Professional Documents

Culture Documents

Experiment 3: Resistor Color Coding

Uploaded by

Victoria De Guzman0 ratings0% found this document useful (0 votes)

19 views3 pagesOriginal Title

De Guzman_Experiment 3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views3 pagesExperiment 3: Resistor Color Coding

Uploaded by

Victoria De GuzmanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

De Guzman, Victoria Mae T.

BS Chemical Engineering

EXPERIMENT 3: RESISTOR COLOR CODING

OBJECTIVE:

1. To use resistor color coding scheme to determine the resistance value.

2. To determine different types of resistors according to construction.

ACTIVITY:

A. Enumerate the five (5) different types of resistors according to construction. Discuss the

functions of each resistor.

1. The carbon composition resistor is a type of fixed resistor

that reduces or restricts the electric current flow to a certain

level. Carbon composition resistors are made by mixing carbon

granules with the help of binder which is a binding agent and

then converted into a small rod. They can be used in RF loads.

2. The carbon film resistor acts as the resistive material to the

electric current. Hence, the carbon film blocks some amount of

electric current. The ceramic substrate acts as the insulating

material to the heat or electricity. Carbon film resistors have the

carbon film on the ceramic former and they are covered with

insulation coating material like epoxy (for protection). This type

of resistor is not used today as superior resistor technologies are

available at lower cost.

3. The wire wound resistor is used in a variety of

applications and in particular as a power resistor where

larger amounts of power need to be dissipated. Normally

the resistive wire is insulated, so that adjacent wires do not

short together. The wire wound resistor is made by

winding the metal wire around a metal core. These

resistors have low noise and can be supplied to much more

close tolerance and thus make them far superior from

carbon film resistors. This type of resistors is used in almost all applications now.

4. The metal film resistor acts in the same way as resistance wire,

and as the thickness, width and length can be accurately controlled,

the metal film resistor can be produced to a high tolerance. Metal

film resistors can be obtained in a wide range of resistance values

from a few Ohms to tens of millions of Ohms with a very small

tolerance. These resistors are made from small rods of ceramic

coated with metal such as a nickel alloy or a metal oxide such as

tin oxide.

5. Thick film resistors are produced by applying a resistive film or

paste, a mixture of glass and conductive materials, to a substrate.

Thick film technology allows high resistance values to be printed

on a cylindrical or flat substrate either covered entirely or in

various patterns.

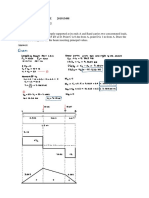

B. Fill in the blanks with the values of the resistors corresponding to the colors.

First Color Second Color Third Color Resistance Value

1. Brown Blue Brown 160 Ω

2. Red Blue Black 26 Ω

3. Brown Black Yellow 100 K Ω

4. Yellow White Red 4.9 K Ω

5. Brown Black Red 1KΩ

6. Yellow Yellow Silver 0.44 Ω

7. Red Brown Gold 2.1 Ω

8. Brown Black Gold 1Ω

9. Violet Red Black 72 Ω

10. Orange Black Green 3MΩ

C. Fill in the blanks with the colors of the resistors corresponding to their values.

Resistance Value First Color Second Color Third Color

1. 10 Ω Brown Black Black

2. 620 Ω Blue Red Brown

3. 110 Ω Brown Brown Brown

4. 50 K Ω Green Black Orange

5. 1.9 K Ω Brown White Red

6. 300 Ω Orange Black Brown

7. 1000 Ω Brown Black Red

8. 2.2 M Ω Red Red Green

9. 350 Ω Orange Green Brown

10. 330 K Ω Orange Orange Yellow

You might also like

- Resistor color coding experimentDocument3 pagesResistor color coding experimentVictoria De GuzmanNo ratings yet

- Resistor Color Coding: Experiment 3Document2 pagesResistor Color Coding: Experiment 3Kienth MatibagNo ratings yet

- Laboratory Exercise No. 1 Resistor Color Codes: John Clement Husain, Kayla Millicent Plazo, Mark Allan AntipuestoDocument3 pagesLaboratory Exercise No. 1 Resistor Color Codes: John Clement Husain, Kayla Millicent Plazo, Mark Allan AntipuestoJohn Clement HusainNo ratings yet

- LESSON 2 ResistorDocument3 pagesLESSON 2 ResistorDar N. AgasangNo ratings yet

- LESSON 2 resistorDocument3 pagesLESSON 2 resistorgeronimoalvin400No ratings yet

- Independent University, Bangladesh: Department of Computer Science & EngineeringDocument5 pagesIndependent University, Bangladesh: Department of Computer Science & EngineeringHridoy SarkarNo ratings yet

- Electronics Handbook: A Simplified Reference For Teachers © 2000 J P FullerDocument70 pagesElectronics Handbook: A Simplified Reference For Teachers © 2000 J P FullerJai KumarNo ratings yet

- Lab ManualDocument7 pagesLab ManualAlain JimeneaNo ratings yet

- Exercise No. 1 FinalDocument10 pagesExercise No. 1 FinalWyndellRioNo ratings yet

- Ece20L-2 - Electronics Laboratory Activity 1.2 - Familiarization of Components and EquipmentsDocument6 pagesEce20L-2 - Electronics Laboratory Activity 1.2 - Familiarization of Components and EquipmentsMALAKIPWETKONo ratings yet

- Basic Electronic DevicesDocument26 pagesBasic Electronic DevicesAudelon Ramiscal BenitoNo ratings yet

- Lecture 1 - RESISTOR PDFDocument59 pagesLecture 1 - RESISTOR PDFNaitsirhc AganirobNo ratings yet

- Lab Manual.Document64 pagesLab Manual.appu12245No ratings yet

- Essentials of Electronic CircuitDocument7 pagesEssentials of Electronic CircuitRam VigneshNo ratings yet

- Color Coded ResistorDocument24 pagesColor Coded ResistorG19 OMBAC, CHLOE BETINA NICOLENo ratings yet

- Example: Red, Blue, Red, Gold: Color Bands Nominal Resistance Value Minimum Value Maximum ValueDocument1 pageExample: Red, Blue, Red, Gold: Color Bands Nominal Resistance Value Minimum Value Maximum ValueJaved Maralit100% (1)

- IE WS 1 Resistor Color CodeDocument1 pageIE WS 1 Resistor Color CodeAster Jane ArjonaNo ratings yet

- EE2166-01-Resistor Color CodeDocument3 pagesEE2166-01-Resistor Color CodeRuth MayledNo ratings yet

- Resistor PDFDocument58 pagesResistor PDFJohn Miko Javier100% (1)

- Resistors CotDocument14 pagesResistors CotArmileo C AuxteroNo ratings yet

- Topic 1.3Document3 pagesTopic 1.3Ivan SimonNo ratings yet

- Resistor and capacitor color codesDocument59 pagesResistor and capacitor color codeshassanNo ratings yet

- Resistor Color Code: Lesson 5Document12 pagesResistor Color Code: Lesson 5L. RikaNo ratings yet

- Voltage:: Name: Kamran Mustafa Registration No: FA20-BPH-033 Course: Circuit TheoryDocument3 pagesVoltage:: Name: Kamran Mustafa Registration No: FA20-BPH-033 Course: Circuit TheoryJawad AliNo ratings yet

- Understanding Resistors and Their ApplicationsDocument145 pagesUnderstanding Resistors and Their ApplicationskusumaNo ratings yet

- CP Flame Test Lab - MR OwenDocument4 pagesCP Flame Test Lab - MR OwenKate CaballeroNo ratings yet

- Resistor Measurement Using Color CodingDocument4 pagesResistor Measurement Using Color CodingAlain JimeneaNo ratings yet

- Creative Technologies 9 ResistorsDocument18 pagesCreative Technologies 9 ResistorsgiovsleonxhaviermalabananabreuNo ratings yet

- Lecture 1Document6 pagesLecture 1muhammad dawoodNo ratings yet

- Lab Report Experiment 3: Muhammad Ashraf 1040997 Smae Dmro 1A/01Document10 pagesLab Report Experiment 3: Muhammad Ashraf 1040997 Smae Dmro 1A/01Achap LanunNo ratings yet

- Generally To CW 1308: Insulation ResistanceDocument2 pagesGenerally To CW 1308: Insulation ResistanceJason SecretNo ratings yet

- Fundamental Principles in DC CircuitsDocument25 pagesFundamental Principles in DC CircuitsGabriel Carl Alpuerto100% (1)

- Circuit Theory AND Electronic Components: First YearDocument17 pagesCircuit Theory AND Electronic Components: First YearNithish KingNo ratings yet

- Resistor Color Code LessonDocument8 pagesResistor Color Code LessonMARFE IMPASTANo ratings yet

- Perform Mensuration and Calculations: Lesson 2Document8 pagesPerform Mensuration and Calculations: Lesson 2MARFE IMPASTANo ratings yet

- Test Report For CablesDocument11 pagesTest Report For CablesSunil SinghNo ratings yet

- Example: Red, Blue, Red, Gold: Resistors Minimum and Maximum ValueDocument1 pageExample: Red, Blue, Red, Gold: Resistors Minimum and Maximum ValueNecole Ira BautistaNo ratings yet

- Group 06 Lab 02Document7 pagesGroup 06 Lab 02ZabeehullahmiakhailNo ratings yet

- Resistors Exercise WADocument2 pagesResistors Exercise WALimuel OliverNo ratings yet

- "Technological University of Altamira": Practice 1Document7 pages"Technological University of Altamira": Practice 1Evelyn Sánchez RomeroNo ratings yet

- Electrical Cables Handout #2Document3 pagesElectrical Cables Handout #2HealthyCut FarmsNo ratings yet

- Electrical Power Lab Session 03 Soil Resistivity & Earthing ResistanceDocument8 pagesElectrical Power Lab Session 03 Soil Resistivity & Earthing ResistanceHermain Fayyaz KarimNo ratings yet

- MODULE-3Document13 pagesMODULE-3Ritchell Mae MalolotNo ratings yet

- Resistor Color Coding ActivityDocument4 pagesResistor Color Coding ActivityEisle Keith Rivera TapiaNo ratings yet

- Compilation of Lab Activity No. 3Document109 pagesCompilation of Lab Activity No. 3Anthony CortezNo ratings yet

- 41, 42, 43. ADSS(Single Jacket)Span 100m 2200nDocument4 pages41, 42, 43. ADSS(Single Jacket)Span 100m 2200nAlex VelezNo ratings yet

- Experiment No. 2 Measurement of ResistanceDocument13 pagesExperiment No. 2 Measurement of ResistanceLynndon VillamorNo ratings yet

- Nanomaterial PropertiesDocument5 pagesNanomaterial PropertiesParth PatelNo ratings yet

- Resistor Color Codes and ValuesDocument87 pagesResistor Color Codes and ValuesJENNIFER SERVONo ratings yet

- Resistor & Color CodingDocument94 pagesResistor & Color Codingapi-19822723No ratings yet

- Testing Fixed ResistorsDocument4 pagesTesting Fixed ResistorsDaniel Angelo IslaNo ratings yet

- I See Your True Colors ActivityDocument4 pagesI See Your True Colors ActivityEisle Keith TapiaNo ratings yet

- Measure Circuit ComponentsDocument10 pagesMeasure Circuit ComponentsHER OICNo ratings yet

- Competency 7 - Questions On Colour CodingDocument5 pagesCompetency 7 - Questions On Colour CodingSelvenNo ratings yet

- CW 1128/1179 Telephone Cable SpecificationDocument2 pagesCW 1128/1179 Telephone Cable SpecificationJason SecretNo ratings yet

- 4 Band ResistorsDocument1 page4 Band Resistorspatrick mNo ratings yet

- A2 Relleta JamesDocument9 pagesA2 Relleta JamesLorenzo AbolarNo ratings yet

- Carbon Resistors: Structure, Uses and Colour CodingDocument18 pagesCarbon Resistors: Structure, Uses and Colour CodingAnil Thakur83% (6)

- Physics ResistancesDocument3 pagesPhysics ResistancesAyato KamisatoNo ratings yet

- Ion-Selective Electrode Reviews: Volume 5From EverandIon-Selective Electrode Reviews: Volume 5J. D. R. ThomasNo ratings yet

- Resume PrelimDocument3 pagesResume PrelimVictoria De GuzmanNo ratings yet

- ViDocument2 pagesViVictoria De GuzmanNo ratings yet

- Resume PrelimDocument3 pagesResume PrelimVictoria De GuzmanNo ratings yet

- De Guzman Activity 1 BEE-LabDocument1 pageDe Guzman Activity 1 BEE-LabVictoria De GuzmanNo ratings yet

- Stress and Strain of Steel Bar and TubeDocument2 pagesStress and Strain of Steel Bar and TubeVictoria De GuzmanNo ratings yet

- Beam carrying loads - SF and BM diagramsDocument1 pageBeam carrying loads - SF and BM diagramsVictoria De GuzmanNo ratings yet

- De Guzman - Quiz 1Document2 pagesDe Guzman - Quiz 1Victoria De GuzmanNo ratings yet

- De Guzman Activity 1 BEE-LabDocument1 pageDe Guzman Activity 1 BEE-LabVictoria De GuzmanNo ratings yet

- Module 5 - Activity 3Document3 pagesModule 5 - Activity 3Victoria De GuzmanNo ratings yet

- Experiment No. 4 Ohm'S Law: Adamson University College of Engineering Chemical Engineering DepartmentDocument17 pagesExperiment No. 4 Ohm'S Law: Adamson University College of Engineering Chemical Engineering DepartmentVictoria De GuzmanNo ratings yet

- Strength of Materials: de Guzman, Victoria Mae T. 201913498Document2 pagesStrength of Materials: de Guzman, Victoria Mae T. 201913498Victoria De GuzmanNo ratings yet

- Prelim Exam - Engg EcoDocument3 pagesPrelim Exam - Engg EcoVictoria De GuzmanNo ratings yet

- Prelim Exam - Engg EcoDocument3 pagesPrelim Exam - Engg EcoVictoria De GuzmanNo ratings yet

- Experiment 5: Resistors in Series and Parallel CircuitsDocument2 pagesExperiment 5: Resistors in Series and Parallel CircuitsVictoria De GuzmanNo ratings yet

- Experiment No. 4 Ohm'S Law: Adamson University College of Engineering Chemical Engineering DepartmentDocument17 pagesExperiment No. 4 Ohm'S Law: Adamson University College of Engineering Chemical Engineering DepartmentVictoria De GuzmanNo ratings yet

- Schedule:: The Practical Unit of Electric Charge. 2Document1 pageSchedule:: The Practical Unit of Electric Charge. 2Victoria De GuzmanNo ratings yet

- Schedule:: The Practical Unit of Electric Charge. 2Document1 pageSchedule:: The Practical Unit of Electric Charge. 2Victoria De GuzmanNo ratings yet

- Adamson University Exercise No 3: Annuities ScoreDocument3 pagesAdamson University Exercise No 3: Annuities ScoreVictoria De GuzmanNo ratings yet

- Experiment 5: Resistors in Series and Parallel CircuitsDocument2 pagesExperiment 5: Resistors in Series and Parallel CircuitsVictoria De GuzmanNo ratings yet

- V4-CWD-A200: Double Door Check ValveDocument1 pageV4-CWD-A200: Double Door Check ValveArthur DeiparineNo ratings yet

- Selection of Right Cladding Material For PolyhouseDocument45 pagesSelection of Right Cladding Material For Polyhousepink girlNo ratings yet

- Slides 01Document29 pagesSlides 01Anudwaipaon AntuNo ratings yet

- Theoretical prediction of temperature-dependent fracture strength for UHTC compositesDocument27 pagesTheoretical prediction of temperature-dependent fracture strength for UHTC compositesRamancoronaNo ratings yet

- Pentair Series H ValveDocument78 pagesPentair Series H Valvea_osorioNo ratings yet

- ASME Code Cases for Nuclear ComponentsN-71-18N-71-18N-122-2N-131-1N-133-3N-154-1N-155-2N-160-1N-192-3N-201-5N-208-1N-213N-243N-249-14N-253-14N-254N-257N-258-2Document14 pagesASME Code Cases for Nuclear ComponentsN-71-18N-71-18N-122-2N-131-1N-133-3N-154-1N-155-2N-160-1N-192-3N-201-5N-208-1N-213N-243N-249-14N-253-14N-254N-257N-258-2Biyong SantocildesNo ratings yet

- Analysis of Bond Stress Distribution For Prestressing Strand by StandardDocument8 pagesAnalysis of Bond Stress Distribution For Prestressing Strand by StandardSameerKareeeemNo ratings yet

- Solid Solution HardeningDocument5 pagesSolid Solution HardeningVasantha SudasinghaNo ratings yet

- Heat Trace DesignDocument60 pagesHeat Trace DesignnbsmaniannNo ratings yet

- How Refrigerators and AC Systems WorkDocument10 pagesHow Refrigerators and AC Systems WorkJagadish PasumarthiNo ratings yet

- TKDN Certificate ListDocument6 pagesTKDN Certificate ListwahyuNo ratings yet

- Dialight Led Highbay Specsheet ATEX HEADocument8 pagesDialight Led Highbay Specsheet ATEX HEAsachusunil008No ratings yet

- 2 - Structural Precast Concrete Structures in Seismic Areas - USA Experience - Jason KrohnDocument21 pages2 - Structural Precast Concrete Structures in Seismic Areas - USA Experience - Jason KrohnNavendu RaiNo ratings yet

- 3.0 Convection Heat TransferDocument41 pages3.0 Convection Heat Transfershariza91No ratings yet

- AISI 1045 Medium Carbon Steel Properties and UsesDocument4 pagesAISI 1045 Medium Carbon Steel Properties and Usessingaravelan narayanasamyNo ratings yet

- Pinnacle Security Renovation Works Bill of QuantitiesDocument4 pagesPinnacle Security Renovation Works Bill of QuantitiesNakimera JosephineNo ratings yet

- Testing Procedure For Ball Valve MAPDocument16 pagesTesting Procedure For Ball Valve MAPbasuki100% (3)

- Bae72 S eDocument1 pageBae72 S eKumar sssssNo ratings yet

- Notes Class 1Document9 pagesNotes Class 1Mahir MahmoodNo ratings yet

- E 50B 4KG1 - Fire PDFDocument2 pagesE 50B 4KG1 - Fire PDFPatricia J Ángeles100% (1)

- 1.layout and Design: Hot Runner GuideDocument22 pages1.layout and Design: Hot Runner Guideاحمد حمديNo ratings yet

- MECHANICAL SCHEMATICS - H&C B70 V6-Base 71Document1 pageMECHANICAL SCHEMATICS - H&C B70 V6-Base 71Slobodan HristovNo ratings yet

- SB 221Document9 pagesSB 221Siva PrasadNo ratings yet

- API 608 Floating Ball ValvesDocument2 pagesAPI 608 Floating Ball Valvesjkhgvdj mnhsnjkhgNo ratings yet

- Instrumentation, Measurements, and Experiments in FluidsDocument13 pagesInstrumentation, Measurements, and Experiments in FluidsKishore KumarNo ratings yet

- K2 Lab ReportDocument10 pagesK2 Lab ReportNorRizan AbuOsman100% (1)

- Substrate: QV3 Mechanical Fastening System Using T-Rails K20Document17 pagesSubstrate: QV3 Mechanical Fastening System Using T-Rails K20tudorica37No ratings yet

- FALK Fallas en Engranajes, Ejes2Document7 pagesFALK Fallas en Engranajes, Ejes2Adriano AdrianoNo ratings yet

- Accessories ListDocument10 pagesAccessories ListShashank HegdeNo ratings yet

- Bill of Quantity: NO Uraian Pekerjaan Sat Volume Jumlah (RP) Harga Satuan (RP)Document2 pagesBill of Quantity: NO Uraian Pekerjaan Sat Volume Jumlah (RP) Harga Satuan (RP)KrisantoNo ratings yet