Professional Documents

Culture Documents

Toaz - Info Risk Assessment Installation of Ventilation Fandoc PR

Toaz - Info Risk Assessment Installation of Ventilation Fandoc PR

Uploaded by

belhareth seifeddineOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toaz - Info Risk Assessment Installation of Ventilation Fandoc PR

Toaz - Info Risk Assessment Installation of Ventilation Fandoc PR

Uploaded by

belhareth seifeddineCopyright:

Available Formats

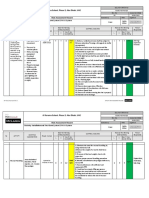

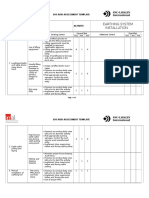

HS.SAF.34.

F02

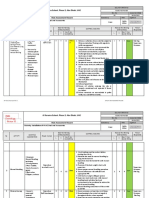

TASK RISK ASSESSMENT

Task: INSTALLATION OF VENTILATION FAN. SOP No: Department: Area: POWER PLANT OFFICE

Sr # Activity Personnel Hazard Risk Countermeasures Responsible Residual

Involved Risk

P S T P S T

1 PREPARATION. Emal Interference 3 3 9 Supervisor to ensure approved Emal 2 2 4

Arranging the operators/ with operational PTW from Emal operation is operation /

tools and electrician activity available prior to enter any contractor

materials s Hazard due Emal facilities. supervisor

Barrication to operational Only competent and

Conduct toolbox activitY authorized personnel to be

talk deployed, supervisor to

Inform EMAL control.

shift in charge Supervisor to give tool box talk

before starting prior to start the task and

the work. must be documented. This

shall cover the method

statement and risk

assessment.

Proper coordination with Emal

shift supervisor prior to

commencement of the activity.

Activity shall be carried out

the personnel supervision of

receiving activity.

Ensure all workers received

the Big 5 training from EMAL

training

Work check list has to be

completed.

Area to be cordon off and

proper sign boards to be

File: Revision: 1(13-Jun-2013) Page 1 of 1

HS.SAF.34.F02

placed.

Follow the Golden Rules "TEST

BEFORE YOU TOUCH"

In case of emergency,

immediately contact EMAL

Emergency Response Team,

EMERGENCY NO:02-509

2111

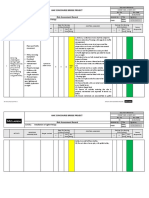

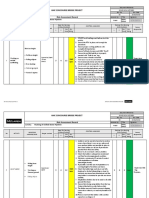

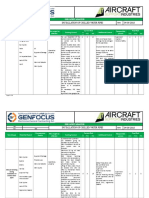

2 INSTALLATION OF Supervisor Trips/Slips 3 2 6 Observe good contractor 2 1 2

VENTILATION FAN & housekeeping around the supervisor

electrician working area.

s Walkway and gangway to be

kept free of obstruction.

Electrician Using 3 3 9 Supervisor/operatives must contractor 2 2 4

s & damaged/uninsp inspect the drill machine and supervisor

Helpers ected drill make sure it is in good

machine.

condition with valid colour

Electrocution

coding.

Ensure where ever to do

drilling that area is clear from

service.

CAT SCAN to be done before

prior to start the drilling works,

ensure CAT SCANNER is

calibrated

Don’t use excessive force to

drill machine during drilling.

Supervisor to ensure all power

sources connected with ELCB

and only 110V industrial

socket to be used at site.

File: Revision: 1(13-Jun-2013) Page 1 of 1

HS.SAF.34.F02

Appropriate fire extinguisher

to be provided if necessary

Electrician 3 2 6 contractor 2 1 2

s & Unauthorized Only competent and supervisor

Helpers using of hand authorized worker for using of

power tools power tools

Electrician 3 2 6 contractor 2 1 2

s & Provide appropriate safety supervisor

Dust while drilling

Helpers glass &dust mask while drilling

Electrician Using damaged 3 2 6 All hand tools must be in contractor 2 1 2

s& hand tools good condition with valid supervisor

Helpers colour code, no homemade

hand tools to be used at site,

supervisor to check.

Electrician Use only wooden or GRP contractor 2 2 4

s & ladder. supervisor

Helpers Don’t leave cut cable

inside the porta cabin

Inspect ladder before

use; assign one man to hold

the ladder on the ground while

in used.

Fall from height 3 3 9 Always climb up and

or from ladder.

down facing the ladder.

Don't carry tools or

materials in your hand while

climbing up and down ladder.

All workers involve in working

at height must wear their full

body harness and 100% tie

off.

File: Revision: 1(13-Jun-2013) Page 1 of 1

HS.SAF.34.F02

Electrician Cordon the work area to avoid contractor 2 2 4

s & unauthorized entry. supervisor

Helpers Provide applicable safety

warning signboards

Do not keep unwanted

3 3 9

Fall of materials materials on top of the ladder.

Materials to be removed

should be in safe manner –

one by one--, ensure no

materials to be dropped.

Supervisor Poor illumination. 3 2 6 Supervisor to ensure contractor 2 1 2

& good illumination at working supervisor

electrician area prior to start the job.

s

Electrician Incompetent 3 2 6 Competent workers to be contractor 2 1 2

s& workers. deployed, supervisor to check supervisor

Helpers the competency of the

workers.

All workers Working without 3 2 6 All personnel involve in the contractor 2 1 2

involved in proper PPE’s activities must wear proper supervisor

the activity PPE’s (hard hat, clear safety

glass, appropriate hand

gloves, dust mask, coverall

and reflective vest).

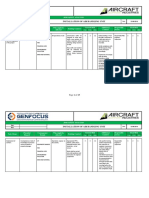

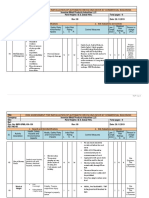

3 INSTALLATION OF PVC Electrician Supervisor/operatives to contractor 2 1 2

TRUNKING s& ensure that all hand tools supervisor

Helpers Using damaged must be in good condition with

3 2 6

hand tools valid colour coding inspection

tag, no homemade hand tools

to be used at site.

Electrician Manual handling 3 2 6 Examine the load to make sure contractor 2 1 2

s& hazards (Back it is not too heavy or awkward supervisor

Helpers

File: Revision: 1(13-Jun-2013) Page 1 of 1

HS.SAF.34.F02

injury to Always get close to the object

personnel, Hand to carry.

and foot injury) Ensure to see over the load

when carrying it.

Use proper Hand gloves and

foot protection

Supv. Elec, Clear all debris after the contractor 2 1 2

and completion of work supervisor

helpers Slip and fall 3 2 6

Walkway and gangway to be

kept free of obstruction

Electrician 3 3 9 Cordon the work area to avoid contractor 2 2 4

s & unauthorized entry. supervisor

Helpers Provide applicable safety

warning signboards

Do not keep unwanted

Fall of materials materials on top of the ladder.

Materials to be removed

should be in safe manner –

one by one--, ensure no

materials to be dropped.

Electrician 3 3 9 All workers involve in working contractor 2 2 4

s & Fall from height supervisor

at height must wear their full

Helpers body harness and 100% tie

off.

Barricade the working area by

using safety cones warning

tape / signboard.

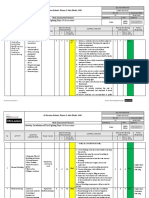

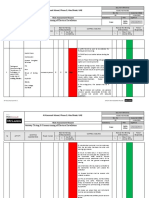

4 CONNECT CABLE TO Use of sharp 4 3 12 All hand tools must be in good contractor 2 2 4

Engr.,

FAN AND PLUG hand tools. condition with valid colour supervisor

Supv.,

Elec., & Competency of code, no homemade hand

helpers electrician tools to be used at site,

Using damaged supervisor to check.

File: Revision: 1(13-Jun-2013) Page 1 of 1

HS.SAF.34.F02

Supervisor to ensure the

competency of

electrician/cable jointer.

hand tools

Inspect heat gun before use;

Use of Heat gun

ensure that heat gun is in

(hot blower),

good condition with valid

electrocution/

colour coded.

burns.

Only 110 V to be used at site

Provide firewatcher and fire

extinguisher as required.

Consequence

insignificant catastrophic

Probability -1 minor-2 moderate-3 major-4 -5 TRA Conducted By (Name & Emp#): TRA Approved By (Name, Emp# &

Signature):

rare-1 1 2 3 4 5 1.

possible-2 2 4 6 8 10 2.

likely-3 3 6 9 12 15 3.

often-4 4 8 12 16 20 4.

frequent-5 5 10 15 20 25

File: Revision: 1(13-Jun-2013) Page 1 of 1

You might also like

- Risk Assessment HVAC DuctingDocument5 pagesRisk Assessment HVAC DuctingAsad Zakria100% (6)

- 08 Cable Termination Risk AssessmentDocument2 pages08 Cable Termination Risk AssessmentBaranidaranRavi72% (18)

- JSA FOR Fixing of Light FittingsDocument1 pageJSA FOR Fixing of Light Fittingswahyu nugroho100% (2)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Cable Pulling / Laying, Glanding and Termination SopDocument12 pagesCable Pulling / Laying, Glanding and Termination SopStansilous Tatenda Nyagomo0% (1)

- Installation of Copper Pipes and Fittings.: Barq Group Risk AssessmentDocument8 pagesInstallation of Copper Pipes and Fittings.: Barq Group Risk AssessmentYousaf Richu75% (4)

- Risk Assessment of Installation of Chilled Water PipesDocument19 pagesRisk Assessment of Installation of Chilled Water PipesAnandu Ashokan80% (10)

- Risk Assessment - Breaking ConcreteDocument2 pagesRisk Assessment - Breaking Concretednmule83% (6)

- Job Hazard Assessment For Cable TestingDocument4 pagesJob Hazard Assessment For Cable TestingSamuel Carlos100% (2)

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsAnandu Ashokan89% (9)

- Risk Assessment For Installation & Testing Commissioning of PumpsDocument17 pagesRisk Assessment For Installation & Testing Commissioning of PumpsAnandu Ashokan75% (8)

- Risk Assessment of Conduit Pipe InstallationDocument17 pagesRisk Assessment of Conduit Pipe InstallationJayson Escamillan75% (4)

- Cable PullingDocument4 pagesCable Pullingmykelrenz92% (12)

- MS For Installation of Light FittingsDocument11 pagesMS For Installation of Light FittingsAnandu Ashokan100% (2)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 pagesRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan80% (5)

- Checklist For Access Control System InstallationDocument6 pagesChecklist For Access Control System Installationnsadnan71% (7)

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 pagesRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan86% (14)

- Chilled Water Pipe Installation - ACMVDocument4 pagesChilled Water Pipe Installation - ACMVbinhjuki100% (2)

- Installation of Air Handling UnitDocument15 pagesInstallation of Air Handling UnitAnandu Ashokan100% (2)

- Risk Assessment For Installation of Fan Coil UnitsDocument18 pagesRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Risk Assessment For Installation & Testing of BMS UnitDocument15 pagesRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Risk Assessment For Installation of Sanitary WaresDocument14 pagesRisk Assessment For Installation of Sanitary WaresAnandu Ashokan71% (7)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocument6 pagesRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocument6 pagesRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- Risk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light FittingsDocument6 pagesRisk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light Fittingsnsadnan86% (21)

- Ehs Risk AssessmentDocument2 pagesEhs Risk AssessmentRohit Singh100% (1)

- Risk Assessment For Installation of Fire Fighting Pipe & AccessoriesDocument15 pagesRisk Assessment For Installation of Fire Fighting Pipe & AccessoriesAnandu Ashokan83% (6)

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead Cranensadnan100% (1)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Cable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentDocument23 pagesCable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentMon Trang Nguyễn100% (2)

- Mapeh 8 1st Summative TestDocument5 pagesMapeh 8 1st Summative TestHezel Mercado Edrozo100% (2)

- DDC Systems2Document28 pagesDDC Systems2nsadnan100% (1)

- Risk Assessment (Electric Works)Document4 pagesRisk Assessment (Electric Works)Raza Muhammad Soomro100% (4)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocument6 pagesRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel Factor50% (4)

- Risk Assessment For Installation of Sanitary Fixtures and Mixers (New)Document12 pagesRisk Assessment For Installation of Sanitary Fixtures and Mixers (New)Anandu Ashokan100% (1)

- RA For Hvac Duct InstallationDocument10 pagesRA For Hvac Duct InstallationAnandu Ashokan88% (8)

- 009 Installation of Pumps Risk AssessmentDocument2 pages009 Installation of Pumps Risk Assessmentgangadharan000100% (13)

- Risk Assessment For Installation of Fire Alarm System & PAVA SystemDocument11 pagesRisk Assessment For Installation of Fire Alarm System & PAVA SystemAnandu Ashokan88% (8)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDocument12 pagesRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- Unlock Transformation Ebook by Dr. Mohit Bhandari PDFDocument21 pagesUnlock Transformation Ebook by Dr. Mohit Bhandari PDFVarinder AnandNo ratings yet

- Risk Assessment of Fire Hose Reel InstallationDocument9 pagesRisk Assessment of Fire Hose Reel Installationfidgety100% (2)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Risk Assessment For Flushing of Chilled Water PipingDocument9 pagesRisk Assessment For Flushing of Chilled Water PipingAnandu AshokanNo ratings yet

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDocument14 pagesRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDocument14 pagesRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Document12 pagesRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanNo ratings yet

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 pagesRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- Risk Assessment For Installation of Toilet Exhaust FanDocument11 pagesRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- RE Property Management Appointment 547 DenmDocument17 pagesRE Property Management Appointment 547 DenmBolboNo ratings yet

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument8 pagesRisk Assessment For Installation of Automatic Revolving Door Installationsabirbdk100% (1)

- Risk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Document12 pagesRisk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Anandu Ashokan100% (1)

- Method Statement & Risk Assessment For Roller ShutterDocument3 pagesMethod Statement & Risk Assessment For Roller Shutterchandanprakash30100% (1)

- Risk Assessment - Installation of Air-Cooled ChillersDocument4 pagesRisk Assessment - Installation of Air-Cooled ChillersBabar ShehzadNo ratings yet

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 pagesRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 pagesRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Flushingchemical Cleaning of Chilled Water PipesDocument9 pagesFlushingchemical Cleaning of Chilled Water PipesAnandu AshokanNo ratings yet

- Risk Assessment For GIS Preparation For HV Cable TestDocument11 pagesRisk Assessment For GIS Preparation For HV Cable Testnsadnan100% (3)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- Chiller Plant RADocument2 pagesChiller Plant RAarifzakir67% (9)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment For Water Heaters InstallationDocument6 pagesRisk Assessment For Water Heaters Installationfidgety100% (2)

- 012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1Document6 pages012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1nsadnan100% (11)

- Safety and Health Committee Regulations 1996 Law PresentationzzDocument20 pagesSafety and Health Committee Regulations 1996 Law PresentationzzParveendah RajNo ratings yet

- Risk Assessment - CHW PumpDocument4 pagesRisk Assessment - CHW PumpAdnan Attish100% (1)

- RA For Phase 1 Existing LV Panel and Cable Dismantling WorkDocument9 pagesRA For Phase 1 Existing LV Panel and Cable Dismantling WorkAnandu Ashokan100% (1)

- Checklist For Pre Commissioning of CCTV SystemDocument1 pageChecklist For Pre Commissioning of CCTV Systemnsadnan75% (8)

- Testing and Commissioning Pre-Check List (ID 1506)Document1 pageTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Installation of Chilled Water PipesDocument6 pagesInstallation of Chilled Water PipesAnandu Ashokan0% (1)

- Ra For Installation of Grills, Diffusers & LouversDocument8 pagesRa For Installation of Grills, Diffusers & LouversAnandu Ashokan100% (1)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Document1 pageCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- Pediatric Nursing AssessmentDocument8 pagesPediatric Nursing Assessmentmiss RN87% (15)

- Checklist For Commissioning of CCTV SystemDocument2 pagesChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- Risk Assessment - FM 200Document5 pagesRisk Assessment - FM 200Nangyal KhanNo ratings yet

- Overview of Iso 31000 Iso-Iec 31010 & Iso Guide 73Document54 pagesOverview of Iso 31000 Iso-Iec 31010 & Iso Guide 73pcstorecenter100% (2)

- 005 Risk Assessment T&C Fire Suppression SystemDocument10 pages005 Risk Assessment T&C Fire Suppression SystemJohn RazaNo ratings yet

- EEEPL - JSA Light Fitting ErectionDocument6 pagesEEEPL - JSA Light Fitting ErectionnishanthNo ratings yet

- ONVIF Profile Feature Overview v2-2Document6 pagesONVIF Profile Feature Overview v2-2nsadnanNo ratings yet

- ONVIF Profile T Specification v1-0Document77 pagesONVIF Profile T Specification v1-0nsadnanNo ratings yet

- ONVIF Profile - S Specification v1-2Document42 pagesONVIF Profile - S Specification v1-2nsadnan0% (1)

- 1 45Document3 pages1 45nsadnan0% (1)

- BSIA Cyber Secure It January 2019Document16 pagesBSIA Cyber Secure It January 2019nsadnanNo ratings yet

- Excel Intelligent Pdu User InstructionsDocument2 pagesExcel Intelligent Pdu User InstructionsnsadnanNo ratings yet

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocument5 pagesPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanNo ratings yet

- Contractor Work Method Statement (Ehs)Document11 pagesContractor Work Method Statement (Ehs)nsadnanNo ratings yet

- Communication Skills AssignmentDocument6 pagesCommunication Skills AssignmentArshad Khan ShamsNo ratings yet

- International Dictionary of PsychoanalysisDocument4 pagesInternational Dictionary of PsychoanalysisPutri Yuni UtamiNo ratings yet

- The Accord On: Fire and Building Safety in BangladeshDocument2 pagesThe Accord On: Fire and Building Safety in BangladeshNavila Al MonaNo ratings yet

- APA 6th Reference HandoutDocument7 pagesAPA 6th Reference HandoutKhairun Nisa JNo ratings yet

- Jurnal HipertensiDocument13 pagesJurnal Hipertensi44Esri nubanNo ratings yet

- Interconnection Chart 2012Document1 pageInterconnection Chart 2012Noah EspesethNo ratings yet

- ANAT3004Document9 pagesANAT3004jzho9697No ratings yet

- BIND Score PDFDocument1 pageBIND Score PDFSindhumv GowdaNo ratings yet

- Mcmillan Sample Print Out1Document3 pagesMcmillan Sample Print Out1CrizarNo ratings yet

- The Pathophysiology of Sepsis - 2021 Update - Part 2, Organ Dysfunction and AssessmentDocument13 pagesThe Pathophysiology of Sepsis - 2021 Update - Part 2, Organ Dysfunction and AssessmentValerie ZimmermannNo ratings yet

- Pangestuti, Arifin - 2018 - Medicinal and Health Benefit Effects of Functional Sea CucumbersDocument11 pagesPangestuti, Arifin - 2018 - Medicinal and Health Benefit Effects of Functional Sea CucumbersGREESTYNo ratings yet

- Targeted Public Distribution SystemDocument20 pagesTargeted Public Distribution SystemTanushka shuklaNo ratings yet

- Research PlanDocument8 pagesResearch Planjhonpaulsamante13No ratings yet

- Health Infrastructure and Economic Development in IndiaDocument9 pagesHealth Infrastructure and Economic Development in IndiaAkanksha PalNo ratings yet

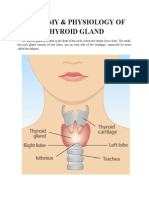

- Anatomy & Physiology of Thyroid GlandDocument5 pagesAnatomy & Physiology of Thyroid GlandJohnpaul DelapenaNo ratings yet

- 10 1016@j Accpm 2019 10 019Document6 pages10 1016@j Accpm 2019 10 019Sri NingsihNo ratings yet

- January DSR 2023Document9 pagesJanuary DSR 2023tgaurozin08No ratings yet

- Sally Rogers Dinner Conference: Clinical and Developmental Aspects of AutismDocument1 pageSally Rogers Dinner Conference: Clinical and Developmental Aspects of Autismaaspen3190No ratings yet

- Child-Centered Disaster Risk Reduction and Management/Climate Change Adaptation (Drrm/Cca) ProgrammingDocument59 pagesChild-Centered Disaster Risk Reduction and Management/Climate Change Adaptation (Drrm/Cca) ProgrammingJoseph P. CagconNo ratings yet

- Skeletal and Muscular SystemDocument118 pagesSkeletal and Muscular SystemMark Kevin AguilarNo ratings yet

- Temporary Stress Reduction TechniquesDocument4 pagesTemporary Stress Reduction TechniquesMitterra SibandaNo ratings yet

- Emily Rubin Interview 1Document5 pagesEmily Rubin Interview 1api-375491369No ratings yet

- Job Announcement FormDocument3 pagesJob Announcement FormPuravRajNo ratings yet

- Changes That HealDocument3 pagesChanges That HealLight Learning ClubNo ratings yet