Professional Documents

Culture Documents

Designing a DM plant ion exchange process

Uploaded by

D Nageswara RaoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Designing a DM plant ion exchange process

Uploaded by

D Nageswara RaoCopyright:

Available Formats

Designing of DM plant

The parameters given below have been taken from the resin catalogue but it is best to use

the value given by your resin supplier.

Important Note :- In Sheet 1 We have done the same calculation but protected the sheet . If this sheet some

Changes due to than some reaon reenter the values from sheet 1 but don’t copy them .

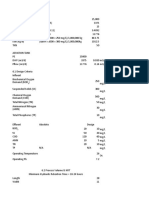

Design parameters SBA WBA DGWt SAC WAC

Backwash Velocity M/Hr 6 6 8 8

Chemical injection % 4 4 4 4

Injection Rate BV/Hr 2 2 3.5 3.5

Displacement rate BV/Hr 2 2 3.5 3.5

Displacement Volume BV 1.5 1.5 1.5 1.5

Fast Rinse Rate M/Hr 15 15 15 15

Fast Rinse Volume BV 10 10 8 8

Hold up time Hours 0.33

Feed your Water Analysis for Scheme Selection

Raw Water analysis

Turbidity 10

Colour 2

Free Cl2 2

Organics 2

pH 7.5

Dissolved solids Cation as CaCO3 Anion as CaCO3

Ca 150 HCO3 225

Mg 75 Cl 175

Na 230 SO4 65

K NO3 0

Total Cation 455 Total anion 465

Alk/TC % 0.48 SiO2 10

Na/TC % 0.51

SO4/EMA 0.27

SiO2/TA 0.02

EMA 240

TH 225

EMA/ TA% 0.52

Alk/ TA 0.48

Regeneration Level & Exchange Capacity

MB SBA SBA WBA SAC WAC

type1 type 2

Regeneration Level Cation 80 80 120

Regeneration level Anion 80 80 80 60

Exchange capacity Cation 44 60 100

Exchange Capacity Anion 24 24 35 60

Minimum Linear Velocity 16

Maximum Linear Velocity 40

Minimum Space Velocity 8

Maximum Space Velocity 50

ION EXCHANGE BASIC PROCESS DGT

WAC SAC WBA DGWT SBA

Data for Regeneration

SBA WBA SAC

Regenerant Level gm/L 80 60 80

Regenerant concentration % 4 4 4

Regenerant flowrate M3/Hr/M3 2 4 4

Backwash velocity M/Hr 6 6 9

Total rinse BV 3 3 5

Displacement Rinse BV 1.5 1.5 1.5

Fast Rinse BV 8 8 16

4 % NaOH contains 41.76 gm/lter

50 % NaOH contains 763 gm/lter

99 % NaOH contains 803 gm/lter

4 % NaOH applied 1.916 BV

99 % NaOH applied 0.0996 BV

Product Dilution water 1.816 BV

4 % HCl contains 40.72 gm/lter

32 % HCl contains 479.2 gm/lter

4% HCL applied 1.96 BV

30% HCl applied 0.167 BV

Product Dilution water 1.798 BV

water used for regenerant

dilution & rinse

For Cation 6.96 BV

For Anion 4.916 BV

SCHEME Selection Conductivity Alk/TC EMA/TA Flow Silica

SAC + WBA + DG + SBA 30 >50% >50% >5 <0.5

SAC + WBA + SBA 30 >50% >50% <5 <0.5

SAC + WBA + DG 50 >50% >50% >5 NR

SAC + WBA 50 <50% >50% <10 NR

SAC + SBA + DG 30 >50% <50% >5 <0.5

SAC+ SBA 30 >50% <50% <5 <0.5

Select the Scheme based on the water analysis & The quality of Water required and Click on the same

Load Calculation for Various units Mixed Bed

Scheme SAC SBA WBA DG Cation Anion

SAC + SBA 455 465 0 0 22.7 22.73

SAC + WBA 455 465 0 30 30

SAC + SBA + DG 455 240 0 225

SAC + WBA + DG 455 240 225

SAC + SBA + WBA 455 225 240

SAC + SBA + WBA +DG 455 33.00 240 225

SCHEME SBA WBA SAC DG SBA

UNIT

Flow Rate M3/Hr 25 25 25 25 5

Service Cycle Hours 24 24 24 24 24

Net OBR M3 600 600 600 600 120

Gross OBR M3. 608 618 632 600 128

Ionic Load ppm CACO3 33.00 240.00 455 225 225

Bed Depth M 1.2 1.2 1.2 1.2

Area by Velocity M2 1.56 1.56 1.56 0.50 0.31

Volumeof Resin By Velocity M3 1.875 1.875 1.875 0.375

OBR By Velocity M3 1363.64 468.75 247.25 40.00

Volume of Resin By Ionic Load M3 0.84 2.47 4.79 1.20

Area by Bed Depth M3 0.70 2.06 3.99 1.00

Select Area M2 0.70 1.56 1.56 0.31

Number of Regeneration /Day 1 1.318 2.56 3.21

OBR M3 608.33 468.75 247.25 40.00

Cross sectional Area M2 0.70 1.56 1.56 0.31

Flow rate For 24 Hour 25.35 19.53 10.30 1.67

Flow rate For 12 Hour 50.69 39.06 20.60 3.33

Flow rate For 8 hour 76 59 31 5

Linear Velocity For 24 Hour 36.36 12.50 6.59 5.33

Linear Velocity For 12 Hour 0.00 25.00 13.19 10.67

Linear Velocity For 8 hour 0.00 37.50 19.78 16.00

The Best option is to use the cycle in which the linear velocity is acceptable Selecting a 12 hour cy

Increasing the bed depth slightly of SAC will increase the LV to the minimum can also select 8 hou

acceptable level. may give you a cycle

Technical Details SBA WBA SAC DG SBA

Area M2 0.70 1.56 1.56 0.50 0.31

Diameter M 0.900 1.400 1.400 0.800 0.600

Bed Depth M 1.3 1.3 1.3 1.2

Resin quantity M3 0.827 2.000 2.000 0.339

OBR M3 601.2 500.0 263.8 36.2

Service Cycle Hours 24.0 20.0 10.55 7.2

100% HCl Kgs NA NA 160.01 NA

100% NaOH Kgs * 66.1284 120.01 0 27.13

Shell height(upflow) M 1.404 1.404 1.404 1.296

Shell height(downflow) M 2.275 2.16 2.16 2.1

Regen.flow M3/Hr 1.653 8.00 8.00 0.678

Regen time Minutes 57.47 21.55 29.47 57.47

Displacement Rinse rate M3/Hr 1.653 8.001 8.001 0.678

Displacement Time Minutes 45 22.5 22.5 45

Fast Rinse flow M3/Hr 10.46 23.44 23.44 4.6875

Fast Rinse Time Minutes 40.00 40.00 32.00 32.00

Backwash flow M3/Hr 7.80 7.80 10.40 9.60

Backwash Volume M3. 1.95 1.95 2.60 2.40

Regeneration Waste M3. 1.58 2.87 3.93 0.65

Slow Rinse Volume M3. 1.24 3.00 3.00 0.51

Fast Rinse Volume M3. 6.97 15.63 12.50 2.50

Total Water For Regeneration M3

11.74 23.45 22.03 6.06

Degasser Tank M3 8.33

Degasser Blower M3/Hr at 100 mm to 200 mm water column 500

this sheet some

MB

Most common and Conventional

WBA SAC Particulars SCHEME SBA

UNIT

5 5 Flow Rate M3/Hr 25

24 24 Service Cycle Hours 24

120 120 Net OBR M3

600

132 129 Gross OBR M3. 600

240 455 Ionic Load ppm CACO3 240.00

1.2 1.2 Bed Depth M 1.2

0.31 1.25 Area by Velocity M2 1.56

0.375 1.500 Volumeof Resin By Velocity M3 1.875

93.75 197.80 OBR By Velocity M3 273.44

0.53 0.98 Volume of Resin By Ionic Load M3 4.11

0.44 0.82 Area by Bed Depth M3 3.43

0.31 0.82 Select Area M2 1.56

1.41 1.00 Number of Regeneration /Day 2.194

93.75 129.33 OBR M3 273.44

0.31 0.82 Cross sectional Area M2 1.56

3.91 5.39 Flow rate For 24 Hour 11.39

7.81 10.78 Flow rate For 12 Hour 22.79

12 16 Flow rate For 8 hour 34

12.50 6.59 Linear Velocity For 24 Hour 7.29

25.00 13.19 Linear Velocity For 12 Hour 14.58

37.50 19.78 Linear Velocity For 8 hour 21.88

Selecting a 12 hour cycle is the best but by reducing the bed depth you

can also select 8 hour cycle . Increasing bed depth to a reasonable amount

may give you a cycle of 16 or 20 hours Most common and Conventional (SAC, DG, SBA, MB)

WBA SAC Technical Details SBA

0.31 0.82 Area M2 1.56

0.600 1.000 Diameter M 1.400

1.2 1.2 Bed Depth M 1.3

0.339 0.942 Resin quantity M3 2.000

84.8 124.2 OBR M3 291.7

17.0 24.84 Service Cycle Hours 11.7

NA 75.36 100% HCl Kgs NA

20.35 NA 100% NaOH Kgs * 160.01

1.296 1.296 Shell height(upflow) M 1.404

2.1 2.1 Shell height(downflow) M 2.275

1.36 3.77 Regen.flow M3/Hr 4.000

21.55 29.47 Regen time Minutes 57.47

1.356 3.768 Displacement Rinse M3/Hr 4.000

22.5 22.5 Displacement Time Minutes 45

4.69 12.26 Fast Rinse M3/Hr 23.44

0.00 0.00 Fast Rinse Time Minutes 40.00

0.00 0.00 Backwash flow M3/Hr 7.80

0.00 0.00 Backwash Volume M3. 1.95

0.49 1.85 Regeneration Waste M3. 3.83

0.51 1.41 Slow Rinse Volume M3. 3.00

0.00 0.00 Fast Rinse Volume M3. 15.63

1.00 3.26 Total Water For Regeneration M3

24.41

Degasser Tank M3

Degasser Blower M3/Hr at 100 mm to 200 mm water col

nd Conventional

SAC DG SBA SAC Particulars

MB

25 25 5 5 Flow Rate

24 24 24 24 Service Cycle

600 600 120 120 Net OBR

600 600 120 120 Gross OBR

455 225 465 455 Ionic Load

1.2 1.2 1.2 Bed Depth

1.56 0.31 0.31 Area by Velocity

1.875 0.375 0.375 Volumeof Resin By Velocity

247.25 28.23 49.45 OBR By Velocity

4.55 1.59 0.91 Volume of Resin By Ionic Load

3.79 1.33 0.76 Area by Bed Depth

1.56 0.31 0.31 Select Area

2.43 4.25 2.43 Number of Regeneration /Day

247.25 28.23 49.45 OBR

1.56 0.31 0.31 Cross sectional Area

10.30 1.18 2.06 Flow rate For 24 Hour

20.60 2.35 4.12 Flow rate For 12 Hour

31 4 6 Flow rate For 8 hour

6.59 3.76 6.59 Linear Velocity For 24 Hour

13.19 7.53 13.19 Linear Velocity For 12 Hour

19.78 11.29 19.78 Linear Velocity For 8 hour

tional (SAC, DG, SBA, MB)

SAC DG SBA SAC Technical Details

1.56 0.00 0.31 0.31 Area

1.400 0.000 0.600 0.600 Diameter

1.3 1.2 1.2 Bed Depth

2.000 0.339 0.339 Resin quantity

263.8 25.5 44.7 OBR

10.55 5.1 8.94 Service Cycle

160.01 NA 27.13 100% HCl

0 27.13 NA 100% NaOH

1.404 1.296 1.296 Shell height(upflow)

2.16 2.1 2.1 Shell height(downflow)

8.00 0.678 1.36 Regen.flow

29.47 57.47 29.47 Regen time

8.001 0.678 1.356 Displacement Rinse

22.5 45 22.5 Displacement Time

23.44 4.6875 4.69 Fast Rinse

32.00 40.00 32.00 Fast Rinse Time

10.40 7.20 9.60 Backwash flow

2.60 1.80 2.40 Backwash Volume

3.93 0.65 0.67 Regeneration Waste

3.00 0.51 0.51 Slow Rinse Volume

12.50 3.13 2.50 Fast Rinse Volume

22.03 6.08 6.07 Total Water For Regeneration

8.33 Degasser Tank

m to 200 mm water col 500 Degasser Blower

SCHEME WBA SAC DG WBA SAC

UNIT

M3/Hr 25 25 25 5 5

Hours 24 24 24 24 24

M3 600 600 600 120 120

M3. 600 600 600 120 120

ppm CACO3 240.00 455 225 465 465

M 1.3 1.2 1.2 1.2

M2 1.56 1.56 0.31 1.25

M3 2.031 1.875 0.375 1.500

M3 507.81 247.25 48.39 193.55

M3 2.40 4.55 0.93 0.93

M3 1.85 3.79 0.78 0.78

M2 1.56 1.56 0.31 0.78

1.182 2.43 2.48 1.00

M3 507.81 247.25 48.39 120.00

M2 1.56 1.56 0.31 0.78

21.16 10.30 2.02 5.00

42.32 20.60 4.03 10.00

63 31 6 15

13.54 6.59 6.45 6.45

27.08 13.19 12.90 12.90

0.00 19.78 19.35 19.35

WBA SAC DG WBA SAC

M2 1.56 1.56 0.00 0.31 0.78

M 1.400 1.400 0.000 0.600 1.000

M 1.3 1.3 1.3 1.3

M3 2.000 2.000 0.367 1.021

M3 500.0 263.8 47.4 131.7

Hours 20.0 10.55 9.5 26.34

Kgs NA 160.01 NA 81.64

Kgs * 120.01 NA 22.04 NA

M 1.404 1.404 1.404 1.404

M 2.16 2.16 0.40 1.10

M3/Hr 8.00 8.00 1.47 4.08

Minutes 21.55 29.47 21.55 29.47

M3/Hr 8.001 8.001 1.470 4.082

Minutes 22.5 22.5 22.5 22.5

M3/Hr 23.44 23.44 4.69 11.63

Minutes 40.00 32.00 40.00 32.00

M3/Hr 7.80 10.40 7.80 10.40

M3. 1.95 2.60 1.95 2.60

M3. 2.87 3.93 0.53 2.00

M3. 3.00 3.00 0.55 1.53

M3. 15.63 12.50 3.13 6.20

M3

23.45 22.03 6.15 12.34

M3 8.33

M3/Hr at 100 mm to 200 mm water column 500

You might also like

- SBR Design CalculationsDocument26 pagesSBR Design Calculationsn_zeinoun78% (9)

- Process Calculations - 1 MLD - SBRDocument164 pagesProcess Calculations - 1 MLD - SBRRAJ100% (8)

- Anoxic Tank Design & Aeration Requirement-Lanka Hospitals: Wastewater Characteristics Parameter Concentration (G/M)Document4 pagesAnoxic Tank Design & Aeration Requirement-Lanka Hospitals: Wastewater Characteristics Parameter Concentration (G/M)Vaish Kan100% (4)

- Degasser Tower CalculationDocument1 pageDegasser Tower Calculationbalaji krishnan100% (2)

- Loadline-ChartpdfDocument2 pagesLoadline-ChartpdfCapt. Amarinder Singh BrarNo ratings yet

- 50kld STP MBBRDocument15 pages50kld STP MBBRSanjay67% (3)

- Design 2 MLDDocument9 pagesDesign 2 MLDANIL KUMAR H CNo ratings yet

- Sequencing Batch Reactor (SBR) Design Calculations - S.I. UnitsDocument37 pagesSequencing Batch Reactor (SBR) Design Calculations - S.I. UnitsOn Gnios Ingeniería67% (6)

- Demineralisation Plant CalculationDocument14 pagesDemineralisation Plant Calculationsmbhat25100% (2)

- DM Plant GuideDocument6 pagesDM Plant Guidepremrrs60% (15)

- DmwatersDocument70 pagesDmwatersSamay Desai100% (1)

- O & M - Kalpataru STP MBBRDocument43 pagesO & M - Kalpataru STP MBBROmkar Bharankar100% (2)

- Optimize DAF Performance StudyDocument4 pagesOptimize DAF Performance StudyNoureddine MerahNo ratings yet

- DM Plant Design CalculationDocument6 pagesDM Plant Design CalculationGoutham Naveen0% (5)

- Mixed Beds Regeneration - 45-D01129-EnDocument7 pagesMixed Beds Regeneration - 45-D01129-EnDFMNo ratings yet

- Process Design For 1.70 IFAS STPDocument18 pagesProcess Design For 1.70 IFAS STPGenesis International0% (1)

- 30 KLD EtpDocument9 pages30 KLD Etppintu pandeyNo ratings yet

- Air Requirement For SBR STPDocument2 pagesAir Requirement For SBR STPBS supportNo ratings yet

- 18.12.2019 Proposal For 70 KLD Etp On UasbrDocument24 pages18.12.2019 Proposal For 70 KLD Etp On Uasbrgnbuildtech Pvt ltdNo ratings yet

- DM DesignDocument13 pagesDM Designluckynaveenraj67% (3)

- Mixed BedDocument10 pagesMixed BedAbdulSalamathNo ratings yet

- SOP: Calculate OBR for DM-MB and CPU-MBDocument1 pageSOP: Calculate OBR for DM-MB and CPU-MBsoumitrabanNo ratings yet

- Techno Commercial Proposal For 50KLD STP For Bhakti EnterprisesDocument21 pagesTechno Commercial Proposal For 50KLD STP For Bhakti Enterprisesamol100% (1)

- Process Calculations 1 MLD SBRDocument168 pagesProcess Calculations 1 MLD SBRAngelo EndozoNo ratings yet

- 20 KLD STP Upgreation PROPOSAL-GMCPLDocument7 pages20 KLD STP Upgreation PROPOSAL-GMCPLTech Monger100% (1)

- 20 KLD STP - Offer - MBBRDocument10 pages20 KLD STP - Offer - MBBRHarish Kumar MahavarNo ratings yet

- 100 KLD STP New-1Document13 pages100 KLD STP New-1Anjita KumariNo ratings yet

- Design of 100KLD STP Using MBBR TechnoloDocument9 pagesDesign of 100KLD STP Using MBBR TechnoloSTP VermifiltrationNo ratings yet

- DM PlantDocument2 pagesDM PlantDarakhshan Sheikh100% (1)

- Thermax Water SolutionsDocument13 pagesThermax Water SolutionsAjay Kasture100% (3)

- O & M - Shrijee EtpDocument44 pagesO & M - Shrijee EtpOmkar BharankarNo ratings yet

- Design of clariflocculator flow and sizing parametersDocument8 pagesDesign of clariflocculator flow and sizing parametersAshish GulrandheNo ratings yet

- Techno-Commercial Offer For 5 KLD ETP CUM 12 STP .Document10 pagesTechno-Commercial Offer For 5 KLD ETP CUM 12 STP .Anshika RaiNo ratings yet

- Cooling Water Treatment Chlorination WorkoutDocument3 pagesCooling Water Treatment Chlorination WorkoutMohsin ModiNo ratings yet

- 20 KLD STP Proposal Abha Shree Hotel at BetulDocument10 pages20 KLD STP Proposal Abha Shree Hotel at BetulTech MongerNo ratings yet

- STP Design Report - IndiqubeDocument20 pagesSTP Design Report - IndiqubeRajkishore NayakNo ratings yet

- 150 KLD AhlayaDocument17 pages150 KLD Ahlayaalok_rajpoot786100% (1)

- Techno-Commercial Offer .For Krishna Hospital Cpacity of 100 KLD ETP Cum STPDocument9 pagesTechno-Commercial Offer .For Krishna Hospital Cpacity of 100 KLD ETP Cum STPAnshika RaiNo ratings yet

- Demineralization plant process overviewDocument16 pagesDemineralization plant process overviewVenkat Dora100% (4)

- Water Treatment Plant ProcessDocument27 pagesWater Treatment Plant ProcessArya Singh Rathod100% (1)

- Design of WTP and STPDocument14 pagesDesign of WTP and STPVenu Ch100% (1)

- 150 KLD Quotation Chouhan JiDocument8 pages150 KLD Quotation Chouhan JiTech Monger100% (1)

- DM Plant CulationDocument2 pagesDM Plant CulationMukesh KumarNo ratings yet

- DM Plant Manual-10 KLDDocument5 pagesDM Plant Manual-10 KLDenqNo ratings yet

- Symrpl 15 KLD STPDocument15 pagesSymrpl 15 KLD STPDnyaneshwar Dattatraya Phadatare100% (3)

- Design Basis Report - STP 90 KLDDocument11 pagesDesign Basis Report - STP 90 KLDvishu talapeNo ratings yet

- 45 KLD STP PROPOSAL VRANDAVAN GREENS PDFDocument9 pages45 KLD STP PROPOSAL VRANDAVAN GREENS PDFTech MongerNo ratings yet

- Softener CalculationDocument5 pagesSoftener CalculationAri WijayaNo ratings yet

- DM PlantDocument30 pagesDM Plantapi-19775783No ratings yet

- DM Plant Design CalculationDocument10 pagesDM Plant Design CalculationLutfur RahmanNo ratings yet

- Design of STP for HapurDocument5 pagesDesign of STP for HapurKalyca Nazhifa SalwaNo ratings yet

- SBR - 6 MLDDocument38 pagesSBR - 6 MLDsharan kommi100% (1)

- Design Spreadsheet Calculation For SBR Sequential Biological ReactorDocument12 pagesDesign Spreadsheet Calculation For SBR Sequential Biological ReactorHenry SPNo ratings yet

- Techno-Commercial Proposal of 100 KLD STPDocument9 pagesTechno-Commercial Proposal of 100 KLD STPpccmitsNo ratings yet

- 2000 LPH Reverse Osmosis Plant FRPDocument20 pages2000 LPH Reverse Osmosis Plant FRPt m murshedNo ratings yet

- Clarifier Sizing SpreadsheetDocument1 pageClarifier Sizing Spreadsheetarvin4dNo ratings yet

- Budgetary Offer: Sms Envocare Limited For Muzafarpur CetpDocument41 pagesBudgetary Offer: Sms Envocare Limited For Muzafarpur Cetpsreekanth reddyNo ratings yet

- Shrimp Litopenaeus Vannamei Production in Clear Water and Biofloc Systems PDFDocument19 pagesShrimp Litopenaeus Vannamei Production in Clear Water and Biofloc Systems PDFRizky IkwanNo ratings yet

- Karbala Refinery Naphtha Hydrotreating Unit TrainingDocument72 pagesKarbala Refinery Naphtha Hydrotreating Unit Trainingضياء محمدNo ratings yet

- STD Assay PDFDocument27 pagesSTD Assay PDFJesusNo ratings yet

- Reverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018Document3 pagesReverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018unconformistNo ratings yet

- Physico Chemical Treatment Assignment IDocument1 pagePhysico Chemical Treatment Assignment ID Nageswara RaoNo ratings yet

- Statastics Assignment 2Document1 pageStatastics Assignment 2D Nageswara RaoNo ratings yet

- Statastics Asighnment-1Document1 pageStatastics Asighnment-1D Nageswara RaoNo ratings yet

- Hydrochloric acid Regeneration of Cation Exchange Resin 225 HDocument8 pagesHydrochloric acid Regeneration of Cation Exchange Resin 225 HPravin BoteNo ratings yet

- Part 4 Excitation System (In English)Document22 pagesPart 4 Excitation System (In English)powerabsolut myanmarNo ratings yet

- Tropical ForestsDocument8 pagesTropical Forestsadi govindNo ratings yet

- A. ETP Janardan FuelsDocument2 pagesA. ETP Janardan FuelsAmol ThombareNo ratings yet

- Water ResourcesDocument27 pagesWater Resourcessharon ranjitha paulNo ratings yet

- Description - Components of Wet FGD SystemDocument55 pagesDescription - Components of Wet FGD SystemDo Ngoc TriuNo ratings yet

- Antarctica: Earth Russian Vostok Station Subliming Dry IceDocument2 pagesAntarctica: Earth Russian Vostok Station Subliming Dry IceAndi Tri WidodoNo ratings yet

- SF6 Gas-insulated Switchgear Powers China's Massive Three Gorges Dam ProjectDocument8 pagesSF6 Gas-insulated Switchgear Powers China's Massive Three Gorges Dam ProjectVictor GuzmanNo ratings yet

- Chlorine Electrolysis System Chlorinsitu - II Assembly and Operating InstructionsDocument56 pagesChlorine Electrolysis System Chlorinsitu - II Assembly and Operating InstructionsWillian A. Palacio MurilloNo ratings yet

- Introduction To Marine Biology 4Th Edition Karleskint Test Bank Full Chapter PDFDocument39 pagesIntroduction To Marine Biology 4Th Edition Karleskint Test Bank Full Chapter PDFotisfarrerfjh2100% (10)

- Chapter Visions, Scenarios and Future Pathways Towards Sustainable DevelopmentDocument11 pagesChapter Visions, Scenarios and Future Pathways Towards Sustainable DevelopmentShanaia Kaye Bais PamintuanNo ratings yet

- Environmental Movements in IndiaDocument11 pagesEnvironmental Movements in Indiamohini saranNo ratings yet

- CPI - Lesson 3Document16 pagesCPI - Lesson 3Kim Tracey LadagaNo ratings yet

- Rehabilitation of Septic Tank WorksDocument4 pagesRehabilitation of Septic Tank WorksAbdi MusaNo ratings yet

- Assignment AC U2 Final eDocument28 pagesAssignment AC U2 Final eYuenHei KwokNo ratings yet

- Hydraulic Structures - Siphon SpillwayDocument5 pagesHydraulic Structures - Siphon SpillwayMatsobane LekalaksNo ratings yet

- Iv. The HydrosphereDocument43 pagesIv. The HydrosphereJohn Alfred FernandezNo ratings yet

- June 2018 p1Document24 pagesJune 2018 p1Uncle TravisNo ratings yet

- Heterotrophic BacteriaDocument1 pageHeterotrophic Bacterianavina01No ratings yet

- Catalog DeCODECK Pardoseala Compozita Pentru TeraseDocument2 pagesCatalog DeCODECK Pardoseala Compozita Pentru TeraseIosif BabiasNo ratings yet

- MBR Membrane Offer for 30 MLD STPDocument8 pagesMBR Membrane Offer for 30 MLD STPakshay salviNo ratings yet

- Review On Causes and Consequences of Wetland Loss in Dhaka CityDocument6 pagesReview On Causes and Consequences of Wetland Loss in Dhaka Cityjoy058No ratings yet

- SAFETY DATA SHEET According To 2001/58/EC: Union Derivan, S.A. Trade Name: 02/05 Date: 11/7/05Document8 pagesSAFETY DATA SHEET According To 2001/58/EC: Union Derivan, S.A. Trade Name: 02/05 Date: 11/7/05Filipe MartinsNo ratings yet

- K. Subramanya - Engineering Hy-Hill Education (India) (2009) 12 PDFDocument1 pageK. Subramanya - Engineering Hy-Hill Education (India) (2009) 12 PDFcivilengeeNo ratings yet

- Ellis County, Texas: Custom Soil Resource Report ForDocument21 pagesEllis County, Texas: Custom Soil Resource Report Forapi-105867910No ratings yet

- Condensor AKMDocument14 pagesCondensor AKMSharmin SumiNo ratings yet

- Plumbing Fixtures Terms and StandardsDocument2 pagesPlumbing Fixtures Terms and StandardsEugene MicarandayoNo ratings yet

- E Book16CrocodileDocument18 pagesE Book16CrocodileNUR ALIAH IZZATI BINTI MOHD RAFI BS20160556No ratings yet

- Experience CV. JatraDocument24 pagesExperience CV. Jatrasugiarto budiNo ratings yet

- KARNATAKA'S BIODIVERSITY AT A GLANCEDocument96 pagesKARNATAKA'S BIODIVERSITY AT A GLANCESameer MajliNo ratings yet