加人员:

accomplished at:

会议地点:

Results:

结果:

Signatures/签名:

P/QMM: Name: Date: Signature:

工厂质量部经理 名字: 日期: 签名:

Sponsor: Name: Date: Signature:

监管人: 名字: 日期: 签名:

Editor: BR/QMM1 FR 08958-1 Page 4 / 4

You might also like

- 模具试模前评审报告Document1 page模具试模前评审报告api-3832465100% (3)

- 注塑模具基本结构Document51 pages注塑模具基本结构王振华No ratings yet

- FMEA标准模板Document12 pagesFMEA标准模板cong daNo ratings yet

- FMEA标准模板Document12 pagesFMEA标准模板cong daNo ratings yet

- 8D报告模板Document3 pages8D报告模板cong da100% (1)

- 8D报告模板Document3 pages8D报告模板cong da100% (1)

- APQP (全套) 表格最新版Document178 pagesAPQP (全套) 表格最新版cong daNo ratings yet

- QRCI Training 普及版 中英文Document27 pagesQRCI Training 普及版 中英文cong daNo ratings yet

- 产品质量先期策划和控制计划Document88 pages产品质量先期策划和控制计划Jialu LINo ratings yet

- APQP全套表格Document177 pagesAPQP全套表格cong daNo ratings yet

- FMEA潜在失效模式和后果分析Document155 pagesFMEA潜在失效模式和后果分析ALLAN YUENo ratings yet

- (PPAP管理) 东风日产PPAP表格Document13 pages(PPAP管理) 东风日产PPAP表格cong daNo ratings yet

- 如何编制过程流程图、PFMEA、控制计划文件Document71 pages如何编制过程流程图、PFMEA、控制计划文件張為政No ratings yet

- 五大工具Document60 pages五大工具zhang xuefengNo ratings yet

- FMEA试题Document3 pagesFMEA试题isolong50% (2)

- 控制计划CP培训教材Document123 pages控制计划CP培训教材張為政No ratings yet

- IATF16949标准全中文整合Document75 pagesIATF16949标准全中文整合Jerry lungNo ratings yet

- SWOT分析法Document51 pagesSWOT分析法cong daNo ratings yet

- GP12培训 (供应商管理)Document38 pagesGP12培训 (供应商管理)peterNo ratings yet

- 8D報告Document14 pages8D報告ericNo ratings yet

- PPAP文件包全套文件 (内含33个文件)Document68 pagesPPAP文件包全套文件 (内含33个文件)cong daNo ratings yet

- APQP全套表格范例Document99 pagesAPQP全套表格范例cong daNo ratings yet

- Vda6 3 2016Document34 pagesVda6 3 2016Andy WangNo ratings yet

- Process FMEA EddieDocument84 pagesProcess FMEA Eddie邓师傅No ratings yet

- IATF 五大工具 (APQP -CP -PPAP -FMEA -SPC -MSA) 口訣重點整理Document28 pagesIATF 五大工具 (APQP -CP -PPAP -FMEA -SPC -MSA) 口訣重點整理江義翔No ratings yet

- Five Manual关系及难点Document41 pagesFive Manual关系及难点许勇No ratings yet

- IATF16949 2016中文版Document46 pagesIATF16949 2016中文版sin low100% (1)

- 生产件批准程序(PPAP)Document103 pages生产件批准程序(PPAP)api-3712408100% (3)

- 先期质量工程师在项目各阶段的职责AQEDocument27 pages先期质量工程师在项目各阶段的职责AQE白子健No ratings yet

- 5508aiag & Vda Fmea 1st Edition 2019新版簡介與應用Document10 pages5508aiag & Vda Fmea 1st Edition 2019新版簡介與應用QilinNo ratings yet

- 如何做控制计划Document19 pages如何做控制计划張為政No ratings yet

- Aiag & Vda Fmea-msr表格Document1 pageAiag & Vda Fmea-msr表格isolongNo ratings yet

- IATF 16949汽车质量管理体系Document55 pagesIATF 16949汽车质量管理体系jackhanNo ratings yet

- IATF 16949策划表Document4 pagesIATF 16949策划表isolongNo ratings yet

- 上汽GVDP 整车开发流程Document83 pages上汽GVDP 整车开发流程cong da100% (3)

- 新版 AIAG-VDA FMEADocument146 pages新版 AIAG-VDA FMEALEE-WANG Lin100% (1)

- GR&R Msa FormatDocument3 pagesGR&R Msa FormatĐỗ Thành NhươngNo ratings yet

- GM 1927-02 Timing ChartDocument1 pageGM 1927-02 Timing CharthuangjlNo ratings yet

- MLA培训大纲Document1 pageMLA培训大纲isolongNo ratings yet

- apqp第三版中文Document83 pagesapqp第三版中文Zhijun WuNo ratings yet

- PPAP 第四版Document74 pagesPPAP 第四版王金源No ratings yet

- anpqp手册Document89 pagesanpqp手册zhouhao100% (1)

- Plan de Control PDFDocument3 pagesPlan de Control PDFPaulinaTrejoLealNo ratings yet

- 鴻海公司常用英語Document14 pages鴻海公司常用英語wenic99No ratings yet

- Vda 6.3-2023红皮中文版 (扫描)过程审核 第四版Document8 pagesVda 6.3-2023红皮中文版 (扫描)过程审核 第四版cdmingNo ratings yet

- 8D及5C报告Document26 pages8D及5C报告cong daNo ratings yet

- Iatf 16949 2016 170218122139 - Compress PDFDocument67 pagesIatf 16949 2016 170218122139 - Compress PDFPatirck ShaoNo ratings yet

- PPAPDocument78 pagesPPAPTimimin100% (1)

- MMOG V4.0 ChineseDocument13 pagesMMOG V4.0 ChineseAdriana HubleaNo ratings yet

- GBT 19001-2016质量管理体系要求Document30 pagesGBT 19001-2016质量管理体系要求thilly OUNo ratings yet

- 《软件研发效能度量规范》(T IQA 15-2022)Document56 pages《软件研发效能度量规范》(T IQA 15-2022)tank100% (1)

- APQPDocument97 pagesAPQPmapalptsNo ratings yet

- camds使用手册cnDocument154 pagescamds使用手册cncong daNo ratings yet

- 9.50171 Saldatura Elettrica Per Resistenza A SovrapposizioneDocument15 pages9.50171 Saldatura Elettrica Per Resistenza A SovrapposizioneRamon PonteNo ratings yet

- Gbt 19000-2016质量管理体系 基础和术语Document59 pagesGbt 19000-2016质量管理体系 基础和术语thilly OUNo ratings yet

- q2-Cx-qa02 量測系統分析管理程序書 v02 VnDocument16 pagesq2-Cx-qa02 量測系統分析管理程序書 v02 VnLoc HuynhNo ratings yet

- JK-T 782G PDFDocument72 pagesJK-T 782G PDFRafael CamposNo ratings yet

- 03. SPC (第2版)Document115 pages03. SPC (第2版)许勇No ratings yet

- 东康海外抱怨表格 (9106)Document1 page东康海外抱怨表格 (9106)JimmyNo ratings yet

- PI FedexDocument1 pagePI FedexRomain DonatoNo ratings yet

- 服务单Document2 pages服务单吕康慧No ratings yet

- Ced 335Document5 pagesCed 335Alex LeungNo ratings yet

- Sds/Msds Application FormDocument7 pagesSds/Msds Application FormPeter ChangNo ratings yet

- 国际咨询服务合同Document7 pages国际咨询服务合同jeffliu1211No ratings yet

- 乘用车滑轨角调性能指标Document47 pages乘用车滑轨角调性能指标cong daNo ratings yet

- 佛吉亚 7QB审核表答案Document2 pages佛吉亚 7QB审核表答案cong daNo ratings yet

- 佛吉亚QRQC到QRCI,质量问题快速反应到持续改善Document16 pages佛吉亚QRQC到QRCI,质量问题快速反应到持续改善cong daNo ratings yet

- FES手册Document26 pagesFES手册cong daNo ratings yet

- 佛吉亚卓越体系知识手册Document12 pages佛吉亚卓越体系知识手册cong daNo ratings yet

- Formel q 过程审核佛吉亚Document26 pagesFormel q 过程审核佛吉亚cong daNo ratings yet

- 8D报告模板Document3 pages8D报告模板cong daNo ratings yet

- 5W1H分析法Document50 pages5W1H分析法cong daNo ratings yet

- Flow ChartDocument3 pagesFlow Chartcong daNo ratings yet

- 8D及5C报告Document26 pages8D及5C报告cong daNo ratings yet

- 高强度汽车座椅调角器核心件Document19 pages高强度汽车座椅调角器核心件cong daNo ratings yet

- Control PlanDocument2 pagesControl Plancong daNo ratings yet

- Material&Performance Test ReportDocument3 pagesMaterial&Performance Test Reportcong daNo ratings yet

- Dimension InspectionDocument4 pagesDimension Inspectioncong daNo ratings yet

- Control PlanDocument2 pagesControl Plancong daNo ratings yet

- VDA6 3过程审核应用实例(支持限时转发下载)Document43 pagesVDA6 3过程审核应用实例(支持限时转发下载)cong daNo ratings yet

- Control - Plan CHK011Document3 pagesControl - Plan CHK011cong daNo ratings yet

- 佛吉亚327A 8D报告Document1 page佛吉亚327A 8D报告cong daNo ratings yet

- SWOT分析法Document16 pagesSWOT分析法cong daNo ratings yet

- 佛吉亚工厂五级评价标准内容Document42 pages佛吉亚工厂五级评价标准内容cong daNo ratings yet

- 产品质量先期策划(APQP) 实例Document31 pages产品质量先期策划(APQP) 实例cong daNo ratings yet

- QRCI training 普及版 中英文Document27 pagesQRCI training 普及版 中英文cong daNo ratings yet

- CPK,Sigma和PPM之间的换算Document9 pagesCPK,Sigma和PPM之间的换算cong daNo ratings yet

- 8 IATF16949 2016汽车行业质量管理体系标准Document46 pages8 IATF16949 2016汽车行业质量管理体系标准cong daNo ratings yet

- 娜菲扎八字五行Document5 pages娜菲扎八字五行shancao323No ratings yet

- 110.11.09 正念減壓初體驗 詹翔霖老師 薩提爾的自我覺察練習喬鑫鍋物Document68 pages110.11.09 正念減壓初體驗 詹翔霖老師 薩提爾的自我覺察練習喬鑫鍋物詹翔霖0955268997No ratings yet

- 每日诵祷补编(新增圣人专辑、中华圣人专辑)Document109 pages每日诵祷补编(新增圣人专辑、中华圣人专辑)pppan777No ratings yet

- 集成电路标准纵览Document5 pages集成电路标准纵览jerryNo ratings yet

- ISG CM2880 - 01 - Overview - CN - 20140528Document15 pagesISG CM2880 - 01 - Overview - CN - 20140528cx zNo ratings yet