Professional Documents

Culture Documents

Drum Roller: Mobile Plant Prestart Checklist

Uploaded by

fdfddf dfsdfOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drum Roller: Mobile Plant Prestart Checklist

Uploaded by

fdfddf dfsdfCopyright:

Available Formats

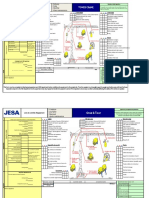

Mobile Plant DRUM ROLLER Form:

Issue No.: 1

Prestart Checklist Date:

Statement of Operator Competence - Required

Supplier Verification & Plant Details Verify CAB Verify Check WARNING DEVICES

Check Cleanliness Horn

Plant Owner: Seat Condition OK Reversing Alarm

Operator Restraint Provided

Address: WARNING SIGNS (In Cabin)

Instruments Operational & Labelled Verify Check

City/Suburb: Levers / Controls Operational SEAT BELTS MUST BE WORN

Pedals in Good Condition Verify Check

Phone: Windows / Wipers / Washers

DANGER – SAFE WORKING LIMITS ON BATTERS

Rear View Mirrors

Plant Make: Operator Instruction Ratio 4 to 1

(available on plant) Eg only – As per Manufacturers Specifications

Plant Model:

Verify Check

Serial No.: Locating lock for Verify Check

Low/Neutral/Lower Range

Exhaust

Signature: Pad lock provided

Date: Warning sign – Hasp must be

locked in position before

operating Verify Check

Engine Guarding

Plant to conform to manufacturer’s specifications and RoK Plant

Regs.

Plant Operator is to provide daily checksheets to plant group on a

weekly basis Verify Check

Where applicable, Personal Protective Equipment must be worn.

Plant Log Book Detailing service history in accordance with Tyres

Manufacturer’s specifications should be written legibly in

English. Wheels

Contractor must produce proof of competence of operator, e.g., Brakes

Certificate of Competence, Licence, Detailed Log Book

Park Brake

Verify Check

Verify Check Hydraulics Crush Point Hazard Verify Check

NOTE: Sign only when all items have been checked Sign displayed both

Hoses sides Handrails

Plant Check By: Connections Steps

(check for excessive wear,

Position:

leaks and creep)

Instructions:

Date: / / Verify Box to be ticked by Owner / Supplier / Operator prior to arrival onsite.

Check Box to be ticked after visual inspection by HSE Department

This is to certify that the plant being supplied conforms to the relevant RoK OH&S Legislation, and the requirements as detailed above. HSE Dept will assess this Pre-start Checklist to ensure the supplier has verified compliance to Legislative requirements and, to

register the plant onto the site. The operator will be required to participate in ongoing training and perform work in accordance with the relevant Work Method Statement. Should the plant be found to not conform to the above, then it will be prevented from

commencing work on the site until the non-compliance is rectified. Management will not reimburse the Owner / Supplier / Contractor for any down / lost time so caused from the non-conformance.

This form does not remove any liability for the plant supplier to conform with the relevant RoK OH&S Legislation

You might also like

- Loader: Mobile Plant Prestart ChecklistDocument1 pageLoader: Mobile Plant Prestart Checklistfdfddf dfsdfNo ratings yet

- 05 INSP 0005 DrumRoller CheckDocument1 page05 INSP 0005 DrumRoller CheckBarock NaturelNo ratings yet

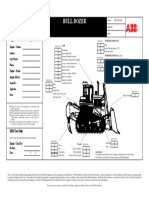

- 04 INSP 0004 BullDozer CheckDocument1 page04 INSP 0004 BullDozer CheckBarock NaturelNo ratings yet

- Mobile Plant Checklist - ForkliftDocument1 pageMobile Plant Checklist - Forkliftosama F. MohamedNo ratings yet

- Qusahwira Field Development Phase Ii Project Project No. 14395 Forklift ChecklistDocument1 pageQusahwira Field Development Phase Ii Project Project No. 14395 Forklift ChecklistJayaprakasan Koyadan KorothNo ratings yet

- Backhoe: Mobile Plant Prestart ChecklistDocument1 pageBackhoe: Mobile Plant Prestart Checklistfdfddf dfsdfNo ratings yet

- Compactor CheckDocument1 pageCompactor CheckABDERRAHMANE SILKANNo ratings yet

- Mobile Plant Checklist - Drum RollerDocument1 pageMobile Plant Checklist - Drum Rollerosama F. MohamedNo ratings yet

- Heavy Equipment Inspection Checklist TürkçeDocument18 pagesHeavy Equipment Inspection Checklist TürkçeErdal Margarito Karpuz100% (2)

- 09 INSP 0009 Forklift CheckDocument1 page09 INSP 0009 Forklift CheckBarock NaturelNo ratings yet

- 03 INSP 0003 Compactor CheckDocument1 page03 INSP 0003 Compactor CheckBarock NaturelNo ratings yet

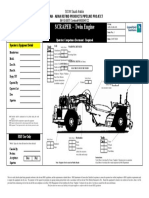

- 16 INSP 0016 One Engine Scraper CheckDocument1 page16 INSP 0016 One Engine Scraper CheckBarock NaturelNo ratings yet

- Truck and TrailerDocument1 pageTruck and TrailerAviects Avie JaroNo ratings yet

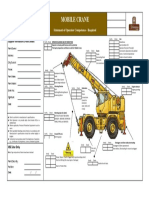

- 8 - Mobile Plant Checklist - Mobile CraneDocument1 page8 - Mobile Plant Checklist - Mobile Craneahmed draiNo ratings yet

- Forklift: Equipment Prestart ChecklistDocument1 pageForklift: Equipment Prestart ChecklistWalyd BmdhNo ratings yet

- 13 INSP 0013 MultiWheel Roller CheckDocument1 page13 INSP 0013 MultiWheel Roller CheckBarock NaturelNo ratings yet

- 02 INSP 0002 BackHoe Check - ListeDocument1 page02 INSP 0002 BackHoe Check - ListeBarock NaturelNo ratings yet

- Heavy Equipment ChecklistDocument18 pagesHeavy Equipment Checklistfullbar9No ratings yet

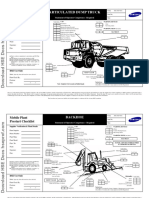

- 01 INSP 0001 Articulated DTruck CheckDocument1 page01 INSP 0001 Articulated DTruck CheckBarock NaturelNo ratings yet

- JAPL-F-HE-019 Scraper CheckDocument1 pageJAPL-F-HE-019 Scraper CheckAli HassanNo ratings yet

- 07 INSP 0007 Scissor Lift CheckDocument1 page07 INSP 0007 Scissor Lift CheckBarock NaturelNo ratings yet

- Mobile Plant ChecklistDocument2 pagesMobile Plant Checklistosama F. MohamedNo ratings yet

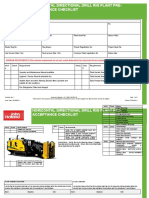

- Horizontal Directional Drill Rig Plant Pre-Acceptance ChecklistDocument2 pagesHorizontal Directional Drill Rig Plant Pre-Acceptance ChecklistEdiPrawiraSimanjuntakNo ratings yet

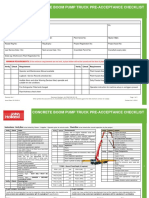

- JH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistFeroz Gull100% (1)

- JH FRM Pae 001 06 Dozer Plant Pre Acceptance ChecklistDocument3 pagesJH FRM Pae 001 06 Dozer Plant Pre Acceptance ChecklistYoung Lin SaengNo ratings yet

- Boom Placer ChecklistDocument3 pagesBoom Placer ChecklistAlves Edattukaran100% (3)

- Concrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistDocument2 pagesConcrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistTFattahNo ratings yet

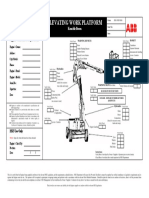

- 06 INSP 0006 Elevating Platform CheckDocument1 page06 INSP 0006 Elevating Platform CheckBarock NaturelNo ratings yet

- JAPL-F-HE-007-Concrete Pump ChecklistDocument1 pageJAPL-F-HE-007-Concrete Pump ChecklistFarrukh IjazNo ratings yet

- JAPL-F-HE-007-Concrete Pump ChecklistDocument1 pageJAPL-F-HE-007-Concrete Pump ChecklistAli HassanNo ratings yet

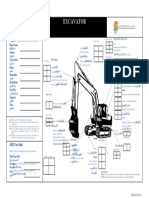

- Mobile Plant Checklist - ExcavatorDocument1 pageMobile Plant Checklist - Excavatorosama F. Mohamed100% (1)

- Piling Rig Plant Pre-Acceptance ChecklisDocument3 pagesPiling Rig Plant Pre-Acceptance Checklisosama F. MohamedNo ratings yet

- JH FRM Pae 001 15 Drum Roller Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 15 Drum Roller Plant Pre Acceptance ChecklistStansilous Tatenda NyagomoNo ratings yet

- Jumbo Drilling Rig Plant Pre Acceptance ChecklistDocument3 pagesJumbo Drilling Rig Plant Pre Acceptance ChecklistRubén López LemaNo ratings yet

- Concrete Boom Pump Truck Pre-Acceptance Checklist: Plant DetailsDocument2 pagesConcrete Boom Pump Truck Pre-Acceptance Checklist: Plant DetailsBassam HSENo ratings yet

- JH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistAnwar DeenNo ratings yet

- Drill Rig Plant Pre Acceptance ChecklistDocument2 pagesDrill Rig Plant Pre Acceptance ChecklistRubén López Lema100% (1)

- Process Audit Check SheetDocument5 pagesProcess Audit Check SheetaliNo ratings yet

- Pre-Commissioning Check Sheet: InstrumentsDocument1 pagePre-Commissioning Check Sheet: InstrumentshrimklimNo ratings yet

- Phalaborwa - ZBS Upgrade ProjectDocument3 pagesPhalaborwa - ZBS Upgrade Projectcontrax8No ratings yet

- Concrete Truck Plant Pre-Acceptance ChecklistDocument3 pagesConcrete Truck Plant Pre-Acceptance ChecklistMohamed El NasharNo ratings yet

- Plan de Surveillance ExempleDocument2 pagesPlan de Surveillance ExempleAudrey GavaletNo ratings yet

- 7 - HSE-SOP-007 Radiography Permit FormDocument2 pages7 - HSE-SOP-007 Radiography Permit FormEngr. Muhammad Hassan AzizNo ratings yet

- Phalaborwa - ZBS Upgrade Project S&D ConsortiumDocument2 pagesPhalaborwa - ZBS Upgrade Project S&D Consortiumcontrax8No ratings yet

- Check List Grue A Tour Tower CraneDocument3 pagesCheck List Grue A Tour Tower Cranemed sarhanNo ratings yet

- Checklist ExcavatorDocument2 pagesChecklist ExcavatorMahar Dika100% (1)

- SMT Generic Control PlanDocument2 pagesSMT Generic Control Plansmtdrkd81% (21)

- Control PlanDocument4 pagesControl PlanJosué PérezNo ratings yet

- Cmivates Yan Spot: A Rams, Pas Al KhaimadDocument2 pagesCmivates Yan Spot: A Rams, Pas Al KhaimadBKONo ratings yet

- Jsa Heat Exchanger Inspection Water Cleaning 2Document5 pagesJsa Heat Exchanger Inspection Water Cleaning 2halfy safitri100% (2)

- Inspection Check List For Installation of FcuDocument2 pagesInspection Check List For Installation of FcuRAJANo ratings yet

- Inspection Check List For Installation of FahuDocument2 pagesInspection Check List For Installation of FahuRAJANo ratings yet

- Checkliste Abwhebeanl Schachtanl Version 1.0 0113 en Fillable - Mary-AnneDocument2 pagesCheckliste Abwhebeanl Schachtanl Version 1.0 0113 en Fillable - Mary-AnneMauricio OrtizNo ratings yet

- Phalaborwa - ZBS Upgrade ProjectDocument2 pagesPhalaborwa - ZBS Upgrade Projectcontrax8No ratings yet

- JSA For BM - To Dry Up at Site, Remove Motor To Workshop For Repair, Re-Install & Perform Run Test-CRMDocument10 pagesJSA For BM - To Dry Up at Site, Remove Motor To Workshop For Repair, Re-Install & Perform Run Test-CRMChung TrịnhNo ratings yet

- Engine Room Pre-Vetting: SR - No Part /equipment Checks Done Yes/ NoDocument10 pagesEngine Room Pre-Vetting: SR - No Part /equipment Checks Done Yes/ Noharry vatsaNo ratings yet

- Field Service Report: Trip Dispatch Arrival at Jobsite Travel Hour Mileage Date Time Date Time 1 2 3Document2 pagesField Service Report: Trip Dispatch Arrival at Jobsite Travel Hour Mileage Date Time Date Time 1 2 3Henny Komala Sari SibaraniNo ratings yet

- Check List de Inspeccion de Taladro - S&G 00001 - 2021Document1 pageCheck List de Inspeccion de Taladro - S&G 00001 - 2021javierNo ratings yet

- HSE FRM-32 Accident Investigation ReportDocument1 pageHSE FRM-32 Accident Investigation Reportfdfddf dfsdfNo ratings yet

- Material Safety Data Sheet: Barium Sulfate MSDSDocument7 pagesMaterial Safety Data Sheet: Barium Sulfate MSDSfdfddf dfsdfNo ratings yet

- Key Responsibilities & AuthoritiesDocument1 pageKey Responsibilities & Authoritiesfdfddf dfsdfNo ratings yet

- Key Responsibilities & AuthoritiesDocument1 pageKey Responsibilities & Authoritiesfdfddf dfsdfNo ratings yet

- TC03 - Maraba AL-Iraq AL-Kadhraa CoDocument2 pagesTC03 - Maraba AL-Iraq AL-Kadhraa Cofdfddf dfsdfNo ratings yet

- Preventive Maintenance and Inspections PolicyDocument4 pagesPreventive Maintenance and Inspections Policyfdfddf dfsdfNo ratings yet

- Key Responsibilities & AuthoritiesDocument1 pageKey Responsibilities & Authoritiesfdfddf dfsdfNo ratings yet

- Elija Andjelich LUKOIL PetrochemicalDocument15 pagesElija Andjelich LUKOIL Petrochemicalfdfddf dfsdfNo ratings yet

- Job Safety Analysis: Manual ExcavationDocument2 pagesJob Safety Analysis: Manual Excavationfdfddf dfsdfNo ratings yet

- Preventive Maintenance and Inspections PolicyDocument4 pagesPreventive Maintenance and Inspections Policyfdfddf dfsdfNo ratings yet

- Audit Procedure and PolicyDocument1 pageAudit Procedure and Policyfdfddf dfsdfNo ratings yet

- MIK-QHSE-ML-001 IMS Manual (00000002)Document48 pagesMIK-QHSE-ML-001 IMS Manual (00000002)fdfddf dfsdfNo ratings yet

- Jsa For TIE INS in Accommodation BlockDocument4 pagesJsa For TIE INS in Accommodation BlockAliNo ratings yet

- Maraba Al Iraq Al Khadraa: Emergency Drill ReportDocument3 pagesMaraba Al Iraq Al Khadraa: Emergency Drill Reportfdfddf dfsdfNo ratings yet

- Backhoe: Mobile Plant Prestart ChecklistDocument1 pageBackhoe: Mobile Plant Prestart Checklistfdfddf dfsdfNo ratings yet

- List of Fire Fighting TeamDocument1 pageList of Fire Fighting Teamfdfddf dfsdfNo ratings yet

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Document4 pages0017 JS A Hot Job (Welding, Grinding & Cutting)midozotyNo ratings yet

- Health, Safety and EnvironmentDocument8 pagesHealth, Safety and Environmentfdfddf dfsdfNo ratings yet

- List of Emergency EquipmentsDocument3 pagesList of Emergency Equipmentsfdfddf dfsdfNo ratings yet

- ALJ-HSEM-01 HSE Manual-Procedure Safe Work PracticesDocument27 pagesALJ-HSEM-01 HSE Manual-Procedure Safe Work Practicesfdfddf dfsdfNo ratings yet

- Integrated Management System Manual in Compliance With Iso 9001-2015 - 14001-2015 - Ohsas 18001-2007Document44 pagesIntegrated Management System Manual in Compliance With Iso 9001-2015 - 14001-2015 - Ohsas 18001-2007fdfddf dfsdfNo ratings yet

- Integrated Management System Manual in Compliance With Iso 9001-2015 - 14001-2015 - Ohsas 18001-2007Document44 pagesIntegrated Management System Manual in Compliance With Iso 9001-2015 - 14001-2015 - Ohsas 18001-2007fdfddf dfsdfNo ratings yet

- OP-10Procedure For Incident Accident Reporting Investigation & AnalysisDocument9 pagesOP-10Procedure For Incident Accident Reporting Investigation & Analysisfdfddf dfsdfNo ratings yet

- JOB DESCRIPTION MANUAL Rev.2Document27 pagesJOB DESCRIPTION MANUAL Rev.2fdfddf dfsdfNo ratings yet

- ALJ-HSEM-01 HSE Manual-Procedure Safe Work PracticesDocument27 pagesALJ-HSEM-01 HSE Manual-Procedure Safe Work Practicesfdfddf dfsdfNo ratings yet

- 21-Health, Safety & Environment PolicyDocument1 page21-Health, Safety & Environment Policyfdfddf dfsdfNo ratings yet

- Questionnaire FinishedDocument6 pagesQuestionnaire FinishedTamarah PaulaNo ratings yet

- Sree Buddha College of Engineering, Pattoor: 08.607 Microcontroller Lab (TA) Lab ManualDocument103 pagesSree Buddha College of Engineering, Pattoor: 08.607 Microcontroller Lab (TA) Lab ManualAr UNNo ratings yet

- Oras Maišytuvai Kainynas 2021, UAB AnagaDocument35 pagesOras Maišytuvai Kainynas 2021, UAB AnagaMarius ImbrusNo ratings yet

- Lp-s070 User Manual AutonicsDocument175 pagesLp-s070 User Manual AutonicsPatricio DavidNo ratings yet

- Honeywell Sensor LlamaDocument8 pagesHoneywell Sensor Llamarobin castañoNo ratings yet

- 4 Run Life OpsDocument29 pages4 Run Life Opshatem_eldawyNo ratings yet

- E7 TiempoDocument12 pagesE7 TiempoJonatan Arango Gomez67% (3)

- S400-User Manual EN - Set-1340243890Document15 pagesS400-User Manual EN - Set-1340243890noriel llanetaNo ratings yet

- Cerberus Pyrotronics Strobes 2 4952870316 2Document2 pagesCerberus Pyrotronics Strobes 2 4952870316 2Rafael DantasNo ratings yet

- SpellmanDocument204 pagesSpellmanSebastian Cruz CNo ratings yet

- Data Sheet: SMPS630-GDocument11 pagesData Sheet: SMPS630-GXuân TrườngNo ratings yet

- Precision L S A: EAD Crew SsembliesDocument15 pagesPrecision L S A: EAD Crew SsembliesramiresSNo ratings yet

- Ecolink Flood FL007 150 200wDocument5 pagesEcolink Flood FL007 150 200wMohammad WildhanNo ratings yet

- LG 42PQ30 Block DiagramDocument2 pagesLG 42PQ30 Block DiagrammakotoNo ratings yet

- Fraunhofer HSF Report Presentation 2018Document15 pagesFraunhofer HSF Report Presentation 2018Taso GegiaNo ratings yet

- Speller Effect Sign DisplayDocument1 pageSpeller Effect Sign Displayshrankruk4364No ratings yet

- User Manual: PF0.9 1K/1.5K/2K/3K Online UPSDocument19 pagesUser Manual: PF0.9 1K/1.5K/2K/3K Online UPSDuvan VacaNo ratings yet

- 10 Wiring Diagram 08 F.700PDocument222 pages10 Wiring Diagram 08 F.700PQui Ngô Xuân100% (2)

- 6000!CCO - 6000 COO - Manual Instalare Si Fisa TehnicaDocument2 pages6000!CCO - 6000 COO - Manual Instalare Si Fisa TehnicaMohamed Abdel MageedNo ratings yet

- EMERSON - Fisher - Data Sheets-627-Series-Pressure-Reducing-RegulatorsDocument38 pagesEMERSON - Fisher - Data Sheets-627-Series-Pressure-Reducing-RegulatorsFrancoNo ratings yet

- Spek ETS 2017-HighDocument1 pageSpek ETS 2017-HighValentino Budi PratamaNo ratings yet

- Automation and Controls - Nick DawkinsDocument56 pagesAutomation and Controls - Nick DawkinsRiky Fitriadi100% (1)

- "2005" Seminar Information: Jeep With 2.5 or 4.0 Liter Engines & Aw4 TransmissionDocument2 pages"2005" Seminar Information: Jeep With 2.5 or 4.0 Liter Engines & Aw4 TransmissionRoman NavaNo ratings yet

- Rf-7800r-Rc Universal Remote Control System Tcm26-12078Document2 pagesRf-7800r-Rc Universal Remote Control System Tcm26-12078Lavanda Focsani50% (2)

- Lecture 24 Hydr Valves 1Document23 pagesLecture 24 Hydr Valves 1cheikh ahmedNo ratings yet

- Asus Eee PC P901 R1 3G Free Laptop SchematicDocument50 pagesAsus Eee PC P901 R1 3G Free Laptop SchematicLmd O Génio NazarovNo ratings yet

- CVTT Series: Belt Driven Cabinet FansDocument7 pagesCVTT Series: Belt Driven Cabinet Fansbasheer9No ratings yet

- GPL 12260Document2 pagesGPL 12260cozocNo ratings yet

- Fireclap & Feederclap: Positive Safety Swing Check ValvesDocument12 pagesFireclap & Feederclap: Positive Safety Swing Check ValveslutNo ratings yet

- Isuzu D Max Owners Manual Combined 17myDocument698 pagesIsuzu D Max Owners Manual Combined 17myMauricio GonzalezNo ratings yet