Professional Documents

Culture Documents

Short Circuit Force Calculation

Short Circuit Force Calculation

Uploaded by

Artur EckertCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Short Circuit Force Calculation

Short Circuit Force Calculation

Uploaded by

Artur EckertCopyright:

Available Formats

ETHS1S/3002074160/ED2.104.

001

s

SHORT-CIRCUIT FORCE CALCULATION ON

FLEXIBLE CONDUCTOR FOR

400 kV Switchyard at O P Jindal Super Thermal Power Plant,

4X600 MW Units, Tamnar, Raigarh, Chattisgarh

Client : Jindal Power Limited

Name Department Telephone Place Date Signature

Author: Mohd. Sharib SPEL 4344251 Gurgaon 25.08.10

Approval: Saurabh Jain SPEL 4344046 Gurgaon 25.08.10

Index of Revisions:

Name of Name of

Rev: Date Revised Items Page Remarks

Reviser Approver

Siemens Power Engineering Pvt. Ltd.,

Copying of this document, and giving it to others and the use or communication of the contents thereof, are forbidden

without express authority. Offenders are liable to the payment of damages. All rights are reserved in the event of the

grant of patent or registration of a utility model or design.

400 kV Switchyard at O P Jindal Super Thermal Power Plant Page 1 of 11

ETHS2S/3002074160/ED2.104.001

s

Contents Page

1.0 Introduction .....…………………………………………………………………………… 3

2.0 System Data .....…………………………………………………………………………… 3

3.0 Conductor Data…………………………………………………………………………….. 3

4.0 Installation Data…………………………………………………………………………….. 3

5.0 Calculation .....…………………………………………………………………………… 4

6.0 Attachments .....…………………………………………………………………………… 4

7.0 Conclusion .....…………………………………………………………………………… 4

8.0 References .....…………………………………………………………………………… 4

400 kV Switchyard at O P Jindal Super Thermal Power Plant Page 2 of 11

ETHS3S/3002074160/ED2.104.001

s

1 Introduction

In installations with strained flexible conductors the short circuit current carried by the conductors causes

development of stress in the conductors due to the electromagnetic force amongst the conductors in par-

-allel phases. This conductor force is in addition to the static tension on the conductor (measured from

sag-tension calculation) and is sustained by the supporting structures. The objective of this calculation

is to determine the maximum force generated on the conductor bundle during a short circuit in order to

design the switchyard structures to sustain such forces.

Further for line-to-line short circuits, conductor swing out typically results in decreasing phase-to-phase

clearance between conductors strung in parallel. In this calculation the 'spacer span' on conductor bun-

-dle is determined to optimize the tensile forces to values that enables maintaining of the minimum air

clearances between phases during horizontal span displacements of conductor bundles at L-L short

circuit.

2 System Data

Switchyard

1 Nominal System Voltage 400 kV

2 System Frequency 50 Hz

3 Short Circuit Fault Current at Bus 50 kA

4 Duration of Fault Current 1 sec

5 Average (daily ambient) Temperature 32 °C

6 Maximum Operating Temperature 75 °C

3 Conductor Data

ACSR MOOSE

1 Conductor Diameter

31.77

mm

2 Total Cross-sectional Area mm 2

597

3 Conductor Weight kg/m

2.004

4 Modulus of Elasticity N / m2

6.73E+10

5 Mass of Spacer Unit kg

1.94

Effective distance between sub-conductor in

6 m

bundle 0.45

4 Installation Data

1 Phase-to-Phase Spacing m

7

2 Length of Insulator String - TWIN ACSR MOOSE m

3.843

400 kV Switchyard at O P Jindal Super Thermal Power Plant Page 3 of 11

ETHS4S/3002074160/ED2.104.001

s

5 Calculation

The basic methodology of this is as explained in IEC-865 (Part 1) : 1993 and further elaborated in the so-

-lved examples of IEC-865 (Part 2) : 1994. All the terms , factors and some miscellaneous data used in

the calculation are as defined in IEC-865 (Part 1) : 1993.

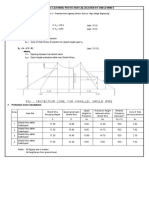

As per the values obtained in the calculation, we have plotted curves of Pinch Force ( F pi ), Drop Force

( F f ) and Tensile Force ( Ft) against the spacer span varying from 1.0 m to 10.0 m through every 0.5 m.

The curves give the maximum force in the conductor and the 'critical spacer span' at which it occurs.

The actual spacer span selected is a span lower than the critical spacer span. Minimum air clearance

is determined for the force optimized with the selected spacer span and with the value of static normal

tension as the minimum tension under no wind condition (from sag-tension calculation) for line-to-line

fault current.

6 Attachments

Attachment - 1: Detailed Calculation for TWIN ACSR MOOSE conductor of 137 m.

Attachment - 2: Characteristic curves showing behavior of Short Circuit forces against spacer span for arrangement

of conductors in different spans.

Attachment - 3: Summary of Results.

7 Conclusion

1. For design of support structure the maximum value of short circuit force to be considered is to be

decided from Attachment 3. This includes the tensile forces owing to dead load of conductor and wind

load on conductor, and has been expressed on 'per phase' basis. This force shall be applied to two

Phases of the girder supporting them whereas the third phase shall have normal static tension from

sagtension calculation. This is as per note no. 2 under clause no. 2.4.2 of IEC-865 (Part 1).

2. As per IEC-61936 (Part-1, Clause 5.4.3), the minimum air clearance between phase conductors at

maximum swing out position due to short circuit shall be at least 50 % of the mandatory phase-to-phase

clearance. 400 kV outdoor switchyard with rated Lightning Impulse Withstand voltage of 1425 kV,

the mandatory phase-to-phase clearance is 4 m. Thus the minimum air clearance shall be greater

than 2 m.

8 References

1. IEC-865 (Part 1) : 1993 Short Circuits Currents - Calculation of Effects.

2. IEC-865 (Part 2) : 1994 Short Circuits Currents - Calculation of Effects.

3. IEC-61936 (Part 1) : 2002 Power installations exceeding 1 kV a.c. - Common Rules

4. Technical Data sheets for ACSR Moose Conductor Manufacturer.

5. Technical Specification for 400 kV Switchyard

6 400kV ELECTRICAL LAYOUT PLAN - DRAWING NO. (0)-G71770-AC152-L152-001

7. 400kV ELECTRICAL LAYOUT SECTION - DRAWING NO. (0)-G71770-AD152-L153-001

8. 400kV CLEARANCE DIAGRAM PLAN & SECTION- DRAWING NO. (0)-G71770-AD152-L156-001

400 kV Switchyard at O P Jindal Super Thermal Power Plant Page 4 of 11

Attachment - 1 ETHS1S/3002074160/ED2.104.001

s

Detailed Calculation for TWIN ACSR MOOSE conductor of 137 m

1.0 Input Data

Following are the input data for the calculation. Other terms, factors and data used in the

calculation are as defined in IEC-865, Part-I.

Centre line distance between conductors (phase

a: 7 {ref.: Layout Plan}

to phase spacing) = m

as : Effective distance between sub-conductors = 4.50E-01 m {assumed}

As : Cross-section of one sub-conductor = 5.97E+02 mm 2 {ref.: Vendor Data}

= 5.97E-04 m2

ds : Diameter of the sub-conductor in bundle = 31.77 mm {ref.: Vendor Data}

= 0.03177 m

Final value of Young's modulus of elacticity of

E: = 6.73E+10 N/m2 {ref.: Vendor Data}

the sub-conductor

2

= 6.73E+10 N/m

Fst (max): Max Initial static tensile force in main conductor = 137428.96 N{No.of sub-conductor x 7005 x 9.81}

Fst (min): Min Initial static tensile force in main conductor = 60068.40 N{No.of sub-conductor x 3062 x 9.81}

f: System frequency = 50 Hz {ref.: Tech Spec.}

gn : acceleration due to gravity = 9.81 m/s 2

I"k3 : 3φ initial symmetrical short circuit current (r.m.s) = 50000 A {ref.: Tech Spec.}

Centre line distance between supports (main

l: = 137.00 m {ref.: Layout Plan}

conductor span)

Cord length of the main conductor in the span.

lc : = 127.315 m

(l - 2lb-2li)

li : Length of one insulator string = 3.8425 m {ref.: Vendor Data}

lb: Beam Depth = 1.00 m

m' : Mass per unit length of one sub-conductor = 2.004 kg / m {ref.: Vendor Data}

Resultant mass per unit length of one sub-

conductor after considering the mass of spacers

ms' : = 2.38 kg / m {ref.: IEC-865-Part 2}

within the span = m' +

{(ns x mz)/(n x lc)}

Conductor Type = ACSR MOOSE

No. of sub-conductor in a main conductor

n: = 2 TWIN

bundle

Resultant spring constant of both supports of

S: = 1.00E+05 N/m {ref.: IEC-865-Part 1}

one span

ns : Nos. of spacers in the span = 50

mz : Mass of one set of connecting pieces (spacer) = 1.94 kg {ref.: Vendor Data}

ls : Distance between two adjacent spacer = 2.5 m {selected}

Tk1 : Duration of first short circuit current flow = 1 Sec

-2

μ0 : Magnetic constant, permeability of vacuum = 1.257E-06 N A

Factor for the calculation of peak short

κ: circuit current = 1.8

τ: Time constant of the network = 0.042

Factor for the relevant natural frequency

= 1.49

γ: estimation

2.0 Detailed Calculation

Calculation for Short Circuit Forces

2.1 The characteristic Electromagnetic Load per unit length on flexible main conductor in 3φ system is given by :

400 kV Switchyard at O P Jindal Super Thermal Power Plan Page 5 of 11

Attachment - 1 ETHS2S/3002074160/ED2.104.001

s

Detailed Calculation for TWIN ACSR MOOSE conductor of 137 m

F' = (μ0/2π) x (0.75) x (I"k32/a) x (lc/l) N/m {ref.: Eqn. 19 of IEC-865-I}

= 49.78 N/m

2.2 The ratio of electromagnetic force under short circuit to gravitational force on a conductor is given by :

r = F'/(n x m's x gn) {ref.: Eqn. 20 of IEC-865-I}

= 1.06

2.3 The direction of the resulting force exerted on the conductor is given by :

δ1 = tan-1 r degrees {ref.: Eqn. 21 of IEC-865-I}

= 46.77 degrees

2.4 The equivalent static conductor sag at midspan is given by :

bc = (n x m's x gn x l2 ) / (8 x Fst) m {ref.: Eqn. 22 of IEC-865-I}

= 0.80 m

2.5 The period, T, of conductor oscillations is given by :

T = 2π x {0.8 x (bc / gn)}1/2 sec {ref.: Eqn. 23 of IEC-865-I}

= 1.60 sec

2.6 The resulting period, Tres, of the conductor oscillation during the short circuit current flow is given by :

Tres = T/[{1+r2}1/4 x {1-(π2/64) x (δ1/900)2}] sec {ref.: Eqn. 24 of IEC-865-I}

= 1.38 sec

2.7 Actual Young's modulus of conductor, E s, is given by:

Es = E[0.3+0.7 x sin{Fst /(n x As) x (900 /σfin)}] N/m2 for : Fst/nAs ≤ σfin {ref.: Eqn. 26

= E N/m2 for : Fst/nAs > σfin IEC-865-I}

where, σfin = 5.00E+07 N/m2 {ref.: Eqn. 27 of IEC-865-I}

=> Es = 5.00E+07 N/m2

2.8 The stiffness norm is given by:

N = {1/(S x l)} + {1/(n x Es x As)} 1/N {ref.: Eqn. 25 of IEC-865-I}

= 1.68E-05 1/N

2.9 The stress factor, ζ, of the main conductor is given by:

ζ = (n x gn x ms' x l)2 / (24 x Fst3 x N) {ref.: Eqn. 28 of IEC-865-I}

= 0.00

2.10 During or at the end of the short circuit current flow, the span will have oscillated out of the steady state to the

angle given by:

δk = δ1[1-cos(3600 xTk1/Tres)] degrees for :0 ≤ (Τk1/Τres) ≤ 0.5 {ref.: Eqn. 29 IEC:865-1}

or δk = 2δ1 degrees for : (Tk1/Tres) > 0.5

where, Duration of the first short circuit current flow is given by:

Tk1 = 0.64 sec

now, Tk1/Tres= 0.46 sec

therefore, as per Cl. No. 2.3.2.1 of IEC 865-1, the value of Tk1 (=0.4T) shall be used to calculate δk

400 kV Switchyard at O P Jindal Super Thermal Power Plan Page 6 of 11

Attachment - 1 ETHS3S/3002074160/ED2.104.001

s

Detailed Calculation for TWIN ACSR MOOSE conductor of 137 m

=> δk = 92.30 degrees

2.11 Maximum swing out angle during or after short circuit current flow, δm, is given by:

δm = 1.25 cos-1χ degrees for : 0.766 ≤ χ ≤ 1 {ref.: Eqn. 31 of IEC-865-I}

or δm = 100 + cos-1χ degrees for : -0.985 ≤ χ < 0.766

or δm = 1800 degrees for : χ < -0.985

2.11.1 where, Quantity for the maximum swing-out angle, χ, is given as:

χ = 1-r sinδk for : 0 ≤ δk ≤ 900 {ref.: Eqn. 30 of IEC-865-I}

or χ = 1-r for : δk > 900

=> χ = -0.06

therefore

δm = 103.67 degrees

2.12 The load parameter, ϕ, is obtained as follows:

ϕ = 3[ √(1+r2) - 1] for : Tk1≥ Tres/4 {ref.: Eqn. 32 of IEC-865-I}

or ϕ = 3[r x sin(δk) + cos(δk) -1] for : Tk1< Tres/4

=> ϕ = 1.38

2.13 Span reaction factor, ψ (ϕ,ζ), is calculated as a real solution of the equation:

ϕ2ψ3 + ϕ(2 + ζ)ψ2 + (1 + 2ζ)ψ − ζ(2 + ϕ) = 0 for : 0 ≤ ψ ≤ 1 {ref.: Eqn. 33 of IEC-865-I}

=> ψ = 0.024 (approximately)

2.14 The 'short circuit tensile force', F t, is given by: {ref.: Eqn. 34 of IEC-865-I}

Ft = Fst(1 + ϕψ) for : n = 1, single conductor

or Ft = 1.1 x Fst(1 + ϕψ) for : n ≥ 2, bundled conductor

=> Ft = 156199.57 N

2.15 The 'drop force' is given by:

Ff = 1.2 x Fst √(1+ 8ζ x δm/1800) for : r > 0.6, δm ≥ 700 {ref.: Eqn. 35 of IEC-865-I}

or Ff = non-significant for : r < 0.6, δm < 700

=> Ff = 164929.65 N

2.16 Short circuit current force between sub-conductors in a bundle is given as:

Fν = (n-1) x (μ0/2π) x (I"k3/n)2 x (ls/as) x (ν2/ν3) {ref.: Eqn. 45 of IEC-865-I}

where,

the factor, v2, is given by figure 8 of IEC:865-1, as a function of factor v 1 which is in turn given as:

2.16.1 ν1 = {f /sin(1800/n)} x [{(as-ds) x m's}/{(μ0/2π) x (I"k3/n)2 x (n-1)/as}]1/2

= 3.00 {ref.: Eqn. 46 of IEC-865-I}

corresponding to this value of factor ν1, the value of ν2 is observed from curve as:

ν2 = 1- {sin(4πfTpi-2γ) + sin2γ} / 4πfTpi + fτ / fTpi x (1-e-2fTpi/fτ) x sin2γ-8πfτsinγ/{1+(2πfτ)2} x

[{2πfτ x cos(2πfTpi-γ)/2πfTpi + sin(2πfTpi-γ)/2πfTpi} x e-fTpi/fτ + (sinγ-2πfτcosγ)/2πfTpi]

2.16.2 ν2 = 1.68 {ref.: AnnexA. A.6 of IEC-865-I}

the factor, v3, is given by :

2.16.3 ν3 = {(ds/as)/sin(1800/n)} x [{(as/ds)-1}1/2 / {tan-1{(as/ds)-1}1/2}] {ref.: AnnexA. A.7 of IEC-865-I}

= 0.20

=> Fν = 5946.95 N

2.17 Tensile force, Fpi,caused by pinch effect is given as:

Fpi = Fst x {1+ (νe/εst) x ξ} for : j ≥ 1, i.e. sub-conductors in bundle clash against

each other during short circuit.

{ref.: Eqn. 50 of IEC-865-I}

400 kV Switchyard at O P Jindal Super Thermal Power Plan Page 7 of 11

Attachment - 1 ETHS4S/3002074160/ED2.104.001

s

Detailed Calculation for TWIN ACSR MOOSE conductor of 137 m

or Fpi = Fst x {1+ (νe/εst) x η2} for : j < 1, i.e. sub-conductors in bundle reduce their

distance but don't clash during short circuit.

{ref.: Eqn. 54 of IEC-865-I}

2.17.1 The parameter j, determines the bundle configuration during short circuit current flow and is given as:

j = {εpi / (1 + εst)}1/2 {ref.: Eqn. 49 of IEC-865-I}

= 0.3582

2.17.2 where the strain factors characterizing the contraction of the bundle shall be calculated from :

2.17.2.1 εst = 1.5 x {(Fst x ls2 x N)/(as-ds)2} x {sin(1800/n)}2 {ref.: Eqn. 47 of IEC-865-I}

= 123.92

2.17.2.2 εpi = 0.375 x n x {(Fν x ls3 x N)/(as-ds)3} x {sin(1800/n)}3 {ref.: Eqn. 48 of IEC-865-I}

= 16.03

2.17.3 Now, for : j ≥ 1, the factor νe is given as:

2.17.3.1 νe = 1/2 + [9/8 x n(n-1) x (μ0/2π) x (I"k3/n)2 x N x ν2 x {ls/(as-ds)}4 x [{sin(1800/n)}4 / ξ3] x [1

-{tan-1√ν4} / √ν4]-1/4]1/2 {ref.: Eqn. 52 of IEC-865-I}

2.17.3.2 with, ν4 = (as - ds) / ds {ref.: Eqn. 53 of IEC-865-I}

= N.A

2.17.3.3 and ξ is given by the real solution of ξ3 + εst ξ2 −εpi = 0 for : j2/3 ≤ ξ ≤ j

=> ξ = NA {ref.: Eqn. 51of IEC-865-I}

=> νe = N.A

2.17.4 Now, for : j < 1, the factor νe is given as:

2.17.4.1 νe = 1/2 + [9/8 x n(n-1) x (μ0/2π) x (I"k3/n)2 x N x ν2 x {ls/(as-ds)}4 x [{sin(1800/n)}4 / η4] x [1

-{tan-1√ν4} / √ν4]-1/4]1/2 {ref.: Eqn. 55 of IEC-865-I}

2.17.4.2 with, ν4 = η(as - ds) / (as -η(as - ds)) {ref.: Eqn. 56 of IEC-865-I}

= 0.03

3

2.17.4.3 and η is given by the real solution of η +εstη−εpifn=0

ya = 1/2 x {as-η(as-ds)}

= 2.2E-01

asw = as x (2ya/as) / sin(1800/n) x {(1-2ya/as)/2ya/as}1/2/arctan{(1-2ya/as)/2ya/as}1/2

0.44

fn = asv3/asw

=> η= 0.03

=> νe = 408.14

thereby the magnitude of Pinch Force, Fpi, is calculated as :

Fpi = 137753.16 N

Calculation for Horizontal Span Displacement and Minimum Air Clearance

Note: Values of all parameters are at 75 °C (maximum conductor temperature ) and L-L fault current of 43.3 kA

2.18 The elastic expansion is given by :

εela = N x (Ft - Fst) {ref.: Eqn. 36 of IEC-865-I}

= 1.34E-03

where, at final conductor Temperature (=75°C )

N = 8.54E-08 1/N

Ft = 75703.31 N

Fst = 60068.40401 N

2.19 The thermal expansion is given by :

εth = cth {I"k3/(n x As)}2 x Tres/4 for : Tk1≥ Tres/4 {ref.: Eqn. 37 of IEC-865-I}

or εth = cth {I"k3/(n x As)}2 x Tk1 for : Tk1< Tres/4

400 kV Switchyard at O P Jindal Super Thermal Power Plan Page 8 of 11

Attachment - 1 ETHS5S/3002074160/ED2.104.001

s

Detailed Calculation for TWIN ACSR MOOSE conductor of 137 m

where,

cth = 2.7E-19 m4/A2sec for : Aluminium, aluminium alloy & aluminium/steel

conductors with cross-section ratio of Al/St >6

I"k3 = 43.30 kA

Tk1 = 0.97 sec at final conductor Temperature (=75°C )

Tres = 2.21 sec at final conductor Temperature (=75°C )

=> εth = 1.96E-04

2.20 Dilation factor, CD, allows for sag increase caused by elastic and thermal elongation of the conductor is given by:

CD = {1 + 3/8 x (l/bc)2 x (εela +εth)}1/2 {ref.: Eqn. 38 of IEC-865-I}

= 2.06

where, at final conductor Temperature (=75°C )

bc = 1.83 m

εela = 1.34E-03

εth = 1.96E-04

2.21 Form factor, CF, allows for a possible increase in the dynamic sag of the conductor caused by a change in shape

of the conductor curve and is given by:

CF = 1.05 for : r ≤ 0.8 {ref.: Eqn. 39 of IEC-865-I}

or CF = 0.97 +0.1r for : 0.8 < r < 1.8

or CF = 1.15 for : r ≥ 1.8

=> CF = 1.05

2.22 The maximum horizontal displacement within a span, b h, due to short circuit in spans with strained conductors

connected to potrals with tension insulator strings is given by:

bh = CF CD bc sinδ1 for : δm ≥ δ1 {ref.: Eqn. 41 of IEC-865-I}

or bh = CF CD bc sinδm for : δm < δ1

=> bh = 2.46 m

where, at final conductor Temperature (=75°C )

δm = 86.65 degrees

2.23 The distance between the midpoints of the two main conductors during a line-to-line two-phase short circuit is in

the worst case given by:

amin = a - 2bh {ref.: Eqn. 42 of IEC-865-I}

amin = 2.08 m

400 kV Switchyard at O P Jindal Super Thermal Power Plan Page 9 of 11

Attachment - 2 ETHS1S/3002074160/ED2.104.001

s

C

h

a

r

a

c

t

e

r

i

s

t

i

c

c

u

r

v

e

s

s

h

o

w

i

n

g

b

e

h

a

v

i

o

r

o

f

S

h

o

r

t

C

i

r

c

u

i

t

f

o

r

c

e

s

a

g

a

i

n

s

t

S

p

a

c

e

r

S

p

a

n

f

o

r

t

h

e

a

r

r

a

n

g

m

e

n

t

o

f

T

W

I

N

A

C

S

R

M

O

O

S

E

c

o

n

d

u

c

t

o

r

f

o

r

S

p

a

n

L

e

n

g

t

h

1

3

7

m

Sl. No. Spacer Span Tensile Force (Ft) Drop Force (Ff) Pinch Force (Fpi)

(m) (N) (N) (N) Short Circuit Forces Vs Spacer Span

1 1.0 154540.27 167450.01 139415.11 200000

2 1.5 155467.93 167670.69 139675.50

180000

3 2.0 155919.98 167766.64 141092.88

Short Circuit Forces (N)

4 2.5 156199.57 167822.58 142050.24 160000

5 3.0 156371.57 167856.7 143116.65 140000

6 3.5 156500.57 167882.09 144260.10 120000

7 4.0 156608.08 167903.09 145483.20 100000

8 4.5 156672.59 167915.62 146715.84

80000

9 5.0 156737.12 167928.08 148028.73

10 5.5 156780.14 167936.36 149383.46 60000

11 6.0 156823.17 167944.61 150814.57 40000

12 6.5 156866.2 167952.83 152350.69 20000

13 7.0 156887.72 167956.93 154012.39 0

14 7.5 156930.77 167965.1 189262.12

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

8.5

9.0

9.5

10.0

15 8.0 156952.3 167969.18 187356.11 Tensile Force (N)

16 8.5 156973.83 167973.24 185635.29 Drop Force (N)

17 9.0 156973.83 167973.24 184034.48 Pinch Force (N)

18 9.5 156995.36 167977.3 182609.85 Spacer Span (m)

19 10.0 157016.9 167981.35 181316.99

400 kV Switchyard at O P Jindal Super Thermal Power Plant Page 10 of 11

Attachment - 3 ETHS1S/3002074160/ED2.104.001

s

SUMMARY OF RESULTS

No. of sub conductors Critical Spacer Chosen Spacer Short Circuit Force at minimum Initial Static Tension at Maximum Minimum air clearance Maximum Short Circuit Force

Serial No. Span per phase Span Span temperature and Full Wind at 3-Ph fault temperature and Full Wind amin for L-L fault per phase for design structures

(m) (m) (m) (N) (N) (m) (N) (kg)

l n ls Fst Ft Ff Fpi Fst amin

1 137 2 7 2.5 137429 156199.6 167822.6 142050.2 60068.4 2.076 167822.58 17107.30

400 kV Switchyard at O P Jindal Super Thermal Power Plant Page 11 of 11

You might also like

- National Contracting Co. LTD.: ProjectDocument58 pagesNational Contracting Co. LTD.: ProjectNavneeth100% (1)

- A Brief History of ElectromagnetismDocument15 pagesA Brief History of ElectromagnetismHernán H.No ratings yet

- Transmission Line Sag & TensionDocument37 pagesTransmission Line Sag & TensionCatrina Federico100% (2)

- Calculation of Earthing Sys.Document12 pagesCalculation of Earthing Sys.Rania Fathy Mohammed100% (4)

- DSLP Calculation by VikasDocument7 pagesDSLP Calculation by Vikasvikasrajput1989100% (2)

- Earthing CalculationDocument14 pagesEarthing CalculationNatarajan Ramakrishnan100% (18)

- 400KV 34.5MTRS Sag Tension CalculationDocument7 pages400KV 34.5MTRS Sag Tension CalculationRaisinghani BhushanNo ratings yet

- Calculations For Sag and Swing of Strung ConductorDocument27 pagesCalculations For Sag and Swing of Strung ConductorHugh cabNo ratings yet

- Earthing of Gis Type ElkDocument21 pagesEarthing of Gis Type ElkJairo Morales100% (1)

- Earthing Mat Design Calculation SheetDocument15 pagesEarthing Mat Design Calculation Sheetmaddy100% (1)

- Short Circuit Force For Equipment InterconnectionDocument17 pagesShort Circuit Force For Equipment Interconnectionudayakumart100% (4)

- DSLP of Sub-Station Using Shield Wire by Razevig MethodDocument1 pageDSLP of Sub-Station Using Shield Wire by Razevig MethodSomen Sarkar100% (2)

- DSLP Dirct Srole Lightning ProtectionDocument7 pagesDSLP Dirct Srole Lightning Protectiongsaiswaroopg100% (2)

- M-Caps-02: Physics: NEET - XI StudyingDocument3 pagesM-Caps-02: Physics: NEET - XI StudyingAbhishek Kumar VermaNo ratings yet

- Sag-Tension For EarthwireDocument1 pageSag-Tension For Earthwirelalit123indiaNo ratings yet

- Short Circuit Force For EquipmentDocument17 pagesShort Circuit Force For EquipmentHassen100% (1)

- Short Circuit Force For Equipment PDFDocument17 pagesShort Circuit Force For Equipment PDFblaagica100% (1)

- Claulation For Check Suitability of IPSDocument45 pagesClaulation For Check Suitability of IPSannuvyas100% (1)

- SAG Tension For TWIN-QUAD Conductor Considering Wind Effect - InputsDocument2 pagesSAG Tension For TWIN-QUAD Conductor Considering Wind Effect - InputsCassie Harvey100% (2)

- Gult-TS1-GTS1 - Sheath Voltage Cal - 2016!07!10Document31 pagesGult-TS1-GTS1 - Sheath Voltage Cal - 2016!07!10Apichartj JusuayNo ratings yet

- 87971GS Generator Resistance Tables Rev 7Document130 pages87971GS Generator Resistance Tables Rev 7Splinterbond100% (5)

- GT TRANSFORMER Soak Pit Sizing.Document1 pageGT TRANSFORMER Soak Pit Sizing.Thangarajan NagarajanNo ratings yet

- Iletken Elektriki Hesaplar 2Document11 pagesIletken Elektriki Hesaplar 2robinknit2009100% (1)

- DSLPDocument31 pagesDSLPvikasrajput198971% (7)

- Cable SizingDocument11 pagesCable Sizingshrieers100% (1)

- Zebra Current Capacity Calculation SheetDocument1 pageZebra Current Capacity Calculation SheetbinodeNo ratings yet

- 220 KV Sag Tension Calculation - ThyottarDocument13 pages220 KV Sag Tension Calculation - Thyottarannuvyas100% (3)

- Transmission Voltage and Conductor Selection Methodology With Loss and Max Current CalculationDocument9 pagesTransmission Voltage and Conductor Selection Methodology With Loss and Max Current CalculationSaurav BhattaraiNo ratings yet

- Engineering Method For Calculation of Short-CircuitDocument8 pagesEngineering Method For Calculation of Short-CircuitHakkim Sheik Thauth J100% (1)

- Razevig Method DSLPDocument19 pagesRazevig Method DSLPsunny171083_901235920% (2)

- Sag-Tension Calculation IEEE STD 605 2008Document10 pagesSag-Tension Calculation IEEE STD 605 2008vishnuvyasNo ratings yet

- 220kV PGCIL BUSBARDocument24 pages220kV PGCIL BUSBARJayam Harinatha Guptha100% (1)

- 500SQMM-Buried Cable Current Carrying Capacity - RevisedDocument2 pages500SQMM-Buried Cable Current Carrying Capacity - RevisedBijaya Kumar MohantyNo ratings yet

- Process Calculation Cover Page: References: (Include Version No., Date of Publication, Etc.)Document15 pagesProcess Calculation Cover Page: References: (Include Version No., Date of Publication, Etc.)Silas OnyekweNo ratings yet

- Sag Tension 765kVDocument11 pagesSag Tension 765kVvikasrajput1989100% (1)

- Calculo CortoCircuito IEC 865Document32 pagesCalculo CortoCircuito IEC 865Víctor RojasNo ratings yet

- 132 KV Aluminium Tube Bus Sizing CalculaDocument12 pages132 KV Aluminium Tube Bus Sizing CalculakamaleshsNo ratings yet

- Current Rating Calculation For Bare ConductorDocument9 pagesCurrent Rating Calculation For Bare Conductorrajinipre-1No ratings yet

- Sag Template of ConductorDocument49 pagesSag Template of Conductormyselfashinthedark0% (2)

- Calculation For Induced Voltage in CableDocument1 pageCalculation For Induced Voltage in CablePramod B.Wankhade50% (2)

- Acsr Panther Conductor Sizing Xls 0 PDFDocument6 pagesAcsr Panther Conductor Sizing Xls 0 PDFRavindra GoyalNo ratings yet

- Forces On Gantry-34Document5 pagesForces On Gantry-34vkjainabc100% (1)

- 132kV SAG CalculationDocument14 pages132kV SAG CalculationPramod B.Wankhade100% (4)

- Busbar Sizing For SubstationDocument22 pagesBusbar Sizing For Substationdundi_kumarNo ratings yet

- Short-Circuit Design Forces in Power Lines & SubstationsDocument28 pagesShort-Circuit Design Forces in Power Lines & Substationscustomerx100% (2)

- DSLP Calculation by LMDocument8 pagesDSLP Calculation by LMPrasad YeluripatiNo ratings yet

- Short-Circuit Currents - Calculation of Effects The Second Edition of Iec Publication 865Document10 pagesShort-Circuit Currents - Calculation of Effects The Second Edition of Iec Publication 865Hassan Bagheri100% (1)

- Zebra Current Capacity Calculation SheetDocument1 pageZebra Current Capacity Calculation Sheetbinode100% (1)

- DSLP (11 3m)Document7 pagesDSLP (11 3m)Ashutosh MishraNo ratings yet

- Cantilever Strength CalculationsDocument2 pagesCantilever Strength Calculationsakash_ing7683100% (5)

- Acsr Panther Conductor Sizing - Xls 0Document6 pagesAcsr Panther Conductor Sizing - Xls 0Rakesh Kumar Shukla0% (2)

- Siemens - CCDocument11 pagesSiemens - CCtrymskvedaNo ratings yet

- ACSR Conductor SizingDocument13 pagesACSR Conductor SizingraghuvarmaNo ratings yet

- Insulation Coordination Studies For 400 KV Gis in A Hydroelectric Project in IndiaDocument6 pagesInsulation Coordination Studies For 400 KV Gis in A Hydroelectric Project in IndiaAchint KumarNo ratings yet

- CIGRE Vol2Document64 pagesCIGRE Vol2reinscNo ratings yet

- SCF CalculationDocument158 pagesSCF Calculationvikasrajput1989100% (2)

- ABB Testing of Power TransformerDocument55 pagesABB Testing of Power TransformerM Kumar Marimuthu100% (3)

- Sag Tension Calculation IEEE STD 605 2008Document8 pagesSag Tension Calculation IEEE STD 605 2008Hassen LazharNo ratings yet

- Datacenter References Rev1Document13 pagesDatacenter References Rev1Achint KumarNo ratings yet

- Analysis and Design of 220 KV Transmission Line Tower (A Conventional Method of Analysis and Indian Code Based Design)Document10 pagesAnalysis and Design of 220 KV Transmission Line Tower (A Conventional Method of Analysis and Indian Code Based Design)PiyushNo ratings yet

- DSLP 11 3mDocument7 pagesDSLP 11 3msureshn829No ratings yet

- Evaluation of The Transient Overvoltage Stresses On 132 KV Power Transmission NetworkDocument8 pagesEvaluation of The Transient Overvoltage Stresses On 132 KV Power Transmission NetworkIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- By J. R. HILL, B.Sc. (Eng.), A. HUNT, B.Sc. (Eng.), W. J. JOYCE, B.SC, and D. H. TOMPSETT, B.Sc. (Eng-), Associate MembersDocument11 pagesBy J. R. HILL, B.Sc. (Eng.), A. HUNT, B.Sc. (Eng.), W. J. JOYCE, B.SC, and D. H. TOMPSETT, B.Sc. (Eng-), Associate MembersOgar OjugboNo ratings yet

- Calculations For Short Circuit Withstand Capability of A Distribution TransformerDocument9 pagesCalculations For Short Circuit Withstand Capability of A Distribution Transformerkasuna1No ratings yet

- Baliga Figure of MeritDocument3 pagesBaliga Figure of MeritKyle BotheNo ratings yet

- 33 KV Capacitor Bank February 2019 PDFDocument10 pages33 KV Capacitor Bank February 2019 PDFAchint KumarNo ratings yet

- Corporate Identity Number (CIN) - U40109RJ2000SGC016483: S.N O. Name of Item Quantity (Approx)Document45 pagesCorporate Identity Number (CIN) - U40109RJ2000SGC016483: S.N O. Name of Item Quantity (Approx)Achint KumarNo ratings yet

- Charoong Thai Wire & Cable Public Company Limited: Ctw-AcsrDocument2 pagesCharoong Thai Wire & Cable Public Company Limited: Ctw-AcsrAchint KumarNo ratings yet

- Charoong Thai Wire & Cable Public Company Limited: CTW - Aluminum RodDocument1 pageCharoong Thai Wire & Cable Public Company Limited: CTW - Aluminum RodAchint KumarNo ratings yet

- Acsr Astm B Aluminium Conductor Steel ReinforcedDocument10 pagesAcsr Astm B Aluminium Conductor Steel ReinforcedAchint KumarNo ratings yet

- HyperlinkPublicNoticeforwebsite PDFDocument1 pageHyperlinkPublicNoticeforwebsite PDFAchint KumarNo ratings yet

- Aluminum Round Bar 6082Document1 pageAluminum Round Bar 6082Achint KumarNo ratings yet

- Charoong Thai Wire & Cable Public Company Limited: Ctw-AcsrDocument6 pagesCharoong Thai Wire & Cable Public Company Limited: Ctw-AcsrAchint KumarNo ratings yet

- Transmission Division Anjar Tender (Web) : Gujarat Energy Transmission Corporation LimitedDocument29 pagesTransmission Division Anjar Tender (Web) : Gujarat Energy Transmission Corporation LimitedAchint KumarNo ratings yet

- Aluminum Round Bar 6082Document1 pageAluminum Round Bar 6082Achint KumarNo ratings yet

- FACTS CatalogDocument28 pagesFACTS CatalogAchint KumarNo ratings yet

- Bus Bar Sizing Calcs - Substation and Switchboard - ExamplesDocument15 pagesBus Bar Sizing Calcs - Substation and Switchboard - ExamplesAchint Kumar100% (1)

- KPN Data Center KPNDocument6 pagesKPN Data Center KPNAchint KumarNo ratings yet

- Sentron 3WT BrochureDocument6 pagesSentron 3WT BrochureAchint KumarNo ratings yet

- 1Document15 pages1Achint KumarNo ratings yet

- 7SG17 - Rho3 Complete Technical ManualDocument80 pages7SG17 - Rho3 Complete Technical ManualAchint KumarNo ratings yet

- FBTDocument2 pagesFBTAchint Kumar100% (1)

- 7ss60x ManualDocument134 pages7ss60x ManualAchint KumarNo ratings yet

- Gis 72 800 KVDocument6 pagesGis 72 800 KVAchint KumarNo ratings yet

- Chapter 1 Mark Scheme Foundation: Number Answer Marks Level/ Band Guidance 1 2 3Document3 pagesChapter 1 Mark Scheme Foundation: Number Answer Marks Level/ Band Guidance 1 2 3Adam Steven GuzyNo ratings yet

- MCQ em WavesDocument16 pagesMCQ em WavesMADHAVNo ratings yet

- EE302Document6 pagesEE302Parthasarothi SikderNo ratings yet

- Waves-Quantum and Nuclear-Resolution-Atomic and NuclearDocument45 pagesWaves-Quantum and Nuclear-Resolution-Atomic and NuclearMartinNo ratings yet

- PDF Fluid Mechanics Second Edition Falkovich Ebook Full ChapterDocument53 pagesPDF Fluid Mechanics Second Edition Falkovich Ebook Full Chapterdavid.reed970100% (1)

- Powerex PS11014Document6 pagesPowerex PS11014S. C.No ratings yet

- Constructional & Electrical Performance Data LUL S1108 (Formerly 1-108 & EME-SP-14-025 A2) - 500sqmm TrackfeederDocument3 pagesConstructional & Electrical Performance Data LUL S1108 (Formerly 1-108 & EME-SP-14-025 A2) - 500sqmm Trackfeederamitvaishnav1No ratings yet

- Understand Ripples in RF Performance Measurements Theory and ExperimentsDocument11 pagesUnderstand Ripples in RF Performance Measurements Theory and ExperimentsFarin MahzabeenNo ratings yet

- Ides-Edu: Lecture 7: Sizing Natural Ventilation SystemsDocument17 pagesIdes-Edu: Lecture 7: Sizing Natural Ventilation Systemsabhijeet7362No ratings yet

- Usain Bolt Peregrine Falcon Cheetah: Illustration 1. Sir Isaac NewtonDocument7 pagesUsain Bolt Peregrine Falcon Cheetah: Illustration 1. Sir Isaac NewtonNeema RelucioNo ratings yet

- Overhead Distribution SystemsDocument13 pagesOverhead Distribution Systemsmujeeb.alam4No ratings yet

- Britton High School Chapter 7 Gases: ChemistryDocument89 pagesBritton High School Chapter 7 Gases: ChemistryMatthew GraceNo ratings yet

- 131 QuestionDocument7 pages131 QuestionMohammed kashimNo ratings yet

- The InductorDocument25 pagesThe InductorSureshraja9977No ratings yet

- The Use of Digsilent Power Factory Simulator For "Introduction Into Power Systems" LecturesDocument5 pagesThe Use of Digsilent Power Factory Simulator For "Introduction Into Power Systems" Lecturesveljal6317No ratings yet

- TEJ HS1 Quiz Electricity Safety StudentDocument2 pagesTEJ HS1 Quiz Electricity Safety StudentZaw Htet MyintNo ratings yet

- Accuracy of Voltage Sag AnalysisDocument29 pagesAccuracy of Voltage Sag AnalysisLalita VNo ratings yet

- MAU SIP-Adaptive A4 E Ansicht 190306Document5 pagesMAU SIP-Adaptive A4 E Ansicht 190306Renato BastosNo ratings yet

- Design Simulation and Construction of An IEEE 14-Bus Power SystDocument42 pagesDesign Simulation and Construction of An IEEE 14-Bus Power Systsowmya beraNo ratings yet

- Physics I ForcesDocument10 pagesPhysics I ForcesisellsaniNo ratings yet

- 2007-2008 Physics Olympiad Preparation Program: 2.4 V, and TheDocument2 pages2007-2008 Physics Olympiad Preparation Program: 2.4 V, and TheNguyen TuanNo ratings yet

- Elec1111 - T08 - S2 2018Document57 pagesElec1111 - T08 - S2 2018Conqueror VictoryNo ratings yet

- Triac Tutorial and Triac Switching CircuitsDocument7 pagesTriac Tutorial and Triac Switching CircuitsBill WhiteNo ratings yet

- Unit 3 Mass Transfer: StructureDocument22 pagesUnit 3 Mass Transfer: StructureUdop CharlesNo ratings yet

- Statics SPDocument67 pagesStatics SPDianne VillanuevaNo ratings yet