Professional Documents

Culture Documents

Gas Turbine Questions and Answers

Gas Turbine Questions and Answers

Uploaded by

Jêmš Navik0 ratings0% found this document useful (0 votes)

9 views10 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views10 pagesGas Turbine Questions and Answers

Gas Turbine Questions and Answers

Uploaded by

Jêmš NavikCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 10

Gas Turbine Questions and Answers

What is Gas turbine?

It is a thermic machine running according to the admission-compression-combustion-exhaust 4 step

cycle.

How many stages are there in gas turbine?

3 stages

How many stages are there in the compressor?

17 stages

What type of compressor is there in the gas turbine?

Axial flow compressor

How many bleed valves are there in the compressor?

4 nos. of bleed valve’s

At what stage of the compressor, air will be extracted through bleed valves?

11th stage of the compressor

Why air bleeding required through bleed valves?

Pulsation protection during start-up

When these compressor bleed valves will be closed?

Speed relay (14HS) corresponding to 95 % speed

What are the IGV minimum and maximum position in gas turbines?

Minimum – 34 DGA and Maximum – 85 DGA

When IGV will start opening?

Speed relay (14HS) corresponding to 95% speed.

How many combustion chambers are there in frame # 9 & # 6?

Frame #9 – 14 nos. and Frame #6 – 10 no’s . Of combustion chambers

How many spark Plugs?

2 nos. of spark plugs

What is the function of crossfire tube?

All combustion chambers are interconnected by means of crossfire tube. This tube enables flame

from the fired chambers to propagate to the unfired chambers.

How spark plugs will retract after igniting combustion chambers?

After the turbine rotor approximates operating speed, combustion chamber pressure causes the

spark plugs to retract to remove their electrodes from the hot flame zone.

Where exactly transition pieces are located?

Transition pieces are attached to the aft end of the combustion chamber liners.

Explain the stages of the Gas turbine?

Each stage consists of a row of fixed nozzles followed by a row of rotatable turbine buckets. In each

nozzle row, the kinetic energy of the jet is increased, with an associated pressure drop, and in each

following row of moving buckets, a portion of the kinetic energy of the jet is absorbed as useful work

on the turbine rotor.

Where exactly turning vanes are located?

Exhaust hood and diffuser contains turning vanes located in the exhaust path.

What is the function of turning vanes?

Turning vanes turn the gases from the axial direction to a radial direction to minimize exhaust hood

losses.

What is the function of turbine legs?

Turbine legs assist in maintaining alignment between the turbine and the generator. Support legs

maintain the axial and vertical positions of the turbine.

Why turbine legs cooling is required?

Cooling water is circulated through the jackets to minimize the thermal expansion of the supports

legs and assist in maintaining alignment between the turbine and generator.

How many types of blades are there in the compressor?

2 types of blades. Rotor & Stator blades.

What is the function of rotor blades in the compressor?

Rotor blades supply the force needed to compress the air in each stage.

What is the function of stator blades in the compressor?

Stator blades guide the air so that it enters the following rotor stage at the proper angle.

Where does compressor air will be used?

Turbine cooling, bearing sealing, pulsation control, purging.

Describe the compressor rotor

Compressor rotor is an assembly of 15 individual wheels, 2 stud shafts, each with an integral wheel,

a speed ring, tie bolts and the compressor rotor blades.

Describe the compressor stator?

The stator (casing) area of the compressor section is composed of inlet casing, forward compressor

casing, aft compressor casing, compressor discharge casing.

Where the compressor inlet casing is located?

Compressor inlet casing is located at the forward end of the gas turbine.

What is the function of the compressor inlet casing?

Its prime function is to uniformly direct air into the compressor. It also supports no.1 bearing

housing.

Where IGV is located?

Inlet guide vanes are located at the aft end of the compressor inlet casing.

What does the compressor forward casing contain?

Forward compressor casing contains the first 4 compressor stator stages.

What does aft compressor casing contains?

Aft compressor casing contains the 5th & 11th stages of the compressor

Where does the extracted air used for 5th & 11th stages of compressor?

This air is used for cooling & sealing functions and also used for starting and shutdown pulsation

control.

Explain the functions of the compressor discharge casing?

The functions of the compressor discharge casings are to contain the final 7 compressor stages, to

form both the inner and outer walls of the compressor diffuser and to join the compressor and

turbine stators.

They also provide support for no.2 bearing, the forward end of the combustion wrapper, and the

inner support of the first stage turbine nozzle.

What type of combustion system is there in gas turbine?

Reverse flow type.

Where does spark plugs located?

Combustion chamber no.13 & 14

Where does flame detectors are located?

Combustion chamber no.4, 5, 10 &11

What is the function of combustion wrapper?

The combustion wrappers form a plenum in which the compressor discharge air flow is directed to

the combustion chambers. Its secondary purpose is to act as a support for the combustion chamber

assemblies.

In turn, the wrapper is supported by the compressor discharge casing and the turbine shell.

Why flame detectors are required?

During the starting sequence, it is essential that an indication of the presence or absence of flame be

transmitted to the control system.

How do flame detectors work?

The ultraviolet flame sensor consists of a lame sensor containing a gas-filled detector. The gas within

this flame sensor detector is sensitive to the presence of ultraviolet radiation which is emitted by a

hydrocarbon flame. D.C. voltage, supplied by the amplifier, is impressed across the detector

terminals.

If flame is present, the ionization of the gas in the detector allows conduction in the circuit which

activates the electronic to give an output defining flame. Conversely, the absence of flame will

generate an opposite output defining “on flame”.

What is the function of the fuel nozzle?

The fuel nozzle functions to distribute the liquid or gas fuel into the reaction zone of the combustion

liner, in a manner that promotes uniform rapid and complete combustion.

How atomizing air does is utilized?

Atomizing air is utilized with liquid fuel to assist in the formation of a finely divided spray.

What is the function of transition pieces?

Transition pieces direct the hot gases from the liners to the turbine first stage nozzle. Thus, the first

nozzle area is divided into 14 equal areas receiving the hot gas flow.

Which components are included in the combustion section?

The combustion system includes fuel nozzles, spark plugs ignition system, flame detectors, and

crossfire tubes.

Which components are included in the turbine section?

The turbine section components include the turbine rotor, a turbine rotor, a turbine shell, nozzles,

shrouds, exhaust frame, and exhaust diffuser.

Which components are included in the turbine rotor assembly?

The turbine rotor assembly consists of 2 wheel shafts, the 1st, 2nd, and 3rd stage turbine wheels

with buckets and 2 turbine spacers.

What is the function of diaphragms?

Diaphragms prevent air leakage past the inner sidewall of the nozzles and turbine rotor. Attached to

the inside diameters of both the second and third stage nozzle segments are the nozzle diaphragms.

What is shroud?

Unlike the compressor blading, the turbine bucket tips don’t run directly against an integral

machined surface of the casing but against annular curved segments called turbine shrouds.

What are the functions of shrouds?

The primary function of the shrouds is to provide a cylindrical surface for minimizing tip clearance

leakage. The secondary function is to provide a high thermal resistance between the hot gases and

the comparatively cool shell.

By accomplishing this function, the shell cooling load is drastically reduced, the shell diameter is

controlled, the shell roundness is maintained, and important turbine clearances are assured.

How many bearing are there is in gas turbine?

3 bearings

Which types of bearing are those?

Journal bearings, elliptical type

Where these 3 bearings does located?

No.1 bearing-center of the inlet casing assembly.(Compressor inlet)

No.2 bearing-pressurized space between the compressor and the turbine

No.3 Bearing-aft end of the turbine shaft in the center of the exhaust frame assembly.

What is the capacity of the lube oil tank?

12540 liters.

What is function coupling?

Couplings are used to transmit starting torque from the accessory gear to the gas turbine axial

compressor and to transmit shaft horsepower from the turbine to the generator.

Where exactly accessory drive gear is located?

The accessory drive gear, located at the compressor end of the gas turbine.

What is the function of the accessory gear drive?

Its function is to drive each gas turbine accessory at its proper speed, in addition, it contains the

system’s main lube oil pump and the turbine over-speed bolt trip mechanism.

Name auxiliaries driven by accessory drive gear?

Main lube oil pump, main hydraulic pump, liquid fuel pump, main atomizing air compressor.

How gas turbine will trip on mechanical over speed?

A high-pressure turbine over speed trip capable of mechanically dumping the oil in the trip circuits,

the over speed bolt which actuates the trip upon over speed is installed in the main shaft.

At what speed gas turbine will trip on normal over speed?

107% TNH or 3210 RPM.

At what speed gas turbine will trip on electrical over speed?

110% TNH or 3300 RPM

What is pour point?

Pour point is the lowest temperature at which a fluid is observed to flow.

What is flashpoint?

Flashpoint is the temperature at which the fluid contained in a test cup and heated at a constant

rate will flash but not burn when a flame is passed over the cup.

What is fire point?

Fire point is the temperature at which the fluid contained in a test cup and heated at a constant rate

will burn for at least 5 seconds when a flame is passed over the cup.

Explain coded designation for GE gas turbine?

12 will be used for the over speed mechanism.

20 for solenoid valve

23 for the heating device

26 for the temperature switch

33 for the limit switch

39 for the vibration detector

43 for the manual switches

45 for the fire detector

49 for the over load protection

63 for the pressure switches

65 for the servo valve

71 for the level detecting system

77 for the speed sensors

88 for the electrical motor

90 for the modulating valve

96 for the pressure transmitter

Why gas turbine should come on turning gear following a shutdown?

Immediately following a shutdown, after the turbine has been in the fired mode, the rotor should be

turned to provide uniforms cooling.

Uniform cooling of the turbine rotor prevents rotor bowing and resultant, rubbing and imbalance,

and related damage that might otherwise occur when subsequent starts are attempted without cool

down.

How many hours turbines will remain on turning gear following a shutdown?

At least 14 hours as per cooldown timer.

Why the turbine compartment fan (SSBT) will cut off soon after off?

To avoid the fast cooling of the turbine.

When turbine compartment fan (SSBT) will remain in service after flame off?

With flame off, it will cut off and again it will start after 1 hour.

How long turbine compartment fan (SSBT) will remain in service after flame off?

Till wheel space temperature reaches 148 degrees.

What will happen if the accessories are stopped when the unit is not yet cool down?

The shaft line will continue to cool but it will bow and important vibration may occur at the next

start up, with possible damage to the bearings.

Name particular parameters to be noticed or to be adjusted during unit synchronization with the

system grid?

Machine speed, machine voltage system voltage and power factor.

How many extractions are used from air compressor?

3 extractions (5th / 11th/ 17th)

Where air will be used from the 5th, 11th, and 17th stages?

From 5th stage air will be used for cooling & sealing of bearings

From 11th stage air will be used for pulsation protections

From 17th stage air will be used for combustion chamber.

How hot gas will flow from the combustion chamber towards exhaust plenum?

The hot gases from the combustion chamber expand into the 14th separate transition pieces attach

to the aft end of the combustion chamber liners and flow towards the 3 stage turbine section of the

machine.

Each stage consists of a row of fixed nozzles followed by a row of rotatable buckets, in each nozzle

row, the kinetic energy of the jet is increased, with an associated pressure drop, and in each

following row of moving buckets, a portion of the kinetic energy jet is absorbed as useful work on

the turbine rotor.

After passing through the 3rd stage buckets, the exhaust gases directed into the exhaust hood and

diffuser. Then, the gases pass into exhaust plenum.

What types of spark plugs are provided in the gas turbine?

High voltage, retractable electrodes, spring injected & pressure-retractable types of spark plugs are

provided.

What is the function of the transition piece?

The transition piece directs the hot gases from the liners to the first stage nozzles.

Turbine buckets increase in size from the 1st to the 3rd stage. Why?

Because of the pressure reduction resulting from energy conversion in each stage, an increased

annulus area is required to accommodate the gas flow, thus necessitating increasing the size of the

buckets.

What’s the definition of wheel space?

Space between the turbine wheel with the bucket and the stator, into the main gas stream area, is

called the wheel space.

How wheel space is being cooled by air?

The first stage forward wheel space is cooled by air that passes through the high pressure passing

seal at the aft end compressor rotor.

The second stage forward wheel space is cooled by the compressor discharge air that passes through

the stage 1 shroud and then secondary inward through stage 2 nozzles vanes, the 3rd aft wheel

space is cooled by cooling air exit from the exhaust frame cooling circuit.

What is the cooling provision provided fro turbine shell, why it is required?

3 exhaust frame cooling fans( 88TK ) are provided for turbine shell cooling.

The turbine shell controls the axial & radial positions of the shrouds and nozzles. It determines

turbine clearances and the relative position of the nozzles to the turbine buckets. The position is

critical to gas turbine performance.

What is the function of turbine nozzles?

Turbine nozzles direct the high-velocity flow of the expanded hot combustion gas against the turbine

buckets, causing the rotor to rotate.

How many nozzle segments consisted of 1st, 2nd & 3rd stage nozzle?

18, 16, 16 segments respectively.

How many bearings are contained in bearing # 1 assembly?

Bearing # 1 contained 3 nos. of bearings.

Active thrust bearing, inactive thrust bearing & journal bearing.

What type of load coupling provided between turbine shaft and generator?

Hollow coupling.

What do you mean by the axial flow compressor?

Axial flow means that air flow general direction is axial.

How does pressure & velocity behave in compressor?

The pressure is increased from stage to stage by reducing in the stator blade row the air velocity

obtained from the rotation of the rotor blade row, that’s why, on the fixed blade of the stator,

whirled air velocity decreases and air pressure increases.

How many percentages of the air used for the thermal insulation as well as for the combustion?

70 to 80% of compressed air is used for thermal insulation, the remaining 20 to 30% air is used for

combustion.

How much percentage of power consumed or absorbed by the axial compressor?

53% of the total machine output.

Which factors are affecting the performance of the gas turbine?

Load, ambient pressure, ambient temperature rate of humidity, steam injection.

How generator output will increase by decreasing the ambient temperature?

Inlet air density increases at lower temperatures, so the compressor supplies a higher mass flow into

the combustor, so the generator output will increase.

How generator output will increase by increasing the atmospheric pressure?

As pressure increases, air density increases, and the compressor supplies a greater mass flow. Flow

into the combustor, so the generator output will increase.

How generator output can be measured?

The generator output is measured by the help of 2 wattmeters, which are connected to the

appropriate sockets on the generator control panel.

Which are the standard conditions to get maximum output from the machine?

Ambient temperature – 15 degree C

Atmospheric pressure – 1.0132 bar

Relative humidity – 60%

Which factors can affect generator output?

Pressure loss in the inlet duct.

Pressure loss in the exhaust duct,

Ambient temperature.

Atmospheric pressure.

Name the location we can carry out the baroscopic test?

Compressor stages no 4, 12 & 17

1st,2nd & 3rd stage nozzle trailing edge

2nd & 3rd stage nozzle leading edge

1st,2nd & 3 rd stage bucket leading edge

1st,2nd stage bucket trailing edge

Liners and transition pieces.

What are the interlocks for offline water wash?

The machine must be down

The temperature difference between water wash & wheel space temperature must not be greater

than 67 degrees C.

The maximum wheel space temperature must not be greater than 149 degrees C.

What are the interlocks for online water wash?

IGV must be in fully open condition

Water wash tank temperature should be @ 70 degrees C

The turbine must be running at maximum load and not in the process of shutdown

The ambient temperature must be superior to 10 degrees C

Which factors are affecting the heat rate in gas turbine?

Ambient temperature

Pressure loss in the inlet duct

Pressure loss in the exhaust duct.

Name the composition of natural gas

CH4 – 89.55 % (methane)

C2H6 – 5.68 % (ethane)

CO2 – 3.94 % (carbon dioxide)

C3H8 – 0.14 %

C4H10- 0.11 %

C6H14- 0.06 %

C5H12- 0.03 %

N2 – 0.50 % (nitrogen)

How we can determine the firing temperature in the combustion chamber?

Firing temperature can be determined as a function of exhaust temperature and pressure ration

across the turbine, it is also determined from the measured CPD & FSR.

Which factors can cause high wheel space temperature?

High wheel space temperature may be caused by any of the following reasons.

Restriction in cooling air liner

Wear in turbine seals

Excessive distortion of the turbine stator

Improper positioning of the thermocouples

Malfunctioning of the combustion system

Leakage in external piping’s

Excessive distortion of exhaust inner diffuser

Which circuit or system needs to be isolated for offline water wash?

Atomizing air circuit

Cooling air circuit

Sealing air circuit.

What is firing temperature?

The temperature control system is designed to measure and control turbine exhaust temperature

because it is impractical to measure temperature in the combustion chamber or at the turbine inlet

directly, this indirect control of the turbine inlet temperature called firing temperature.

What is the direction of gas turbine?

Anti-clockwise ( viewing from compressor end towards generator )

What is the direction of gas turbine during ratcheting (frame#6)?

Clockwise (reverse compare to normal because of the load gear)

At what speed A.O.P will cut off during start up of gas turbine?

95 % TNH (FSNL)

At what speed starting motor will cut off during start up of gas turbine?

60 % TNH

Why on 60% TNH starting motor will cut off?

At 60% TNH, machine will have a self-sustaining speed so further there is no need for the starting

motor as shaft RPM will increase itself up to FSNL.

How does humidity affect the machine output power?

The rate of humidity affects the compressibility of atmospheric air. The energy absorbed by the

compressor decreases and the output power slightly decreases.

How does steam injection improves the machine output?

If we inject the steam into the combustion chamber, the massic flow expanded through the turbine

is higher, the expansion work provided by the turbine is higher while the compression energy

required keeps constant, thus the machine output improves slightly.

What is the definition of the nominal speed of the compressor?

An axial compressor is designed and optimized of a given speed which is called nominal speed, at

nominal speed, the compressor is able to pressurized or constant air flow with the operating range

of pressure rations.

At what turbine speed compressor capability will be very low?

The starting engine drives the turbine, from 50% of nominal speed, the pressure inside the

combustion zone will rapidly increase du toe temperature increases. AT this intermediate speed the

capability of the compressor will be vey low.

Why ambient temperature is being measured under the shade, why not directly in the inlet side?

Ambient temperature is measured in the shade near the filter inlet because the thermometer should

not be positioned directly in the inlet air flow, as its speed provokes pressure drops that affect the

temperature.

After synchronizing the machine which criteria you will consider as machine has been warmed up

uniformly?

When wheel space temperature does not increase any more than 3 degrees C within 15 minutes, we

can assume that the machine has been warmed up uniformly. Machine should not be loaded until it

is not warmed up.

On which atmospheric conditions, the performance of gas turbine strongly depends?

Atmospheric pressure

Ambient temperature

Relative humidity.

How does pressure drops in the inlet duct, how could we measure the total loss of inlet pressure?

The pressure drop in the inlet duct is a result of line losses, the drop in the pressure in the air filter

and in the silencers.

To measure the total loss of inlet pressure, a water-filled U tube is connected to the appropriate

checkpoint on the inlet duct. The pressure difference to atmospheric pressure will be read in

mmh2o.

On which factors exhaust temperature depends, how?

Ambient temperature

Pressure losses in inlet duct

Pressure losses in exhaust duct.

Exhaust temperature increases with rising ambient temperature as well as pressure losses.

When exhaust over-temperature damage can occur. Why so?

The particularly critical period for over-temperature damage to occur is during the start-up phase

before the turbine reaches governing speed. At this time air flow is low and the turbine is unable to

accelerate away from the excess fuel.

Name the accessories being examined during combustion inspection?

Fuel nozzles

Combustion liners and cross fire tube

Transition pieces

Firing system and flame detectors

Possibility to achieve a boroscopic inspection.

Which types of inspection include in hot gas path inspection?

The inspection includes the combustion inspection, in addition, a detailed inspection of the following

parts which can be achieved after removal of the upper shell of the turbine.

1st 2nd and 3rd stage nozzles

1st 2nd and 3rd stage buckets of the turbine wheels

Condition of thermocouples

Condition of inlet and exhaust plenum

Appearance of compressor inlet blades

Condition of couplings and auxiliaries gear teeth.

Which types of inspection are involved in major overhauling?

This inspection involves the inspection of all the major flange to flange components of the gas

turbine. It is the most complete of all, After a major inspection, the turbine is considered in new

condition.

It required all operations required for combustion inspection and HGPI and in addition.

Complete rotor inspection

Compressor fixed blades examinations

Bearing and seals inspection

Control and safety system

On base auxiliaries

Off base auxiliaries

Generator and auxiliaries.

What is FSR

FSR – Fuel stroke reference is the electrical signal that determines the amount of fuel delivered to

the turbine combustion system.

What’s the duration being followed for C.I /HGPI/Major overhaul?

Combustion inspection – 8000 fire hours (1 year)

HGPI – 24000 fired hours(3 years)

Major overhaul – 48000 fired hours(6 years)

You might also like

- Construction of Gas TurbineDocument88 pagesConstruction of Gas Turbinesanjeev kushwaha100% (3)

- Process Control Instrumentation QuestionsDocument5 pagesProcess Control Instrumentation QuestionsJêmš NavikNo ratings yet

- Jenish Navik: Instrument TechnicianDocument8 pagesJenish Navik: Instrument TechnicianJêmš NavikNo ratings yet

- Emergency EchocardiographyDocument62 pagesEmergency Echocardiographyansarijaved100% (1)

- DLN2 6+Document10 pagesDLN2 6+Ubair Kazi100% (2)

- Gullivers TravelsDocument38 pagesGullivers TravelshafsahNo ratings yet

- GE MS6001B - EmissionDocument33 pagesGE MS6001B - EmissionMohamad Afif100% (1)

- Ge Frame 9eDocument22 pagesGe Frame 9eAs C100% (2)

- Dry Low NoxDocument10 pagesDry Low NoxIvan Poma Montes100% (2)

- Turbochargers in Diesel EnginesDocument6 pagesTurbochargers in Diesel EnginesSrini VasanNo ratings yet

- Basics of Valves Interview Questions & Answers: Directional Control ValveDocument7 pagesBasics of Valves Interview Questions & Answers: Directional Control ValveJêmš NavikNo ratings yet

- GT Operation (Nanjin)Document146 pagesGT Operation (Nanjin)Ady Fardy100% (1)

- DLN 1.0 MS9001Document20 pagesDLN 1.0 MS9001Atif Khan100% (10)

- Combustion Monitor GEK106832Document16 pagesCombustion Monitor GEK106832alaal67% (3)

- Exhaust Temperature SpreadDocument5 pagesExhaust Temperature Spreadchdeepak96100% (7)

- Frame 9e Gas Turbine PresentationDocument98 pagesFrame 9e Gas Turbine PresentationSONU100% (2)

- O&M-System Description-Fuel GAS (DLN 2.0+) - MS9001FA+e PDFDocument16 pagesO&M-System Description-Fuel GAS (DLN 2.0+) - MS9001FA+e PDFMaulik100% (4)

- Swirl AngleDocument3 pagesSwirl AngleNIGERE100% (5)

- What Is The Difference Between Dln-1 & Dln-2? Like ReplyreportDocument49 pagesWhat Is The Difference Between Dln-1 & Dln-2? Like ReplyreportSahariar Bin Shafique100% (2)

- Industrial Automation Engineers Interview QuestionsDocument5 pagesIndustrial Automation Engineers Interview QuestionsJêmš NavikNo ratings yet

- Gas Turbine Startup Per Missives For GeDocument5 pagesGas Turbine Startup Per Missives For Gejeromejoe100% (6)

- Combustion InspectionsDocument81 pagesCombustion InspectionsPhong le100% (1)

- Gas Turbine Start-UpDocument36 pagesGas Turbine Start-UpHeryanto Syam100% (3)

- Servo Valve Null Bias CurrentDocument41 pagesServo Valve Null Bias CurrentRam MeenaNo ratings yet

- lIQUID FUEL SYSTEM PDFDocument23 pageslIQUID FUEL SYSTEM PDFJJNo ratings yet

- Gas Turbine Control SystemDocument1 pageGas Turbine Control SystemSreedev Sureshbabu100% (1)

- STARTING SYSTEM Diesel Engine System Description PDFDocument21 pagesSTARTING SYSTEM Diesel Engine System Description PDFAwad ElfadniNo ratings yet

- 1 - CONTROL SYSTEM CONCEPTS Rev2Document38 pages1 - CONTROL SYSTEM CONCEPTS Rev2Mohamed Bin Ierous100% (1)

- 9fa ProbsDocument12 pages9fa ProbsMarbz Al MonteNo ratings yet

- GT6B FoundamentalDocument53 pagesGT6B FoundamentalThanapaet RittirutNo ratings yet

- Startup Shutdown Seq DLNDocument35 pagesStartup Shutdown Seq DLNBozar Tgt92% (12)

- GT Frame 9 ManualDocument102 pagesGT Frame 9 ManualSSC & GSC of Lebanon100% (1)

- G T Start Up ProcedureDocument11 pagesG T Start Up ProcedureJJ100% (2)

- I.G.V Openning and Closing CurveDocument3 pagesI.G.V Openning and Closing CurveHussam Baiee100% (4)

- Gas Turbine Lecture (LOGICS)Document8 pagesGas Turbine Lecture (LOGICS)Vikas Oza100% (1)

- Ge Ms5001pDocument14 pagesGe Ms5001pMohamed Hamed100% (1)

- Ge GT Tag NameDocument9 pagesGe GT Tag NameCris Ronald100% (2)

- PLC Interview Questions and AnswersDocument6 pagesPLC Interview Questions and AnswersJêmš NavikNo ratings yet

- GT FSR ControlDocument15 pagesGT FSR ControlNaveed Irshad67% (3)

- Gas Turbine SlideDocument212 pagesGas Turbine SlideMuhd RizzuwanNo ratings yet

- GT ControlDocument81 pagesGT ControlGnanaseharan ArunachalamNo ratings yet

- Gas Detectors Questions & AnswersDocument14 pagesGas Detectors Questions & AnswersJêmš NavikNo ratings yet

- Gas Turbin Mark VIDocument42 pagesGas Turbin Mark VIpradeeps2007_1777402100% (4)

- GE Exhaust Temperature ControlDocument3 pagesGE Exhaust Temperature Controlmacrespo100% (6)

- Gas Turbine Combustion SystemDocument14 pagesGas Turbine Combustion Systemrohit u100% (3)

- Check The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001Document5 pagesCheck The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001jose Alberto uribe Minier100% (2)

- GE Control MK - VI PDFDocument34 pagesGE Control MK - VI PDFThanapaet Rittirut100% (2)

- Learn Gas Turbine by SimulationDocument41 pagesLearn Gas Turbine by SimulationAnonymous 8RRc42G100% (1)

- Terms and Abbreviation For GE Gas TurbinesDocument3 pagesTerms and Abbreviation For GE Gas TurbinesFazalur Rehman Babar100% (1)

- HART Protocol and Fieldbus Interview QuestionsDocument12 pagesHART Protocol and Fieldbus Interview QuestionsJêmš Navik100% (1)

- Grade 9 - First Quarter Test Questions Mapeh 9Document7 pagesGrade 9 - First Quarter Test Questions Mapeh 9305948No ratings yet

- Gas Turbine Interview QuestionsDocument26 pagesGas Turbine Interview QuestionsVenkata Madhav ModugaNo ratings yet

- Mechanical Interview Questions & Answers (Gas Turbine)Document14 pagesMechanical Interview Questions & Answers (Gas Turbine)Chidu100% (1)

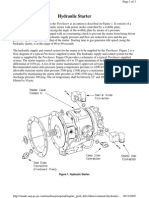

- Figure 1. Hydraulic StarterDocument3 pagesFigure 1. Hydraulic StarterDenis JimenezNo ratings yet

- Gas Turbine - Traning Report Bhel - 14 PageDocument14 pagesGas Turbine - Traning Report Bhel - 14 PageVivek Patel100% (1)

- Gas Turbine Performance Based On Inlet ADocument82 pagesGas Turbine Performance Based On Inlet Afateh1982100% (1)

- GT Trip ProtectionsDocument2 pagesGT Trip Protectionsakeel_haq100% (8)

- Gas Turbine ControlDocument16 pagesGas Turbine Controltetsa zangetsu100% (1)

- Gas Turbine Start SystemDocument108 pagesGas Turbine Start Systemhumane2897% (29)

- Gas Turbine ControlDocument8 pagesGas Turbine ControlDAHRAOUI Mohamed Riad100% (2)

- Tab 05 GEK 106899 Startup and Shutdown ControlDocument10 pagesTab 05 GEK 106899 Startup and Shutdown Controlherysyam100% (2)

- REPHRASING EXERCISES RepasoDocument5 pagesREPHRASING EXERCISES RepasoMónica Hidalgo JuradoNo ratings yet

- GE Frame 7FA Gas Turbine OffLine Water Wash ProcedureDocument18 pagesGE Frame 7FA Gas Turbine OffLine Water Wash ProcedurePetrovich10100% (1)

- Tab 07 Startup and Shutdown Flow ChartDocument12 pagesTab 07 Startup and Shutdown Flow Chartherysyam100% (1)

- Functional Safety Questions & AnswersDocument5 pagesFunctional Safety Questions & AnswersJêmš NavikNo ratings yet

- Overview of Start-Up of Gas TurbineDocument38 pagesOverview of Start-Up of Gas TurbineJulio Cesar Barajas Aguilar100% (3)

- GT 9E StartupDocument41 pagesGT 9E StartupNaveed IrshadNo ratings yet

- Manalili v. CA PDFDocument3 pagesManalili v. CA PDFKJPL_1987100% (1)

- Gas Turbine StartupDocument9 pagesGas Turbine Startuppawangwl100% (3)

- Gas Turbine QuestionsDocument4 pagesGas Turbine Questionspramod saljoshiNo ratings yet

- Turbochargers in Diesel EnginesDocument5 pagesTurbochargers in Diesel Enginesmister_no34No ratings yet

- Research Work Week 9Document3 pagesResearch Work Week 9jonas lintagNo ratings yet

- Turbo BlowerDocument5 pagesTurbo BlowerAmruth ParimiNo ratings yet

- Beauty Consultation FormDocument2 pagesBeauty Consultation FormJêmš NavikNo ratings yet

- Hemantkumar Narendrabhai Patel: Application For The Post Of: Instrumentation TechnicianDocument3 pagesHemantkumar Narendrabhai Patel: Application For The Post Of: Instrumentation TechnicianJêmš NavikNo ratings yet

- Bryan Enon Cledoro: Instrument Maintenance/Commissioning TechnicianDocument5 pagesBryan Enon Cledoro: Instrument Maintenance/Commissioning TechnicianJêmš NavikNo ratings yet

- COI Definition GuidelineDocument1 pageCOI Definition GuidelineJêmš NavikNo ratings yet

- Pressure Measurement: Selecting A Pressure GaugeDocument5 pagesPressure Measurement: Selecting A Pressure GaugeJêmš NavikNo ratings yet

- COI Definition GuidelineDocument1 pageCOI Definition GuidelineJêmš NavikNo ratings yet

- Email ID: Contact No: +971562398104, +917358302902: Name: R.VishnushankarDocument6 pagesEmail ID: Contact No: +971562398104, +917358302902: Name: R.VishnushankarJêmš NavikNo ratings yet

- C V O Durairaj Ravi: Contact DetailsDocument9 pagesC V O Durairaj Ravi: Contact DetailsJêmš NavikNo ratings yet

- Micrometer: ProbeDocument27 pagesMicrometer: ProbeJêmš NavikNo ratings yet

- Interview Questions For Instrument EngineersDocument4 pagesInterview Questions For Instrument EngineerszhangyiliNo ratings yet

- Instrumentation Cables Questions & AnswersDocument7 pagesInstrumentation Cables Questions & AnswersJêmš NavikNo ratings yet

- Curriculum Vitae: Seeking A Position As A SR Commissioning Instrument Technician)Document5 pagesCurriculum Vitae: Seeking A Position As A SR Commissioning Instrument Technician)Jêmš NavikNo ratings yet

- Pneumatic Circuits.: Also Read: Field Instruments Questions & AnswersDocument2 pagesPneumatic Circuits.: Also Read: Field Instruments Questions & AnswersJêmš NavikNo ratings yet

- PID Controllers: Final Control ElementDocument3 pagesPID Controllers: Final Control ElementJêmš NavikNo ratings yet

- Thermocouple Questions and AnswersDocument12 pagesThermocouple Questions and AnswersJêmš Navik0% (1)

- ProfiBus Questions and AnswersDocument7 pagesProfiBus Questions and AnswersJêmš NavikNo ratings yet

- RTD Questions and AnswersDocument19 pagesRTD Questions and AnswersJêmš NavikNo ratings yet

- Control Room Questions and AnswersDocument15 pagesControl Room Questions and AnswersJêmš NavikNo ratings yet

- Orifice Metering: Orifice Flow Meters: Detailed SpecificationsDocument18 pagesOrifice Metering: Orifice Flow Meters: Detailed SpecificationsJêmš NavikNo ratings yet

- Ralph LaurenDocument11 pagesRalph LaurenAnushkaNo ratings yet

- Tanjung Rhu Summary Malay Translation (Joseph)Document3 pagesTanjung Rhu Summary Malay Translation (Joseph)Sui Yang NguiNo ratings yet

- 4 Bond Valuation - PPT PDFDocument79 pages4 Bond Valuation - PPT PDFJocel LactaoNo ratings yet

- Steven Holt 2015Document76 pagesSteven Holt 2015SOS MVDNo ratings yet

- Mitosis & Cell Cycles MSDocument12 pagesMitosis & Cell Cycles MSNabindra RuwaliNo ratings yet

- IASB - Wayne Upton - Article - Depreciation in IFRS PDFDocument7 pagesIASB - Wayne Upton - Article - Depreciation in IFRS PDFSanath Fernando100% (1)

- JmunitplanDocument15 pagesJmunitplanapi-302258576No ratings yet

- Dissertation Jean GiraudouxDocument6 pagesDissertation Jean GiraudouxPayForAPaperBuffalo100% (1)

- Amateur Photographer-31 January 2023Document102 pagesAmateur Photographer-31 January 2023Andrei LucianNo ratings yet

- Pakistan Bait Ul MaalDocument21 pagesPakistan Bait Ul MaalSaaDii KhanNo ratings yet

- Critique Paper - Hidden FiguresDocument4 pagesCritique Paper - Hidden FiguresLance Daniel CamposanoNo ratings yet

- Strategic Management Individual Assignment: Critique On Disney Goes OTT: The Launch That Defined A Major Industry ShiftDocument8 pagesStrategic Management Individual Assignment: Critique On Disney Goes OTT: The Launch That Defined A Major Industry ShiftShivam TiwariNo ratings yet

- Land Value Capture Case Study PDFDocument45 pagesLand Value Capture Case Study PDFSamir SharmaNo ratings yet

- AHU To ALH Pedal. How To TDIClub ForumsDocument1 pageAHU To ALH Pedal. How To TDIClub Forumswkm5jsmxzzNo ratings yet

- Run No Ip When Debian BootedDocument3 pagesRun No Ip When Debian BootedamitkrayNo ratings yet

- Can Marketing Learn From Religion?Document3 pagesCan Marketing Learn From Religion?quresh1983No ratings yet

- Chennai Public School: English Class - ViiiDocument2 pagesChennai Public School: English Class - ViiiAbishek ThiyagarajanNo ratings yet

- Purpose of Drama in The ChurchDocument12 pagesPurpose of Drama in The ChurchagbiredoNo ratings yet

- Smile and Smile DesigningDocument6 pagesSmile and Smile DesigningLucky Singanamala100% (1)

- Tussle Digital Employment Handbook - As at 01.03.2023Document28 pagesTussle Digital Employment Handbook - As at 01.03.2023Khushboo MathurNo ratings yet

- Tuition Payment Plan M.Sc. National-6Document3 pagesTuition Payment Plan M.Sc. National-6GwagsiGlennNo ratings yet

- 1.1 Introduction of VC & Huawei TE30 & TE60Document19 pages1.1 Introduction of VC & Huawei TE30 & TE60Musharaf AshrafNo ratings yet

- ELC650 Assessment 5 Directed ReflectionDocument3 pagesELC650 Assessment 5 Directed Reflectiondanish rasid50% (2)

- Environmental Principles and ConceptsDocument7 pagesEnvironmental Principles and ConceptsMary Rose BaluranNo ratings yet

- Information Reference PointsDocument6 pagesInformation Reference PointsikyabdullahNo ratings yet