Professional Documents

Culture Documents

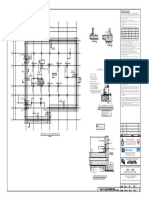

Elevation of Multiplane Anchorage (Ma) : Legend

Uploaded by

UmesgOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elevation of Multiplane Anchorage (Ma) : Legend

Uploaded by

UmesgCopyright:

Available Formats

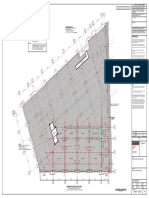

UPS-DSI GENERAL STRUCTURE NOTES: NOTES

GROUT INLET/OUTLET FOLLOWING NOTES SHALL BE TAKEN IN TO ACCOUNT AS

INSITU CONCRETED AFTER

1. THESE DRAWINGS ARE TO BE READ IN CONJUNCTION WITH APPLICABLE WHEN READING DRAWINGS LAUNCHING THE GIRDERS.

THE ARCHITECTS/CONSULTANTS/CONTRACTORS DRAWINGS A H B 1. ALL LEVELS DIMENSIONS AS SHOWN IN THE DRAWINGS ARE IN

G BONDING AGENT WILL BE

WEDGE PLATE K METERS MILLIMETERS EXCEPT WHERE AS DESCRIBED

AND SPECIFICATIONS. J

APPLIED BEFORE CONCRETING

BEAM EDGE

2. VERIFY ALL DIMENSIONS WITH RELEVANT CONSULTANTS 2. DESIGN COMPRESSIVE STRENGTH OF CONCRETE

BOX GIRDER - C 55 / 67

DRAWINGS. DO NOT SCALE DRAWINGS. ØC SUBSTRUCTURE - C 35 / 40

ØB

ØC

ØB

A

3 . DESIGN YIELD STRENGTH OF STEEL

UPS-DSI POST-TENSIONING NOTES: YIELD STRENGTH - 500N/mm2

DUCT POST TENSIONED TENDONS = 1860N/mm2

1. ALL MATERIAL AND WORKMANSHIP SHALL CONFORM TO SLS EN -1992-2:2014 ØF+N

A D E B POST TENSIONING TENDONS OF THE

2. STRANDS SHALL COMPLY TO PR EN 10138 BEAM CONSIST OF 7 WIRE, 15 7mm

SECTION A SECTION B UNCOATED STRANDS ACCORDING

(LIVE END BURSTING REINFT.) TO EUROPEAN LOW RELAX

NOMINAL Ø NOMINAL TENSILE NOMINAL (mm2) CHARACTERISTIC

STRENGTH. (N/mm2) CROSS-SECTIONAL,A

4. LAP LENGTHS

TENSILE FORCE (KN)

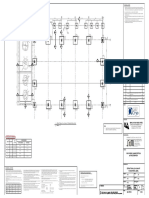

ELEVATION OF MULTIPLANE ANCHORAGE (MA) TENSION REINFORCEMENTS - 51XBAR DIAMETER

"0.62" ( 15.7mm ) 1860 150 279

5. DUCT SIZES

TENDON 12X15.7mm = 85mm

TENDON 5X15.7mm = 23mm X 90mm

* STRAND TO BE STRESS RELIEVED, LOW RELAXATION DSI MULTI PLANE ANCHORAGE (MA) & ANTI-BURSTING REINFORCEMENT DATA

INITIAL PRE STRESSING FORCE =75% Fu =209.25 kN

6.COVER TO REINFORCEMENT

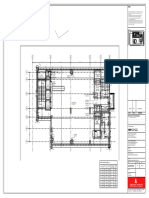

TRANSVERSE CONNECTION

USS MULTIPLANE ANCHORAGE (MA)

FRICTION : ANGULAR COEFFICIENT U = 0.2/rad

AND BOX-OUT DETAILS

BURSTING REINFT. SCHEDULE BOX GIRDERS

BOX GIRDER OUTER AND INNER PERIMETER - 45mm

WOBBLE COEFFICIENT K = 0.0017 NO OF DUCT DIA. (S4/SX1)

ANCHORAGE TYPE BURSTING REINFT. TURNS ID/OD MINIMUM DISTANCE TO DUCT FROM CONCRETE FACE

3. THE MINIMUM CONCRETE CUBE STRENGTH AT TRANSFER A ØB ØC D E

ØF G H J K N DUCT WITH TENDON 12X15.7 = 80mm

4. TENDON PROFILE DIMENSIONS INDICATED ARE MEASURED

DUCT WITH TENDON 5X15.7 = 45mm

FROM BOTTOM OF GIRDER TO SOFFIT OF DUCT 10 TO 12 - 0.62" ( 15.7mm ) 270 220 170 100 180 T16 300 40 45 280 7 80/85

FOR MA TENDONS. AT ANCHORAGES MINIMUM DISTANCE BETWEEN DUCTS

THE DIMENSION IS TO C.G. OF THE TENDON. DUCT WITH TENDON 12X15.7 = 85mm

DUCT WITH TENDON 5X15.7 = 90mm

TENDON DESIGNATION :

1MA-MA-"0.62"-12

FOR STRESSING POCKET PIER PIER

2x2T12(T&B) SLAB DISTRIBUTION BARS(T&B)

SIZE SEE PLAN C.L. C.L.

L=2400 2T12(T&B) ANTI-BURSTING 55 Thick 55 Thick

NO. OF TENDONS

wearing surface 600

REINFORCEMENT wearing surface 600

END 1 ANCHOR TYPE L=1200

END 2 ANCHOR TYPE

LEGEND:

SLAB REBAR WHICHEVER

SLAB REBAR WHICHEVER

Fixed End

STRAND SIZE

Anchor

T12-200(T&B) OR

STRESSING END. Anchor

IS GREATER

IS GREATER

T12-200(T&B) OR

NO. OF STRANDS Cap Cap

/

LAP LENGTH

DEAD END Pipe

Sleeve Sleeve

Fixed End Cap

Anchor

Sleeve

Pipe

Clear

Anchor

25

Steel

Ø Stainless

Dowel

Gap

bar

Anchor bar Anchor bar

5. THE COMPRESSIVE STRENGTH (100mm CUBES) TENDON 40 Ø Stainless 40 Ø Stainless

OF GROUT SHALL BE NOT LESS THAN 27 N/mm Steel Dowel (1m intervals) Steel Dowel(1m Intervals)

AT 7 DAYS. Box Girder 2500 15mm Clear Gap

Box Girder 15mm

Profile 2500 Clear Gap

800 H10-50 LINKS Profile

2T12(T&B)

6. TENDONS ARE TO BE GROUTED AFTER COMPLETION OF ALL

L=2200 SLAB DISTRIBUTION BARS(T&B)

STRESSING. THE GROUT SHALL BE A NEAT CEMENTITIOUS GROUT

WITH A MAX. WATER/CEMENT RATIO OF 0.44 TYPICAL TRIMMER BAR DETAIL FOR STRESSING POCKET

7. ALL THE SITE ADJUSTMENT WORK OF ALL TYPE OF REINFORCEMENT SHALL BE

A B

ACCORDING TO THE FOLLOWING PRIORITY U.O.S.

G C

A. PRESTRESSING TENDONS. WEDGES ØH

J ANCHOR BODY

B. NON-PRESTRESSED REINFORCEMENT. CONCRETE SURFACE FLAT DUCT.

FLAT DUCT.

A

PLASTIC TRUMPET PLASTIC TRUMPET

WEDGE PLATE FIXED END

WEDGE PLATE FREE END

ANCHOR BODY 2H10(T&B)

C D WEDGES

A PLAN B ELEVATION Anchor cap

F L 110

ANCHOR

2H10 CAP t=3.2

3 110x40x3.2 thick.

40

Welded to pipe Stainless Steel Plate D25 Stainless

E

2H10 Steel Bar (Gr.316)

65

D40 Stainless

ANCHOR BODY WEDGE PLATE Steel Bar (Gr.316) 3.2

ANCHOR BAR

SECTION-A SECTION-B D40 1

100x30x3.2 thkck. 3- ANCHOR CAP 100x30x3.2 thick. Stainless

Steel Pipe (Gr.316)

Stainless Steel Pipe 1:5

295

360

(Gr.316)

600

PIPE SLEEVE

UPS FLAT ANCHORAGE (SA) & ANTI-BURSTING REINFORCEMENT DATA 15

t=3.2mm

2

DETAIL "X" 5 100

TECHNICAL DATA ANTI-BURSTING REINFORCEMENT Cast-in-situ

MIN. SLAB D8

80

4 End

NO OF THK. AT SA 950 mm Diaphragm

TYPE 0.5" TYPE 0.6"/0.62" A B C D E F G ØH J K L 15

5 X 50

LINKS ANCHORAGE T8

4

290

STIRRUP

6 5 215 125 90 300 115 195 250 H12 35 160 225 7 240

250

1- ANCHOR BAR

1 : 10 3.2 100 3.2

4- STIRRUP 5-DETAIL "X"

1 : 10

Longitudinal 1:5

30

DETAIL OF ANCHOR - FREE END

1 : 10

Expansion Joint 2- PIPE SLEEVE

1:5

FREE END DOWEL DETAILS

Employer CONTRACTOR Scale As Shown Project Title

DESIGN AND CONSTRUCTION OF TWO FLYOVERS IN SLAVE ISLAND ALONG

DEMOCRATIC SOCIALIST REPUBLIC OF SRI LANKA

Maga Engineering (Pvt) Ltd. Designed Malith JUSTICE AKBAR MAWATHA AND UTTARANANDA MAWATHA OVER RAILWAY TRACKS

MINISTRY OF HIGHWAYS

200, Nawala Road, Narahenpita Drawn Harshaka Drawing Title

GENERAL NOTE

ROAD DEVELOPMENT AUTHORITY

PROJECT DIRECTOR - MFA PROJECT

MAGA Colombo 05, Sri Lanka. Checked Laknatha

Drawing No. Sheet No. REV

Tel :2808835 to 2808844 Fax :2808846 & 2808847 Approved

Wing C 12th Floor, Sethsiripaya Stage II, Battaramulla. Email : maga@maga.lk MAGA/FLOB/UM-GN-1 01 of 01 00

Date 18-05-2021 REV DATE DESCRIPTION

You might also like

- D C B A D C B A: Ground Floor Plan SCALE 1:100 1 3 Architectural Floor Plan SCALE 1:100Document1 pageD C B A D C B A: Ground Floor Plan SCALE 1:100 1 3 Architectural Floor Plan SCALE 1:100Ahmed Daahir AdenNo ratings yet

- Equipment Layout Plan DetailsDocument1 pageEquipment Layout Plan DetailsAhmed SalahNo ratings yet

- Custom LayoutDocument1 pageCustom Layouttalk2olaolu1962No ratings yet

- General Notes:: SSL +72.910 MDocument1 pageGeneral Notes:: SSL +72.910 MAnonymous qEPNPwANo ratings yet

- Sectional Elevation-A Sectional Elevation-B: EQ EQ EQDocument1 pageSectional Elevation-A Sectional Elevation-B: EQ EQ EQSAL ARCHITECTURENo ratings yet

- Appendix - B DrawingsDocument7 pagesAppendix - B DrawingsShreekant KeraiNo ratings yet

- See "Detail A" For Ventilation: NotesDocument1 pageSee "Detail A" For Ventilation: NotesMohamed AslamNo ratings yet

- DfghbsfgbhsdbllntusdyDocument3 pagesDfghbsfgbhsdbllntusdyBen TigerXNo ratings yet

- 8948 Rev1 Milton Wsg001 Eng Sh3 1Document1 page8948 Rev1 Milton Wsg001 Eng Sh3 1tshepo hlakudiNo ratings yet

- El 06 09R2Document4 pagesEl 06 09R2Nasser SabrNo ratings yet

- 10-Beasment Foundation LayoutDocument1 page10-Beasment Foundation LayoutUzair QuraishiNo ratings yet

- First Floor Level Beam Details Part-2 (Sheet-2 of 2)Document1 pageFirst Floor Level Beam Details Part-2 (Sheet-2 of 2)Sumit LathwalNo ratings yet

- Ar Main MajlisDocument32 pagesAr Main MajlisAli BaiasiNo ratings yet

- General notes and specifications for masonry, concrete and reinforcementDocument1 pageGeneral notes and specifications for masonry, concrete and reinforcementajNo ratings yet

- ASTER-C 9 Kitchen Detail-Aster C Unit-3Document1 pageASTER-C 9 Kitchen Detail-Aster C Unit-3simranNo ratings yet

- D-446 To D-447 Column P1-P15 GrpADocument2 pagesD-446 To D-447 Column P1-P15 GrpAChristian MendozaNo ratings yet

- Luul Gelle-Structural PDFDocument4 pagesLuul Gelle-Structural PDFCOSOB BILANo ratings yet

- General notes for construction drawingsDocument1 pageGeneral notes for construction drawingsAnonymous qEPNPwANo ratings yet

- Ca 477021 002Document1 pageCa 477021 002Sehna SerajNo ratings yet

- Ef 025 Cidco PTR ST 109 FDocument1 pageEf 025 Cidco PTR ST 109 FAshok PalNo ratings yet

- Residential Project - Group Housing: Doors/Windows ScheduleDocument1 pageResidential Project - Group Housing: Doors/Windows SchedulePrakriti GoelNo ratings yet

- K H110984001V00Document1 pageK H110984001V00Anonymous X3PnFL6No ratings yet

- (0030) Salman Town Solar Project Solar SMDBDocument6 pages(0030) Salman Town Solar Project Solar SMDBSavio SunnyNo ratings yet

- Appendix 6 - Tile Location - REFERENCEDocument10 pagesAppendix 6 - Tile Location - REFERENCEJpbNo ratings yet

- Multilateral. Multilateral.: Construction IssueDocument1 pageMultilateral. Multilateral.: Construction IssueAnonymous qEPNPwANo ratings yet

- TOILETDocument1 pageTOILETShruti KhatanNo ratings yet

- 20024-000000u-D003 - Ufd - Plant Water Rev 0Document1 page20024-000000u-D003 - Ufd - Plant Water Rev 0oscar alfredoNo ratings yet

- General notes for construction drawingsDocument1 pageGeneral notes for construction drawingsmhazarath murariNo ratings yet

- St-Hidd-01 Security Room DetailsDocument1 pageSt-Hidd-01 Security Room Detailsmhazarath murariNo ratings yet

- Notes:: Hinge DetailsDocument1 pageNotes:: Hinge DetailsYazan MohammadNo ratings yet

- 3rd & 4th Floor Plan-Layout1Document1 page3rd & 4th Floor Plan-Layout1yadvikram7No ratings yet

- 2nd Floor Plan Bridge-Layout1Document1 page2nd Floor Plan Bridge-Layout1yadvikram7No ratings yet

- FS0654-DOD-XX-01-DR-P-4004 - First Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0Document1 pageFS0654-DOD-XX-01-DR-P-4004 - First Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0mvrisleyNo ratings yet

- 21 - Rafter FINAL - ModelDocument1 page21 - Rafter FINAL - ModelsonofalexanderNo ratings yet

- 1.air Blower-Tesr - Sludge Sump STR DetailDocument1 page1.air Blower-Tesr - Sludge Sump STR DetailRohit JangidNo ratings yet

- G.F PlanDocument1 pageG.F Plankush jindalNo ratings yet

- Arch HM: On HoldDocument1 pageArch HM: On Holdanandit sharmaNo ratings yet

- 4217-Csd-C-1a-0504-R1-Details - Typical Fence - Sheet 01Document1 page4217-Csd-C-1a-0504-R1-Details - Typical Fence - Sheet 01Adi PriyapurnatamaNo ratings yet

- Ground Floor Slab Layout 110477 - 3010: VastintDocument1 pageGround Floor Slab Layout 110477 - 3010: VastintjudeNo ratings yet

- 04_HOUSE HUGO_REV 2_12.03.2024-DOOR SCHDocument1 page04_HOUSE HUGO_REV 2_12.03.2024-DOOR SCHD HOLNo ratings yet

- 04_HOUSE HUGO_REV 3_16.04.2024-DOOR SCHDocument1 page04_HOUSE HUGO_REV 3_16.04.2024-DOOR SCHD HOLNo ratings yet

- Hpcl-02a - Hvac SectionDocument1 pageHpcl-02a - Hvac SectionBN YADAVNo ratings yet

- Drawings - Civil & MEP-6Document1 pageDrawings - Civil & MEP-6KasunTilinaChathurangaNo ratings yet

- G+M ArchDocument16 pagesG+M ArchMUQEET ahmedNo ratings yet

- CTW320 Msy 00 El Abd 5002 05Document1 pageCTW320 Msy 00 El Abd 5002 05Jafffar MahasnehNo ratings yet

- A-100 - Basement PlanDocument1 pageA-100 - Basement Planvt7dcjvbwqNo ratings yet

- General notes for foundation drawingDocument1 pageGeneral notes for foundation drawingAnonymous qEPNPwANo ratings yet

- Structural design liability conditionsDocument1 pageStructural design liability conditionsMadhavi GanbavaleNo ratings yet

- General notes for CO2 and N2 tank foundationDocument1 pageGeneral notes for CO2 and N2 tank foundationmhazarath murariNo ratings yet

- Rajeevs Residence Revised Electrical LayoutDocument1 pageRajeevs Residence Revised Electrical Layoutavyukth.akNo ratings yet

- HVAC Duct Layout and NotesDocument1 pageHVAC Duct Layout and NotesᏗᎷᎥᏖᏕᎥᏁᎶᏂNo ratings yet

- Exist/ New Asphalt Road & Rig Road Crossing Details Table-1Document1 pageExist/ New Asphalt Road & Rig Road Crossing Details Table-1Er Md AamirNo ratings yet

- PD 0158 SM 06Document1 pagePD 0158 SM 06FAIZAN AHMEDNo ratings yet

- GC ST 01Document1 pageGC ST 01mhazarath murariNo ratings yet

- Unique: Non Fire Rate Door Non Fire Rate DoorDocument1 pageUnique: Non Fire Rate Door Non Fire Rate Doorwaseem alkhailNo ratings yet

- K H110984004V00Document1 pageK H110984004V00Anonymous X3PnFL6No ratings yet

- 1st Floor Plan - 201217t-Layout1Document1 page1st Floor Plan - 201217t-Layout1yadvikram7No ratings yet

- General Construction Notes Design Criteria: Schedule of Minimum Slab Reinforcement Lintels in Block WallsDocument1 pageGeneral Construction Notes Design Criteria: Schedule of Minimum Slab Reinforcement Lintels in Block WallsMItchNo ratings yet

- 218140-100 RS-02 First Floor Reinforcement LayoutDocument1 page218140-100 RS-02 First Floor Reinforcement LayoutrendaninNo ratings yet

- Slab GFDocument1 pageSlab GFUmesgNo ratings yet

- RANGADocument33 pagesRANGAUmesgNo ratings yet

- COMPLETED DRAWING Rev-1Document1 pageCOMPLETED DRAWING Rev-1UmesgNo ratings yet

- Foundation LayoutDocument1 pageFoundation LayoutUmesgNo ratings yet

- Proposed Extension To The Building at WanahagodaDocument1 pageProposed Extension To The Building at WanahagodaUmesgNo ratings yet

- UFDocument1 pageUFUmesgNo ratings yet

- P. Side Elevation DrawingDocument1 pageP. Side Elevation DrawingUmesgNo ratings yet

- Pitakotte - Thalawatugoda Road. (B - 368) BRIDGE NO. 3/4 Km. - (Widening)Document1 pagePitakotte - Thalawatugoda Road. (B - 368) BRIDGE NO. 3/4 Km. - (Widening)UmesgNo ratings yet

- Butterfly Flag Type (0+195, 0+120)Document12 pagesButterfly Flag Type (0+195, 0+120)UmesgNo ratings yet

- 3.000 M X 1.200 M Board (CKE 8+430)Document12 pages3.000 M X 1.200 M Board (CKE 8+430)UmesgNo ratings yet

- Reference Output 1.0 Genaral Details CalculationsDocument11 pagesReference Output 1.0 Genaral Details CalculationsUmesgNo ratings yet

- 3.000 X 1200m Flag Type (7+965)Document13 pages3.000 X 1200m Flag Type (7+965)UmesgNo ratings yet

- Completed DrawingDocument1 pageCompleted DrawingUmesgNo ratings yet

- COMPLETED DRAWING NewDocument1 pageCOMPLETED DRAWING NewUmesgNo ratings yet

- Reference Output 1.0 Genaral Details CalculationsDocument11 pagesReference Output 1.0 Genaral Details CalculationsUmesgNo ratings yet

- Pitakotte - Thalawatugoda Road. (B - 368) BRIDGE NO. 3/4 Km. - (Widening)Document1 pagePitakotte - Thalawatugoda Road. (B - 368) BRIDGE NO. 3/4 Km. - (Widening)UmesgNo ratings yet

- 3.000 M X 1.200 M Board (CKE 8+430)Document12 pages3.000 M X 1.200 M Board (CKE 8+430)UmesgNo ratings yet

- Butterfly Flag Type (0+195, 0+120)Document12 pagesButterfly Flag Type (0+195, 0+120)UmesgNo ratings yet

- 272003-C-StructuralComponents-structural Capasity of PileDocument5 pages272003-C-StructuralComponents-structural Capasity of PileVirendra Kumar PareekNo ratings yet

- Reference Output 1.0 Genaral Details CalculationsDocument11 pagesReference Output 1.0 Genaral Details CalculationsUmesgNo ratings yet

- Design Submission Programme - RevisedDocument8 pagesDesign Submission Programme - RevisedUmesgNo ratings yet

- Substructure Design of Via Duct Ch. 54+600 To 54+750: Pier P-4 RhsDocument2 pagesSubstructure Design of Via Duct Ch. 54+600 To 54+750: Pier P-4 RhsUmesgNo ratings yet

- 11.0 Structural Design of Pile For PiersDocument6 pages11.0 Structural Design of Pile For PiersUmesgNo ratings yet

- Substructure Design of Via Duct Ch. 54+600 To 54+750: Pier P-4 RhsDocument2 pagesSubstructure Design of Via Duct Ch. 54+600 To 54+750: Pier P-4 RhsUmesgNo ratings yet

- Substructure Design of Via Duct Ch. 54+600 To 54+750: Pier P-4 RhsDocument2 pagesSubstructure Design of Via Duct Ch. 54+600 To 54+750: Pier P-4 RhsUmesgNo ratings yet

- PC PDFDocument3 pagesPC PDFUmesgNo ratings yet

- 11.0 Structural Design of Pile For PiersDocument6 pages11.0 Structural Design of Pile For PiersUmesgNo ratings yet

- Resultant H: 10. Calculation of Circular Pile Capacity VerticalDocument3 pagesResultant H: 10. Calculation of Circular Pile Capacity VerticalUmesgNo ratings yet

- PC PDFDocument3 pagesPC PDFUmesgNo ratings yet

- Structure 1Document34 pagesStructure 1Yoon Myat BoNo ratings yet

- Proposed Design For A Four-Storey Building From A Two-Storey Building of Public School in Mandaue CityDocument42 pagesProposed Design For A Four-Storey Building From A Two-Storey Building of Public School in Mandaue CityRitchmon GonzalesNo ratings yet

- SSRN Id3376351Document6 pagesSSRN Id3376351Hema Chandra Reddy KarimireddyNo ratings yet

- Segmental Concrete Bridges: International Case StudiesDocument4 pagesSegmental Concrete Bridges: International Case StudiesSantosoNo ratings yet

- Intro to Structure: Definitions, Stability & DeterminacyDocument83 pagesIntro to Structure: Definitions, Stability & DeterminacyKerol Kerol KerolNo ratings yet

- NCCC Supermarket Interior Fit-out Remaining WorksDocument2 pagesNCCC Supermarket Interior Fit-out Remaining WorksGD BERDINNo ratings yet

- AWI Architectural-Woodwork-Standards-2nd-Edition PDFDocument510 pagesAWI Architectural-Woodwork-Standards-2nd-Edition PDFZeenath ShakirNo ratings yet

- 232 Structural Concrete Building Code (Aci 318-11) and CommentaryDocument1 page232 Structural Concrete Building Code (Aci 318-11) and CommentarySriram KiranNo ratings yet

- ITW Product Catalog22Document1 pageITW Product Catalog22johnNo ratings yet

- Tarea 2 Diseño de EstructurasDocument14 pagesTarea 2 Diseño de EstructurasRodolfo Carrillo VelderrainNo ratings yet

- Chapter Two Sector Analysis: (MBAM)Document23 pagesChapter Two Sector Analysis: (MBAM)Ferlyn PelayoNo ratings yet

- Visual Control in The Kaizen Conception: C) Toyota Production SystemDocument2 pagesVisual Control in The Kaizen Conception: C) Toyota Production SystemKrzysiek KNo ratings yet

- Innovative Peanut-Shaped Diaphragm Wall at The Sail @ Marina BayDocument14 pagesInnovative Peanut-Shaped Diaphragm Wall at The Sail @ Marina BayLasse Severin Bonde StouNo ratings yet

- Steel Beams Astm A36Document4 pagesSteel Beams Astm A36Wala LangNo ratings yet

- Case Study For ResidencDocument7 pagesCase Study For ResidencGizachew Begna100% (1)

- Calculation SheetDocument21 pagesCalculation SheetEngAmr ElmohndesNo ratings yet

- Schedule B PDFDocument122 pagesSchedule B PDFHarun RashidNo ratings yet

- Design of Bridges Using Limit State by IRC-112 CodeDocument45 pagesDesign of Bridges Using Limit State by IRC-112 CodeTIRTH100% (1)

- Svendsen 1967 Drained PE Joint Wall Principles of One-Stage and Two-Stage SealsDocument4 pagesSvendsen 1967 Drained PE Joint Wall Principles of One-Stage and Two-Stage SealsJohn StraubeNo ratings yet

- NA To Sls en 1993-6Document12 pagesNA To Sls en 1993-6Shan Sandaruwan AbeywardeneNo ratings yet

- Directors Associated With Soc Pune Search Able 21092017Document282 pagesDirectors Associated With Soc Pune Search Able 21092017Satish VermaNo ratings yet

- BIM Essential Guide For ContractorsDocument62 pagesBIM Essential Guide For ContractorsAriel Pagcaliwagan100% (1)

- Carpentry 9 Summative TestDocument9 pagesCarpentry 9 Summative TestJymaer GeromoNo ratings yet

- Weld-Crete® Concrete Bonding AgentDocument3 pagesWeld-Crete® Concrete Bonding AgentMario LanzaNo ratings yet

- Handbook: Smart BricksDocument12 pagesHandbook: Smart Bricksvamsi NathNo ratings yet

- Types of Pavements - Flexible Pavements and Rigid PavementsDocument2 pagesTypes of Pavements - Flexible Pavements and Rigid PavementsHitesh YadavNo ratings yet

- How Are Buildings and Structures Classified in The Current Building CodeDocument4 pagesHow Are Buildings and Structures Classified in The Current Building CodeGautam Kamra100% (1)

- ME522 Reports on Food, Packaging and Plastic ProcessesDocument8 pagesME522 Reports on Food, Packaging and Plastic ProcessesGodisGood AlltheTimeNo ratings yet

- Flex-Box Reefer Technical SpecificationDocument28 pagesFlex-Box Reefer Technical SpecificationJUAN MUÑOZNo ratings yet

- Computer Aided Analysis and Design of Retaining Walls: Harshit Raj Akhileshwar Kumar SinghDocument1 pageComputer Aided Analysis and Design of Retaining Walls: Harshit Raj Akhileshwar Kumar SinghHarshit Raj GuptaNo ratings yet