Professional Documents

Culture Documents

MMPL-PSA-02-Casting Surface Defect Acceptance Standard - Brake - Drums

Uploaded by

Vishal MaliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MMPL-PSA-02-Casting Surface Defect Acceptance Standard - Brake - Drums

Uploaded by

Vishal MaliCopyright:

Available Formats

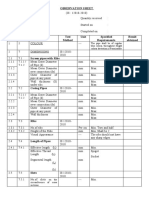

PSA BRAKE DRUM - SURFACE & INTERNAL DEFECT ACCEPTANCE STANDARD

Part Name:- BRAKE DRUM REV.NO/DATE : - 00 / 24-06-2021

SCOPE:- Casting Surface Defect Acceptable Sizes

Sr. No Characteristics Expression of results Requirments

1 1.1. ALLOWED DEFECTS SUCH AS BLOWHOLES AND PINHOLES Min. Max.

Defects on Section A No defects allowed on Section A. _ _

Diameter Ø ‒ 1.0 mm

Depth ‒ 0.5 mm

Defects on Section B

Distance from edges and from holes 5.0 mm ‒

Defects on Section an C and B must not be opposite but staggered 12 mm. ‒

Diameter Ø ‒ 2.0 mm

Depth ‒ 1.0 mm

Total Quantity ‒ 2

Defects on Section C

Distance from edges and from holes 2.0 mm ‒

Distance between 2 defects 50.0 mm ‒

Defects on Section an C and B must not be opposite but staggered 12 mm. ‒

Diameter Ø 2.0 mm ‒

Depth 1.0 mm ‒

Defects on Section D Total Quantity ≤ 2 2.0 mm ‒

Distance from edges and from holes 50.0 mm ‒

Defects on Section D must not be opposite but staggered 12 mm ‒

Defects on Section E Defects Not Allowed ‒ ‒

1.2. ALLOWED DEFECTS SUCH AS MICRO-POROSITY Min. Max.

Defects on Section A Defects Not Allowed ‒ ‒

Defects on Section B Accept all drums with only single defect of Micro porosity measuring. ‒ 8.5 mm²

Diameter Ø ‒ 1.0 mm

Depth ‒ 0.5 mm

Defects on Section C Total Quantity ‒ 4

Distance from edges and from holes 2.0 mm

On Area of Ø 30.0 mm

Defects on Section D Defects Not Allowed ‒ ‒

Defects on Section E Defects Not Allowed ‒ ‒

1.3 INTERNAL DEFECTS (RADIOGRAPHY) ‒

Up to Level 2 defects will be accepted as per ASTM E 446 / 192. Only internal defects like Gas porosity, Inclusions & Shrinkage

porosity will be accepted. Internal Defects such as Cracks & Hot Tears not accepted at all.

1.4 DESCRIPTION OF THE DESIGNATED AREAS

Section A -

Section B -

Section C -

Section D -

Section E -

Foundry Development Foundry Quality M/c Shop Quality Customer Approval

You might also like

- MMPL-PSA-01-Casting Surface Defect Acceptance Standard - Brake - DiscsDocument3 pagesMMPL-PSA-01-Casting Surface Defect Acceptance Standard - Brake - DiscsVishal MaliNo ratings yet

- Visual inspection areas of interest for IGU glass panesDocument1 pageVisual inspection areas of interest for IGU glass panesRimon GawandeNo ratings yet

- Nohab Acceptance Criteria For The Usability of Plunger and Barrel AssembliesDocument1 pageNohab Acceptance Criteria For The Usability of Plunger and Barrel AssembliesDPNo ratings yet

- Field Inspection of JFEBEAR (Rev.2)Document5 pagesField Inspection of JFEBEAR (Rev.2)Cong BuiNo ratings yet

- Sr. No. Operation Inspection Parameters Tolerances: 1.0 PurposeDocument2 pagesSr. No. Operation Inspection Parameters Tolerances: 1.0 PurposeSwarup SontakkeNo ratings yet

- Gun Drilling c-1140-543 PDFDocument24 pagesGun Drilling c-1140-543 PDFclcorjlgNo ratings yet

- Field Inspection of JFEBEAR (Rev.1)Document5 pagesField Inspection of JFEBEAR (Rev.1)Cong BuiNo ratings yet

- 'TDS ONDULINE TILE (Asia) 2018-03 PDFDocument2 pages'TDS ONDULINE TILE (Asia) 2018-03 PDFIwan SetiawanNo ratings yet

- ISO 2400-Calibration Block No.1Document1 pageISO 2400-Calibration Block No.1bhavin178No ratings yet

- Twi CodeDocument1 pageTwi CodeHadi Azfar Bikers PitNo ratings yet

- Fitting Inspection Report (Built-Up Section) : BLDG: PH No: Date: Project Name: Customer Name: Job NoDocument1 pageFitting Inspection Report (Built-Up Section) : BLDG: PH No: Date: Project Name: Customer Name: Job NoMd. Sahabul IslamNo ratings yet

- Observation Sheet: The Pipe Shall Be of Regular Blue Colour, Throughout. Slight Colour Deviation Is PermissibleDocument6 pagesObservation Sheet: The Pipe Shall Be of Regular Blue Colour, Throughout. Slight Colour Deviation Is Permissiblebishnu pandaNo ratings yet

- Porcelanato Sandy beach graniglia technical data sheetDocument2 pagesPorcelanato Sandy beach graniglia technical data sheetCamilo Ponce de LeonNo ratings yet

- GB T 2694 2003 English VersionDocument19 pagesGB T 2694 2003 English Versionsaliyarumesh2292No ratings yet

- Sunflag Crack IssueDocument7 pagesSunflag Crack IssueKumaravelNo ratings yet

- Tolerances As Per en 12493Document5 pagesTolerances As Per en 12493prasad raikarNo ratings yet

- Paint Accepatnce Standard UpdatedDocument1 pagePaint Accepatnce Standard Updatedsachin pataneNo ratings yet

- Flameproof Motors: Aluminium 56-180Document32 pagesFlameproof Motors: Aluminium 56-180Gloria Hamilton100% (1)

- UNI - Z241 - 17 - 5 - 600x300 ModifiedDocument23 pagesUNI - Z241 - 17 - 5 - 600x300 ModifiedpaulaNo ratings yet

- General Dimensional Tolerance For Parts Formed by Press Working From Sheet MetalDocument2 pagesGeneral Dimensional Tolerance For Parts Formed by Press Working From Sheet MetalRicardo F.A.100% (3)

- Zlevel.1: Part Operation: Part Operation.1 Program: Manufacturing Program.1Document3 pagesZlevel.1: Part Operation: Part Operation.1 Program: Manufacturing Program.1valericaNo ratings yet

- High-Performance Pushbutton Switch With Built-In Subminiature Basic SwitchDocument3 pagesHigh-Performance Pushbutton Switch With Built-In Subminiature Basic Switchkasim leeNo ratings yet

- RP ProcessesDocument1 pageRP ProcessesDevarakonda KondayyaNo ratings yet

- Welding ProcedureDocument11 pagesWelding ProcedureAziz RanaNo ratings yet

- Appendix 1: Quality Standards For Structural WorksDocument2 pagesAppendix 1: Quality Standards For Structural WorkskaranNo ratings yet

- Fitting Inspection Report (Built-Up Section) : Project Name: BLDG: Customer Name: PH No: Job No: DateDocument2 pagesFitting Inspection Report (Built-Up Section) : Project Name: BLDG: Customer Name: PH No: Job No: DateMd. Sahabul IslamNo ratings yet

- 3D Printing Design RulesDocument1 page3D Printing Design RulesShahadatuliskandar RosliNo ratings yet

- Investment Castings, Surface Acceptance Standards, Visual ExaminationDocument2 pagesInvestment Castings, Surface Acceptance Standards, Visual ExaminationJerry BeanNo ratings yet

- Superior accelerometer for high-temp applications up to 150°CDocument2 pagesSuperior accelerometer for high-temp applications up to 150°CMuhammad luthfi fadilahNo ratings yet

- A3DXYZ 3D Printing Design RulesDocument1 pageA3DXYZ 3D Printing Design Rulespaxiyo5216No ratings yet

- SL045016-D-PP: Cylindrical Roller BearingDocument2 pagesSL045016-D-PP: Cylindrical Roller BearingOlawale John AdeotiNo ratings yet

- ST Velo Vetro EngDocument1 pageST Velo Vetro Engluca.laniNo ratings yet

- Acceptance Criteria Level B-B+Document2 pagesAcceptance Criteria Level B-B+Alin TomozeiNo ratings yet

- Tolerance For CHSDocument1 pageTolerance For CHSpbp2956No ratings yet

- Metal/polymer composite bush technical detailsDocument1 pageMetal/polymer composite bush technical detailsRajeshNo ratings yet

- TI-013 Tolerances For Connection Flanges and Installation DimensionsDocument2 pagesTI-013 Tolerances For Connection Flanges and Installation DimensionsCesar Pablo Moreno VillagranNo ratings yet

- Jde 10030Document3 pagesJde 10030X800XLNo ratings yet

- IS 1538:1993 - Pipe Fitting Dimensions and TolerancesDocument1 pageIS 1538:1993 - Pipe Fitting Dimensions and TolerancesAkshat JainNo ratings yet

- 2014 Cadet Chassis Fiches 02 Cad 22 BirelDocument4 pages2014 Cadet Chassis Fiches 02 Cad 22 BirelTamás MakaiNo ratings yet

- Honda StandardDocument4 pagesHonda StandardBjorn Fejer67% (6)

- Triton Cargo Worthy Standards - May2017 RevisionDocument57 pagesTriton Cargo Worthy Standards - May2017 RevisionHoan VuNo ratings yet

- CSWIP Practical Plate AnswersDocument31 pagesCSWIP Practical Plate AnswersSha Zha100% (1)

- Fabrication Tolerances 51G14r1Document7 pagesFabrication Tolerances 51G14r1Selvakpm06100% (1)

- Connector: Board-To-Board ConnectorsDocument4 pagesConnector: Board-To-Board Connectorsm3y54mNo ratings yet

- CSWIP Welding Inspection Plate Section PracticalDocument31 pagesCSWIP Welding Inspection Plate Section PracticalManoj Balla100% (3)

- Ge40 Fo 2RSDocument1 pageGe40 Fo 2RSrakhikishore143No ratings yet

- Sheet Metal Fabrication TolerancesDocument1 pageSheet Metal Fabrication Tolerancestam daoNo ratings yet

- Slip Wear DataDocument12 pagesSlip Wear Dataguadalupe.montejo2683No ratings yet

- Ultrasonic TestingDocument33 pagesUltrasonic TestingAshraf Bottani100% (1)

- Ge45 Fo 2RSDocument1 pageGe45 Fo 2RSEngin YasharNo ratings yet

- Visual Plate Inspection Report SummaryDocument4 pagesVisual Plate Inspection Report SummaryLaith Salman100% (1)

- ISO 8038-2 2001 (E) - Character PDF DocumentDocument8 pagesISO 8038-2 2001 (E) - Character PDF DocumentMohammedNo ratings yet

- En SNR Muctbl205Document2 pagesEn SNR Muctbl205Koen BidlotNo ratings yet

- Procedure for steel cutting and drillingDocument2 pagesProcedure for steel cutting and drillingNitin SharmaNo ratings yet

- Glass Specifications ClicktouchDocument7 pagesGlass Specifications ClicktouchAldrian BarbasanNo ratings yet

- Standar Kualitas GalanganDocument151 pagesStandar Kualitas GalanganFebri RoziNo ratings yet

- Annex3 - SMI-Salvador (Aprobado)Document6 pagesAnnex3 - SMI-Salvador (Aprobado)Luis SabogalNo ratings yet

- Specification for Disk Varistor ReleaseDocument4 pagesSpecification for Disk Varistor ReleaseGonzalo RojasNo ratings yet

- Information Corodrill PDFDocument19 pagesInformation Corodrill PDFNicoleAlexandraNo ratings yet

- Pa-Disc 14''-FRT Disc - 51712-0X700Document1 pagePa-Disc 14''-FRT Disc - 51712-0X700Vishal MaliNo ratings yet

- 2.WI Rework Casting-Plant - 3Document1 page2.WI Rework Casting-Plant - 3Vishal MaliNo ratings yet

- 3.retention Period For CustomersDocument1 page3.retention Period For CustomersVishal MaliNo ratings yet

- Application Manual Chapter 7 - Process GeneralDocument102 pagesApplication Manual Chapter 7 - Process GeneralVishal MaliNo ratings yet

- Application Manual Chapter 2 - Pattern Equipment GeneralDocument32 pagesApplication Manual Chapter 2 - Pattern Equipment GeneralVishal MaliNo ratings yet

- Application Manual Chapter 6 - Feeding & GatingDocument148 pagesApplication Manual Chapter 6 - Feeding & GatingVishal MaliNo ratings yet

- Capa - CWT Jep MNC 00029211Document4 pagesCapa - CWT Jep MNC 00029211Vishal MaliNo ratings yet

- Application Manual Chapter 1 - Moulding SandDocument98 pagesApplication Manual Chapter 1 - Moulding SandVishal MaliNo ratings yet

- Application Manual Chapter 5 - Moulding of Green Sand CoresDocument18 pagesApplication Manual Chapter 5 - Moulding of Green Sand CoresVishal MaliNo ratings yet

- Cold Box Overview enDocument20 pagesCold Box Overview enVishal MaliNo ratings yet

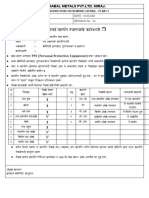

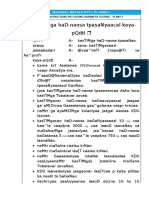

- Kaoar Potimga Va Baokimga Krnyaacai Kaya-Pqdti : Mahabal Metals PVT - Ltd. MirajDocument2 pagesKaoar Potimga Va Baokimga Krnyaacai Kaya-Pqdti : Mahabal Metals PVT - Ltd. MirajVishal MaliNo ratings yet

- Cold Box Overview enDocument20 pagesCold Box Overview enVishal MaliNo ratings yet

- 09 TabellerDocument26 pages09 TabellerVishal MaliNo ratings yet

- Application Manual Chapter 5 - Moulding of Green Sand CoresDocument18 pagesApplication Manual Chapter 5 - Moulding of Green Sand CoresVishal MaliNo ratings yet

- 2.37 Rso Training Standard Syllabi For Training Courses On Radiological SafetyDocument96 pages2.37 Rso Training Standard Syllabi For Training Courses On Radiological SafetyashwiniNo ratings yet

- Influence of Alloying, Inoculation and Preconditioning On Grey Iron For Automotive IndustryDocument6 pagesInfluence of Alloying, Inoculation and Preconditioning On Grey Iron For Automotive IndustryVishal MaliNo ratings yet

- Kastimga Disap Ca Krnyaacai Kaya-Pqdti : Mahabal Metals PVT - Ltd. MirajDocument3 pagesKastimga Disap Ca Krnyaacai Kaya-Pqdti : Mahabal Metals PVT - Ltd. MirajVishal MaliNo ratings yet

- WI For Orgon Furance ON OFFDocument2 pagesWI For Orgon Furance ON OFFVishal MaliNo ratings yet

- WI Steel Shot Size CheckDocument2 pagesWI Steel Shot Size CheckVishal MaliNo ratings yet

- T-03 - Inoculant Alloy CompositionDocument2 pagesT-03 - Inoculant Alloy CompositionVishal MaliNo ratings yet

- WI For Cold Box Core PreparationDocument2 pagesWI For Cold Box Core PreparationVishal MaliNo ratings yet

- CASTING HARDNESS TESTING PROCEDURE PLANT 3Document2 pagesCASTING HARDNESS TESTING PROCEDURE PLANT 3Vishal MaliNo ratings yet

- MAHABAL METALS PVT.LTD. WORK INSTRUCTION REWORK CASTING PLANT 2Document2 pagesMAHABAL METALS PVT.LTD. WORK INSTRUCTION REWORK CASTING PLANT 2Vishal MaliNo ratings yet

- WI Core Sand PreparationDocument2 pagesWI Core Sand PreparationVishal MaliNo ratings yet

- Inoculation of Cast IronDocument2 pagesInoculation of Cast Ironarnaldorcr8646No ratings yet

- Inoculation PracticesDocument2 pagesInoculation Practicesarnaldorcr8646No ratings yet

- 5 Mechanisms Graphite Nucleation Cast IronDocument2 pages5 Mechanisms Graphite Nucleation Cast Ironmarcotulio123No ratings yet

- Effects of Minor and Trace Elements in Cast IronDocument2 pagesEffects of Minor and Trace Elements in Cast Ironarnaldorcr864667% (3)

- Jvme 30 3 226Document4 pagesJvme 30 3 226Chelwin Glenn Pelaez AsuncionNo ratings yet

- Pretreatment For Powder CoatingDocument15 pagesPretreatment For Powder Coatingsateeshsingh100% (1)

- BMCT 5 Market Surey SteelDocument25 pagesBMCT 5 Market Surey SteelAastha ShrivastavaNo ratings yet

- Draft Wps Astm A 743 GR - Ca6nmDocument2 pagesDraft Wps Astm A 743 GR - Ca6nmIlham PaneNo ratings yet

- 1 Kulgemeyer 2018Document26 pages1 Kulgemeyer 2018JUNAR SANTIAGONo ratings yet

- Analysis of Defects in Thin-Walled CastingsDocument2 pagesAnalysis of Defects in Thin-Walled CastingsashokjkhannaNo ratings yet

- ManufacturingDocument17 pagesManufacturingPadmaNo ratings yet

- YCC ISASMELT™ Workshop PresentationDocument32 pagesYCC ISASMELT™ Workshop PresentationÁlvaro JaraNo ratings yet

- Approved Supplier ListDocument2 pagesApproved Supplier ListUmesh SakhareliyaNo ratings yet

- BMP - CastingDocument217 pagesBMP - Castingmantra2010No ratings yet

- Hot Dip Galvanizing Design ConsiderationsDocument10 pagesHot Dip Galvanizing Design ConsiderationsAndreasNo ratings yet

- 12 - Sheet Metal FormingDocument138 pages12 - Sheet Metal FormingShihe Song100% (1)

- Bohler GradesDocument19 pagesBohler GradesYudistira IjoNo ratings yet

- Welding SymbolDocument57 pagesWelding SymbolGanesh Sridhar100% (2)

- Computer Aided Engineering: Assignment On CNC ProgrammingDocument13 pagesComputer Aided Engineering: Assignment On CNC ProgrammingShaswata BoseNo ratings yet

- Casting Material Gray Iron in ASTM A278Document4 pagesCasting Material Gray Iron in ASTM A278GousePeerzadeNo ratings yet

- Te Imp (Veena)Document17 pagesTe Imp (Veena)Sidpara DeepNo ratings yet

- Rolling PDFDocument14 pagesRolling PDFNkongho JohnsonNo ratings yet

- C4C - 1.0303 - SteelNumber - Chemical Composition, Equivalent, PropertiesDocument1 pageC4C - 1.0303 - SteelNumber - Chemical Composition, Equivalent, PropertiesSergiNo ratings yet

- Peeled Round Steel BarsDocument9 pagesPeeled Round Steel BarsaxgasaNo ratings yet

- PTG 402 Litho 5Document7 pagesPTG 402 Litho 5Ahmad OlaiyaNo ratings yet

- Machining GuideDocument29 pagesMachining Guidegopi_ggg20016099No ratings yet

- 8 Module 8 Powder Metallurgy (20231031191430)Document18 pages8 Module 8 Powder Metallurgy (20231031191430)Belle MateoNo ratings yet

- Super Dive LogDocument1 pageSuper Dive LogWalt WhimpennyNo ratings yet

- Iso 2553Document8 pagesIso 2553Eduardo TeixeiraNo ratings yet

- Dautsons Infratech India Private Limited: Gold Piping WorksDocument59 pagesDautsons Infratech India Private Limited: Gold Piping WorksDautsons InfratechNo ratings yet

- Nes D2188Document6 pagesNes D2188prasannaNo ratings yet

- Chapter 3Document47 pagesChapter 3eiman bataNo ratings yet

- MIL-STD-645B Dip Brazing of Aluminum AlloysDocument16 pagesMIL-STD-645B Dip Brazing of Aluminum AlloysRichard BennardoNo ratings yet

- ISO 8501 Surface PreparationDocument4 pagesISO 8501 Surface Preparationraseen pNo ratings yet