Professional Documents

Culture Documents

02 en

02 en

Uploaded by

Eduardo JuliánOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 en

02 en

Uploaded by

Eduardo JuliánCopyright:

Available Formats

Engine Component

FIG. 486: Remove muffler (3).

Loosen clamp (1) and remove flex exhaust tube (2).

3

1 P100506011

FIG. 486

FIG. 487: Remove flex exhaust tube.

Loosen clamp (1) and remove flex exhaust tube (2).

2

1

N022606001

FIG. 487

FIG. 488: Remove battery cable.

Remove positive battery cables (1) from starter (2) on left

side of machine.

1

2

P100506033

FIG. 488

FIG. 489: Remove cable.

Remove ground cable (1) from starter (2) on left side of

machine. Fasten out of the way.

1 2

P100506034

FIG. 489

79033095 D Rev. 02-179

Engine Component

FIG. 490: Remove solenoid wire.

Remove solenoid wire (1) from starter (2) on left side of

machine. Fasten out of the way.

1 2

P100506035

FIG. 490

FIG. 491: Remove battery cable.

Remove positive battery cable (1) from starter (2) on right

side of machine.

Remove P-clip (3) and fasten positive battery cable out of

the way.

3

1

2

N031706003

FIG. 491

FIG. 492: Remove cable.

Remove ground cable (1) from starter (2) on right side of 2

machine. Fasten out of the way.

1

N031706004

FIG. 492

FIG. 493: Remove solenoid wire.

Remove solenoid wire (1) from starter (2) on right side of 1

machine. Fasten out of the way.

N031706004

FIG. 493

02-180 79033095 D Rev.

Engine Component

FIG. 494: Remove cable.

Remove positive battery cable (1) from alternator (2). 2

Remove P-clip (3) and fasten positive cable out of the

way.

1

3

N031706005

FIG. 494

FIG. 495: Remove cable.

Remove ground cable (1) from alternator (2) and fasten

out of the way.

1

2

N031706006

FIG. 495

FIG. 496: Remove terminal wire.

Remove terminal wire (1) from alternator (2).

2

1

N031706006

FIG. 496

FIG. 497: Remove chassis harness.

5

Remove air conditioning clutch and high pressure switch

wire (1).

Remove Alternator terminal wire (2). 3 7

Remove air intake restriction switch wire (3).

1

Remove ether start wire (4). 4

Remove front and rear washer pump wire (5).

Remove engine ECM wire (6). 2

Remove chassis harness (7) and neatly wrap all the wires 6 P100506036

up and fasten out of the way. FIG. 497

79033095 D Rev. 02-181

Engine Component

FIG. 498: Remove air conditioning lines.

IMPORTANT: Only a certified technician with certified

equipment should service the air conditioning

system.

IMPORTANT: Refer to Refrigerant section for proper

removal of hoses. 1

A certified technician must recover refrigerant and remove

air conditioning lines (1). Refer to Refrigerant section for

proper removal of hoses. Fasten air conditioning lines out

of the way.

N030806003

FIG. 498

FIG. 499: Remove air conditioning line.

Remove P-clip (1) and fasten air conditioning line (2) out

of the way.

2

N031706009

FIG. 499

FIG. 500: Serpentine belt removal.

Use a ratchet wrench in the square hole (1) on the belt

tensioner (2) and turn clockwise to relieve belt tension.

Remove serpentine belt (3). Slowly release the belt

tensioner to relax into a neutral position.

1 2

m

WARNING: Equipment or parts under

spring tension can cause bodily injury. Use

caution in releasing belt tension. 3

NOTE: Be sure to allow enough room for the swing of the

ratchet to allow belt tensioner to relax into a

neutral position.

N021606002

FIG. 500

FIG. 501: Remove air conditioning compressor.

Remove bolts (1) and compressor (2). The weight of the

air conditioning compressor is approximately 10 kg (21

lb). 2

N030806004

FIG. 501

02-182 79033095 D Rev.

Engine Component

FIG. 502: Remove alternator.

Remove the two top bolts (1) and bottom bolt (2). Remove

alternator (3). The weight of the alternator is

approximately 27 kg (60 lb). 1

N031706008

FIG. 502

FIG. 503: Drain air from air reservoir.

Location of air reservoir tank (1) is located in the right front 1

frame rail (2).

P100506025

FIG. 503

FIG. 504: Drain air from air reservoir.

Pull pin (1) sideways on drain valve (2) and drain air from

system.

1

P100506026

FIG. 504

FIG. 505: Air compressor location. (If equipped)

The air compressor (1) is located on the left side of the

engine.

1

N032006001

FIG. 505

79033095 D Rev. 02-183

Engine Component

FIG. 506: Remove hose. (If equipped)

Remove oil hose (1) and fasten out of the way.

N032006002

FIG. 506

FIG. 507: Remove hose. (If equipped)

Remove hose (1) and fasten out of the way.

N032006003

FIG. 507

FIG. 508: Remove tube. (If equipped)

Remove air discharge tube (1).

N032006004

FIG. 508

FIG. 509: Remove coolant tube. (If equipped)

Remove coolant tubes (1).

1

1

N032006006

FIG. 509

02-184 79033095 D Rev.

Engine Component

FIG. 510: Remove air inlet tube. (If equipped)

Remove air inlet tube (1).

1

N032006007

FIG. 510

FIG. 511: Remove support bracket. (If equipped)

Remove two bolts (1).

Loosen bolt (2) and rotate bracket (3) out of the way.

1

2

N032006010

FIG. 511

FIG. 512: Remove air compressor. (If equipped)

Remove three nuts (1) and remove air compressor (2).

The weight of the air compressor is approximately 21 kg

(46 lb).

2

1

N032006008

FIG. 512

FIG. 513: Remove air compressor hoses. (If equipped)

Disconnect hose (1) and remove P-clip (2).

Remove cable ties from hose (3). 1 3

2

N032606001

FIG. 513

79033095 D Rev. 02-185

Engine Component

FIG. 514: Remove air compressor hoses. (If equipped)

Disconnect tube (1), remove P-clip (2) and remove tube

(1).

2

2

2

1

P100506037

FIG. 514

FIG. 515: Air conditioning accumulator location.

The location of the air conditioning accumulator (1) is on

the left side of the machine and behind the step (2). The

step is behind the left front fender in front of the cab.

2

P100506015

FIG. 515

FIG. 516: Remove air conditioning lines.

Remove air conditioning lines (1) and disconnect low 2

pressure switch (2) from air conditioning accumulator (3).

IMPORTANT: Only a certified technician with certified 1

equipment should service the air conditioning

system.

IMPORTANT: Refer to Refrigerant section for proper

removal of hoses.

3

A certified technician must recover refrigerant and remove

air conditioning lines (1). Refer to Refrigerant section for 1

proper removal of hoses. Fasten air conditioning lines out P100506016

of the way. FIG. 516

FIG. 517: Remove accumulator.

Remove bolt (1), two piece clamp (2) and accumulator

(3).

2

P100506017

FIG. 517

02-186 79033095 D Rev.

Engine Component

FIG. 518: Remove bolts and remove plate (1).

1

P100506038

FIG. 518

FIG. 519: Fuel shut off.

On the fuel tank (1) on the right side of the fuel tank, turn 1

shut off valve handles (2) 90 degrees clockwise. Shut off

valve handles (2) should be perpendicular to the valve.

2

P100506039

FIG. 519

FIG. 520: Fuel shut off.

At the primary fuel filter / water separator (1) on the left

side of the engine, turn shut off valve handle (2) 90

degrees clockwise. Shut off valve handle (2) should be

perpendicular to the valve. 2

1

N033006001

FIG. 520

FIG. 521: Remove fuel line.

Remove supply fuel lines (1) and fasten out of the way.

1

1

P100506040

FIG. 521

79033095 D Rev. 02-187

Engine Component

FIG. 522: Remove window washer hoses.

Disconnect window washer hoses (1) from pump (2).

2

Remove P-clip (3) and cable straps (4) and fasten washer 1

hoses (1) out of the way.

3 4

N031906005

FIG. 522

FIG. 523: Remove ether start hose.

Remove ether start hose (1) and fasten out of the way.

N031906006

FIG. 523

FIG. 524: Remove engine coolant fill hose.

Loosen hose clamp (1) and remove hose (2).

1

N031906007

FIG. 524

FIG. 525: Remove hose.

Loosen hose clamp (1) and remove hose (2).

1

N031906008

FIG. 525

02-188 79033095 D Rev.

Engine Component

FIG. 526: Remove bracket.

Remove bolts (1) and remove bracket (2).

1

2

N032706003

FIG. 526

FIG. 527: Disconnect support.

Remove bolts (1) from bearing pad and cooling assembly

(2) on the right side of machine.

1

2

P100506041

FIG. 527

FIG. 528: Disconnect support.

Remove bolts (1) from bearing pad and cooling assembly

(2) on the right side of machine.

Remove the component support (3) and the components

still fastened to it.

3

2

1

P100506042

FIG. 528

FIG. 529: Disconnect the input shaft.

Remove bolts (1) and remove the input shaft (2).

2

1

P100506021

FIG. 529

79033095 D Rev. 02-189

Engine Component

FIG. 530: Attach lifting device.

Attach approved lifting device to the lifting brackets (1) at

the front and rear of engine. The weight of the engine is

approximately 1332 kg (2930lb).

1

P100506043

FIG. 530

FIG. 531: Remove engine mounting hardware.

Remove two bolts (1) on each side of engine.

P100506044

FIG. 531

FIG. 532: Remove engine.

Remove the engine (1). The weight of the engine is

approximately 1332 kg (2930 lb).

P100506043

FIG. 532

FIG. 533: Clean beneath engine mounting isolators.

Remove the four sets of mounting hardware (1). Clean

mounting surface to be free of rust and dirt.

1

1

P100506045

FIG. 533

02-190 79033095 D Rev.

Engine Component

Engine Installation

FIG. 534: Install engine mounting hardware.

Ensure mounting surfaces (1) are clean and free of rust.

Install washer (2), primary support pad (3) and sleeve (4) 4

on the four engine mounting points, two on each side.

3

1 2

P100506046

FIG. 534

FIG. 535: Install engine.

Install the engine (1). The weight of the engine is

approximately 1332 kg (2930lb).

P100506043

FIG. 535

FIG. 536: Install engine mounting hardware.

Install rebound pad (1), washer (2), washer (3) and bolt

(4) on the four engine mounting points, two on each side. 3 4

Tighten bolts to 800 Nm (590 lbf ft).

1

P100506047

FIG. 536

FIG. 537: Connect the input shaft.

NOTE: If the bolt pattern on the input shaft and the input 3

coupling do not line up, then refer to the CAT

engine manual on how to rotate the flywheel.

Connect the input shaft (2) to the input coupling (3) and

install bolts and washers (1). Tighten to 350 Nm (258 lbf

ft).

2

1

P100506021

FIG. 537

79033095 D Rev. 02-191

Engine Component

FIG. 538: Connect support.

Install the component support (3) and the components

still fastened to it. 5

Install bolts and washers (1) into bearing pad (2) on the

right side of machine. Tighten to 240 Nm (177 lbf ft).

Install bolts and washers (4) onto cooling assembly (5) on 3

the right side of machine. Tighten to 55 Nm (40 lbf ft). 4

1 2

P100506042

FIG. 538

FIG. 539: Connect support.

Install bolts and washers (1) into bearing pad (2) on the

right side of machine. Tighten to 240 Nm (177 lbf ft).

Install bolts and washers (3) onto cooling assembly (4) on

the right side of machine. Tighten to 55 Nm (40 lbf ft).

2

3 4

1 P100506041

FIG. 539

FIG. 540: Install bracket.

Install bracket (2) and install four bolts and washers (1).

Tighten to 100 Nm (74 lbf ft).

1

2

N032706003

FIG. 540

FIG. 541: Install hose.

Install hose (2) and tighten hose clamp (1).

1

N031906008

FIG. 541

02-192 79033095 D Rev.

Engine Component

FIG. 542: Install hose.

Install hose (2) and tighten hose clamp (1).

1

N031906007

FIG. 542

FIG. 543: Install ether start hose.

Install ether start hose (1).

N031906006

FIG. 543

FIG. 544: Install window washer hoses.

Install hose (1), P-clip (3) and cable straps (4).

2

Connect window washer hoses (1) to the pumps (2). 1

3 4

N031906005

FIG. 544

FIG. 545: Install fuel line.

Install supply fuel lines (1). Tighten to 55 Nm (40 lbf ft).

1

1

P100506040

FIG. 545

79033095 D Rev. 02-193

Engine Component

FIG. 546: Turn on fuel shut off.

At the fuel filter (1) on the left side of the engine, turn shut

off valve handle (2) 90 degrees counter clockwise. Shut

off valve handle (2) should be parallel to the valve.

2

1

N033006001

FIG. 546

FIG. 547: Turn on fuel shut off.

On the fuel tank (1) turn shut off valve handle (2) 90 1

degrees counter clockwise. Shut off valve handle (2)

should be parallel to the valve.

2

P100506039

FIG. 547

FIG. 548: Remove bolts and remove plate (1). Install

plate (1). Install washers and bolts, tighten to 55 Nm (40

lbf ft).

1

P100506038

FIG. 548

FIG. 549: Install accumulator.

Install two piece clamp (2) around accumulator (3) and

install on bracket (4). Install bolt and washer (1) and

tighten.

4

3

2

P100506017

FIG. 549

02-194 79033095 D Rev.

Engine Component

FIG. 550: Install air conditioning lines.

IMPORTANT: Only a certified technician with certified 2

equipment should service the air conditioning

system.

1

IMPORTANT: Refer to Refrigerant section for proper

removal of hoses.

A certified technician must install air conditioning lines (1)

and charge the air conditioning system. Reconnect the

low pressure switch (2). Refer to Refrigerant section for

proper installation of hoses. 1

P100506016

FIG. 550

FIG. 551: Install air compressor hoses. (If equipped)

Connect tube (1) and tighten to 86 Nm (63 lbf ft). Install

P-clip (2) and tighten to 70 Nm (51 lbf ft).

2

2

2

1

P100506037

FIG. 551

FIG. 552: Install air compressor hoses. (If equipped)

Connect tube (1) and tighten to 86 Nm (63 lbf ft). Install

P-clip (2). 1 3

Install hose (3) and install cable ties for hose (3).

2

N032606001

FIG. 552

FIG. 553: Install air compressor. (If equipped)

Surfaces (1) must be free of primer, topcoat, cleaning

solutions and corrosion.

The weight of the air compressor is approximately 21 kg

(46 lb).

1

1

N032006009

FIG. 553

79033095 D Rev. 02-195

Engine Component

FIG. 554: Install air compressor. (If equipped)

Install air compressor (2) and install three nuts and

washers (1). Tighten bolts to 105 Nm (77 lbf ft).

2

1

N032006008

FIG. 554

FIG. 555: Install support bracket. (If equipped)

Rotate bracket (3) to the air compressor.

Install two bolts (1) into the air compressor. Tighten bolt to

55 Nm (40 lbf ft). 1

Tighten bolt (2) to 215 Nm (158 lbf ft).

3

2

N032006010

FIG. 555

FIG. 556: Install air inlet tube. (If equipped)

Install the connector (1). Tighten to 135 Nm (100 lbf ft).

Install air inlet tube (2). Tighten to 156 Nm (115 lbf ft).

N032106001

FIG. 556

FIG. 557: Install coolant tube. (If equipped)

Install 90 degree elbow (1). Tighten to 82 Nm (60 lbf ft).

Install coolant tubes (2). Tighten to 55 Nm (40 lbf ft).

1

N032106002

FIG. 557

02-196 79033095 D Rev.

Engine Component

FIG. 558: Install coolant tube. (If equipped)

2

Install the connector (1). Tighten to 55 Nm (40 lbf ft).

Install coolant tubes (2). Tighten to 55 Nm (40 lbf ft).

N032106003

FIG. 558

FIG. 559: Install tube. (If equipped)

Install the connector (1). Tighten to 140 Nm (103 lbf ft).

Install air discharge tube (2). Tighten to 86 Nm (63 lbf ft).

1 2

N032006004

FIG. 559

FIG. 560: Install hose. (If equipped)

Install fitting and hose(1). Tighten to 16 Nm (11 lbf ft).

N032006003

FIG. 560

FIG. 561: Install oil hose. (If equipped)

Install the connector (1). Tighten to 22 Nm (16 lbf ft).

Install oil hose. Tighten to 18 Nm (13 lbf ft).

N032006002

FIG. 561

79033095 D Rev. 02-197

Engine Component

FIG. 562: Install oil hose. (If equipped)

Install the connector (1). Tighten to 22 Nm (16 lbf ft).

Install oil hose (2). Tighten to 18 Nm (13 lbf ft). 1

N032106004

FIG. 562

FIG. 563: Install alternator.

Place alternator (3) and install the two top bolts (1) and

bottom bolt (2). Tighten top two bolts to 71 N.m. (52 ft.lb.).

Tighten bottom bolt to 105 N.m. (77 lb.ft.). The weight of 1

the alternator is approximately 27 kg (60 lb).

N031706008

FIG. 563

FIG. 564: Install air conditioning compressor

Install compressor (2) and tighten bolts and washers (1).

Tighten to 28 Nm (20 lbf ft). The weight of the air

conditioning compressor is approximately 10 kg (21 lb). 2

N030806004

FIG. 564

FIG. 565: Belt install.

Install serpentine belt (3) over pulleys on front of engine,

leaving it off of alternator pulley. Ensure that belt ribs are

properly seated in pulley valleys.

Insert square drive of ratchet into square hole (1) on belt 1 2

tensioner (2) and rotate tensioner clockwise and hold.

m

WARNING: Equipment or parts under 3

spring tension can cause bodily injury. Use

caution in applying pressure to belt

tensioner.

Carefully place belt onto air conditioning compressor 4

pulley (4) ensuring belt ribs are properly seated in pulley

valleys and slowly allow belt tensioner to release until it

makes contact with belt. N021606002

FIG. 565

02-198 79033095 D Rev.

You might also like

- Rack and Pinion2Document18 pagesRack and Pinion2Romy MNo ratings yet

- Introduction To Statistical Thinking For Decision MakingDocument13 pagesIntroduction To Statistical Thinking For Decision MakingJing Sagittarius100% (1)

- Rudolph Ganz Piano ExercisesDocument1 pageRudolph Ganz Piano ExercisesChristopher DanielNo ratings yet

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- Emcee ScriptDocument4 pagesEmcee Scriptmitch galax67% (3)

- 14 en FusionadoDocument1,366 pages14 en FusionadoEduardo Julián100% (1)

- Fina HSINC 50Document56 pagesFina HSINC 50rp100% (1)

- ErrorDocument16 pagesErrorيوسف وليد عبد الرحيمNo ratings yet

- Technical Specification - 32m Guyed MastDocument7 pagesTechnical Specification - 32m Guyed Mastashraf04_ceNo ratings yet

- SECTION 9001 Cab RemovalDocument12 pagesSECTION 9001 Cab Removallungu mihaiNo ratings yet

- Manual Hi-Lo CO PDFDocument7 pagesManual Hi-Lo CO PDFLeonel Zavarizi NetoNo ratings yet

- 11 42 020 Removing and Installing - Replacing Full-Flow Oil Filter (B48B)Document8 pages11 42 020 Removing and Installing - Replacing Full-Flow Oil Filter (B48B)BAO ANH LÊNo ratings yet

- 05 Upper Struck-CabDocument60 pages05 Upper Struck-Cabkampungsaya79No ratings yet

- Bulldozer D61EX-15E0 D61PX-15E0: 50 Disassembly and AssemblyDocument10 pagesBulldozer D61EX-15E0 D61PX-15E0: 50 Disassembly and AssemblyJose nildo lobato Mendes MendesNo ratings yet

- Section 90 Cab Interior ComponentsDocument6 pagesSection 90 Cab Interior ComponentsDra MiNo ratings yet

- 02 enDocument20 pages02 enEduardo JuliánNo ratings yet

- Remove The Delivery FanDocument40 pagesRemove The Delivery FanFábio AndréNo ratings yet

- Removal: CO-5 EM-34Document5 pagesRemoval: CO-5 EM-34marran almarranyNo ratings yet

- Toyotacorollarm1106esupp1496 Password Removed PDFDocument1 pageToyotacorollarm1106esupp1496 Password Removed PDFHenrry MendezNo ratings yet

- 5 - Manual Trans Removal PDFDocument3 pages5 - Manual Trans Removal PDFEduardo SantosNo ratings yet

- M - Fi - 0022 Fuel InjectorDocument1 pageM - Fi - 0022 Fuel InjectorhugocarbouNo ratings yet

- Removal:: 2 ClipsDocument4 pagesRemoval:: 2 ClipsWawan SatiawanNo ratings yet

- Crank Shaft Change Work InstructionDocument5 pagesCrank Shaft Change Work InstructionRay PutraNo ratings yet

- Ac 37Document1 pageAc 37Tung NguyenNo ratings yet

- How To Remove Cutter Unit From Mechanism Unit of Printer TSP100III ModelDocument2 pagesHow To Remove Cutter Unit From Mechanism Unit of Printer TSP100III ModelHelen MoanNo ratings yet

- N52 StarterreplacementDocument18 pagesN52 StarterreplacementsamadNo ratings yet

- Section 41: Steering Column and Steering Hand Pump Removal and Installation TG Series TractorsDocument12 pagesSection 41: Steering Column and Steering Hand Pump Removal and Installation TG Series Tractorsjeffrey pelletierNo ratings yet

- Kd-lx30r Lx10r (SM)Document72 pagesKd-lx30r Lx10r (SM)Roberd MihailovNo ratings yet

- Cambio Di Velocita' DifferenzialeDocument7 pagesCambio Di Velocita' DifferenzialewezawezaNo ratings yet

- In-Vehicle Repair: Valve Cover LHDocument4 pagesIn-Vehicle Repair: Valve Cover LHJarraad BenjaminNo ratings yet

- 5.0 JibDocument96 pages5.0 JibSergeyNo ratings yet

- Engine Mechanical - 3.6L (Off Vehicule)Document395 pagesEngine Mechanical - 3.6L (Off Vehicule)maxrojanNo ratings yet

- CAT 226B2 Piston Motor (Hydrostatic) - DisassembleDocument10 pagesCAT 226B2 Piston Motor (Hydrostatic) - DisassembleRaul FletcherNo ratings yet

- Removal Procedure: 4/5/6/6.5/7 HP ClassDocument10 pagesRemoval Procedure: 4/5/6/6.5/7 HP Classwirawat patthumNo ratings yet

- Henry Yaris 3Document4 pagesHenry Yaris 3Miguel AngelNo ratings yet

- Section 90 - Cab - Chapter 2Document38 pagesSection 90 - Cab - Chapter 2Esteban MunaresNo ratings yet

- BC-5300 Preventive Maintenance Kit ManualDocument8 pagesBC-5300 Preventive Maintenance Kit ManualAbdel MUNDENNo ratings yet

- Automatic Transaxle2 PDFDocument11 pagesAutomatic Transaxle2 PDFluisNo ratings yet

- Removal: 2Uz-Fe Engine Mechanical - Timing BeltDocument4 pagesRemoval: 2Uz-Fe Engine Mechanical - Timing BeltmarranNo ratings yet

- 2.5DCI Engine MechanicalDocument1,243 pages2.5DCI Engine MechanicalandresNo ratings yet

- Polea Del Cigüeñal - Quitar e Instalar (SENR5553)Document3 pagesPolea Del Cigüeñal - Quitar e Instalar (SENR5553)Grover Escobal MendezNo ratings yet

- HP LaserJet Enterprise M607 - M608 - M609. MFP M631 Repair Manual - EnWW.3Document250 pagesHP LaserJet Enterprise M607 - M608 - M609. MFP M631 Repair Manual - EnWW.3Dennis LeeNo ratings yet

- New Holland 100hp - 115hp - 135hp - 160hp Power Take-Off Part2Document13 pagesNew Holland 100hp - 115hp - 135hp - 160hp Power Take-Off Part2Drag TrakNo ratings yet

- ReplacementDocument8 pagesReplacementJavier SiñaniNo ratings yet

- 03 Disassembly and Reassemble PDFDocument6 pages03 Disassembly and Reassemble PDFRobert CarNo ratings yet

- Service Manual JVC kd-s743r / kd-s741rDocument42 pagesService Manual JVC kd-s743r / kd-s741ra637888No ratings yet

- 02 enDocument20 pages02 enEduardo JuliánNo ratings yet

- Refitting: 4450B12 Front or Rear Wheels (Two) - R+RDocument9 pagesRefitting: 4450B12 Front or Rear Wheels (Two) - R+RAlexTocuNo ratings yet

- RemoDocument1 pageRemoMansur KhanNo ratings yet

- CPAP Dissassembly InstructionsDocument4 pagesCPAP Dissassembly InstructionsDan LehrNo ratings yet

- HP Laserjet 4345 MFP Swing Plate Removal PDFDocument3 pagesHP Laserjet 4345 MFP Swing Plate Removal PDFlexNo ratings yet

- TDIRem&InstDocument23 pagesTDIRem&InstkjellekopNo ratings yet

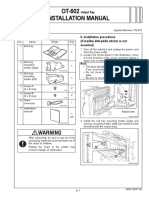

- Installation Manual OT-602: I. Accessory Parts II. Installation Procedures (If Mailbin Kit/saddle Sticher Is Not Mounted)Document4 pagesInstallation Manual OT-602: I. Accessory Parts II. Installation Procedures (If Mailbin Kit/saddle Sticher Is Not Mounted)hashemNo ratings yet

- 12 - Cylinder Head - RemovalDocument3 pages12 - Cylinder Head - RemovaljordantNo ratings yet

- tài liệu tham khảoDocument52 pagestài liệu tham khảoTrung Nghia Phan NguyenNo ratings yet

- SIS 2.0 - Desmontagem Motor de Partida 950HDocument9 pagesSIS 2.0 - Desmontagem Motor de Partida 950HBelline SilveiraNo ratings yet

- Removal & Installation and Disassembly & Reassembly: 1. Remove Floor Carpet Cover Center LH (See Page)Document3 pagesRemoval & Installation and Disassembly & Reassembly: 1. Remove Floor Carpet Cover Center LH (See Page)dongheep811No ratings yet

- Disassembly: Screw ExtractorDocument3 pagesDisassembly: Screw ExtractorMoh DeBrNo ratings yet

- Manual de Servico Janone MC550EDocument59 pagesManual de Servico Janone MC550EandersondelgadogomesNo ratings yet

- Transmission Planetary - Disassemble: Disassembly and AssemblyDocument23 pagesTransmission Planetary - Disassemble: Disassembly and AssemblyMbahdiro KolenxNo ratings yet

- Remanufacturing Instructions: HP Laserjet P 3005Document9 pagesRemanufacturing Instructions: HP Laserjet P 3005Gabriel AnastasiuNo ratings yet

- HP 3390-3392 MFP Fuser ReplaceDocument13 pagesHP 3390-3392 MFP Fuser Replaceicatalind1713100% (2)

- MDX 650 PDFDocument51 pagesMDX 650 PDFBillyNo ratings yet

- Panasonic PT 43LC14 Dis Assembly InstructionsDocument28 pagesPanasonic PT 43LC14 Dis Assembly InstructionsJoe TingerthalNo ratings yet

- ToyotaDocument12 pagesToyotaZarate CruzNo ratings yet

- P1D32C016 - 11-2014 - EN (1) - Compactado-1-1Document129 pagesP1D32C016 - 11-2014 - EN (1) - Compactado-1-1geronimojuarez179No ratings yet

- MT Series - ServiceDocument8 pagesMT Series - ServiceВаня БойкоNo ratings yet

- 03-En (1) - FusionadoDocument336 pages03-En (1) - FusionadoEduardo JuliánNo ratings yet

- Challenger: MT835C / MT845C / MT855C / MT865C / MT875C Rubber Track TractorDocument20 pagesChallenger: MT835C / MT845C / MT855C / MT865C / MT875C Rubber Track TractorEduardo JuliánNo ratings yet

- 02 enDocument20 pages02 enEduardo JuliánNo ratings yet

- Air Compressor Installation: Engine ComponentDocument20 pagesAir Compressor Installation: Engine ComponentEduardo JuliánNo ratings yet

- 02 enDocument20 pages02 enEduardo JuliánNo ratings yet

- Engine Component: Remove O-Ring Seal. Remove O-Ring SealDocument20 pagesEngine Component: Remove O-Ring Seal. Remove O-Ring SealEduardo JuliánNo ratings yet

- Engine Component: IMPORTANT: Radiator Must Lifted Evenly On All Four CornersDocument20 pagesEngine Component: IMPORTANT: Radiator Must Lifted Evenly On All Four CornersEduardo JuliánNo ratings yet

- Hydraulic/Transmission/Axle Cooler Installation: Engine ComponentDocument20 pagesHydraulic/Transmission/Axle Cooler Installation: Engine ComponentEduardo JuliánNo ratings yet

- PSR E363 Ypt 360 FR Songbook r1Document212 pagesPSR E363 Ypt 360 FR Songbook r1Eduardo JuliánNo ratings yet

- Renr7213renr7213 PDFDocument2 pagesRenr7213renr7213 PDFEduardo JuliánNo ratings yet

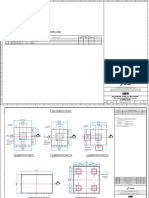

- PS 7500na Bom DrawingDocument1 pagePS 7500na Bom DrawingEmanuel VidalNo ratings yet

- Clutch CB PDFDocument45 pagesClutch CB PDFLuis Eduardo Albarracin RugelesNo ratings yet

- SV91Document2 pagesSV91nclogesh_1981No ratings yet

- Canon PIXMA MP830 Parts CatalogDocument8 pagesCanon PIXMA MP830 Parts Catalogaperez999No ratings yet

- AIP Sample PaperDocument6 pagesAIP Sample PaperHaris IfroniNo ratings yet

- Mechanic SupervisorDocument3 pagesMechanic SupervisorFharishPutraNo ratings yet

- 332 Indian Food Recipes (Sanjeev Kapoor)Document3 pages332 Indian Food Recipes (Sanjeev Kapoor)rnpirani33% (3)

- SMPS - Topologies PDFDocument2 pagesSMPS - Topologies PDFLungu CristianNo ratings yet

- DIN 906 - 1983hexagon Socket Pipe PlugsDocument4 pagesDIN 906 - 1983hexagon Socket Pipe PlugsChris StefanouNo ratings yet

- GurujiDocument12 pagesGurujiAnkur SinghNo ratings yet

- Grinding Media Technical Datasheet Ecomax ForgedDocument1 pageGrinding Media Technical Datasheet Ecomax ForgedEduardo MendozaNo ratings yet

- CutViewer Mill Assignment by Sumit Singal and Parkash RaghavDocument16 pagesCutViewer Mill Assignment by Sumit Singal and Parkash RaghavandljnnjdsNo ratings yet

- PANASONIC MD2 and E3D Chassis Technical GuideDocument108 pagesPANASONIC MD2 and E3D Chassis Technical GuideavrelecNo ratings yet

- Well 900 C Fou 1015 Rev4Document4 pagesWell 900 C Fou 1015 Rev4HAKIKI SIF EDDINENo ratings yet

- SaecoDocument8 pagesSaecoVivi RaduNo ratings yet

- A Louis ArmstrongDocument8 pagesA Louis ArmstrongPaulo VianaNo ratings yet

- Packet Tracer 4.0 Skill Building Activity: Lab 1.1.4a Configuring NAT SolutionDocument3 pagesPacket Tracer 4.0 Skill Building Activity: Lab 1.1.4a Configuring NAT SolutionGlaiza LacsonNo ratings yet

- Flow V Notch WeirsDocument3 pagesFlow V Notch WeirsMalith MadushanNo ratings yet

- Asbestoswise ASEA Information SheetsDocument32 pagesAsbestoswise ASEA Information SheetsHeung Yeung CheukNo ratings yet

- Text For RBA Drilling and CompletionsDocument47 pagesText For RBA Drilling and Completionsfahrain2012No ratings yet

- How Does Cockroft Walton Voltage Multiplier Circuit Work?: 2 AnswersDocument5 pagesHow Does Cockroft Walton Voltage Multiplier Circuit Work?: 2 AnswersSrinjay DasNo ratings yet

- BSS EMEA 2021 CatalogueDocument1,072 pagesBSS EMEA 2021 Cataloguemep sbcuNo ratings yet

- IS - 11585-2009 - Steel Silos For Milk Storage CapacityDocument11 pagesIS - 11585-2009 - Steel Silos For Milk Storage CapacityStacy WilsonNo ratings yet

- Dokumen - Tips - Hal Rudra Alh Wsi Attack Helicopter IndiaDocument14 pagesDokumen - Tips - Hal Rudra Alh Wsi Attack Helicopter IndiaAbdul QaderNo ratings yet