Professional Documents

Culture Documents

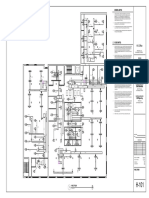

8948 Rev1 Milton Wsg001 Eng Sh3 1

Uploaded by

tshepo hlakudiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8948 Rev1 Milton Wsg001 Eng Sh3 1

Uploaded by

tshepo hlakudiCopyright:

Available Formats

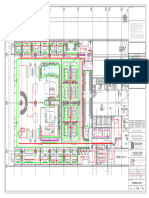

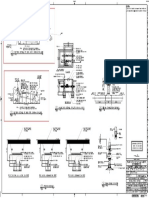

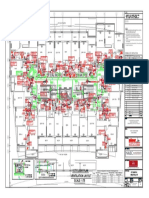

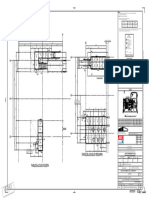

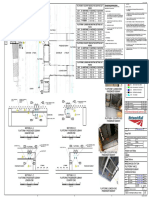

ALL AND LEVELS ARE TO BE VERIFIED ON SITE BY THE

CONTRACTOR BEFORE COMMENCING ANY WORK.

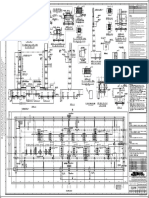

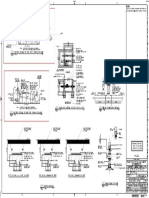

REINFORCING NOTES: GENERAL CONCRETE NOTES

1. MIN. CONCRETE COVER TO REINFORCEMENT:

1. GENERALLY ALL CONCRETE WORK IS TO BE IN ACCORDANCE WITH THE

- FOUNDATIONS = 50mm

FOLLOWING - CONTRACT SPECIFICATION, SANS 1200, SANS 10100 AND

- SLABS = 30mm

SANS 10161

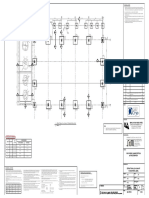

1 2 3 4 5 6 7 - BEAMS/COLUMNS = 30mm

2. READ THIS DRAWING IN CONJUNCTION WITH THE RELEVANT

2. REINFORCEMENT TO BE SECURELY WIRED AT ALL INTERSECTIONS

13580 13580

SPECIFICATIONS; ARCHITECTS DRAWINGS;AND SERVICES DRAWINGS

3. REINFORCEMENT MUST BE FORMED AROUND, AND AS CLOSE AS

4527 4527 4527 4527 4527 4527 3. DIMENSIONS MUST NOT BE SCALED OR ASSUMED

ALLOWED TO HOLES, AND MUST NOT BE CUT. (SEE NOTE 1)

4. CONCRETE MIXES: MASS CONCRETE

4. BARS INDICATED THUS Y10, Y12 ETC. ARE HIGH TENSILE STEEL

MASS CONCRETE (USED AS BACKFILL TO OVERBREAK) 10/19

FOUNDATIONS(LOAD BEARING WALLS) 25/19

5. ALL LAPS TO BE STAGGERED

EAVE CUT FROM SLABS 25/19

305 x 102 x 25 I-SECTION BEAMS/COLUMNS 25/19

6. MILD STEEL TO COMPLY WITH SABS 920 TYPE A - GRADE 3

SURFACE BEDS 25MPa

7. HIGH TENSILE STEEL TO COMPLY SABS 920 TYPE C - GRADE 1

5. ALL REINFORCEMENT FIXING AND PLACING MUST BE INSPECTED AND

APPROVED BY THE ENGINEER PRIOR TO POURING CONCRETE

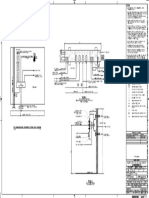

150 x 75 x 20 x 2,0 C-CHANNEL 150 x 75 x 20 x 2,0 C-CHANNEL 8. BENDING DIMENSIONS IN ACCORDANCE WITH SABS 82 GENERAL NOTES

PURLINS PURLINS 6. COVER TO REINFORCING:

9. STIRRUP DIMENSIONS GIVEN AS OVERALL

1578 1578 FOUNDATIONS = 50 (EARTHFACE = 40mm) 1.0 SETTING OUT AND GENERAL

305 x 102 x 25 I-SECTION 3157 305 x 102 x 25 I-SECTION BEAMS/COLUMNS = 30 (EARTHFACE = 40mm)

2600

RAFTER RAFTER 10. DIMENSION D MUST ALLWAYS BE GREATER THAN 2 x BAR DIAMETER 1.1 ALL WORK TO BE DONE IN ACCORDANCE WITH

7. CONCRETE FINISHES: TOP OF SLABS TO BE POWER FLOATED

NATIONAL BUILDING REGULATIONS AND

11. RADII OF ALL BENDS ARE STANDARD UNLESS r IS GIVEN IN THE MUNICIPAL BYLAWS.

SCHEDULE 1.1 ALL DIMENSIONS TO BE CHECKED ON SITE PRIOR

8. COLD/WET WEATHER CONCRETING AS PER SPECIFICATION

TO CONSTRUCTION.

12. DIMENSIONS ARE ALL OUTSIDE DIMENSIONS

9. ALL LOADBEARING BRICKWORK TO BE OF BRICKS WITH A CHARACTERISTIC 1.2 ALL MATERIAL TO MANUFACTURER'S

COMPRESSIVE STRENGTH OF 14 MPA & LAID IN CLASS II MORTAR SPECIFICATIONS

13. MINIMUM LAP LENGTH - 50 x DIAMETER

EXTERNAL WALLS = 220MM WIDE &

2640

2640 10. BRICKFORCE IN EVERY FOURTH COURSE TO LOADBEARING BRICKWORK

14. MINIMUM ANCHORAGE - 50 x DIAMETER INTERNAL WALLS = 110MM WIDE UNLESS

1400

11. STRIPPING OF FORMWORK AS PER SPECIFICATION.(WITH ENGINEERS OTHERWISE STATED.

15. REINFORCEMENT MUST BE STORED ON SITE IN CLEAN DRY AREA TO 1.3 THE DEVELOPER RESERVES THE RIGHT TO

APPROVAL)

AVOID RUST FORMING.

ADAPT ALL LEVELS AND VARY POSITIONING OF

12. DPC FORMED BRICKWORK OF 2 LAYERS OF 3 PLY MALTOID LAID ON UNITS TO SUIT SITE CONDITIONS.

HAUNCH CUT FROM HAUNCH CUT FROM SMOOTH MORTAR BED ON TOP OF BRICKWORK. VERTICAL SURFACES OF 1.4 ALL CONSTRUCTION WORK SHOULD COMPLY

305 x 102 x 25 I-SECTION 305 x 102 x 25 I-SECTION CONCRETE TO BE SEPARATED FROM BRICKWORK BY 10 MM WITH STANDARD SPECIFICATION.

POLYETHELENE FILLER BOARD

1.5 PLAN TO BE CHECKED BY DEVELOPER PRIOR TO

9924

13. NO HOLES OR CHASES SHALL BE CUT OR FORMED IN CONCRETE UNLESS

COUNCIL SUBMISSION AND CONSTRUCTION.

SHOWN ON DRAWINGS, DETAILED IN SPECIFICATION OR APPROVED BY 1.6 STRENGTH & STABILITY OF WALLS ACC. SABS

ENGINEER

14. LOADING DURING CONSTRUCTION - MAXIMUM LOAD ON FLOOR DURING

7324

C001 C002 C003 C004 C003 C002 C001 CONSTRUCTION TO BE 500 kg/m²

15. ANY DISCREPANCIES MUST BE BROUGHT TO THE ATTENTION OF THE

ENGINEER AS SOON AS POSSIBLE. IF THERE IS ANY DISCREPANCY

5924

BETWEEN THE DRAWINGS AND THE SPECIFICATION, THE ENGINEER MUST

BE INFORMED

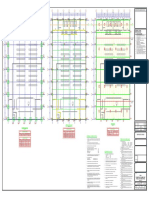

STRUCTURAL STEELWORK:

S1) MATERIAL SPECIFICATION:

a. HOT ROLLED SECTIONS SABS 1431 GRADE 350W

b. COLD FORMED SECTIONS SABS 1431 GRADE 350W

c. PLATES, FLATS AND ROUNDS SABS 1431 GRADE 350W

d. BOLTS AND NUTS (BEARING) SABS 1700 GRADE 8.8

e. HSFG BOLTS SABS 1700 GRADE 8.8S

S2) MINIMUM STANDARD WELD SIZE TO BE 6mm. ALL WELDED PARTS TO BE

SEAL WELDED.

1300

S3) ALL WELDING TO BE DONE BY QUALIFIED WELDERS.

S4) FLOOR BRACES SHALL BE CONNECTED TO ALL FLOOR BEAMS AT POINTS

OF CONTACT.

S5) WHERE NO FORCES OR MOMENTS ARE INDICATED ON THE DRAWING,

THE FABRICATOR WILL BE REQUIRED TO DETAIL THE CONNECTION TO

FT001 FT001 FT001 FT001 FT001 FT001 FT001 RESIST:

a. TRUSSES AND BRACING - 40% OF THE LARGER MEMBERS TENSILE

STRENGTH

b. ROOF AND FLOOR BEAMS - 50% OF THE LARGER MEMBERS SHEAR

STRENGTH

S6) A MINIMUM OF TWO BOLTS SHALL BE USED IN ALL BOLTED CONNECTIONS.

SECTION A-A CROSS BRACES SHALL BE CONNECTED AT THE INTERSECTION WITH A

MINIMUM OF ONE M20 BOLT.

(STRUCTURAL STEEL ONLY) FOOTING LEGEND S7) HSFG BOLTS SHALL BE INSTALLED IN ACCORDANCE WITH SABS 094 USING

THE TURN OF NUT METHOD.

SCALE 1:50

NUMBER BASE SIZE STUB COLUMN SIZE No. OFF S8) BOLTS, NUTS AND WASHERS SHALL BE CADMIUM OR ZINC PLATED.

S9) MILD STEEL GRATING SHALL BE OPEN GRID, NON-SLIP TYPE, WITH 100 X 40

FT001 1500 x 1500 x 400 Dp 440 x 440 x 900 Dp 34 OPENINGS AND 30 X 4.5 BEARER BARS. (<--->) INDICATES DIRECTION OF

SPAN. THE GRATING SHALL BE HOT DIP GALVANISED TO SABS 763.

S10) ALL MOMENT CONNECTIONS SHALL BE FULL STRENGTH.

COLUMN LEGEND S11) VASTRAP PLATE SHALL BE SECURED TO SUPPORTING BEAMS WITH

COUNTERSUNK BOLTS.

NUMBER COLUMN SIZE HEIGHT (mm) No. OFF S12) STAIR TREADS SHALL BE OPEN GRID TYPE 750mm SPAN, WITH NON-SLIP

203 x 133 x 30 UC NOSING.

C001 7280 18

S13) HANDRAILING STANDARDS TO BE 1000mm ABOVE FINISH FLOOR LEVEL.

C002 203 x 133 x 30 UC 7835 4 S14) KICK FLATS TO BE 6mm THICK EXTENDING 130mm ABOVE FINISH FLOOR

C003 203 x 133 x 30 UC 8710 4 LEVEL.

C004 203 x 133 x 30 UC 9254 2 S15) HANDRAIL TO BE FIXED TO FLOOR SUPPORTING STEELWORK AND NOT TO

KICK FLAT.

C005 203 x 133 x 30 UC 2635 6 S16) THE FABRICATOR SHALL SUPPLY ALL BOLTS, NUTS AND WASHERS

NECESSARY FOR ASSEMBLY AND ERECTION.

S17) ITEM NUMBER, DRAWING NUMBER, ORDER NUMBER AND RING NUMBER TO

ROOF LEGEND BE CLEARLY HARD MARKED AND PAINTED ON ALL ITEMS AND PARTS

THEREOF.

1 2 3 4 5 6 7 NUMBER SIZE LENGTH (mm) No.OFF S18) SHOP PREPARATION AND PAINTING TO BE IN ACCORDANCE WITH THE

PROJECT SPECIFICATION.

RT001 305 x 102 x 25 UB 13700 18

S19) THE FABRICATOR SHALL SUPPLY ALL BOLTS FOR CONNECTING

13580 13580 HAUNCH 305 x 102 x 25 UB (CUT) MECHANICAL ITEMS TO STRUCTURAL STEEL AS INDICATED ON THE

BC001 60 x 60 x 8 L DRAWINGS.

4527 4527 4527 4527 4527 4527 S20) BOLTS THAT ARE CADMIUN PLATED SHALL BE DEBRITTLED IN

ACCORDANCE WITH BS 1706 CLASS A. CERTIFICATION OF COMPLIANCE IS

REQUIRED.

S21) CONTACT SURFACES AT FRICTION GRIP CONNECTIONS SHALL BE

SANDBLASTED AND PRIMED.

S22) ALL FLAME-CUT EDGES, BURRS AND SHARP EDGES TO BE GROUND

SMOOTH.

150 x 75 x 20 x 2,0 C-CHANNEL 150 x 75 x 20 x 2,0 C-CHANNEL

PURLINS PURLINS

2600

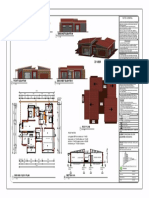

ISSUED FOR

0 - PM PM

CONSTRUCTION

No Date Details Chd Appd

Revisions

Client

METHODIST CHURCH

1400

Engineer

9880

2949

7280

C001 C002 C003 C004 C003 C002 C001

5880

5924

255

ADDRESS

2720

CONTACTS

Project

PROPOSED NEW CHURCH

340

1344

FT001 FT001 FT001 FT001 FT001 FT001 FT001 Description

PLAN:

SECTIONS AND DETAILS

SECTION A-A (SHEET 03)

(INCLUDING SLAB & BRICKWORK)

SCALE 1:50

Scale Date

AS SHOWN JUL 2020

Project No Drg. No Rev

PF005/19 WSG028-ENG 03

You might also like

- Warehouse DrawingsDocument6 pagesWarehouse DrawingsnokoNo ratings yet

- TWPH Rev - 5Document1 pageTWPH Rev - 5pravinmishra1245No ratings yet

- TST1501 MINOR Test OneDocument3 pagesTST1501 MINOR Test Onetshepo hlakudiNo ratings yet

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument7 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateneelNo ratings yet

- Lumina 17 A2 User GBDocument69 pagesLumina 17 A2 User GBAndrewNo ratings yet

- Hoist Load Test ReportDocument2 pagesHoist Load Test ReportSoedarjoto S100% (1)

- Ajc SD 22885 DRG 002Document1 pageAjc SD 22885 DRG 002investor.technicalofficeNo ratings yet

- PLUMBING NTC-ModelDocument1 pagePLUMBING NTC-Modelcyrus juanezaNo ratings yet

- Part C - Wayeni Tender DrawingsDocument26 pagesPart C - Wayeni Tender DrawingsforbeskaNo ratings yet

- Binghati LightingDocument1 pageBinghati Lightingzafrikhan875No ratings yet

- K H110984004V00Document1 pageK H110984004V00Anonymous X3PnFL6No ratings yet

- Lateral View (Left) : Detail ADocument14 pagesLateral View (Left) : Detail ARahul PatelNo ratings yet

- CTW320 Msy 00 El Abd 5002 05Document1 pageCTW320 Msy 00 El Abd 5002 05Jafffar MahasnehNo ratings yet

- Smwsasbt CPG STM SN100 TW PKG 032901Document4 pagesSmwsasbt CPG STM SN100 TW PKG 032901MassimilianoTerenziNo ratings yet

- Unique: Non Fire Rate Door Non Fire Rate DoorDocument1 pageUnique: Non Fire Rate Door Non Fire Rate Doorwaseem alkhailNo ratings yet

- AB AC AA AB AA: General NotesDocument1 pageAB AC AA AB AA: General NotesAnonymous qEPNPwANo ratings yet

- BD 22163 - 02-01 - Rev - I General ArrangementDocument1 pageBD 22163 - 02-01 - Rev - I General ArrangementPhilip MelemuriyilNo ratings yet

- St-Nerf-20 Basement Floor PlanDocument1 pageSt-Nerf-20 Basement Floor Planmhazarath murariNo ratings yet

- A22.22-0043 - Absa Providence Seychelles - Ar00 - Ground Floor - Rev ADocument1 pageA22.22-0043 - Absa Providence Seychelles - Ar00 - Ground Floor - Rev ANithin AbrahamNo ratings yet

- M3 Ton 23 4: Pod1 - Mezz. SlabsDocument1 pageM3 Ton 23 4: Pod1 - Mezz. SlabsHamza QudahNo ratings yet

- Ha431892003v0f1 (Cable Routing Details)Document1 pageHa431892003v0f1 (Cable Routing Details)Malik MalikNo ratings yet

- H041675001V00Document1 pageH041675001V00Mohammed IrfanNo ratings yet

- Back Elevation 3 Side East Elevation 4: 3D ViewDocument1 pageBack Elevation 3 Side East Elevation 4: 3D ViewNgonidzashe ChirevaNo ratings yet

- A29 P LTG Va 240416 003 - 00 PDFDocument1 pageA29 P LTG Va 240416 003 - 00 PDFbillNo ratings yet

- Saudi Arabian Oil Company: S61 S HA-004773 003 00Document1 pageSaudi Arabian Oil Company: S61 S HA-004773 003 00zarrar malikNo ratings yet

- Saudi Arabian Oil Company: S61 S HA-004773 003 00Document1 pageSaudi Arabian Oil Company: S61 S HA-004773 003 00zarrar malikNo ratings yet

- AQUEDUCT@KM 31.925 Final - 1 PDFDocument1 pageAQUEDUCT@KM 31.925 Final - 1 PDFvaranasirk1100% (1)

- Utility Station P&IDDocument1 pageUtility Station P&IDAndri SaputraNo ratings yet

- LS Fence 2Document1 pageLS Fence 2jimNo ratings yet

- Ven-002 - 1st Floor Plan Ventilation Layout (1) - Layout1Document1 pageVen-002 - 1st Floor Plan Ventilation Layout (1) - Layout1ᏗᎷᎥᏖᏕᎥᏁᎶᏂNo ratings yet

- Notes:: Drop 50 MM Drop 50 MM Drop 50 MMDocument1 pageNotes:: Drop 50 MM Drop 50 MM Drop 50 MMassis alihNo ratings yet

- Appendix - B DrawingsDocument7 pagesAppendix - B DrawingsShreekant KeraiNo ratings yet

- A-508-Staircase DetailDocument1 pageA-508-Staircase DetailJohnIsaacNo ratings yet

- Maa Neo Maa1 LD Ga 03 1003 PDF CDocument1 pageMaa Neo Maa1 LD Ga 03 1003 PDF Cvijay kumarNo ratings yet

- A-B-2EKLG (A) Lower GroundDocument1 pageA-B-2EKLG (A) Lower GroundAli SalehNo ratings yet

- Structural 01Document1 pageStructural 01Bj GutierrezNo ratings yet

- Detail Section Detail: NotesDocument1 pageDetail Section Detail: NotesMohamed RamadanNo ratings yet

- UNIT 11 - WORKING DRAWINGS - REV 1-Door & Window ScheduleDocument1 pageUNIT 11 - WORKING DRAWINGS - REV 1-Door & Window ScheduleD HOLNo ratings yet

- Base Plate Detail: A B C DDocument1 pageBase Plate Detail: A B C DajNo ratings yet

- 9d3 - Uukumwe School Hall-Roof LayoutDocument1 page9d3 - Uukumwe School Hall-Roof LayoutshaimenneNo ratings yet

- Bridge No.121Document1 pageBridge No.121RajeshNo ratings yet

- ELEVATIONS (1:100) SECTION A-A (1:50) : NotesDocument2 pagesELEVATIONS (1:100) SECTION A-A (1:50) : NotesLubangakene BrianNo ratings yet

- General Arrangement of Restaurant Building & Deck - Lower LevelDocument1 pageGeneral Arrangement of Restaurant Building & Deck - Lower LevelSampath S. WickramanayakaNo ratings yet

- General Notes:: W A LLDocument1 pageGeneral Notes:: W A LLAnonymous qEPNPwANo ratings yet

- Notes: Edge of Block Paved Roadway - Edge of Asphalt RoadwayDocument1 pageNotes: Edge of Block Paved Roadway - Edge of Asphalt RoadwayFiroj AlamNo ratings yet

- Aa 038608 001Document1 pageAa 038608 001hai sunNo ratings yet

- Section "E-E" Section "G-G": Saudi Arabian Oil CompanyDocument1 pageSection "E-E" Section "G-G": Saudi Arabian Oil Companycherif yahyaouiNo ratings yet

- A51PR02 - Plan ViewDocument1 pageA51PR02 - Plan Viewengrjeromemansueto1996No ratings yet

- Exist/ New Asphalt Road & Rig Road Crossing Details Table-1Document1 pageExist/ New Asphalt Road & Rig Road Crossing Details Table-1Er Md AamirNo ratings yet

- Ar 106Document1 pageAr 106Baby SinghNo ratings yet

- 4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Document1 page4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Adi PriyapurnatamaNo ratings yet

- Notes:: 1F at SSL + 4.00mDocument1 pageNotes:: 1F at SSL + 4.00massis alihNo ratings yet

- GC ST 01Document1 pageGC ST 01mhazarath murariNo ratings yet

- PNG2023 Plumb 012 ADocument1 pagePNG2023 Plumb 012 ANoel MoronaNo ratings yet

- HQ Office: General NotesDocument1 pageHQ Office: General NotesAbrien ZenitramNo ratings yet

- 3ac - 4 Ncaute Drawings-2Document3 pages3ac - 4 Ncaute Drawings-2Mclyb GumbieNo ratings yet

- J414221002PADocument1 pageJ414221002PASehna SerajNo ratings yet

- S. Staircase (St-02) Detail-2Document1 pageS. Staircase (St-02) Detail-2assis alihNo ratings yet

- Fit For Internal Review & Comment: Outer StationsDocument1 pageFit For Internal Review & Comment: Outer StationsAbhishek BouraiNo ratings yet

- Rajeevs Residence Revised Electrical LayoutDocument1 pageRajeevs Residence Revised Electrical Layoutavyukth.akNo ratings yet

- E001 Ground Lighting LayoutDocument1 pageE001 Ground Lighting Layoutcyrus juanezaNo ratings yet

- Annex 10 - KnowledgeDocument1 pageAnnex 10 - KnowledgeHaryono MrNo ratings yet

- DAMAI15032023T1600Document2 pagesDAMAI15032023T1600WL ChaiNo ratings yet

- Valhalla EdVNDocument1 pageValhalla EdVNtshepo hlakudiNo ratings yet

- TUT Flyer 2024Document1 pageTUT Flyer 2024tshepo hlakudiNo ratings yet

- 160.5.4 2D V M and F Diag ExampleDocument24 pages160.5.4 2D V M and F Diag Exampletshepo hlakudiNo ratings yet

- ROUTE 9 Olievenhoutbos To Centurion Via Irene Lyttleton StationDocument1 pageROUTE 9 Olievenhoutbos To Centurion Via Irene Lyttleton Stationtshepo hlakudiNo ratings yet

- Carbon Steel Fact SheetDocument2 pagesCarbon Steel Fact Sheettshepo hlakudiNo ratings yet

- Silverton3 EdISDocument1 pageSilverton3 EdIStshepo hlakudiNo ratings yet

- ROUTE 7 Olievenhoutbos To Wierdapark Eldoraine Clubview A EdVNDocument2 pagesROUTE 7 Olievenhoutbos To Wierdapark Eldoraine Clubview A EdVNtshepo hlakudiNo ratings yet

- GS B0182fDocument11 pagesGS B0182ftshepo hlakudiNo ratings yet

- ROUTE 4 Olievenhoutbos To Centurion Via Highveld Ecopark Southdowns EdVNDocument1 pageROUTE 4 Olievenhoutbos To Centurion Via Highveld Ecopark Southdowns EdVNtshepo hlakudiNo ratings yet

- Graph PaperDocument1 pageGraph Papertshepo hlakudiNo ratings yet

- 2023 EPN2601 Assessment Plan and ScopeDocument3 pages2023 EPN2601 Assessment Plan and Scopetshepo hlakudiNo ratings yet

- PWD Papers 49Document8 pagesPWD Papers 49tshepo hlakudiNo ratings yet

- To Be ReorderedDocument16 pagesTo Be Reorderedtshepo hlakudiNo ratings yet

- The Rustenburg Layered Suite Formed As A Stack of Mush With Transient Magma ChambersDocument13 pagesThe Rustenburg Layered Suite Formed As A Stack of Mush With Transient Magma Chamberstshepo hlakudiNo ratings yet

- The Great Unknown 127Document9 pagesThe Great Unknown 127tshepo hlakudiNo ratings yet

- Wte SuppDocument6 pagesWte Supptshepo hlakudiNo ratings yet

- SUR1501Document5 pagesSUR1501tshepo hlakudiNo ratings yet

- Tshepo Hlakudi MAT ExamDocument11 pagesTshepo Hlakudi MAT Examtshepo hlakudiNo ratings yet

- Week 6Document4 pagesWeek 6tshepo hlakudiNo ratings yet

- Week 8Document14 pagesWeek 8tshepo hlakudiNo ratings yet

- ACC2601 Assignment 2Document6 pagesACC2601 Assignment 2tshepo hlakudiNo ratings yet

- WTE1501 Major Test 01 2022Document8 pagesWTE1501 Major Test 01 2022tshepo hlakudiNo ratings yet

- General Consideration of Structural Steel Design.Document16 pagesGeneral Consideration of Structural Steel Design.tshepo hlakudiNo ratings yet

- Master of Applied Sciences: RemarksDocument2 pagesMaster of Applied Sciences: Remarkstshepo hlakudiNo ratings yet

- Design of Compression MembersDocument56 pagesDesign of Compression Memberstshepo hlakudiNo ratings yet

- 8948 Rev1 Milton Wsg001 Eng Sh5 1Document1 page8948 Rev1 Milton Wsg001 Eng Sh5 1tshepo hlakudiNo ratings yet

- 8948 Rev1 Milton WSG001 Eng SH2 1Document1 page8948 Rev1 Milton WSG001 Eng SH2 1tshepo hlakudiNo ratings yet

- GO16 - PP - CH01 - GRADER - 1G - HW - Northern Lights 1.5 - InstructionsDocument2 pagesGO16 - PP - CH01 - GRADER - 1G - HW - Northern Lights 1.5 - Instructionstshepo hlakudiNo ratings yet

- Comprssibility of Soil - CH2 - Part7Document3 pagesComprssibility of Soil - CH2 - Part7tshepo hlakudiNo ratings yet

- Robotics Unit1 SlidesDocument65 pagesRobotics Unit1 SlidesJanarthanan BalakrishnasamyNo ratings yet

- Formula RioDocument11 pagesFormula RioMoad BouzidaNo ratings yet

- CTD II Deg Mid (April-2019)Document1 pageCTD II Deg Mid (April-2019)Ramesh BabuNo ratings yet

- 6 X 1 Basicequipment 00Document17 pages6 X 1 Basicequipment 00Mweene MuukaNo ratings yet

- Marine Propulsion English Status January 2011Document20 pagesMarine Propulsion English Status January 2011Jodiel CoelhoNo ratings yet

- +DE710-03 - A01 - Manual Actualizado A Julio 2018Document74 pages+DE710-03 - A01 - Manual Actualizado A Julio 2018Juan RafaelNo ratings yet

- Atomic Term SymbolsDocument4 pagesAtomic Term SymbolsM IkhsanNo ratings yet

- Module 2 - Flywheels Part 2Document5 pagesModule 2 - Flywheels Part 2Johnlloyd BarretoNo ratings yet

- BPQ REV. 0 Interactive FormDocument2 pagesBPQ REV. 0 Interactive FormcosmicbunnyNo ratings yet

- 8 Relevant Provisions of IS456Document14 pages8 Relevant Provisions of IS456kiran sreekumarNo ratings yet

- Plate GirdersDocument22 pagesPlate GirdersM Kishore KumarNo ratings yet

- PPM TFC45 - HaishiDocument280 pagesPPM TFC45 - Haishicristian100% (3)

- Project: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Document14 pagesProject: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Mohamed Wasim ShaikhNo ratings yet

- Week 4Document4 pagesWeek 4Waqar AhmadNo ratings yet

- Lafortune - Et - Al - SMST06 - Superelasticity Related Phenomena of Shape Memory Alloy Passive DampersDocument10 pagesLafortune - Et - Al - SMST06 - Superelasticity Related Phenomena of Shape Memory Alloy Passive DamperspilafaNo ratings yet

- Diagnostic Trouble Codes: TroubleshootingDocument9 pagesDiagnostic Trouble Codes: TroubleshootingEva AprianaNo ratings yet

- Presentation On Motors & VFD: Submitted To:-Submitted ByDocument32 pagesPresentation On Motors & VFD: Submitted To:-Submitted Byparth dosiNo ratings yet

- Wheel Loaders VocabularyDocument10 pagesWheel Loaders VocabularyLyanHyangNo ratings yet

- SG Series NewDocument2 pagesSG Series NewSantosh ChaudharyNo ratings yet

- "A Brief Introduction To Particle Physics.": Project ReportDocument23 pages"A Brief Introduction To Particle Physics.": Project ReportdhrubankaNo ratings yet

- Pages From Two - Stage - Booster PDFDocument16 pagesPages From Two - Stage - Booster PDFVRV.RELATORIO.AVARIA RELATORIO.AVARIA100% (1)

- Hoop StressDocument3 pagesHoop Stresskarthikraja21No ratings yet

- SGP SyllabusDocument2 pagesSGP SyllabusPrathap VuyyuruNo ratings yet

- Manual de Partes MTC Husqvarna 545Document45 pagesManual de Partes MTC Husqvarna 545Brandon AlvarezNo ratings yet

- High Performance in Tough Industrial ServiceDocument35 pagesHigh Performance in Tough Industrial ServiceRuan Mendes PereiraNo ratings yet

- 4018 DSK Multi Skid Operation Maintenance Manual Issue 5Document55 pages4018 DSK Multi Skid Operation Maintenance Manual Issue 5Mostafa ElhamadyNo ratings yet

- Metric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityDocument4 pagesMetric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityRodrigoNo ratings yet