Professional Documents

Culture Documents

72-42-00 - (CFMB) - Combustion Chamber Assembly

Uploaded by

kien Duy PhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

72-42-00 - (CFMB) - Combustion Chamber Assembly

Uploaded by

kien Duy PhanCopyright:

Available Formats

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

72-42-00 PB 001 CONF 06 - COMBUSTION CHAMBER

ASSEMBLY - DESCRIPTION AND OPERATION

1. General

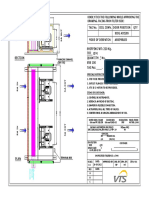

(Ref. Fig. Combustion Chamber SHEET 1)

Print Date: October 05, 2021 Page 1 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

B

COWL

A CONFIGURATIONS

A

DAMPER

WIRE

OUTER OUTER

LINER COWL

BRAZED

INNER

COWL

B

INNER

SUPPORT

FLANGE

INNER

LINER

INNER

COWL

DAMPER

WIRE

INNER AND

OUTER COWLS

OUTER

COWL

IGNITER FERRULE

(2 LOCATIONS)

GMM-1086061-00-B

N_MM_724200_0_RAM0_01_00

Figure 72(CFMB)-42-00-13500-06-A / SHEET 1/1 - Combustion Chamber

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 2 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

(Ref. Fig. Combustion Chamber Section SHEET 1)

Print Date: October 05, 2021 Page 3 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

IGNITER

FERRULE

FUEL NOZZLE

A

PRIMARY INNER

SWIRLER SUPPORT

A

COWL

CONFIGURATIONS

DAMPER WIRE OUTER DAMPER WIRE OUTER

COWL AND BRAZED AND INNER COWLS

INNER COWL

GMM-1086060-00-B

N_MM_724200_0_RBM0_01_00

Figure 72(CFMB)-42-00-13600-06-A / SHEET 1/1 - Combustion Chamber Section

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 4 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

The combustion case contains the combustion chamber, which is a short, annular structure. The combustion

chamber consists of outer and inner cowls, 20 primary swirl nozzles, dome, and outer and inner liners. The

liners and cowls are bolted to the dome.

The function of the combustion chamber is to supply a uniform combustion pattern for low thermal stress.

The staged burning valve, controlled by FADEC, adapts the function of the combustion chamber to the engine

requirements by the use of either 10 or 20 open fuel nozzles.

2. Description

(Ref. Fig. Combustion Chamber SHEET 1)

(Ref. Fig. Combustion Chamber Section SHEET 1)

A. Dome

The dome consists of both cast and machined components. Twenty primary swirl nozzles and 20 secondary

swirl nozzles with venturies and sleeves are used to provide mixing of air and fuel. The entire surface of the

dome is cooled by a film of cooling air.

B. Cowl

The inner and outer cowls are designed to provide uniform and stable airflow profiles to the combustion

chamber.

C. Liners

The outer and inner liners are of an integral design with panel overhangs which contain closely spaced

cooling holes that provide film cooling.

Dilution holes are employed in the liners to provide additional mixing and cooling air which lowers the gas

temperature at the turbine inlet. The outer liner contains 2 ferrules for the spark igniters.

Figure 72(CFMB)-42-00-13500-06-A / SHEET 1/1 - Combustion Chamber

Figure 72(CFMB)-42-00-13600-06-A / SHEET 1/1 - Combustion Chamber Section

72-42-00 PB 601 CONF 06 - COMBUSTION CHAMBER ASSEMBLY - INSPECTION/CHECK

TASK 72-42-00-290-041-A

Borescope Inspection of the Combustion Chamber Liners and Dome Area (SAC engine)

WARNING: BE CAREFUL WHEN YOU DO WORK ON THE ENGINE PARTS AFTER THE ENGINE SHUT-

DOWN. USE APPLICABLE THERMAL GLOVES. THE ENGINE PARTS CAN STAY HOT FOR

ONE HOUR AFTER SHUTDOWN AND CAN BURN YOU.

FIN : 1000EM1 , 1000EM2

1. Reason for the Job

This TASK is applicable for NON/P, /P, /3 and /3 PIP engines equipped with a Single Annular Combustor

chamber.

NOTE: Inspection of the combustion chamber is limited to the areas that can be seen with a rigid borescope,

at the 1, 3, 6 and 10 o'clock borescope ports, and at the 2 spark igniter ports. The borescope ports at

the 1, 3, 6, and 10 o'clock positions are located immediately in front of the fuel manifold. These ports

and the 2 spark igniter ports permit the borescope inspection of the combustion chamber and the HPT

nozzle.

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific AR ACCESS PLATFORM 1M(3 FT)

No specific AR CAP - PROTECTION

No specific AR WARNING NOTICE(S)

Print Date: October 05, 2021 Page 5 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

REFERENCE QTY DESIGNATION

No specific Torque wrench: range to between 57 and 63 lbf.in

(0.64 and 0.71 m.daN)

No specific Torque wrench: range to between 120 and 135 lbf.in

(1.36 and 1.53 m.daN)

(856A1320) 1 BORESCOPE-KIT

(856A1322) 1 BORESCOPE-LIGHT SOURCE SET

(856A1323) 1 MONITOR, RESOLUTION BORESCOPE

B. Consumable Materials

REFERENCE DESIGNATION

(Material No. CP1064) milk of magnesia

(Material No. CP2101) graphite grease

(Material No. CP2619) Never Seez-Pure Nickel, Special

(Material No. CP8001) lockwire 0.032 in. (0.8 mm) dia.

C. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

400 POWER PLANT, NACELLES AND PYLONS

FOR 1000EM1 (ENGINE-1)

437AL, 438AR, 451AL, 452AR

FOR 1000EM2 (ENGINE-2)

447AL, 448AR, 461AL, 462AR

D. Referenced Information

REFERENCE DESIGNATION

(Ref. 71-13-00-010-040-B). Opening of the Fan Cowl Doors

(Ref. 71-13-00-410-040-B). Closing of the Fan Cowl Doors

(Ref. 72-00-00-200-025-A). Over-Serviceable-Limit Extensions

(Ref. 72-00-00-200-025-A-01). Over-Serviceable-Limit Extensions

(Ref. 72-42-00-290-006-A). Borescope Inspection of the Outer Side of the Combustion Chamber

Outer Liners (SAC engine)

(Ref. 72-42-00-290-006-A-01). Borescope Inspection of the Outer Side of the Combustion Chamber

Outer Liners (DAC engine)

(Ref. 73-11-40-790-002-A). Leak Check of the Fuel Nozzles for SAC Engines

(Ref. 73-11-40-790-002-A-01). Leak Check of the Fuel Nozzles for DAC Engines

(Ref. 74-21-30-000-002-A). Removal of the Spark Igniter

(Ref. 74-21-30-400-002-A). Installation of the Spark Igniter

(Ref. 78-30-00-081-041-B). Make the Thrust Reverser Serviceable after Maintenance

(Ref. 78-30-00-481-041-B). Make the Thrust Reverser Unserviceable for Maintenance

(Ref. 78-36-00-010-040-B). Opening of the Thrust Reverser Doors

(Ref. 78-36-00-410-040-B). Closing of the Thrust Reverser Doors

Ref. NTM 720000

Combustion Chamber (Inner and Outer Liner Inspection)

Combustion Chamber (Sectional View)

Cracks and Missing Material in Dome Area

Outer Liner (Inner)

Print Date: October 05, 2021 Page 6 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

REFERENCE DESIGNATION

Inner Liner (Inner)

Print Date: October 05, 2021 Page 7 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

A

OUTER

LINER

INNER SUPPORT

FLANGE

INNER INNER

COWL LINER

OUTER

COWL

IGNITER FERRULE

(2 LOCATIONS)

NOTE: FOR NON/P AND /P ENGINES MODELS.

GMM-1119240-00-B

N_MM_724200_6_RAM0_01_00

Figure 72(CFMB)-42-00-991-30100-06-A / SHEET 1/

2 - Combustion Chamber (Inner and Outer Liner Inspection)

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 8 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

A OUTER

LINER

INNER SUPPORT

FLANGE

INNER INNER

COWL LINER

OUTER

COWL

IGNITER FERRULE

(2 LOCATIONS)

NOTE: FOR /3 ENGINES MODELS. 1256210-00

COMMERCIAL

N_MM_724200_6_RAM0_02_00

Figure 72(CFMB)-42-00-991-30100-06-A / SHEET 2/

2 - Combustion Chamber (Inner and Outer Liner Inspection)

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 9 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

RIB 6

D RIB 5

RIB 1 RIB 4

RIB 3

OUTER LINER

RIB 2

PANEL 5

PANEL 4

SPECTACLE PLATE

PANEL 3

PANEL 2

E PANEL 4

SECONDARY PANEL 1

SWIRL NOZZLE F PANEL 3

DOME BAND

C

PANEL 2

SLEEVE

PANEL 1

PRIMARY

SWIRL DOME BAND

NOZZLE

INNER LINER

DEFLECTOR

NOTE: FOR NON/P AND /P ENGINES MODELS.

GMM-1119241-00-B

N_MM_724200_6_RBM0_01_00

Figure 72(CFMB)-42-00-991-30200-06-A / SHEET 1/2 - Combustion Chamber (Sectional View)

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 10 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

RIB 6

D RIB 5

RIB 1 RIB 4

RIB 3

OUTER LINER

RIB 2

PANEL 5

PANEL 4

SPECTACLE PLATE

PANEL 3

PANEL 2

E PANEL 4

SECONDARY PANEL 1

SWIRL NOZZLE F PANEL 3

DOME BAND

C

PANEL 2

SLEEVE

PANEL 1

PRIMARY

SWIRL DOME BAND

NOZZLE

INNER LINER

DEFLECTOR

NOTE: FOR /3 ENGINES MODELS ONLY.

GMM-1119242-00-A

N_MM_724200_6_RBM0_02_00

Figure 72(CFMB)-42-00-991-30200-06-A / SHEET 2/2 - Combustion Chamber (Sectional View)

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 11 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

MISSING MATERIAL

MISSING BETWEEN THE

MATERIAL CRACKS

(EXAMPLE) (EXAMPLE)

SPECTACLE

PLATE

SLEEVE

G

H J

SECONDARY

SWIRL

NOZZLE

0.05 INCH (1.3mm) DEFLECTOR BURN THROUGH

DIAMETER COOLING HOLE (EXAMPLE)

HOLE (REF)

6011586-00

N_MM_724200_6_RCM0_01_01

Figure 72(CFMB)-42-00-991-30300-06-A / SHEET 1/3 - Cracks and Missing Material in Dome Area

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 12 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

CRACKS AND

MISSING MATERIAL

IN DOME AREA

6011587-00

N_MM_724200_6_RCM0_02_01

Figure 72(CFMB)-42-00-991-30300-06-A / SHEET 2/3 - Cracks and Missing Material in Dome Area

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 13 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

H

SAMPLE REGION WITH 15

EXPOSED COOLING HOLES

QUADRANT 4 QUADRANT 1

QUADRANT 3 QUADRANT 2

DEFLECTOR

EDGE

DOME QUADRANT DEFINITION

(AFT LOOKING FORWARD)

J

SAMPLE EXPOSED COOLING HOLES

QUADRANT 4 QUADRANT 1

ALF

QUADRANT 2

QUADRANT 3

DEFLECTOR

EDGE

OR

QUADRANT 4 ALF QUADRANT 1

QUADRANT 2

QUADRANT 3

DEFLECTOR

EDGE

6011588-00

N_MM_724200_6_RCM0_03_00

Figure 72(CFMB)-42-00-991-30300-06-A / SHEET 3/3 - Cracks and Missing Material in Dome Area

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 14 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

5 PANELS AND DILUTION

HOLES (MISSING MATERIALS)

4 PANELS AND DILUTION HOLE

MAXIMUM PERMITTED

AXIAL CRACKS

MAXIMUM PERMITTED

AXIAL CRACKS

MAXIMUM PERMITTED

AXIAL CRACKS

BURN THROUGH AND

MISSING MATERIAL

6 PANELS CRACKED

BURN THROUGH HOLE-

DAMAGE SIZE DOES NOT

INCLUDE DILUTION HOLE

MISSING

OVERHANG

NOTE: FOR NON/P AND/P

ENGINE MODELS.

DOME PANEL 1 PANEL 3

BAND PANEL 2 PANEL 4 PANEL 5

E

TYPICAL CRACKS AND MISSING MATERIAL

5058004-00

N_MM_724200_6_REM0_01_01

Figure 72(CFMB)-42-00-991-30500-06-A / SHEET 1/2 - Outer Liner (Inner)

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 15 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

D

TYPICAL CRACKS ACROSS RIBS

RIB1 RIB2 RIB3 RIB4 RIB5 RIB6

RIBS 2, 3, 6

CRACKED

RIBS 2, 3, 5

CRACKED

RIBS 5 AND 6

CRACKED

RIBS 2, 3, 4

CRACKED

NO RIBS

CRACKED

DOME BAND PANEL 2 PANEL 4

PANEL PANEL 1 PANEL 3 PANEL 5

NOTE: FOR /3 ENGINES MODELS. 1256213-00

COMMERCIAL

N_MM_724200_6_REM0_02_00

Figure 72(CFMB)-42-00-991-30500-06-A / SHEET 2/2 - Outer Liner (Inner)

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 16 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

F

TYPICAL CRACKS ACROSS PANELS

3 PANELS AND

DILUTION HOLE CRACK

4 PANELS AND

DILUTION HOLE CRACK

4 PANELS, DILUTION HOLE,

AND CIRCUMFERENTIAL CRACK

3 PANELS, DILUTION HOLE,

AND CIRCUMFERENTIAL CRACK

4 PANELS AND

CIRCUMFERENTIAL CRACK

DOME BAND PANEL 1 PANEL 2 PANEL 3 PANEL 4

PANEL

NOTE: FOR NON/P AND /P ENGINES MODELS.

GMM-1089429-01-B

N_MM_724200_6_RFM0_01_00

Figure 72(CFMB)-42-00-991-30600-06-A / SHEET 1/2 - Inner Liner (Inner)

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 17 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

MAX ALLOWABLE

AXIAL CRACKS

TYPICAL

CONNECTED

CRACKS

DILUTION

HOLES

BURN

THROUGH

HOLE

BURN THROUGH

HOLE-DAMAGE

SIZE DOES NOT

INCLUDE DILUTION

HOLE

DOME PANEL 1 PANEL 2 PANEL 3 PANEL 4

BAND

NOTE: FOR/3 ENGINE MODELS.

5058003-00

N_MM_724200_6_RFM0_02_01

Figure 72(CFMB)-42-00-991-30600-06-A / SHEET 2/2 - Inner Liner (Inner)

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 18 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

3. Job Set-up

Subtask 72-42-00-941-053-A

A. Safety Precautions

(1) On the center pedestal, on the ENG panel 115VU:

(a) Put a WARNING NOTICE(S) to tell persons not to start the engine.

(2) Make sure that the engine 1(2) shutdown occurred not less than 5 minutes before you do this

procedure.

(3) On the overhead maintenance panel 50VU:

(a) Make sure that the ON legend of the ENG/FADEC GND PWR/1(2) pushbutton switch is off.

(b) Put a WARNING NOTICE(S) to tell persons not to energize the FADEC 1(2).

Subtask 72-42-00-010-058-A

B. Get Access

(1) Open the fan cowl doors: (Ref. AMM TASK 71-13-00-010-040)

(2) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

(3) FOR 1000EM2 (ENGINE-2)

447AL, 448AR.

(4) Put the ACCESS PLATFORM 1M(3 FT) in position.

Subtask 72-42-00-040-053-A

C. Make the thrust reverser unserviceable for maintenance (Ref. AMM TASK 78-30-00-481-041)

Subtask 72-42-00-010-059-A

D. Open the thrust reverser doors: (Ref. AMM TASK 78-36-00-010-040)

(1) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(2) FOR 1000EM2 (ENGINE-2)

461AL, 462AR.

4. Procedure

(Ref. Fig. Combustion Chamber (Inner and Outer Liner Inspection)) (Ref. Fig. Combustion Chamber (Sectional

View)) (Ref. Fig. Cracks and Missing Material in Dome Area) (Ref. Fig. Outer Liner (Inner)) (Ref. Fig. Inner

Liner (Inner))

Subtask 72-42-00-010-060-A

A. Remove parts before borescope inspection.

(1) Remove the borescope plugs from the approximate 3 and 10 o'clock positions on the combustion

case.

Subtask 72-42-00-290-054-A

B. Do a Borescope Inspection

(1) Use the MONITOR, RESOLUTION BORESCOPE (856A1323) (856A1323G01) to make sure

the borescope and the light source are serviceable. See the Non-Destructive Test Manual for this

procedure Ref. NTM 720000.

(2) Connect the fiber light cable to the BORESCOPE-KIT (856A1320) (856A1320P04/P05) and to the

port on the BORESCOPE-LIGHT SOURCE SET (856A1322) (856A1322P03/P04/P07).

Print Date: October 05, 2021 Page 19 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

(3) Put the rigid borescope (856A1320P04/P05), into the ports and turn on the light source of the

borescope-light source set (856A1322P03 or P04).

(4) Turn the rigid borescope a full 360 degrees to inspect the dome of the combustion chamber, fuel

nozzles, inner and outer liners and aft sections. Adjust the borescope equipment to obtain maximum

clarity of view.

(5) Inspect the following:

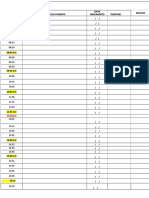

INSPECT/CHECK MAXIMUM SERVICEABLE LIMITS REMARKS

1.All surfaces for:

A.Discoloration Any amount

B.Carbon Accumulation Any amount

C.Missing, chipped or Any amount

spalled areas of thermal

barrier coating

2.Dome Assembly (Spec-

tacle Plate, Deflector and

Sleeve) for:

A.Distortion of deflector Any amount

or sleeve

B.Radial crack in spec- Any number up to 2 in. (50.8 mm) length See limit extension

tacle plate and not connected to each other. (Ref. AMM TASK 72-00-00-

200-025) .

C.Circumferential crack in Any number up to 3 in. (76.2 mm) length See limit extension

spectacle plate separated by 6 in. (152.4 mm). (Ref. AMM TASK 72-00-00-

200-025) .

D.Connected cracks in Not more than 1 radial crack 2 in. (50.80 See limit extension

spectacle plate mm) long with 1 circumferential crack 3 in. (Ref. AMM TASK 72-00-00-

(76.20 mm) long separated by 6 in. (152.4 200-025) .

mm).

E.Missing material from Max. 0.06 in. (1.52 mm) x 0.06 in. (1.52 See limit extension

spectacle plate mm) at intersection of connected crack. (Ref. AMM TASK 72-00-00-

Multiple axial and circumferential cracks 200-025) .

that connect if cracks:

F.Radial crack in deflect- Any number up to 0.5 in. (12.7 mm) length. See limit extension

or or sleeve (Ref. AMM TASK 72-00-00-

200-025) .

G.Circumferential cracks Any number up to 0.75 in. (19.05 mm). See limit extension

in deflector or sleeve (Ref. AMM TASK 72-00-00-

200-025) .

H.Connected cracks in Connection of any radial and circumfer- See limit extension

deflector or sleeve ential cracks within limits of paragraphs (Ref. AMM TASK 72-00-00-

F. and G. above. Limit is exceeded when 200-025) .

third crack connects.

J.Missing material from (1) Up to 15 exposed dome cooling holes See limit extension

extensions on deflector permitted in each deflector quadrant as (Ref. AMM TASK 72-00-00-

shown in the figure . 200-025) and .

Cracks and Missing Material in Dome Area Cracks and Missing Material in

(2) Not more than 20 exposed dome cool- Dome Area

ing holes total in any deflector as shown in

the figure .

Cracks and Missing Material in Dome Area

Print Date: October 05, 2021 Page 20 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

INSPECT/CHECK MAXIMUM SERVICEABLE LIMITS REMARKS

K.Missing material from Any amount up to 0.2 in. (5.08 mm) max- See limit extensions

extensions on sleeve imum depth. (Ref. AMM TASK 72-00-00-

200-025) .

L.Burn through holes 3 per dome 1 in. (25.4 mm) x 1 in. (25.4 See limit extension

mm) maximum. (Ref. AMM TASK 72-00-00-

200-025) .

M.Fuel nozzles for dis- Not serviceable See limit extensions

lodged wear sleeves (Ref. AMM TASK 72-00-00-

200-025) .

N.Notch on the edge of One notch on edge of spectacle plate at See .

the spectacle plate. any cup location can exist. Cracks and Missing Material in

Dome Area

P. Cracks and missing (1) Any number of secondary swirl nozzle See limit extension

material from the second- venturis with indications (cracks) permitted. (Ref. AMM TASK 72-00-00-

ary swirl nozzle venturi (2) Any number of secondary swirl nozzle 200-025) and .

venturis with total missing material at each Cracks and Missing Material in

venturi up to 0.100 in. (2.5 mm) in width Dome Area

permitted.

(3) Up to 6 secondary swirl nozzle venturis

with total missing material at each venturi

more than 0.100 in. (2.5 mm) but not more

than 0.300 in. (7.6 mm) in width permitted .

Cracks and Missing Material in Dome Area

3.Inner and outer liners

for: NOTE: For all non /3 engines:

For the dome bands

NOTE: Axial cracks can and panel 2 of the in-

turn circumferen- ner and outer liner, use

tial for a short dis- the dilution lands (the

tance (less than distance between the

one dilution land edges of the dilution

in length). In this holes) on panel 1.

condition, you For the panels 4 and 5

must think of the on the outer liner and

crack of as one panel 4 of the inner

continuous axial liner, use the dilution

crack. lands on panel 3.

NOTE: For /3 and /3 PIP en-

gines:

For the dome bands

of the inner and out-

er liner, use the dilu-

tion lands (the distance

between the edges of

the dilution holes) on

panel 1.

For the panels 3 to 5 on

the outer liner and pan-

els 3 and 4 on the in-

ner liner, use the dilu-

tion lands on panel 2.

Print Date: October 05, 2021 Page 21 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

INSPECT/CHECK MAXIMUM SERVICEABLE LIMITS REMARKS

A.Outer liner axial cracks Any number across 1 Panel or less and up If a crack extends across

to 4 cracks across more than 1 panel but more than 3 panels, bore-

not longer than 3 panels. scope the outer side of the out-

er liner in the crack locations

(Ref. AMM TASK 72-42-00-

290-006) .

See limit extension

(Ref. AMM TASK 72-00-00-

200-025) .

NOTE: When applying limits,

the dome band is inter-

preted as a panel.

B.Inner liner axial cracks Any number across 1 panel or less and up If up to 1 crack is across 4 pan-

to 4 cracks across more than 1 panel but els and no material is missing

not longer than 2 panels. more than 3 times the diamet-

er of a dilution hole and does

not connect to a circumferen-

tial crack longer than 0.5 in.

(12.7 mm), then reinspect in

750 cycles. See limit exten-

sions (Ref. AMM TASK 72-00-

00-200-025) .

C.Circumferential cracks There is no limit to the number with these See limit extensions

conditions: The cracks are no longer than (Ref. AMM TASK 72-00-00-

2 dilution lands. There are no more than 200-025) .

2 adjacent cracks in a dilution land. The

cracks are separated by a minimum of 3 NOTE: For all non /3 engines:

dilution lands that do not have cracks. For the dome bands

and panel 2 of the in-

ner and outer liner, use

the dilution lands (the

distance between the

edges of the dilution

holes) on panel 1.

For the panels 4 and 5

on the outer liner and

panel 4 of the inner

liner, use the dilution

lands on panel 3.

NOTE: For /3 and /3 PIP en-

gines:

For the dome bands

of the inner and out-

er liner, use the dilu-

tion lands (the distance

between the edges of

the dilution holes) on

panel 1.

For the panels 3 to 5 on

the outer liner and pan-

els 3 and 4 on the in-

Print Date: October 05, 2021 Page 22 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

INSPECT/CHECK MAXIMUM SERVICEABLE LIMITS REMARKS

ner liner, use the dilu-

tion lands on panel 2.

D.Connected cracks Connection of any axial and circumferential See limit extension

cracks up to max limits of paragraphs A. B. (Ref. AMM TASK 72-00-00-

and C. above. Limit is exceeded when third 200-025) .

crack connects.

Multiple axial and circumferential cracks

that connect if cracks:

a. Contained in one panel.

b. Contained in one dilution land area.

c. There are not more than two locations

in the adjacent panels that are axially

aligned.

d. The locations are separated by a minim-

um of three dilution lands that do not have

cracks.

e. There are not more than five locations

with connected cracks.

E.Burn through or miss- Per liner, any number of holes are permit- See limit extension

ing material ted with these conditions: (Ref. AMM TASK 72-00-00-

(1) There are not more than 2 holes in ad- 200-025) .

jacent panels that are axially aligned.

(2) The maximum size of any hole is not

more than 5 times the size of a dilution

hole.

(3) The total area of burn through is not to

exceed 15 times the size of a dilution hole.

F.Missing overhangs Per liner: 14 areas each 2 times the size See limits extensions

of a dilution hole providing maximum axial (Ref. AMM TASK 72-00-00-

alignment of distress is 3 adjacent panels. 200-025) .

G.Distortion Any amount within 0.5 in. (12.7 mm) of ori- See limit extension

ginal contour. (Ref. AMM TASK 72-00-00-

200-025) .

(6) When the inspection is complete, turn off the light source and remove the borescope.

(7) If any defects are found then remove additional borescope plugs and the spark igniters to inspect all

of the combustion chamber.

If no defects are found, install parts removed for borescope inspection.

Subtask 72-42-00-010-064-A

C. Remove parts before additional borescope inspection.

(1) Remove the drain tube from the fuel nozzle adjacent to the 6 o'clock borescope plug.

NOTE: If you remove the drain tube from the fuel nozzle adjacent to the 6 o'clock borescope plug,

you will be required to perform a leak check after this inspection. Use the 6 o'clock borescope

port only if necessary.

(2) Remove the borescope plugs from the approximate 1 and 6 o'clock positions.

(3) Remove both spark igniters (Ref. AMM TASK 74-21-30-000-002) .

(4) Install CAP - PROTECTION on the leads and the spark igniters.

Print Date: October 05, 2021 Page 23 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

Subtask 72-42-00-290-056-A

D. Do a borescope inspection of the entire combustion chamber.

(1) Repeat paragraph 4.B.(1) thru 4.B.(5) for each borescope and spark igniter location.

Subtask 72-42-00-410-059-A

E. Install parts removed for borescope inspection.

(1) Apply a small amount of graphite grease (Material No. CP2101) or Never Seez-Pure Nickel,

Special (Material No. CP2619) or milk of magnesia (Material No. CP1064) to the borescope plug

threads and pressure faces.

(2) Install the borescope plugs.

CAUTION: BE SURE TO INSTALL THE CORRECT BORESCOPE PLUGS. THE COMBUS-

TOR BORESCOPE PLUGS DO NOT HAVE A STEM FEATURE. INADVERTENT IN-

STALLATION OF BORESCOPE PLUGS WITH STEMS FROM OTHER LOCATIONS

WILL RESULT IN THE STEM FEATURE BEING BURNED AWAY BY COMBUSTION

GASES.

(a) Install the borescope plugs and TORQUE to between 57 and 63 lbf.in (0.64 and 0.71 m.daN).

(3) Safety the plugs with lockwire 0.032 in. (0.8 mm) dia. (Material No. CP8001)

(4) If necessary, install the fuel drain tube to the fuel nozzle adjacent to the six o'clock borescope

plug. TORQUE the coupling nuts on the fuel drain tube to between 120 and 135 lbf.in

(1.36 and 1.53 m.daN) and safety with lockwire 0.032 in. (0.8 mm) dia. (Material No. CP8001)

(5) If necessary, remove the protective caps and install the spark igniters (Ref. AMM TASK 74-21-30-

400-002)

Subtask 72-42-00-290-062-A

F. If necessary, do the borescope inspection of the outer side of the outer liner to confirm the extent of outer

liner axial cracks (Ref. AMM TASK 72-42-00-290-006) .

Subtask 72-42-00-790-051-A

G. Do a fuel nozzle leak check.

(1) If you removed the drain tube from the fuel nozzle adjacent to the 6 o'clock borescope plug, do a fuel

nozzle leak check (Ref. AMM TASK 73-11-40-790-002) .

5. Close-up

Subtask 72-42-00-410-057-A

A. Close Access

(1) Make sure that the work area is clean and clear of tools and other items.

(2) Close the thrust reverser doors: (Ref. AMM TASK 78-36-00-410-040)

(a) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(b) FOR 1000EM2 (ENGINE-2)

461AL, 462AR.

(3) Remove the access platform(s).

Subtask 72-42-00-440-055-A

B. Make the thrust reverser serviceable after maintenance (Ref. AMM TASK 78-30-00-081-041)

Subtask 72-42-00-410-058-A

Print Date: October 05, 2021 Page 24 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

C. Close Access

(1) Close the fan cowl doors: (Ref. AMM TASK 71-13-00-410-040)

(a) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

(b) FOR 1000EM2 (ENGINE-2)

447AL, 448AR.

(2) Remove the WARNING NOTICE(S).

TASK 72-42-00-290-041-A01

Borescope Inspection of the Combustion Chamber Liners and Dome Area (DAC engine NON /P only)

FIN : 1000EM1 , 1000EM2

1. Reason for the Job

This TASK is applicable for NON/P engines equipped with a Double Annular Combustor chamber.

NOTE: Inspection of the combustion chamber is limited to the areas that can be seen with a rigid borescope,

at the 1, 3, 6 and 10 o'clock borescope ports, and at the 2 spark igniter ports. The borescope ports at

the 1, 3, 6, and 10 o'clock positions are located immediately in front of the fuel manifold. These ports

and the 2 spark igniter ports permit the borescope inspection of the combustion chamber and the HPT

nozzle.

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific AR ACCESS PLATFORM 1M(3 FT)

No specific AR CAP - PROTECTION

No specific AR WARNING NOTICE(S)

No specific Torque wrench: range to between 38 and 42 lbf.in

(0.43 and 0.47 m.daN)

(856A1320) 1 BORESCOPE-KIT

(856A1322) 1 BORESCOPE-LIGHT SOURCE SET

(856A1323) 1 MONITOR, RESOLUTION BORESCOPE

B. Consumable Materials

REFERENCE DESIGNATION

(Material No. CP2619) Never Seez-Pure Nickel, Special

(Material No. CP8001) lockwire 0.032 in. (0.8 mm) dia.

C. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

400 POWER PLANT, NACELLES AND PYLONS

FOR 1000EM1 (ENGINE-1)

437AL, 438AR, 451AL, 452AR

FOR 1000EM2 (ENGINE-2)

447AL, 448AR, 461AL, 462AR

Print Date: October 05, 2021 Page 25 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

D. Referenced Information

REFERENCE DESIGNATION

(Ref. 71-13-00-010-040-B). Opening of the Fan Cowl Doors

(Ref. 71-13-00-410-040-B). Closing of the Fan Cowl Doors

(Ref. 72-00-00-200-025-A). Over-Serviceable-Limit Extensions

(Ref. 72-00-00-200-025-A-01). Over-Serviceable-Limit Extensions

(Ref. 72-42-00-290-006-A). Borescope Inspection of the Outer Side of the Combustion Chamber

Outer Liners (SAC engine)

(Ref. 72-42-00-290-006-A-01). Borescope Inspection of the Outer Side of the Combustion Chamber

Outer Liners (DAC engine)

(Ref. 72-52-00-290-001-B). Borescope Inspection of HPT Blades (from the front and the rear)

(Ref. 72-52-00-290-001-B-01). Borescope Inspection of HPT Blades (from the front and the rear)

(Ref. 73-11-40-400-002-A). Installation of the Fuel Nozzle for SAC Engines

(Ref. 73-11-40-400-002-A-01). Installation of the Fuel Nozzle for DAC Engines

(Ref. 73-11-40-790-002-A). Leak Check of the Fuel Nozzles for SAC Engines

(Ref. 73-11-40-790-002-A-01). Leak Check of the Fuel Nozzles for DAC Engines

(Ref. 74-21-30-000-002-A). Removal of the Spark Igniter

(Ref. 74-21-30-400-002-A). Installation of the Spark Igniter

(Ref. 78-30-00-081-041-B). Make the Thrust Reverser Serviceable after Maintenance

(Ref. 78-30-00-481-041-B). Make the Thrust Reverser Unserviceable for Maintenance

(Ref. 78-36-00-010-040-B). Opening of the Thrust Reverser Doors

(Ref. 78-36-00-410-040-B). Closing of the Thrust Reverser Doors

Ref. NTM 720000

Combustion Chamber (Inner and Outer Liner Inspection) SHEET 1

Combustion Chamber (Sectional View) for DAC engine NON/P and /P SHEET 1

Cracks and Missing Material in Dome Area SHEET 1

Outer Liner (Inner) SHEET 1

Inner Liner (Inner) SHEET 1

Combustion Chamber (Sectional View) for DAC/2P engine SHEET 1

Cracks and Missing Material in Dome Areafor DAC/2P engine SHEET 1

Inner Liner (Inner)for DAC/2P engine SHEET 1

Print Date: October 05, 2021 Page 26 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

A

OUTER LINER

COWL

IGNITER FERRULE LOCATOR

(2 LOCATIONS) RIDGE

DUAL ANNULAR COMBUSTOR (DAC)

1125994-02-A

N_MM_724200_6_RJM0_01_00

Figure 72(CFMB)-42-00-991-30900-06-A / SHEET 1/

1 - Combustion Chamber (Inner and Outer Liner Inspection)

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 27 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

SPECTACLE

PLATE OUTER LINER

CENTERBODY

OUTER INNER LINER

DEFLECTOR

C E

LINER

OVERHANG

DEFLECTOR

OVERHANG

INNER

DEFLECTOR

SPECTACLE

PLATE

SECTION

B-B

DUAL ANNULAR COMBUSTOR - I (DAC - I)

1125995-03-A

N_MM_724200_6_RKM0_01_00

Figure 72(CFMB)-42-00-991-31000-06-A / SHEET 1/1 - Combustion

Chamber (Sectional View) for DAC engine NON/P and /P

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 28 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

TYPICAL

MISSING OUTER

MATERIAL DEFLECTOR

DEFLECTOR

CENTERBODY

DAC - I

1125996-02-A

N_MM_724200_6_RLM0_01_00

Figure 72(CFMB)-42-00-991-31100-06-A / SHEET 1/1 - Cracks and Missing Material in Dome Area

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 29 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

IGNITER HOLE

TYPICAL

CONNECTED

CRACK

TYPICAL

AXIAL

CRACKS

BURN

THROUGH

HOLE

DOME BAND PANEL 1 PANEL 2 PANEL 3 PANEL 4

TYPICAL CIRCUMFERENTIAL CRACK

GMM-1125998-01-A

N_MM_724200_6_RMM0_01_00

Figure 72(CFMB)-42-00-991-31200-06-A / SHEET 1/1 - Outer Liner (Inner)

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 30 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

BURN THROUGH

HOLE

TYPICAL

AXIAL

CRACKS

TYPICAL CONNECTED

CRACKS

BURN THROUGH

HOLE-DILUTION

HOLE NOT

INCLUDED

TYPICAL

CIRCUMFERENTIAL

CRACK

DOME PANEL 1 PANEL 2 PANEL 3 PANEL 4

BAND

5058005-00

N_MM_724200_6_RNM0_01_01

Figure 72(CFMB)-42-00-991-31300-06-A / SHEET 1/1 - Inner Liner (Inner)

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 31 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

OUTER

LINER

SPECTACLE LINER

PLATE OVERHANG

DEFLECTOR

SPLASHPLATE

INNER

LINER

CENTERBODY

OUTER

DEFLECTOR

C

E

INNER

DEFLECTOR

SPECTACLE

PLATE

SECTION

B-B

DUAL ANNULAR COMBUSTOR - II (DAC - II) 1145071-01-A

N_MM_724200_6_RKN0_01_00

Figure 72(CFMB)-42-00-991-31600-06-A / SHEET 1/

1 - Combustion Chamber (Sectional View) for DAC/2P engine

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 32 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

OUTER

DEFLECTOR

TYPICAL

MISSING

MATERIAL

SPLASH

PLATE

DEFLECTOR CENTERBODY

DAC - II

1145072-01-A

N_MM_724200_6_RLN0_01_00

Figure 72(CFMB)-42-00-991-31700-06-A / SHEET 1/1 -

Cracks and Missing Material in Dome Areafor DAC/2P engine

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 33 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

E

TYPICAL

CONNECTED CRACK

TYPICAL MATERIAL

MISSING FROM

OVERHANG

TYPICAL BURN

THROUGH HOLES

TYPICAL TYPICAL

AXIAL CRACKS CIRCUMFERENTIAL

CRACKS (ONE HALF

OF A DILUTION HOLE)

TYPICAL

AXIAL CRACKS

DOME BAND PANEL 1 PANEL 2 PANEL 3 PANEL 4

DAC - II 1145073-01-A

N_MM_724200_6_RNN0_01_00

Figure 72(CFMB)-42-00-991-31800-06-A / SHEET 1/1 - Inner Liner (Inner)for DAC/2P engine

** ON A/C 001-150, 301-350, 504-504, 550-550, 601-850

Print Date: October 05, 2021 Page 34 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

3. Job Set-up

Subtask 72-42-00-941-065-A

A. Safety Precautions

(1) On the center pedestal, on the ENG panel 115VU:

(a) Put a WARNING NOTICE(S) to tell persons not to start the engine.

(2) Make sure that the engine 1(2) shutdown occurred not less than 5 minutes before you do this

procedure.

(3) On the overhead maintenance panel 50VU:

(a) Make sure that the ON legend of the ENG/FADEC GND PWR/1(2) pushbutton switch is off.

(b) Put a WARNING NOTICE(S) to tell persons not to energize the FADEC 1(2).

Subtask 72-42-00-010-099-A

B. Get Access

(1) Open the fan cowl doors: (Ref. AMM TASK 71-13-00-010-040)

(2) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

(3) FOR 1000EM2 (ENGINE-2)

447AL, 448AR

(4) Put the ACCESS PLATFORM 1M(3 FT) in position.

Subtask 72-42-00-040-065-A

C. Make the thrust reverser unserviceable for maintenance (Ref. AMM TASK 78-30-00-481-041)

Subtask 72-42-00-010-100-A

D. Open the thrust reverser doors: (Ref. AMM TASK 78-36-00-010-040)

(1) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(2) FOR 1000EM2 (ENGINE-2)

461AL, 462AR

4. Procedure

(Ref. Fig. Combustion Chamber (Inner and Outer Liner Inspection) SHEET 1) (Ref. Fig. Combustion

Chamber (Sectional View) for DAC engine NON/P and /P SHEET 1) (Ref. Fig. Cracks and

Missing Material in Dome Area SHEET 1) (Ref. Fig. Outer Liner (Inner) SHEET 1) (Ref. Fig. Inner

Liner (Inner) SHEET 1) (Ref. Fig. Combustion Chamber (Sectional View) for DAC/

2P engine SHEET 1) (Ref. Fig. Cracks and Missing Material in Dome Areafor DAC/2P

engine SHEET 1) (Ref. Fig. Inner Liner (Inner)for DAC/2P engine SHEET 1)

Subtask 72-42-00-010-101-A

A. Remove parts before borescope inspection.

(1) Remove the borescope plugs from the approximate 3 and 10 o'clock positions on the combustion

case.

Subtask 72-42-00-290-074-A

B. Do a borescope inspection

(1) Use the MONITOR, RESOLUTION BORESCOPE (856A1323) (856A1323G01) to make sure

the borescope and the light source are serviceable. See the Non-Destructive Test Manual for this

procedure Ref. NTM 720000.

Print Date: October 05, 2021 Page 35 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

(2) Connect the fiber light cable to the BORESCOPE-KIT (856A1320) (856A1320P04/P05) and to the

port on the BORESCOPE-LIGHT SOURCE SET (856A1322) (856A1322P03/P04/P07).

(3) Put the rigid borescope of the (856A1320P04/P05), into the ports and turn on the light source of the

borescope-light source set (856A1322P03/P04).

(4) Turn the rigid borescope a full 360 degrees to inspect the domes of the combustion chamber, fuel

nozzles, inner and outer liners and aft sections. Adjust the borescope equipment to obtain maximum

clarity of view.

(5) Inspect the following:

INSPECT/CHECK MAXIMUM SER- REMARKS

VICEABLE LIMITS

1.All surfaces for:

A.Discoloration Any amount

B.Carbon Accumulation Any amount

C.Missing, chipped or spalled Any amount

areas of thermal barrier coating

2.Dome Assemblies (Spectacle

Plate and Deflector) for:

A.Distortion of deflector Any amount

B.Radial crack in spectacle Any number up to 1 in. (25.4 See limit extensions

plate mm) length and not connected (Ref. AMM TASK 72-00-00-200-

025) .

C.Circumferential crack in Any number up to 3 in. (76.2 See limit extensions

spectacle plate mm) length separated by 6 in. (Ref. AMM TASK 72-00-00-200-

(152.4 mm) 025) .

D.Connected cracks in spec- Not more than 1 radial crack 1 See limit extensions

tacle plate in. (25.4 mm) long with 1 circum- (Ref. AMM TASK 72-00-00-200-

ferential crack 3 in. (76.2 mm) 025) .

long

E.Missing material from spec- Max. 0.06 in. (1.52 mm) x 0.06 See limit extensions

tacle plate in. (1.52 mm) at intersection of (Ref. AMM TASK 72-00-00-200-

connected crack 025) .

F.Radial crack in deflector Any number up to 0.5 in. (12.7 See limit extensions

mm) length (Ref. AMM TASK 72-00-00-200-

025) .

G.Circumferential cracks in de- Any number up to 0.75 in. (19.05 See limit extensions

flector mm) (Ref. AMM TASK 72-00-00-200-

025) .

H.Connected cracks in deflect- Connection of any radial and cir- See limit extensions

or cumferential cracks within limits (Ref. AMM TASK 72-00-00-200-

of paragraphs F. and G. above. 025) .

Limit is exceeded when third

crack connects.

J.Missing material from over- 10 per dome, 1.0 in. (25.4 mm) See limit extensions

hangs on deflector wide x 0.5 in. (12.7 mm) maxim- (Ref. AMM TASK 72-00-00-200-

um from original edge 025) .

K.Burn through holes 3 per dome 1 in. (25.4 mm) x 1 See limit extensions

in. (25.4 mm) maximum (Ref. AMM TASK 72-00-00-200-

025) .

3.Inner and outer liners for:

Print Date: October 05, 2021 Page 36 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

INSPECT/CHECK MAXIMUM SER- REMARKS

VICEABLE LIMITS

NOTE: Axial cracks can turn

circumferential for a

short distance (less

than one dilution land

in length). In this condi-

tion, you must think of

the crack of as one con-

tinuous axial crack.

A.Outer liner axial cracks Any number across 1 Panel or If up to 3 cracks extend across

less and up to 3 cracks across more than 3 panels, bore-

more than 1 panel but not longer scope the outer side of the out-

than 3 panels er liner in the crack locations

(Ref. AMM TASK 72-42-00-

290-006) . See limit extensions

(Ref. AMM TASK 72-00-00-200-

025) .

NOTE: When applying limits, the

dome band is interpreted as

a panel.

B.Inner liner axial cracks Any number across 1 panel or If up to 1 crack is across 4 panels

less. Up to 15 cracks across and no material is missing more

more than 1 panel but not longer

than 2 times the diameter (or 4

than 2 panels. Up to 3 cracks times the area) of a dilution hole

across more than 2 panels but and does not connect to a circum-

no longer than 3 panels ferential crack longer than 0.5 in.

(12.7 mm), then inspect again in

750 cycles.

C.Inner liner support leg cir- Any amount of cracks that go If there are more than 10 legs

cumferential cracks (can in- part of the way across the leg cracked completely across the leg

clude axial cracks that become is permitted with a maximum of surface, inspect the HPT blade

circumferential) 10 of the 30 legs cracked com- trailing edge every 400 cycles

pletely across the leg surface. (Ref. AMM TASK 72-52-00-290-

001) .

D.Circumferential cracks in in- Any number up to one half of a See limit extensions

ner liner dilution land in length separated (Ref. AMM TASK 72-00-00-200-

by one non- cracked dilution land 025) .

NOTE: For the inner liner DAC-II,

when reference is made

to a dilution hole, or to the

space between the dilution

holes, called a dilution land,

always refer to the dilution

holes in panel 2 unless dif-

ferently specified.

E.Circumferential cracks in out- Length of cracks when added to- If length of all cracks is between 20

er liner gether must not be more than 20 percent and 40 percent of the cir-

percent of circumference. cumference, do an inspection every

Print Date: October 05, 2021 Page 37 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

INSPECT/CHECK MAXIMUM SER- REMARKS

VICEABLE LIMITS

400 cycles. If cracks are more than

40 percent, see limit extensions

(Ref. AMM TASK 72-00-00-200-

025) .

NOTE: If the length of cracks when

added together is great-

er than 20 percent, it is re-

commended that you do

the borescope inspection

on the cold side of the out-

er liner, if possible. Cracks

measured on the cold side

are through cracks. If pos-

sible, use cold side cracks

to identify if the combustor

is serviceable.

F.Connected cracks (1) Up to 3 pairs of one axial and See limit extensions

one circumferential crack that (Ref. AMM TASK 72-00-00-200-

connect if the cracks are in the 025) .

previous limits.

NOTE: Cracks are identified as

(2) More than 3 pairs of connec- missing material as soon as

ted cracks are permitted if the the maximum gap equals

pairs of cracks are a minimum of the diameter of one dilution

two dilution lands apart. hole.

(3) A third connected crack con-

nected to the above two cracks

is permitted if the distance apart

is less than the equivalent length

of 2 dilution hole diameters away

from the adjacent connected

crack and in the opposite direc-

tion of the adjacent connected

crack.

G.Burn through holes Per liner, any number of holes

are permitted with these condi-

tions:

(1) There are not more than 2

holes in adjacent panels that are

axially aligned.

(2) The maximum size of any

hole is not more than 5 times the

size of a dilution hole.

(3) The total area of burn

through is not to exceed 15

times the size of a dilution hole.

H.Distortion Any amount within 0.5 in. (12.7 See limit extensions

mm) of original contour (Ref. AMM TASK 72-00-00-200-

025) .

Print Date: October 05, 2021 Page 38 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

INSPECT/CHECK MAXIMUM SER- REMARKS

VICEABLE LIMITS

J.Missing overhangs Total for both liners: Any amount

4.Centerbodies for:

A.Axial cracks Any amount 0.25 in. (6.35 mm) See limit extensions

from trailing edge, max length of (Ref. AMM TASK 72-00-00-200-

0.75 in. (19.05 mm) 025) .

B.Circumferential cracks One crack per centerbody up to See limit extensions

0.25 in. (6.35 mm) circumferen- (Ref. AMM TASK 72-00-00-200-

tial length 025) .

C.Connecting Circumferential One circumferential and one axi- See limit extensions

and axial cracks al crack allowed within individual (Ref. AMM TASK 72-00-00-200-

crack limits 025) .

D.Spalled or missing any Any amount

amount coating

E.Burn areas One area per centerbody up to See limit extensions

1 in. (25.4 mm) circumferential (Ref. AMM TASK 72-00-00-200-

length by 0.50 in. (12.7 mm) axi- 025) .

al length

F.Burn thru holes Two areas per centerbody up to See limit extensions

a max 0.50 in. (12.7 mm) circum- (Ref. AMM TASK 72-00-00-200-

ferential length by 0.25 in. (6.35 025) .

mm) axial length spaced by a

minimum of 0.25 in. (6.35 mm)

5.Borescope ferrule welds for:

A.Cracks Any amount

(6) When the inspection is complete, turn off the light source and remove the borescope.

(7) If any defects are found then remove additional borescope plugs and the spark igniters to inspect all

of the combustion chamber.

If no defects are found, install parts removed for borescope inspection.

Subtask 72-42-00-010-102-A

C. Remove parts before additional borescope inspection.

(1) Remove the drain tube from the fuel nozzle adjacent to the 6 o'clock borescope plug.

NOTE: If you remove the drain tube from the fuel nozzle adjacent to the 6 o'clock borescope plug,

you will be required to perform a leak check after this inspection. Use the 6 o'clock borescope

port only if necessary.

(2) Remove the borescope plugs from the approximate 1 and 6 o'clock positions.

(3) Remove both spark igniters (Ref. AMM TASK 74-21-30-000-002) .

(4) Install CAP - PROTECTION on the leads and the spark igniters.

Subtask 72-42-00-290-075-A

D. Do a borescope inspection of the entire combustion chamber

(1) Repeat paragraph 4.B.(1) thru (5) for each borescope and spark igniter location.

Subtask 72-42-00-410-094-A

E. Install parts removed for borescope inspection.

Print Date: October 05, 2021 Page 39 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

(1) Apply a small amount of Never Seez-Pure Nickel, Special (Material No. CP2619) or to the borescope

plug threads and pressure faces.

NOTE: It may be necessary to mix a small amount of water with the magnesium hydroxide to make a

paste.

(2) Install the borescope plugs.

CAUTION: BE SURE TO INSTALL THE CORRECT BORESCOPE PLUGS. THE COMBUS-

TOR BORESCOPE PLUGS DO NOT HAVE A STEM FEATURE. INADVERTENT IN-

STALLATION OF BORESCOPE PLUGS WITH STEMS FROM OTHER LOCATIONS

WILL RESULT IN THE STEM FEATURE BEING BURNED AWAY BY COMBUSTION

GASES.

(a) Install the borescope plugs and TORQUE to between 38 and 42 lbf.in (0.43 and 0.47 m.daN).

(3) Safety the plugs with lockwire 0.032 in. (0.8 mm) dia. (Material No. CP8001)

(4) If necessary, replace the O-ring on the fuel drain tube and install the tube to the fuel nozzle adjacent

to the 6 o'clock borescope plug (Ref. AMM TASK 73-11-40-400-002) .

(5) If necessary, remove the protective caps and install the spark igniters (Ref. AMM TASK 74-21-30-

400-002)

Subtask 72-42-00-290-076-A

F. If necessary, do the borescope inspection of the outer side of the outer liner to confirm the extent of outer

liner axial cracks (Ref. AMM TASK 72-42-00-290-006) .

Subtask 72-42-00-790-059-A

G. Do a fuel nozzle leak check.

(1) If you removed the drain tube from the fuel nozzle adjacent to the 6 o'clock borescope plug, do a fuel

nozzle leak check (Ref. AMM TASK 73-11-40-790-002) .

5. Close-up

Subtask 72-42-00-410-095-A

A. Close Access

(1) Make sure that the work area is clean and clear of tools and other items.

(2) Close the thrust reverser doors: (Ref. AMM TASK 78-36-00-410-040)

(a) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(b) FOR 1000EM2 (ENGINE-2)

461AL, 462AR

(3) Remove the access platform(s).

Subtask 72-42-00-440-065-A

B. Make the thrust reverser serviceable after maintenance (Ref. AMM TASK 78-30-00-081-041)

Subtask 72-42-00-410-096-A

C. Close Access

(1) Close the fan cowl doors: (Ref. AMM TASK 71-13-00-410-040)

(a) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

Print Date: October 05, 2021 Page 40 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

(b) FOR 1000EM2 (ENGINE-2)

447AL, 448AR

(2) Remove the WARNING NOTICE(S).

TASK 72-42-00-290-041-A02

Borescope Inspection of the Combustion Chamber Liners and Dome Area (DAC engine /P only)

FIN : 1000EM1 , 1000EM2

1. Reason for the Job

This TASK is applicable for /P engines equipped with a Double Annular Combustor chamber.

NOTE: Inspection of the combustion chamber is limited to the areas that can be seen with a rigid borescope,

at the 1, 3, 6 and 10 o'clock borescope ports, and at the 2 spark igniter ports. the borescope ports at

the 1, 3, 6, and 10 o'clock positions are located immediately in front of the fuel manifold. These ports

and the 2 spark igniter ports permit the borescope inspection of the combustion chamber and the HPT

nozzle.

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific AR ACCESS PLATFORM 1M(3 FT)

No specific AR CAP - PROTECTION

No specific AR WARNING NOTICE(S)

No specific Torque wrench: range to between 38 and 42 lbf.in

(0.43 and 0.47 m.daN)

(856A1320) 2 BORESCOPE-KIT

(856A1322) 2 BORESCOPE-LIGHT SOURCE SET

(856A1323) 2 MONITOR, RESOLUTION BORESCOPE

B. Consumable Materials

REFERENCE DESIGNATION

(Material No. CP2619) Never Seez-Pure Nickel, Special

(Material No. CP8001) lockwire 0.032 in. (0.8 mm) dia.

C. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

400 POWER PLANT, NACELLES AND PYLONS

FOR 1000EM1 (ENGINE-1)

437AL, 438AR, 451AL, 452AR

FOR 1000EM2 (ENGINE-2)

447AL, 448AR, 461AL, 462AR

D. Referenced Information

Print Date: October 05, 2021 Page 41 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

REFERENCE DESIGNATION

(Ref. 71-13-00-010-040-B). Opening of the Fan Cowl Doors

(Ref. 71-13-00-410-040-B). Closing of the Fan Cowl Doors

(Ref. 72-00-00-200-025-A). Over-Serviceable-Limit Extensions

(Ref. 72-00-00-200-025-A-01). Over-Serviceable-Limit Extensions

(Ref. 72-42-00-290-006-A). Borescope Inspection of the Outer Side of the Combustion Chamber

Outer Liners (SAC engine)

(Ref. 72-42-00-290-006-A-01). Borescope Inspection of the Outer Side of the Combustion Chamber

Outer Liners (DAC engine)

(Ref. 73-11-40-400-002-A). Installation of the Fuel Nozzle for SAC Engines

(Ref. 73-11-40-400-002-A-01). Installation of the Fuel Nozzle for DAC Engines

(Ref. 73-11-40-790-002-A). Leak Check of the Fuel Nozzles for SAC Engines

(Ref. 73-11-40-790-002-A-01). Leak Check of the Fuel Nozzles for DAC Engines

(Ref. 74-21-30-000-002-A). Removal of the Spark Igniter

(Ref. 74-21-30-400-002-A). Installation of the Spark Igniter

(Ref. 78-30-00-081-041-B). Make the Thrust Reverser Serviceable after Maintenance

(Ref. 78-30-00-481-041-B). Make the Thrust Reverser Unserviceable for Maintenance

(Ref. 78-36-00-010-040-B). Opening of the Thrust Reverser Doors

(Ref. 78-36-00-410-040-B). Closing of the Thrust Reverser Doors

Ref. NTM 720000

Combustion Chamber (Inner and Outer Liner Inspection) SHEET 1

Combustion Chamber (Sectional View) for DAC engine NON/P and /P SHEET 1

Cracks and Missing Material in Dome Area SHEET 1

Outer Liner (Inner) SHEET 1

Inner Liner (Inner) SHEET 1

Combustion Chamber (Sectional View) for DAC/2P engine SHEET 1

Cracks and Missing Material in Dome Areafor DAC/2P engine SHEET 1

Inner Liner (Inner)for DAC/2P engine SHEET 1

3. Job Set-up

Subtask 72-42-00-941-066-A

A. Safety Precautions

(1) On the center pedestal, on the ENG panel 115VU:

(a) Put a WARNING NOTICE(S) to tell persons not to start the engine.

(2) Make sure that the engine 1(2) shutdown occurred not less than 5 minutes before you do this

procedure.

(3) On the overhead maintenance panel 50VU:

(a) Make sure that the ON legend of the ENG/FADEC GND PWR/1(2) pushbutton switch is off.

(b) Put a WARNING NOTICE(S) to tell persons not to energize the FADEC 1(2).

Subtask 72-42-00-010-103-A

B. Get Access

(1) Open the fan cowl doors: (Ref. AMM TASK 71-13-00-010-040)

(a) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

(b) FOR 1000EM2 (ENGINE-2)

447AL, 448AR

Print Date: October 05, 2021 Page 42 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

(2) Put the ACCESS PLATFORM 1M(3 FT) in position.

Subtask 72-42-00-040-066-A

C. Make the thrust reverser unserviceable for maintenance (Ref. AMM TASK 78-30-00-481-041)

Subtask 72-42-00-010-104-A

D. Open the thrust reverser doors: (Ref. AMM TASK 78-36-00-010-040)

(1) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(2) FOR 1000EM2 (ENGINE-2)

461AL, 462AR

4. Procedure

(Ref. Fig. Combustion Chamber (Inner and Outer Liner Inspection) SHEET 1) (Ref. Fig. Combustion

Chamber (Sectional View) for DAC engine NON/P and /P SHEET 1) (Ref. Fig. Cracks and

Missing Material in Dome Area SHEET 1) (Ref. Fig. Outer Liner (Inner) SHEET 1) (Ref. Fig. Inner

Liner (Inner) SHEET 1) (Ref. Fig. Combustion Chamber (Sectional View) for DAC/

2P engine SHEET 1) (Ref. Fig. Cracks and Missing Material in Dome Areafor DAC/2P

engine SHEET 1) (Ref. Fig. Inner Liner (Inner)for DAC/2P engine SHEET 1)

Subtask 72-42-00-010-105-A

A. Remove parts before borescope inspection.

(1) Remove the borescope plugs from the approximate 3 and 10 o'clock positions on the combustion

case.

Subtask 72-42-00-290-077-A

B. Do a borescope inspection for DAC engine

(1) Use the MONITOR, RESOLUTION BORESCOPE (856A1323) (856A1323G01) to make sure

the borescope and the light source are serviceable. See the Non-Destructive Test Manual for this

procedure Ref. NTM 720000.

(2) Connect the fiber light cable to the BORESCOPE-KIT (856A1320) (856A1320P04/P05) and to the

port on the BORESCOPE-LIGHT SOURCE SET (856A1322) (856A1322P03/P04/P07).

(3) Put the rigid borescope of the (856A1320P04/P05), into the ports and turn on the light source of the

borescope-light source set (856A1322P03/P04).

(4) Turn the rigid borescope a full 360 degrees to inspect the domes of the combustion chamber, fuel

nozzles, inner and outer liners and aft sections. Adjust the borescope equipment to obtain maximum

clarity of view.

(5) Inspect the following:

INSPECT/CHECK MAXIMUM SER- REMARKS

VICEABLE LIMITS

1.All surfaces for:

A.Discoloration Any amount

B.Carbon Accumulation Any amount

C.Missing, chipped or spalled Any amount

areas of thermal barrier coating

2.Dome assemblies (spectacle

plate and deflector) for:

A.Distortion of deflector Any amount

Print Date: October 05, 2021 Page 43 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

INSPECT/CHECK MAXIMUM SER- REMARKS

VICEABLE LIMITS

B.Radial crack in spectacle Any number up to 1 in. (25.4 See limit extensions

plate mm) length and not connected (Ref. AMM TASK 72-00-00-200-

025) .

C.Circumferential crack in Any number up to 3 in. (76.2 See limit extensions

spectacle plate mm) length separated by 6 in. (Ref. AMM TASK 72-00-00-200-

(152.4 mm) 025) .

D.Connected cracks in spec- Not more than 1 radial crack 1 See limit extensions

tacle plate in. (25.4 mm) long with 1 circum- (Ref. AMM TASK 72-00-00-200-

ferential crack 3 in. (76.2 mm) 025) .

long

E.Missing material from spec- Max. 0.06 in. (1.52 mm) x 0.06 See limit extensions

tacle plate in. (1.52 mm) at intersection of (Ref. AMM TASK 72-00-00-200-

connected crack 025) .

F.Radial crack in deflector Any number up to 0.5 in. (12.7 See limit extensions

mm) length (Ref. AMM TASK 72-00-00-200-

025) .

G.Circumferential cracks in de- Any number up to 0.75 in. (19.05 See limit extensions

flector mm) (Ref. AMM TASK 72-00-00-200-

025) .

H.Connected cracks in deflect- Connection of any radial and cir- See limit extensions

or cumferential cracks within limits (Ref. AMM TASK 72-00-00-200-

of paragraphs F. and G. above. 025) .

Limit is exceeded when third

crack connects.

J.Missing material from over- 10 per dome, 1.0 in. (25.4 mm) See limit extensions

hangs on deflector wide x 0.5 in. (12.7 mm) maxim- (Ref. AMM TASK 72-00-00-200-

um from original edge 025) .

K.Burn through holes 3 per dome 1 in. (25.4 mm) x 1 See limit extensions

in. (25.4 mm) maximum (Ref. AMM TASK 72-00-00-200-

025) .

3.Inner and outer liners for:

A.Outer liner axial cracks Any number across 1 Panel or If up to 3 cracks extend across

less and up to 3 cracks across more than 3 panels, bore-

more than 1 panel but not longer scope the outer side of the out-

than 3 panels er liner in the crack locations

(Ref. AMM TASK 72-42-00-

290-006) . See limit extensions

(Ref. AMM TASK 72-00-00-200-

025) .

NOTE: When applying limits, the

dome band is interpreted as

a panel.

B.Inner liner axial cracks Any number across 1 panel or If up to 1 crack is across 4 panels

less and up to 3 cracks across and no material is missing more

more than 1 panel but not longer than 2 times the diameter of a di-

than 3 panels lution hole and does not connect

to a circumferential crack longer

than 0.5 in. (12.7 mm), then inspect

again in 750 cycles.

Print Date: October 05, 2021 Page 44 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

INSPECT/CHECK MAXIMUM SER- REMARKS

VICEABLE LIMITS

C.Inner liner support leg cir- Any amount of cracking that If there are more than 10 legs

cumferential cracks (including goes part of the way across the cracked completely across the leg

axial cracks that become cir- leg is permitted with a maxim- surface, inspect the HPT blade

cumferential). um of 10 of the 30 legs that are trailing edge every 400 cycles.

cracked completely across the

leg surface.

D.Circumferential cracks inner Any number up to 2 dilution See limit extensions

liner lands in length separated by 3 (Ref. AMM TASK 72-00-00-200-

non cracked dilution lands 025) .

NOTE: A dilution land is the area of

the panel between the dilu-

tion holes.

E.Circumferential cracks in out- Length of cracks when added to- If length of all cracks is between 20

er liner gether must not be more than 20 percent and 40 percent of the cir-

percent of circumference. cumference, do an inspection every

400 cycles. If cracks are more than

40 percent, see limit extensions

(Ref. AMM TASK 72-00-00-200-

025) .

NOTE: If the length of cracks when

added together is great-

er than 20 percent, it is re-

commended that you do

the borescope inspection

on the cold side of the out-

er liner, if possible. Cracks

measured on the cold side

are through cracks. If pos-

sible, use cold side cracks

to identify if the combustor

is serviceable.

F.Connected cracks (1) Up to 3 pairs of one axial and See limit extensions

one circumferential crack that (Ref. AMM TASK 72-00-00-200-

connect if the cracks are in the 025) .

limits that were there before.

NOTE: Cracks are identified as

(2) More then 3 pairs of connec- missing material as soon as

ted cracks are permitted if the the maximum gap equals

pairs of cracks are a minimum of the diameter of one dilution

two dilution lands apart. hole.

(3) A third connected crack con-

nected to the above two cracks

is permitted if it is a distance less

than the equivalent length of 2

dilution hole diameters away

from the adjacent connected

crack and in the opposite direc-

Print Date: October 05, 2021 Page 45 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

INSPECT/CHECK MAXIMUM SER- REMARKS

VICEABLE LIMITS

tion of the adjacent connected

crack.

G.Burn through or missing ma- Per liner, any number of holes

terial are permitted with these condi-

tions:

(1) There are not more than 2

holes in adjacent panels that are

axially aligned.

(2) The maximum size of any

hole is not more than 5 times the

size of a dilution hole.

(3) The total area of burn

through is not to exceed 15

times the size of a dilution hole.

H.Distortion Any amount within 0.5 in. (12.7 See limit extensions

mm) of original contour (Ref. AMM TASK 72-00-00-200-

025) .

J.Missing overhangs Total for both liners: Any amount

4.Centerbodies for:

A.Axial cracks Any amount 0.25 in. (6.35 mm) See limit extensions

from trailing edge, max length of (Ref. AMM TASK 72-00-00-200-

0.75 in. (19.05 mm) 025) .

B.Circumferential cracks One crack per centerbody up to See limit extensions

0.25 in. (6.35 mm) circumferen- (Ref. AMM TASK 72-00-00-200-

tial length 025) .

C.Connecting Circumferential One circumferential and one axi- See limit extensions

and axial cracks al crack allowed within individual (Ref. AMM TASK 72-00-00-200-

crack limits 025) .

D.Spalled or missing any Any amount

amount coating

E.Burn areas One area per centerbody up to See limit extensions

1 in. (25.4 mm) circumferential (Ref. AMM TASK 72-00-00-200-

length by 0.50 in. (12.7 mm) axi- 025) .

al length

F.Burn thru holes Two areas per centerbody up to See limit extensions

a max 0.50 in. (12.7 mm) circum- (Ref. AMM TASK 72-00-00-200-

ferential length by 0.25 in. (6.35 025) .

mm) axial length spaced by a

minimum of 0.25 in. (6.35 mm)

5.Borescope ferrule welds for:

A.Cracks Any amount

(6) When the inspection is complete, turn off the light source and remove the borescope.

(7) If any defects are found then remove additional borescope plugs and the spark igniters to inspect all

of the combustion chamber.

If no defects are found, install parts removed for borescope inspection.

Subtask 72-42-00-290-078-A

C. Do a borescope inspection for DAC II engine

Print Date: October 05, 2021 Page 46 of 76

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : VJC Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2021

72-42-00 - (CFMB) - COMBUSTION CHAMBER ASSEMBLY

(1) Use the MONITOR, RESOLUTION BORESCOPE (856A1323) (856A1323G01) to make sure

the borescope and the lightsource are serviceable. See the Non-Destructive Test Manual for this

procedure Ref. NTM 720000.

(2) Connect the fiber light cable to the BORESCOPE-KIT (856A1320) (856A1320P04/P05) and to the

port on BORESCOPE-LIGHT SOURCE SET (856A1322) (856A1322P03/P04/P07).

(3) Put the rigid borescope of the (856A1320P04/P05), into the ports and turn on the light source of

borescope-lightsource set (856A1322P03/P04).

(4) Turn the rigid borescope a full 360 degrees to inspect the domes of the combustion chamber, fuel

nozzles, the inner and outer liners, and the aft sections. Adjust the borescope equipment to obtain

maximum clarity of view.

(5) Inspect the following :

INSPECT/CHECK MAXIMUM SER- REMARKS

VICEABLE LIMITS

1.All surfaces for :

A.Discoloration Any amount

B.Carbon Accumulation Any amount

C.Missing, chipped or spalled Any amount

areas of thermal barrier coating

2.Dome Assemblies (Spectacle

Plate and Deflector) for :

A.Distortion of deflector Any amount

B.Radial crack in spectacle Any number up to 1 in. (25.4 See limit extensions

plate mm) length and not connected (Ref. AMM TASK 72-00-00-200-

025)

C.Circumferential crack in Any number up to 3 in. (76.2 See limit extensions

spectacle plate mm) length separated by 6 in. (Ref. AMM TASK 72-00-00-200-

(152.4 mm) 025)

D.Connected cracks in spec- Not more than (1) radial crack See limit extensions

tacle plate 1 in. (25.4 mm) long with (1) cir- (Ref. AMM TASK 72-00-00-200-

cumferential crack 3 in. (76.2 025)

mm) long