Professional Documents

Culture Documents

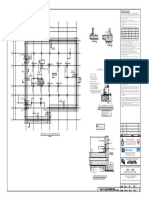

Back Elevation 3 Side East Elevation 4: 3D View

Uploaded by

Ngonidzashe ChirevaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Back Elevation 3 Side East Elevation 4: 3D View

Uploaded by

Ngonidzashe ChirevaCopyright:

Available Formats

NOTES: GENERAL

1. PROTECT AND SAFEGUARD EXISTING BUILDING AND SERVICES

WHICH MAY AFFECTED BY THIS WORK.REPORT ANY UNFORESEEN

CONDITION TO THE GENERAL CONTRACTOR AND CONSULTANT

BEFORE PROCEEDING.

2.ALL DIMENSION TO EXISTING TO BE VERIFIED ON SITE.

3.GIVE TOP OF FOUNDATION , A TROWELL FINI THE FOUNDATION

MUST BE SQUEARE LEVEL,AND SMOOTH

DPC TO ALL WALLS AT FLOOR LEVEL UNDER ALL

WINDOWS VETICAL DPC TO ANY CHANCE OF FLOOR

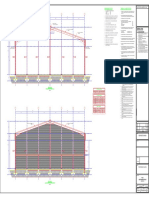

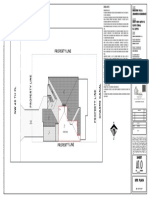

BACK ELEVATION SIDE EAST ELEVATION LEVEL ALL DPC TO BE S.A.B.S. 298 GLAZING TO S.A.B.S

3 1 : 100

4 1 : 100

0137&1263 WINDOWS TO BE MIN 10% FLOOR AREA

NATURAL VENTILATION TO BE MIN 5% FLOOR RAEA

FOUNDANDATION AND FLOOR SLAB TO BE 10 MPA

DRAINAGE

ALL WASTE FITTINGS TO BE 40MM

NO P.V.C PIPES IN FLOOR R.E.S TO TO HEAD OF DRAINS AND TO

ANY BEND EXCEEDING 450EG ANY CHANGE OF GRADIENT.

I.E S TO ALL BEND $ JUNCTIONS OF DRAINS AND WITH MAKED

COVERS AT GROUND LEVEL

ALL WASTE PIPES TO FITTER WITH RESEAL TRAPS TO BE FULLY

ACCESSABLE ALONG THE ENTIRE LENGTH.

ALL DRAINAGE TO COMLPY WITH MUNICIPALITY REGULATIONS

CONCRETE PILES

1.) ALL PILES ARE TO BE CENTERED WITHIN 50MM

OF LOCATION SHOWN ON PLAN AND SHALL NOT BE

OUT OF PLUMB BY MORE THAN 2% OF PILE LENGTH

2.) PROTECT AND SAFEGUARD EXISTING BUILDING

3D VIEW AND SERVICES WHICH MAY BE AFFECTED BY THIS

WORK

3.) CONSOLIDATE TOP 3000 OF DRILLED CAST IN

PLACE PLACE

CAST-IN CONCRETE PILES WITH MECHANICAL

CONCRETE

VIBRATOR

1.) PERFORM CAST-IN-PLACE CONRETE WORK IN

ACCORDDANCE WITH CAN /CSA-A23.1 CONCRETE MATERIALS

AND METHOD OF CONCRETE CONSTRUCTION.

2.) CEMENT TO CSA A5- PORTLAND CEMENT AND AGGREGATES

TO CAN /CSA CONCRETE MATERIALS AND METHOD OF

CONCRETE CONSTRUCTION.

3.) CONCRETE SHOULD HAVE COMPRESSIVE STRENGTH AT THE

END OF 28 DAYS BY STANDARD CYLINDER TEST AS FOLLOWS:

4.) ALL CONCRETE IS TO BE CAST CONTINUOSLY BETWEEN

PREDETERMINED CONSTRUCTION AND CONTROL JOINTS.

FRONT ELEVATION SIDE WEST ELEVATION 5.) JOINTS TO BE FILLED WITH APPROVED JOINTS / CRACK

FILLER.

2 1 : 100

5 1 : 100

6.) BONDING AGENT-SHALL BE A PROPRIETARY PRODUCT

WHICH IS NO WATER SOLUBLE AND ENSURE FULL BOND

BETWEEEN HARD ENED AND FRESH CONCRETE.

SLAB 7.)150MM THICK CARBOARD HONEYCOMB FORM AS

MANUFACTURED BY SHEARMAT STRUCTURES LTD ON MINIMUM

50MM SAND SCREED.

21600 8.) PLACE 6MM TEMPERED HARDBORD OVER VOID FROM FOR

FULL AREA FORMED

9.) COVER WITH 0.15MM POLYETHYLENE

1700 3638 7062 3580 4940 680 10.) DO NOT SUPPORT GRADE BEAM REIFORCING STEEL ON

VOID FORM GRADE

BACKFILLING SUSPEND

BEAMALL RE10FORCING

ON BOTH SIDE STEEL FORM THE

SLAB

1.) GRADE BEAMS ARE NOT DESIGNED TO CARRY CANTILEVER LOADS AND

FORMWORK.

2201480220 3440 220 3940 220 2440 220 3580 220 1700 220 2580 220240 ARE TO BE BACKFILED SIMULTANEOUSLY INSIDE AND OUT ,USING A NON-

EXCEEDING 8 (200MM) COMPACTED TO MINIMUM 98% STANDARD PROCTOR

ie ie ie 440 septic MAX DRY DENSITY

SLAB ON GRADE

VS69 tank 1.) REMOVE ALL ORGANIC AND DELETERIOUS MATERIAL

SLAB

220

TUSCAN PILLER 2.) PROOFROLL SUBGRADE TO DELINEATE ANY SOFT AREAS.ANY SOFT

500

450500

AREAS TO BE EXCAVATED AND RECOMPACTED

220220

2580 3.) BENEATH THE SLAB PROVIDE MINIMUM 250MM GRAVEL FILL COMPACTED

DDT1815 VS69 TO 100% PERCENT OF STANDARD PROCTOR DENSITY.

2510

BIC 2510 4.) FILL IS TO PLACED IN MAXIMUM 100MM LIFTS EACH LIFT BEING

4720

ENSUITE COMPACTED TO 100% OF STANDARD PROCTOR DENSITY BEFOR PLACEMENT

OF NEXT LIFT.

1615

BEDROOM T/BATH DDT1815 5.) CAST SLAB ON 0.15MM POLYETHYLEN VAPOR BARRIER

2540

4870

220

BIC 6.) SAW CUT SLAB AS LOCATED ON DRAWNGS TO DEPTH OF 30MM WITHIN 24

HOURS OF CASTING CAULK WITH JOINT SEALENT .

3800

3980

7.) DO NOT CAST SLAB ON DESICCATED ,FRONZEN OR WET SOIL OR BASE

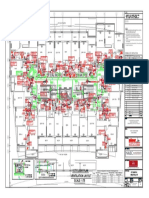

4720 8.) DO NOT ELECTRICAL LEGEND

ALLOW SOIL BENEATH THE SLAB TO FREEZE AFTER CASTING

7950

BIC SLAB

3940

CEILING LIGHT POINT

1615

BEDROOM

DDT1815

BIC

EXTERNAL LIGTH

5000

5000

220

MAIN BED POINT

SLAB

1200

BIC LIGHT SWITCH POINT

980

ie PLUG POINT

220

PTT189

1200

STOVE POINT

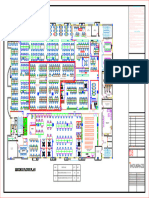

ROOF PLAN

PASS

STOEP KITCHEN

16190

16190

DISTRIBUTION BOARD

220

7 1 : 100 ELECTRICAL LEGEND POWER CAPACITY....60AMPS SINGLE

1300 BEDROOM

PHASE

PTT186

2780 ROOF NOTES

7040

6600

4000

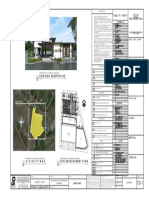

CLIENT:CHINGOMA WILSON

arch

1615

A 8 A

A101 LIVING ROOM 4220 corrugated IBR iron sheets on 114x38 LOCATION: NEMAMWA

7000

7000

DINNING

DOUBLE GARAGE

king posts on 114x38 rafters on 114x38

8240

struts on 114x38 queen posts on 38x38

1615

DDT1815

PROJECT TITLE: PROPOSED DWELLING

brendering on 114x38 tie beams

PTT186

1600 220 220

3353 HOUSE

760

DOOR SLIDING

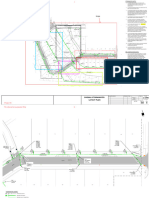

DRAWING TITLE: FLOOR PLAN, ELEVATION,

2661

SECTION, SITE PLAN & 3D

220

1450

STOEP

800

ceiling ceiling

2800

DINING LIVING ROOM BEDROOM DOUBLE GARAGE

2201455245 2780 220 5000 220 4000 220 7000 240

ffl dpc ffl dpc NGL

1675 3025 5440 4000 7460

150mm hardcore fill 150mm hardcore fill

300

300

21600

300x600mm 300x600mm 300x600mm 300x600mm

0795658243

footing footing footing footing

600 600 600 600 Date: 28/06/2021

Drawn by: KWINDA

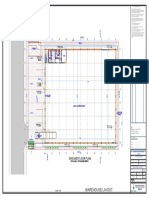

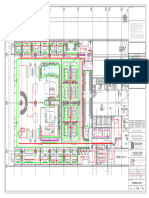

GROUND FLOOR PLAN SECTION A A

1 1 : 100

8 1 : 100

Supervised by: KHOSA M.C

Scale: As shown

You might also like

- Saes A 204Document22 pagesSaes A 204محمد العيسوى100% (2)

- A22.22-0043 - Absa Providence Seychelles - Ar00 - Ground Floor - Rev ADocument1 pageA22.22-0043 - Absa Providence Seychelles - Ar00 - Ground Floor - Rev ANithin AbrahamNo ratings yet

- Ajc SD 22885 DRG 002Document1 pageAjc SD 22885 DRG 002investor.technicalofficeNo ratings yet

- v9r49g3zk0pg - 12. KPLC Warehouse Revised May 2014 GFDocument1 pagev9r49g3zk0pg - 12. KPLC Warehouse Revised May 2014 GFEllyella ElormNo ratings yet

- Unique: Non Fire Rate Door Non Fire Rate DoorDocument1 pageUnique: Non Fire Rate Door Non Fire Rate Doorwaseem alkhailNo ratings yet

- Structural 01Document1 pageStructural 01Bj GutierrezNo ratings yet

- Floor Plan: DRY BalconyDocument1 pageFloor Plan: DRY Balconysaurabh kotechaNo ratings yet

- Appendix - B DrawingsDocument7 pagesAppendix - B DrawingsShreekant KeraiNo ratings yet

- 8948 Rev1 Milton Wsg001 Eng Sh3 1Document1 page8948 Rev1 Milton Wsg001 Eng Sh3 1tshepo hlakudiNo ratings yet

- Ven-002 - 1st Floor Plan Ventilation Layout (1) - Layout1Document1 pageVen-002 - 1st Floor Plan Ventilation Layout (1) - Layout1ᏗᎷᎥᏖᏕᎥᏁᎶᏂNo ratings yet

- Exterior Perspective: The SiteDocument1 pageExterior Perspective: The SiteMark Christian EsguerraNo ratings yet

- Original Technology November Revision - 124458Document2 pagesOriginal Technology November Revision - 124458Bright MuzaNo ratings yet

- Annex 10 - KnowledgeDocument1 pageAnnex 10 - KnowledgeHaryono MrNo ratings yet

- Binghati LightingDocument1 pageBinghati Lightingzafrikhan875No ratings yet

- General Electrical Notes General Site Plan Notes Legend: Power/Comm. Light Fixtures Conduit/WireDocument13 pagesGeneral Electrical Notes General Site Plan Notes Legend: Power/Comm. Light Fixtures Conduit/WireUututNo ratings yet

- K H110984004V00Document1 pageK H110984004V00Anonymous X3PnFL6No ratings yet

- Property Line: SheetDocument1 pageProperty Line: SheetJose MendozaNo ratings yet

- Drawings - Civil & MEP-6Document1 pageDrawings - Civil & MEP-6KasunTilinaChathurangaNo ratings yet

- Part C - Wayeni Tender DrawingsDocument26 pagesPart C - Wayeni Tender DrawingsforbeskaNo ratings yet

- G.F PlanDocument1 pageG.F Plankush jindalNo ratings yet

- Lateral View (Left) : Detail ADocument14 pagesLateral View (Left) : Detail ARahul PatelNo ratings yet

- H D E G: Male C.R. PWD C.R. Female C.R. Pump RMDocument1 pageH D E G: Male C.R. PWD C.R. Female C.R. Pump RMMark Christian EsguerraNo ratings yet

- Elevation (Panel Type P S-Uj) Section A Elevation (Panel Type P N-Uj) Section BDocument1 pageElevation (Panel Type P S-Uj) Section A Elevation (Panel Type P N-Uj) Section BAhmed SamyNo ratings yet

- Public Utilities - Preferred Layout in Footway: General NotesDocument1 pagePublic Utilities - Preferred Layout in Footway: General NotesJaouad IDBOUBKERNo ratings yet

- 1 Ground Floor Ceiling DrawingDocument1 page1 Ground Floor Ceiling DrawingAnishma AyyappanNo ratings yet

- Ef 025 Cidco PTR ST 109 FDocument1 pageEf 025 Cidco PTR ST 109 FAshok PalNo ratings yet

- Acs Schematic DiagramDocument1 pageAcs Schematic DiagramYOGESH SONINo ratings yet

- City of Burnet Restroom BuildingDocument4 pagesCity of Burnet Restroom BuildingThe Servant of Allah SWTNo ratings yet

- Test Fit - 2nd Floor (21-08-2023)Document1 pageTest Fit - 2nd Floor (21-08-2023)GST SS REALTYNo ratings yet

- House MergeDocument26 pagesHouse MergeJamohl AlexanderNo ratings yet

- Portfolio 2 - 218320 - 2023 - Drawing Set 2 - Road and StormwaterDocument39 pagesPortfolio 2 - 218320 - 2023 - Drawing Set 2 - Road and StormwaterXiao LiuNo ratings yet

- UNIT 11 - WORKING DRAWINGS - REV 1-Door & Window ScheduleDocument1 pageUNIT 11 - WORKING DRAWINGS - REV 1-Door & Window ScheduleD HOLNo ratings yet

- B130279002P03Document1 pageB130279002P03Mohammad ShayanNo ratings yet

- ADC Part 2Document1 pageADC Part 2Maung PDDNo ratings yet

- Mep Brioche HoodsDocument1 pageMep Brioche HoodsAhmed SalahNo ratings yet

- Spectrin - Prashant Sir - RCC Foundation - R3-CLDocument1 pageSpectrin - Prashant Sir - RCC Foundation - R3-CLMadhavi GanbavaleNo ratings yet

- Lift - 03Document1 pageLift - 03Masita MattaNo ratings yet

- Roof Deck Sewer Layout: Catch Basin DetailDocument1 pageRoof Deck Sewer Layout: Catch Basin DetailBj GutierrezNo ratings yet

- Staircase Case SectionDocument1 pageStaircase Case SectionradhapunnaNo ratings yet

- LS Fence 2Document1 pageLS Fence 2jimNo ratings yet

- St-Nerf-20 Basement Floor PlanDocument1 pageSt-Nerf-20 Basement Floor Planmhazarath murariNo ratings yet

- 3ac - 4 Ncaute Drawings-2Document3 pages3ac - 4 Ncaute Drawings-2Mclyb GumbieNo ratings yet

- Substation LayoutDocument1 pageSubstation LayoutMohamedNo ratings yet

- See Enlarged Plan & Section: IC ICDocument1 pageSee Enlarged Plan & Section: IC ICAnonymous X3PnFL6No ratings yet

- ScaffoldingDocument1 pageScaffoldingAbrar DigitalNo ratings yet

- FJS 1923000149Document1 pageFJS 1923000149SHAHZAD LATIFNo ratings yet

- 04 - House Hugo - Rev 2 - 12.03.2024-Door SCHDocument1 page04 - House Hugo - Rev 2 - 12.03.2024-Door SCHD HOLNo ratings yet

- Typical Reinforced Concrete Details and Construction Notes - 1Document1 pageTypical Reinforced Concrete Details and Construction Notes - 1Aly Arquillano JrNo ratings yet

- 4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Document1 page4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Adi PriyapurnatamaNo ratings yet

- DAMAI15032023T1600Document2 pagesDAMAI15032023T1600WL ChaiNo ratings yet

- A-B-2EKLG (A) Lower GroundDocument1 pageA-B-2EKLG (A) Lower GroundAli SalehNo ratings yet

- SLD - SIE 3rd Batching Plant - New-ModelDocument1 pageSLD - SIE 3rd Batching Plant - New-ModelRaj ConsultancyNo ratings yet

- Utility Station P&IDDocument1 pageUtility Station P&IDAndri SaputraNo ratings yet

- Uthm 1Document8 pagesUthm 1Firdaus JannahNo ratings yet

- M3 Ton 23 4: Pod1 - Mezz. SlabsDocument1 pageM3 Ton 23 4: Pod1 - Mezz. SlabsHamza QudahNo ratings yet

- Fire Ext. Lay 21.10.2020 R-1Document1 pageFire Ext. Lay 21.10.2020 R-1Avinash singhNo ratings yet

- P4 95 (WD) L113Document1 pageP4 95 (WD) L113Deeksha ChauhanNo ratings yet

- D-446 To D-447 Column P1-P15 GrpADocument2 pagesD-446 To D-447 Column P1-P15 GrpAChristian MendozaNo ratings yet

- Plans For Griffy Lake BoardwalkDocument3 pagesPlans For Griffy Lake BoardwalkIndiana Public Media NewsNo ratings yet

- 20024-000000u-D003 - Ufd - Plant Water Rev 0Document1 page20024-000000u-D003 - Ufd - Plant Water Rev 0oscar alfredoNo ratings yet

- The Year of Advancing in Fulfilling Jesus Mandate 2024Document2 pagesThe Year of Advancing in Fulfilling Jesus Mandate 2024Ngonidzashe ChirevaNo ratings yet

- Section 2: Using Transformations: Pure Mathematics 1 Functions & TransformationsDocument11 pagesSection 2: Using Transformations: Pure Mathematics 1 Functions & TransformationsNgonidzashe ChirevaNo ratings yet

- Full-Time Courses For January 2023 Intake: WWW - Maspoly.ac - ZWDocument2 pagesFull-Time Courses For January 2023 Intake: WWW - Maspoly.ac - ZWNgonidzashe ChirevaNo ratings yet

- Zimbabwe Electricity Transmission & Distribution Company Important Notice To Customers 2022 Load Shedding ProgrammesDocument2 pagesZimbabwe Electricity Transmission & Distribution Company Important Notice To Customers 2022 Load Shedding ProgrammesNgonidzashe ChirevaNo ratings yet

- Summary of TransformationsDocument1 pageSummary of TransformationsNgonidzashe ChirevaNo ratings yet

- UntitledDocument4 pagesUntitledNgonidzashe ChirevaNo ratings yet

- Customer SatisfactionDocument7 pagesCustomer SatisfactionAgnes da'SweetieNo ratings yet

- Hunger A National Security Threat 073635Document4 pagesHunger A National Security Threat 073635Ngonidzashe ChirevaNo ratings yet

- Technopreneurship NotesDocument8 pagesTechnopreneurship NotesNgonidzashe ChirevaNo ratings yet

- Impact of National Security On Food Security Evidence From Pakistan 073613Document9 pagesImpact of National Security On Food Security Evidence From Pakistan 073613Ngonidzashe ChirevaNo ratings yet

- 6023 and 6044 Exam Circular No 17 of 2018Document8 pages6023 and 6044 Exam Circular No 17 of 2018Ngonidzashe ChirevaNo ratings yet

- Agricultural Liquid Broadcasting AircraftDocument21 pagesAgricultural Liquid Broadcasting AircraftNgonidzashe ChirevaNo ratings yet

- Microsoft Visual Basic 6.0: Applied ScienceDocument54 pagesMicrosoft Visual Basic 6.0: Applied ScienceAsma HassanNo ratings yet

- Case Studies For Sustainable Design For Schools in The Rural ContextDocument32 pagesCase Studies For Sustainable Design For Schools in The Rural ContextSpurty LKamathNo ratings yet

- Dbe Directory IndotDocument28 pagesDbe Directory IndotJAGUAR GAMINGNo ratings yet

- Shell Dome Folded PlatesDocument44 pagesShell Dome Folded PlatesAnuj SomaniNo ratings yet

- Chief Mate Naval Arch Phase 1Document95 pagesChief Mate Naval Arch Phase 1arshit sharmaNo ratings yet

- 12-Story Hospital Construction Project: San Francisco, CaliforniaDocument9 pages12-Story Hospital Construction Project: San Francisco, CaliforniaOrlando ValleNo ratings yet

- Sea Conquest-Daily Site Safety Review - 22th 24 HRS PTW Valid 22-01-23 To 04-02-2023Document6 pagesSea Conquest-Daily Site Safety Review - 22th 24 HRS PTW Valid 22-01-23 To 04-02-2023Abdul WaheedNo ratings yet

- Poster Guangzhou CTFDocument3 pagesPoster Guangzhou CTFAlifia Ike PurwantiNo ratings yet

- Om - JB B400 - 19-07 - En-Fr-Es - C - Zeewb575a06Document128 pagesOm - JB B400 - 19-07 - En-Fr-Es - C - Zeewb575a06thanh sang lêNo ratings yet

- Falcon PB2 Update Q3Document63 pagesFalcon PB2 Update Q3Security Lock DistributorsNo ratings yet

- BT 3 - Vernacular TermsDocument3 pagesBT 3 - Vernacular TermsJustin Ramos GollosoNo ratings yet

- Underpin NotesDocument2 pagesUnderpin Notesanele_amisNo ratings yet

- Bs 8110-1 1997 Ribbed SlabsDocument4 pagesBs 8110-1 1997 Ribbed SlabspennacchiettiNo ratings yet

- Concrete TechnologyDocument214 pagesConcrete Technologycheersbeer01No ratings yet

- Pavement Rehabilitation Textbook 2Document25 pagesPavement Rehabilitation Textbook 2Nira LuvNo ratings yet

- Unit-4: Reinforced Cement ConcreteDocument13 pagesUnit-4: Reinforced Cement ConcreteasiyaNo ratings yet

- Blueprint - The Meaning of Symbols - Construction 53202429Document30 pagesBlueprint - The Meaning of Symbols - Construction 53202429jayah15No ratings yet

- Concrete Utopia: Everyday Life and Socialism in Berlin-Marzahn Eli RubinDocument17 pagesConcrete Utopia: Everyday Life and Socialism in Berlin-Marzahn Eli RubinIoana TurcanuNo ratings yet

- Annexure K - ENG-STD-0001 Rev 00 - 0Document21 pagesAnnexure K - ENG-STD-0001 Rev 00 - 0gbharcombeNo ratings yet

- 1-1 Crusher ERPDocument16 pages1-1 Crusher ERPLawzy Elsadig SeddigNo ratings yet

- Agreement (Dosc (Rev.) )Document3 pagesAgreement (Dosc (Rev.) )Lerramie Dela PeñaNo ratings yet

- Different Types of Pile Foundation and Their Use in Construction-9-10Document2 pagesDifferent Types of Pile Foundation and Their Use in Construction-9-10Ashis MingalaNo ratings yet

- Catalog Identificare Curele Combine PDFDocument360 pagesCatalog Identificare Curele Combine PDFAlexandru Nimară GogaNo ratings yet

- Falling WaterDocument28 pagesFalling WaterAnika SethiNo ratings yet

- Recommended Aashto LRFD Tunnel Design and Construction, Aashto ReportDocument78 pagesRecommended Aashto LRFD Tunnel Design and Construction, Aashto ReportIngrid Irreño PalomoNo ratings yet

- Z Purlin, Termo: PurcalcDocument7 pagesZ Purlin, Termo: PurcalcomerNo ratings yet

- Reliable, First Class and Solid.: Concrete Block ProductionDocument16 pagesReliable, First Class and Solid.: Concrete Block ProductionTANVIR AHMED KHANNo ratings yet

- Explain - Deformation CompatibilityDocument18 pagesExplain - Deformation CompatibilityArnold ApostolNo ratings yet

- UK SBS SFS Installation Manual v-4-1Document57 pagesUK SBS SFS Installation Manual v-4-1Adrian JugariuNo ratings yet

- KS 3 - PAM Hoat JoenDocument12 pagesKS 3 - PAM Hoat JoenFaishol Arif StNo ratings yet