Professional Documents

Culture Documents

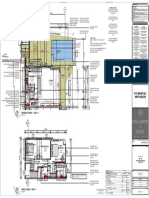

04 - House Hugo - Rev 3 - 16.04.2024-Door SCH

Uploaded by

D HOLOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 - House Hugo - Rev 3 - 16.04.2024-Door SCH

Uploaded by

D HOLCopyright:

Available Formats

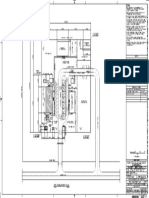

GENERAL NOTES:

COPYRIGHT RESERVED BY HOLLOWAY & HOUND ON ALL DESIGNS AND

DOCUMENTATION.

NO DRAWINGS TO BE SCALED.

ALL MEASUREMENTS, HEIGHTS AND LEVELS TO BE VERIFIED ON SITE PRIOR TO

COMMENCEMENT OF CONSTRUCTION AND ADAPTED TO SUGGESTED BUILDING WORK.

ANY DISCREPANCY OR CONTRADICTION TO BE DISCUSSED WITH THE ARCHITECT

IMMEDIATELY.

ALL DIMENSIONS INDICATED ON PLAN TO BE SET OUT ON A LEVEL HORIZONTAL PLANE .

ALL BRICKWORK TO BE SET OUT USING A PROFILE MARKED 85mm C/C.

THE CONTRACTOR IS RESPONSIBLE FOR THE CORRECT SETTING OUT OF THE BUILDING

WORK ON SITE WITH PARTICULAR REFERENCE TO SITE BOUNDARIES, SERVITUTES AND

BUILDING LINES.

THE CONTRACTOR IS TO BUILD IN APPROVED D.P.C's TO ALL EXTERNAL WALLS, UNDER

FLOORS AND UNDER WINDOW CILLS.

QUALITY OF ALL MATERIAL AND CRAFTMANSHIP TO COMPLY WITH THE RELEVANT S.A.B.S

STANDARDS.

THE CONTRACTOR SHOULD HAVE A FULL SET OF DRAWINGS AVAILABLE ON SITE AT ALL

TIMES.

THE CONTRACTOR IS RESPONSIBLE FOR HIS OWN QUALITY CONTROL.

ALL FLOOR LEVELS SHOWN ON THIS DRAWING REFER TO UNFINISHED FLOOR LEVELS.

GENERAL:

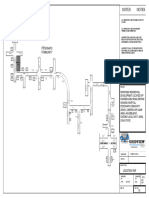

DRAINAGE:

Boundry pegs to be pointed out by

All sewers to be 100mm dia. PVC

owner.

min. fall 1:60, Max fall 1:10.

Contractor must check all levels,

dimentions, steps

Open end of vent pipe to be min.

etc. on site, and report all

2,0m above any opening.

discrepancies to the designer.

All work to comply with the National

Stub vents to be fitted with an

Building Regulations

approved 2-way vent-valve.

FLOORS AND SLABS: Stacks in ducts to be accessable for

Ground floor slab: 85mm thick,

cleaning purpouses.

20MPa minimum concrete, perfectly

level, min 150mm above gl. on All bends and junctions in sewer to

properly compacted be fitted with ie's, all re's under

hardcore: 25mm thick screed and

paving to be fitted with marked

finishes as indicated.

covers.

These floors must be cast on min

Protect drain under foundations in

50mm. thick

accordance with SANS 10400

polystyrene foam and foam is to be

installed around

All waste fittings to have reseal traps

perimeter of room to insulate floor

and pipe to be fully accessable if

from wall.

under floors, with ie's either end or

clamped to wall.

DPC under all walls (except free

standing), floors &

Any sewer pipe not deeper than

window sills & to all vertical changes

350mm under ground level (il.-.46) to

in floor levels. be covered with a concrete slab, wide

and strong enough to protect the

FOUNDATIONS AND sewer, with min 100mm soil between

BRICKWORK pipe and concrete.

All foundations to be minimum 10MPa

concrete (2 sacks cement: The radius at the centerline of bend

4 wheelbarrows river sand: 5 of the foot of discharge stack, shall be

wheelbarrows 22mm stone) not less than 300mm and other bends

at least 200mmx600mm, min. 600mm.

D17 200mm under ground level

D - 16 D - 17 or to eng. details. Where any waste or soil branches

NOTE: THESE ARE MINIMUM are connected to a stack the centre

REQUIREMENTS ONLY line of the waste branch shall not

intersect the stack within 200mm

Beam over Lintels to be supported min. 150mm below the centre line of the soil

for openings up to branch.

to Engineer

D16 design

3,0m and at least 220mm for

openings up to 4,8m. Sewer connection : as shown: with

GLAZING GENERAL NOTES: rodding eye ormanhole within 1,5m

1. The contractor is responsible for checking all Brickforce to built in every course from connection.

levels & dimensions on site when setting out & below floor level and above

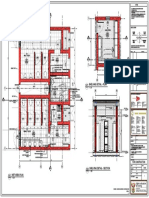

Ceiling height prior to commencing construction. Read only window level, every third course

U/S Floor slab figured dimensions & do not scale. Any between, in continuous bands.

Level 2.380

Level 2.645 discrepancies are to be reported in writing to

dws : sa prior to continuation of work.

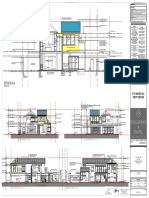

MEASURE DOOR ON 2. The contractor is responsible for the glazing

MEASURE DOOR being executed in strict conformance with glass

SITE BEFORE

ON SITE BEFORE

MANUFACTURING

D16 MANUFACTURING

manufacturerʼs recommendations & all in

accordance with the National Building

Regulations Part N, SANS 10137, SANS

D17 1263-1 & AAAMSA Selection Guide for Safety

Laminated Laminated Laminated Laminated Glazing Materials. A certificate of compliance is

Safety Glass Safety Glass Safety Glass Safety Glass to be issued to dws : sa on completion of the

Laminated Laminated Laminated work.

Fixed panes with sliding window above

Safety Glass Safety Glass Safety Glass 3. The contractor is responsible for providing a

warranty for laminated glass & | or the

hermetically sealed glazing units against

IF IN DOUBT ASK

Level 0.000

Level 0.000

FFL delamination & colour degradation for a period

of not less than 5 years, to be issued to dws :

sa.

DONT ASSUME

FFL

4. All Safety Glazing materials [individual panes]

are to be permanently marked. Such marking

shall be visible after glazing.

5. In the case of structural glazing written proof is

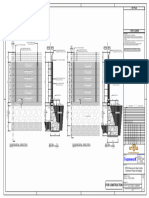

CATALOGUE NR. N/A GENERAL NOTES: CATALOGUE NR. N/A GENERAL NOTES: to be provided that all stages of fabrication &

installation have been executed with disciplined

quality assurance in accordance with the

ALL DIMENTIONS TO BE ALL DIMENTIONS TO BE relevant parts of SANS ISO 9000. Written

DESCRIPTION CUSTOM MADE ALUMINIUM SLIDING DOOR CONFIRMED ON SITE DESCRIPTION CUSTOM MADE ALUMINIUM STACK DOOR CONFIRMED ON SITE confirmation of compatibility of structural

COLOUR TO MATCH EXISTING BEFORE ANY WORK IS PUT COLOUR TO MATCH EXISTING BEFORE ANY WORK IS PUT sealant with extrusion surface, glazing tape &

IN HAND. IN HAND.

glass is to be supplied by the structural sealant

ALL GLAZING TO BE IN ALL GLAZING TO BE IN manufacturer together with the regular relevant

GLAZING 6mm CLEAR SAFETY GLASS

ACCORDANCE WITH

GLAZING 6mm CLEAR SAFETY GLASS

ACCORDANCE WITH

GLAZING AS PER PART N OF SANS 10400 GLAZING AS PER PART N OF SANS 10400 test reports regarding the adhesion of the

AAAMSA. SAGGA AND AAAMSA. SAGGA AND

SANS10160 SANS10160

sealant to the aluminium frame in accordance

SANS10137 SANS10137 with ASTM/C 794-80 [Standard Test for

FINNISH COLOUR TO MATCH EXISTING

SANS 10400 PART N

FINNISH COLOUR TO MATCH EXISTING

SANS 10400 PART N Adhesion-in-Peel of Elastomeric Joint Sealants]

SANS 1263 SANS 1263 6. Glass sizes & thickness is to be designed for

PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS the relevant wind load, to be confirmed by a

PLASTERED DOOR REVEAL PROVISION SHOULD BE PLASTERED DOOR REVEAL PROVISION SHOULD BE suitably qualified competent person. Any

LINTEL & SILL SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO MADE FOR STRUCTURAL LINTEL & SILL SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO MADE FOR STRUCTURAL deviations from the schedules are to be

MANUFACTURER'S SPECIFICATIONS SUPPORT WHERE MANUFACTURER'S SPECIFICATIONS SUPPORT WHERE reported in writing to dws : sa prior to

APPLICABLE APPLICABLE

manufacture.

QUANTITIES TO BE QUANTITIES TO BE

IRONMONGERY AS PER WINDOW MANUFACTURER'S SPECIFICATIONS CONFIRMED ON PLANS IRONMONGERY AS PER WINDOW MANUFACTURER'S SPECIFICATIONS CONFIRMED ON PLANS

QUANTITY 1 QUANTITY 1

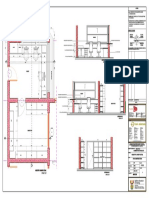

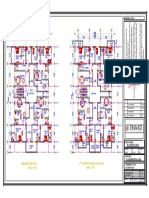

W - 16 W - 17 W - 18 W - 19

32 Clarendon Crescent 021 510 0072 Daleen Holloway - PfSnrArch T

Level 2.645 Ysterplaat 079 502 6645 SACAP Registration - PSAT 20714

Level 2.630 Level 2.630 Cape Town

7405 daleen@hollowayandhound.com

www.hollowayandhound.com

MEASURE WINDOW W16 W17 MEASURE WINDOW W18 MEASURE WINDOW

ON SITE BEFORE

MEASURE WINDOW

ON SITE BEFORE ON SITE BEFORE W19 PROJEK PROJECT

ON SITE BEFORE

MANUFACTURING MANUFACTURING MANUFACTURING

MANUFACTURING

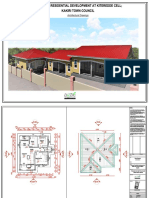

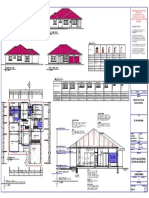

Level 0.000 Level 0.000 MR + MRS HUGO

Level 0.000

FFL FFL ERF 1039

FERNKLOOF ESTATE

STAND NO 55

CATALOGUE NR. CUSTOM MADE ALUMINIUM WINDOW CATALOGUE NR. CUSTOM MADE ALUMINIUM WINDOW CATALOGUE NR. CUSTOM MADE ALUMINIUM WINDOW CATALOGUE NR. CUSTOM MADE TRIANGLE ALUMINIUM WINDOW

GENERAL NOTES: GENERAL NOTES: GENERAL NOTES: GENERAL NOTES:

DESCRIPTION ALUMINIUM WINDOW WITH SLIDING PANELS DESCRIPTION ALUMINIUM WINDOW WITH SLIDING PANELS DESCRIPTION FIXED PANE ALUMINIUM WINDOW DESCRIPTION FIXED PANE ALUMINIUM WINDOW

ALL DIMENTIONS TO BE ALL DIMENTIONS TO BE ALL DIMENTIONS TO BE ALL DIMENTIONS TO BE TITEL TITLE

CLEAR LAMINATED SAFETY GLASS. GLAZING TO BE IN CONFIRMED ON SITE CLEAR LAMINATED SAFETY GLASS. GLAZING TO BE IN CONFIRMED ON SITE CLEAR LAMINATED SAFETY GLASS. GLAZING TO BE IN CONFIRMED ON SITE CLEAR LAMINATED SAFETY GLASS. GLAZING TO BE IN CONFIRMED ON SITE

GLAZING ACCORDANCE WITH AAAMSA. SAGGA AND SANS 10400 BEFORE ANY WORK IS PUT

GLAZING ACCORDANCE WITH AAAMSA. SAGGA AND SANS 10400 BEFORE ANY WORK IS PUT

GLAZING ACCORDANCE WITH AAAMSA. SAGGA AND SANS 10400 BEFORE ANY WORK IS PUT

GLAZING ACCORDANCE WITH AAAMSA. SAGGA AND SANS 10400 BEFORE ANY WORK IS PUT DOOR SCHEDULE

IN HAND. IN HAND. IN HAND. IN HAND.

WINDOW SCHEDULE

ALL GLAZING TO BE IN ALL GLAZING TO BE IN ALL GLAZING TO BE IN ALL GLAZING TO BE IN

FINNISH COLOUR TO MATCH EXISTING ACCORDANCE WITH FINNISH COLOUR TO MATCH EXISTING ACCORDANCE WITH FINNISH COLOUR TO MATCH EXISTING ACCORDANCE WITH FINNISH COLOUR TO MATCH EXISTING ACCORDANCE WITH

AAAMSA. SAGGA AND AAAMSA. SAGGA AND AAAMSA. SAGGA AND AAAMSA. SAGGA AND

SANS10160 SANS10160 SANS10160 SANS10160

PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS PRECAST CONCRETE LINTELS ABOVE ALL OPENINGS SKAAL AS INDICATED SCALE

SANS10137 SANS10137 SANS10137 SANS10137

PLASTERED WINDOW REVEAL AND INNER SILL SANS 10400 PART N PLASTERED WINDOW REVEAL AND INNER SILL SANS 10400 PART N PLASTERED WINDOW REVEAL AND INNER SILL SANS 10400 PART N PLASTERED WINDOW REVEAL AND INNER SILL SANS 10400 PART N

LINTEL & SILL PRECAST CEMENT OUTER WINDOW SILL SANS 1263

LINTEL & SILL PRECAST CEMENT OUTER WINDOW SILL SANS 1263

LINTEL & SILL PRECAST CEMENT OUTER WINDOW SILL SANS 1263

LINTEL & SILL PRECAST CEMENT OUTER WINDOW SILL SANS 1263 GETEKEN DH DRAWN

SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO SEAL PROPERLY WITH SILICONE AROUND FRAME, ACCORDING TO

MANUFACTURER'S SPECIFICATIONS

PROVISION SHOULD BE

MANUFACTURER'S SPECIFICATIONS

PROVISION SHOULD BE

MANUFACTURER'S SPECIFICATIONS

PROVISION SHOULD BE

MANUFACTURER'S SPECIFICATIONS

PROVISION SHOULD BE NAGESIEN DH CHECKED

MADE FOR STRUCTURAL MADE FOR STRUCTURAL MADE FOR STRUCTURAL MADE FOR STRUCTURAL

IRONMONGERY AS PER WINDOW MANUFACTURER'S SPECIFICATIONS SUPPORT WHERE IRONMONGERY AS PER WINDOW MANUFACTURER'S SPECIFICATIONS SUPPORT WHERE IRONMONGERY AS PER WINDOW MANUFACTURER'S SPECIFICATIONS SUPPORT WHERE IRONMONGERY AS PER WINDOW MANUFACTURER'S SPECIFICATIONS SUPPORT WHERE DATUM 14.04.2024 DATE

APPLICABLE APPLICABLE APPLICABLE APPLICABLE

QUANTITIES TO BE QUANTITIES TO BE QUANTITIES TO BE QUANTITIES TO BE ARCHITECTURAL PROFESSIONAL

QUANTITY 1 CONFIRMED ON PLANS QUANTITY 1 CONFIRMED ON PLANS QUANTITY 1 CONFIRMED ON PLANS QUANTITY 4 CONFIRMED ON PLANS DALEEN HOLLOWAY TEK. NO. DRWG. NR:

PSAT 20714

CONTACT NR: 079 502 6645 2024-11-004

You might also like

- UNIT 11 - WORKING DRAWINGS - REV 1-Door & Window ScheduleDocument1 pageUNIT 11 - WORKING DRAWINGS - REV 1-Door & Window ScheduleD HOLNo ratings yet

- UNIT 11 - WORKING DRAWINGS - REV 1-Floor PlanDocument1 pageUNIT 11 - WORKING DRAWINGS - REV 1-Floor PlanD HOLNo ratings yet

- See "Detail A" For Ventilation: NotesDocument1 pageSee "Detail A" For Ventilation: NotesMohamed AslamNo ratings yet

- DATE: 12 / 12 / 2018 Drawing CertifiedDocument1 pageDATE: 12 / 12 / 2018 Drawing CertifiedAnonymous X3PnFL6No ratings yet

- Block A Shelving DetailDocument1 pageBlock A Shelving DetailsachenNo ratings yet

- Steam Boiler SchematicDocument1 pageSteam Boiler Schematicmohamed faragNo ratings yet

- K H110984001V00Document1 pageK H110984001V00Anonymous X3PnFL6No ratings yet

- 20024-000000u-D003 - Ufd - Plant Water Rev 0Document1 page20024-000000u-D003 - Ufd - Plant Water Rev 0oscar alfredoNo ratings yet

- Water SupplyDocument1 pageWater SupplyZiyadawaliNo ratings yet

- Custom LayoutDocument1 pageCustom Layouttalk2olaolu1962No ratings yet

- DAMAI15032023T1600Document2 pagesDAMAI15032023T1600WL ChaiNo ratings yet

- Proposed Residential Development at Kiteredde Cell Kakiri Town CouncilDocument11 pagesProposed Residential Development at Kiteredde Cell Kakiri Town CouncilLubangakene BrianNo ratings yet

- J414221002PADocument1 pageJ414221002PASehna SerajNo ratings yet

- K H110984004V00Document1 pageK H110984004V00Anonymous X3PnFL6No ratings yet

- A8.1 Typical Door Window DetailDocument1 pageA8.1 Typical Door Window DetailVanshika DograNo ratings yet

- Section Aa' Section BB' Section CC': DRG NoDocument1 pageSection Aa' Section BB' Section CC': DRG NoSamta YadavNo ratings yet

- General Sheet Notes: LO P EDocument4 pagesGeneral Sheet Notes: LO P EnvnagarajuNo ratings yet

- 03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrDocument1 page03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrD HOLNo ratings yet

- H041742001V00Document1 pageH041742001V00Mohammed IrfanNo ratings yet

- Ground Floor Slab Layout 110477 - 3010: VastintDocument1 pageGround Floor Slab Layout 110477 - 3010: VastintjudeNo ratings yet

- Proposed 2 Storey Residential BLDG - BT3 1 PDFDocument13 pagesProposed 2 Storey Residential BLDG - BT3 1 PDFJaybenz Jazon100% (1)

- 07 Door 06Document1 page07 Door 06Lawrence MagagaNo ratings yet

- D-446 To D-447 Column P1-P15 GrpADocument2 pagesD-446 To D-447 Column P1-P15 GrpAChristian MendozaNo ratings yet

- Hpcl-02a - Hvac SectionDocument1 pageHpcl-02a - Hvac SectionBN YADAVNo ratings yet

- ARCH264 - R7: A2-1 Rear Elevation A2-2 Left-Side ElevationDocument1 pageARCH264 - R7: A2-1 Rear Elevation A2-2 Left-Side Elevationreynesmarygen9No ratings yet

- 4217-Csd-C-1a-0504-R1-Details - Typical Fence - Sheet 01Document1 page4217-Csd-C-1a-0504-R1-Details - Typical Fence - Sheet 01Adi PriyapurnatamaNo ratings yet

- 4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Document1 page4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Adi PriyapurnatamaNo ratings yet

- ML PDF 1Document1 pageML PDF 1el.ramesh2502No ratings yet

- Appendix - B DrawingsDocument7 pagesAppendix - B DrawingsShreekant KeraiNo ratings yet

- Ha4321650010f4 (Cable Routing Details)Document1 pageHa4321650010f4 (Cable Routing Details)Malik MalikNo ratings yet

- A1-Archt'l Plan Toreno-02.12.2020 PDFDocument1 pageA1-Archt'l Plan Toreno-02.12.2020 PDFWilbert ReuyanNo ratings yet

- DfghbsfgbhsdbllntusdyDocument3 pagesDfghbsfgbhsdbllntusdyBen TigerXNo ratings yet

- Fire Ext. Lay 21.10.2020 R-1Document1 pageFire Ext. Lay 21.10.2020 R-1Avinash singhNo ratings yet

- Ground Floor Plan 1 A1: Land Use and ZoningDocument1 pageGround Floor Plan 1 A1: Land Use and ZoningCharlie Sheen CalmaNo ratings yet

- House MergeDocument26 pagesHouse MergeJamohl AlexanderNo ratings yet

- K L M N O K L M N O: The Corniche TowerDocument3 pagesK L M N O K L M N O: The Corniche Towerajit_archi4nitNo ratings yet

- Block X Revised Detail 120-12Document1 pageBlock X Revised Detail 120-12sachenNo ratings yet

- Ha431892003v0f1 (Cable Routing Details)Document1 pageHa431892003v0f1 (Cable Routing Details)Malik MalikNo ratings yet

- TOILETDocument1 pageTOILETShruti KhatanNo ratings yet

- Tejaswi WCDocument1 pageTejaswi WC026 KolataGangamahendharNo ratings yet

- Sectional Elevation-A Sectional Elevation-B: EQ EQ EQDocument1 pageSectional Elevation-A Sectional Elevation-B: EQ EQ EQSAL ARCHITECTURENo ratings yet

- Ground Floor Water Line Layout Second Floor Water Line LayoutDocument1 pageGround Floor Water Line Layout Second Floor Water Line LayoutJefferson SubilNo ratings yet

- PLUMBING NTC-ModelDocument1 pagePLUMBING NTC-Modelcyrus juanezaNo ratings yet

- D C B A D C B A: Ground Floor Plan SCALE 1:100 1 3 Architectural Floor Plan SCALE 1:100Document1 pageD C B A D C B A: Ground Floor Plan SCALE 1:100 1 3 Architectural Floor Plan SCALE 1:100Ahmed Daahir AdenNo ratings yet

- Drawing7 1Document1 pageDrawing7 1AYAH KHANZA&AYRHANo ratings yet

- Ar 106Document1 pageAr 106Baby SinghNo ratings yet

- PV490-C DrawingDocument15 pagesPV490-C Drawingsajid yaqoobNo ratings yet

- FHDC Aureo Phase 6: PhilmepsincDocument1 pageFHDC Aureo Phase 6: PhilmepsincSEDFREY DELA CRUZNo ratings yet

- Construction Notes: General: Concrete Work: Reinforcement NotesDocument1 pageConstruction Notes: General: Concrete Work: Reinforcement NoteseddieNo ratings yet

- CTW320 Msy 00 El Abd 5002 05Document1 pageCTW320 Msy 00 El Abd 5002 05Jafffar MahasnehNo ratings yet

- Hvac - Schematic - VentDocument1 pageHvac - Schematic - VentRommel Dela SernaNo ratings yet

- Hvac - Schematic - CHWPDocument1 pageHvac - Schematic - CHWPRommel Dela SernaNo ratings yet

- Fourth To Sixt and SectionDocument1 pageFourth To Sixt and SectionAshley Villarico AbanganNo ratings yet

- Mompong Beach Resort-R1 PDFDocument1 pageMompong Beach Resort-R1 PDFDonato Henry LacbayoNo ratings yet

- Saudi Arabian Oil Company: VA-447531 001 S 00 X54 RestrictedDocument1 pageSaudi Arabian Oil Company: VA-447531 001 S 00 X54 RestrictedAHMED TAHERNo ratings yet

- Notes:: Recommended ApprovalDocument1 pageNotes:: Recommended ApprovalJhon SabinoNo ratings yet

- HOUSEDocument1 pageHOUSEJohn BandaNo ratings yet

- Ca 477021 002Document1 pageCa 477021 002Sehna SerajNo ratings yet

- 3ac - 4 Ncaute Drawings-2Document3 pages3ac - 4 Ncaute Drawings-2Mclyb GumbieNo ratings yet

- BoQ 30-10-2023-Rev00 MMDocument32 pagesBoQ 30-10-2023-Rev00 MMD HOLNo ratings yet

- 02 - House Hugo - Rev 2 - 12.03.2024-Elev + SectionsDocument1 page02 - House Hugo - Rev 2 - 12.03.2024-Elev + SectionsD HOLNo ratings yet

- 01 - House Hugo - Rev 2 - 12.03.2024-Site + FloorsDocument1 page01 - House Hugo - Rev 2 - 12.03.2024-Site + FloorsD HOLNo ratings yet

- 03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrDocument1 page03 - House Hugo - Rev 2 - 12.03.2024-Sec + ElectrD HOLNo ratings yet

- 402 Window Schedule & DetailsDocument1 page402 Window Schedule & DetailsD HOLNo ratings yet

- Vetassess Cover LetterDocument3 pagesVetassess Cover LetterD HOLNo ratings yet

- Social Media Post PromptsDocument19 pagesSocial Media Post PromptsD HOLNo ratings yet

- Unabridged Birth Certificate Service ProvidersDocument2 pagesUnabridged Birth Certificate Service ProvidersD HOLNo ratings yet

- ASOURCE Company Profile 2024Document1 pageASOURCE Company Profile 2024D HOLNo ratings yet

- The Profitable Designer Scorecard ReportDocument21 pagesThe Profitable Designer Scorecard ReportD HOLNo ratings yet

- Medina Ar-El-Pl-St PDFDocument14 pagesMedina Ar-El-Pl-St PDFdasmin anne depacaquiboNo ratings yet

- ECO-Panel Design N Installation Manual - ContentsDocument12 pagesECO-Panel Design N Installation Manual - ContentstechnokakiNo ratings yet

- Prestressed ConcreteDocument17 pagesPrestressed Concretenikhilarora1988No ratings yet

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Document6 pagesType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheNo ratings yet

- DuraSeal Installation Instruction WDocument34 pagesDuraSeal Installation Instruction WmroliverridleyNo ratings yet

- RC Chapter01 2016Document7 pagesRC Chapter01 2016Luna Latisya0% (1)

- Load Evaluation PDFDocument9 pagesLoad Evaluation PDFMois DanielNo ratings yet

- PufDocument2 pagesPufsurya325kiranNo ratings yet

- Turbine Ventilators LowresDocument6 pagesTurbine Ventilators LowresmaxmorekNo ratings yet

- Boq Dip 1newDocument157 pagesBoq Dip 1newAnish ChandranNo ratings yet

- Fire Dampers PL 10 19 20 Acc. en 1366 2Document28 pagesFire Dampers PL 10 19 20 Acc. en 1366 2candra trisilawatiNo ratings yet

- Metering Section ExtentionDocument63 pagesMetering Section ExtentionBert EngNo ratings yet

- Architectural Evaluation Checklist (For Building Permit)Document2 pagesArchitectural Evaluation Checklist (For Building Permit)Arnulfo Jose Pi DiNo ratings yet

- Design ConsiderationsDocument5 pagesDesign ConsiderationsAlyssa Harriet MartinezNo ratings yet

- Mapua Univeristy: Muralla ST., Intramuros, Manila Department of Civil, Environmental, and Geological EngineeringDocument43 pagesMapua Univeristy: Muralla ST., Intramuros, Manila Department of Civil, Environmental, and Geological EngineeringCha RobinNo ratings yet

- Print Axial Capacity of Circular Concrete-Filled Tube ColumnsDocument20 pagesPrint Axial Capacity of Circular Concrete-Filled Tube ColumnsMona MahmoudNo ratings yet

- Foundation and PavementDocument26 pagesFoundation and PavementVindicated Wajahat100% (5)

- TCS K 10001 R0 PDFDocument38 pagesTCS K 10001 R0 PDFShahrukh AnsariNo ratings yet

- Apartment Case Study and Litratural Reviewfinal-160416080158Document40 pagesApartment Case Study and Litratural Reviewfinal-160416080158Kassahun Terecha100% (1)

- Dic Loan List: Smsledger Account - No Name Add1 Add2 Activity Project BankDocument19 pagesDic Loan List: Smsledger Account - No Name Add1 Add2 Activity Project BankAkshay RautNo ratings yet

- Detail 2004-10 9Document1 pageDetail 2004-10 9Ibrahim SahinNo ratings yet

- 1 Design Loads - NotesDocument3 pages1 Design Loads - NotesLewis DentonNo ratings yet

- Tica SpecDocument29 pagesTica SpecCong ThanhNo ratings yet

- Dead Loads: Moment Capacity Moment CapacityDocument9 pagesDead Loads: Moment Capacity Moment CapacityklynchelleNo ratings yet

- List of Unauthorized Construction of Building Department-I, South Zone 01.02.2019 To 31.07.2019Document10 pagesList of Unauthorized Construction of Building Department-I, South Zone 01.02.2019 To 31.07.2019BALAJI ASSOCIATESNo ratings yet

- The Residences: Standard Details of Beams (Sheet 2)Document1 pageThe Residences: Standard Details of Beams (Sheet 2)abidimisamNo ratings yet

- Ground Bearing Concrete Slabs - Chapter 2Document37 pagesGround Bearing Concrete Slabs - Chapter 2share4learn100% (1)

- WBDDocument4 pagesWBDPiyush BhandariNo ratings yet

- Historic Construction Materials and TechniquesDocument10 pagesHistoric Construction Materials and TechniquesVinothkumar NamakkalNo ratings yet

- Sistem de Ventilatie Pentru Celule Frigorifice Negative Modulo Freeze Eng 47071Document8 pagesSistem de Ventilatie Pentru Celule Frigorifice Negative Modulo Freeze Eng 47071MIRCEA TOMUSNo ratings yet