Professional Documents

Culture Documents

Job Hazard Analysis Form

Uploaded by

Prakash PalaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Hazard Analysis Form

Uploaded by

Prakash PalaiCopyright:

Available Formats

Task

Arc Welding

Job Hazard Analysis Form Completed by

Scott Brehmer and Frank Chavoya

Required PPE

Arc flash shield/helmet, leather welder’s jacket, insulated

gloves, apron steel-toed boots, and safety glasses

Date Notes

9/28/17 Need to verify local exhaust ventilation. Per Cal/OSHA - Inert-gas

metal-arc welding on stainless steel shall not be performed unless

exposed employees are protected either by local exhaust ventilation

or by wearing supplied air respirators.

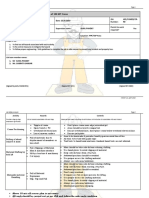

Step Picture Step Description Hazards Controls

• Complete CSUF training on electrical

safety (NFPA 70E), fire extinguisher use

Perform pre-use equipment

1 • NA and arc welder use

inspection

• Inspect insulation, cables, connectors,

grounding, and PPE

• Remove flammable and combustible

materials from the work area (minimum of

35 feet diameter clearance)

• Eye injury from arc flash • Ensure fire extinguishing equipment is

• Fire or explosion maintained and immediately available in

• Health hazards from the work area

2 Prepare for arc welding

accumulation of toxic gases • Evaluate material to be welded for

within the work area flammability and toxicity

• Electric shock • Secure the work area

• Apply and maintain proper grounding

• Open one or more facility doors and use

fans as needed to ensure good ventilation

• Keep wires untangled and away from

3 Turn on power and unwrap wire • Tripping

standing work area

4 Insert arc welding rod in handle • Pinching of fingers • Keep fingers away from pinch points

JHA - Arc Welding Page 1 of 2

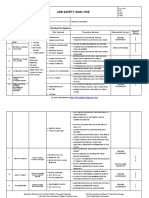

Step Picture Step Description Hazards Controls

• Wear arc flash shield/helmet, insulated

leather gloves and welder’s jacket, steel-

• Eye injury from arc flash toed boots, apron, half-face air purifying

• Burns to skin respirator with particulate filters

• Fire or explosion • Complete CSUF Hot Work Permit

• Health hazards from • Secure the work area

5 Strike arc and perform welding

accumulation of toxic gases • Apply and maintain proper grounding

within the work area • Use supplied air respirators where local

• Electric shock exhaust ventilation is not available

• Heat stress • Take breaks from welding hourly to

prevent heat stress

• Unit will not start with proper grounding

• Wear gloves

• If appropriate spray finished product with

cool water

6 Allow finished product to cool • Burn to skin

• Allow finished product to cool in a safe and

secured location

• Chalk mark the welded area “hot”

• Wear gloves

Remove remainder of arc welding • Allow finished product to cool in a safe and

7 • Burn to skin

rod from handle and allow to cool secured location

• Chalk mark the welded area “hot”

Remove excess slag from • Eye damage from flying debris • Wear safety glasses

8 finished product with chipping as hammer strikes • Avoid striking hands or fingers with

hammer • Injury to hand or fingers hammer

JHA - Arc Welding Page 2 of 2

You might also like

- 04.unloading of MaterialsDocument6 pages04.unloading of MaterialsKiran ChenchalaNo ratings yet

- Job Safety Analysis PSA-MailDocument50 pagesJob Safety Analysis PSA-MailechaNo ratings yet

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 pagesAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640No ratings yet

- JHA Welding Arc and Cutting (Hotwork)Document2 pagesJHA Welding Arc and Cutting (Hotwork)Popo EaldamaNo ratings yet

- Hot Work Activities (Cutting)Document9 pagesHot Work Activities (Cutting)Al Mughsar CompanyNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- HT & PWHT JsaDocument3 pagesHT & PWHT JsaNature BeautiesNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectionjithin shankarNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument4 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- 972 99 100 (Mobile) : Job Safety AnalysisDocument8 pages972 99 100 (Mobile) : Job Safety AnalysisSreeraj Reghunathan Nair VanmazhyNo ratings yet

- Magna Bend SopDocument1 pageMagna Bend SopClarkKent Fabro Batucan0% (1)

- JSA For KAHSDocument6 pagesJSA For KAHSFrancis Enriquez TanNo ratings yet

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- 4.cutting Grinding WeldingDocument5 pages4.cutting Grinding WeldingMohammad Fazal KhanNo ratings yet

- Rigging JSA RiggerDocument12 pagesRigging JSA RiggeraQiLGunawanNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Mig Welding Work JSA HSE ProfessionalsDocument2 pagesMig Welding Work JSA HSE ProfessionalsNoval Febri100% (1)

- Job Safety Analysis Forklift OperationsDocument2 pagesJob Safety Analysis Forklift Operationssufiyanshaikh50% (2)

- Safety Alert 260 - Unsafe Cradle Installation and UsageDocument2 pagesSafety Alert 260 - Unsafe Cradle Installation and UsageAbdulKatherNo ratings yet

- JHA # 009 - Hot WorkDocument7 pagesJHA # 009 - Hot WorkkumarNo ratings yet

- EEEPL - JSA Unloading MaterialsDocument3 pagesEEEPL - JSA Unloading MaterialsnishanthNo ratings yet

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- Jha - Forklift OperationalDocument14 pagesJha - Forklift OperationalAliff ApamNo ratings yet

- JSA - Electrical IsolationDocument1 pageJSA - Electrical IsolationRaju KhalifaNo ratings yet

- Petrochina International Jabung LTD.: Job Safety AnalysisDocument4 pagesPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNo ratings yet

- JSA Forklift PDFDocument2 pagesJSA Forklift PDFfauziNo ratings yet

- Job Hazard Analysis Welding Operations: Job Title: Work Place LocationDocument18 pagesJob Hazard Analysis Welding Operations: Job Title: Work Place Locationmuhammad imtiaz100% (1)

- Websdr PDFDocument11 pagesWebsdr PDFDoruNastaseNo ratings yet

- Workshop Manual: 3LD 450 3LD 510 3LD 450/S 3LD 510/S 4LD 640 4LD 705 4LD 820Document33 pagesWorkshop Manual: 3LD 450 3LD 510 3LD 450/S 3LD 510/S 4LD 640 4LD 705 4LD 820Ilie Viorel60% (5)

- Job Safety Analysis (JSA) : Description Hazard ControlDocument3 pagesJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrNo ratings yet

- Jsa PaintDocument2 pagesJsa PaintKhalid NaseemNo ratings yet

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Document4 pages0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- 15.tube Bundle Puller.Document3 pages15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- Unit 5 and 6Document2 pagesUnit 5 and 6Leo GonellNo ratings yet

- JSA #19 Grinding, Welding, Gas CuttingDocument2 pagesJSA #19 Grinding, Welding, Gas CuttingSubham Sohal100% (1)

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- JSA-For Lifting Activity by CraneDocument3 pagesJSA-For Lifting Activity by CraneEman MantoNo ratings yet

- Hazard Identification and Risk Assessment WorksheetDocument4 pagesHazard Identification and Risk Assessment WorksheetNaveed Ahmed Get-InfoNo ratings yet

- Physical Storage: Data ONTAP 8.0 7-Mode AdministrationDocument71 pagesPhysical Storage: Data ONTAP 8.0 7-Mode AdministrationkurtenweiserNo ratings yet

- Addicted1 - The Inquietude of YouthDocument867 pagesAddicted1 - The Inquietude of YouthIlsa Krisdwiyani100% (1)

- Jsa Loading and Unloading of Pile PipesDocument4 pagesJsa Loading and Unloading of Pile PipesOsiobe Ewomazino100% (1)

- Week 2 Day 1 GRADE 8Document2 pagesWeek 2 Day 1 GRADE 8Anonymous yElhvOhPnNo ratings yet

- Job Safety Analysis Erection SiloDocument3 pagesJob Safety Analysis Erection SiloDanangNo ratings yet

- Tool Box Talk - 8 Lifting EquipmentDocument2 pagesTool Box Talk - 8 Lifting EquipmentMoaatazz Nouisri100% (1)

- JSA - Suface Preparationand Brush PaintingDocument5 pagesJSA - Suface Preparationand Brush PaintingAzad pravesh khanNo ratings yet

- JSA - Dismantling CM ShedDocument4 pagesJSA - Dismantling CM ShedvivekaramanaNo ratings yet

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- Jsa Insulation WorkDocument20 pagesJsa Insulation WorkazerNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document5 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- Z - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Document3 pagesZ - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Din JalilNo ratings yet

- Job Safety Analysis (JSA) - Painting DateDocument2 pagesJob Safety Analysis (JSA) - Painting DatenabeelNo ratings yet

- JSA-03 Shed DismantlingDocument3 pagesJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Job Hazard Analysis (JHA) Report: Rev: 01 Page 1 of 1Document1 pageJob Hazard Analysis (JHA) Report: Rev: 01 Page 1 of 1Siddharth RanaNo ratings yet

- 2020 06 17 JSA For AC Servicing-Server RoomDocument12 pages2020 06 17 JSA For AC Servicing-Server RoomDarren OscarNo ratings yet

- 39-98 - Safe Use of Lifting Machines and Lifting Tackle - 0Document59 pages39-98 - Safe Use of Lifting Machines and Lifting Tackle - 0JakesNo ratings yet

- Job Hazard Analysis - Granite Surface PlateDocument2 pagesJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNo ratings yet

- Job Safety AnalysisDocument2 pagesJob Safety AnalysiscitraNo ratings yet

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- JSA For Flue Gas Duct Height WorkDocument4 pagesJSA For Flue Gas Duct Height Worksubhadipmanna8No ratings yet

- File - 20200905 - 105458 - Jsa Wind PowerDocument10 pagesFile - 20200905 - 105458 - Jsa Wind PowerMon Trang NguyễnNo ratings yet

- Risk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelDocument3 pagesRisk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelMohamed Elnagdy100% (1)

- JSA Erection of Steel StructureDocument9 pagesJSA Erection of Steel StructureOvais FarooqNo ratings yet

- WeldingDocument2 pagesWeldingPrakash PalaiNo ratings yet

- HH:MM Dd/Mm/Yyy HH:MM Dd/Mm/Yyy: Yes No N/A Sr. Yes No N/ADocument3 pagesHH:MM Dd/Mm/Yyy HH:MM Dd/Mm/Yyy: Yes No N/A Sr. Yes No N/AechaNo ratings yet

- MEDUCA04Feb 016Document1 pageMEDUCA04Feb 016echaNo ratings yet

- An Example of Systems Engineering: Andy Paliszewski Siemens Energy Inc. Director Wind R&D Boulder, CODocument18 pagesAn Example of Systems Engineering: Andy Paliszewski Siemens Energy Inc. Director Wind R&D Boulder, COecha100% (1)

- Agitated Thin Film Dryer ClaculationDocument12 pagesAgitated Thin Film Dryer ClaculationakaashNo ratings yet

- Dans Swing Trade StrategyDocument3 pagesDans Swing Trade StrategyDimitrios OuzounisNo ratings yet

- Hotel Management System AbstractDocument8 pagesHotel Management System AbstractJayesh TupeNo ratings yet

- HW - Module 1 & 2 Exercise Questions To Be SolvedDocument7 pagesHW - Module 1 & 2 Exercise Questions To Be Solvedjaryal.sarthak.jaryalNo ratings yet

- Caps 5Document4 pagesCaps 5shheNo ratings yet

- L807268EDocument1 pageL807268EsjsshipNo ratings yet

- Database NotesDocument4 pagesDatabase NotesKanishka SeneviratneNo ratings yet

- Formalismo Geométrico de La Mecánica Cuántica y Sus Aplicaciones A Modelos MolecularesDocument51 pagesFormalismo Geométrico de La Mecánica Cuántica y Sus Aplicaciones A Modelos Moleculareshugo_valles_2No ratings yet

- Cse205 Computer-Architecture-And-Organization TH 2.00 Ac26Document2 pagesCse205 Computer-Architecture-And-Organization TH 2.00 Ac26Ravi ThejaNo ratings yet

- Line-And-Staff Organizations - Examples, Advantages, Manager, Type, Company, Disadvantages, BusinessDocument4 pagesLine-And-Staff Organizations - Examples, Advantages, Manager, Type, Company, Disadvantages, BusinessSangram PradhanNo ratings yet

- Assignment (60%) : ECS312 Counselling in SchoolsDocument6 pagesAssignment (60%) : ECS312 Counselling in SchoolsJelebu Charity RunNo ratings yet

- Pride&PrejudiceDocument88 pagesPride&PrejudiceMà Ř YãmNo ratings yet

- Pms 500 - International Mechanics KitDocument0 pagesPms 500 - International Mechanics KitArsul RNo ratings yet

- THE 3RD INDONESIA EBTKE CONEX 2014 (4-6 June'14) PDFDocument10 pagesTHE 3RD INDONESIA EBTKE CONEX 2014 (4-6 June'14) PDFArik AprilliyantoNo ratings yet

- UK Patient Metronidazole Vaginal Gel Medication LeafletDocument4 pagesUK Patient Metronidazole Vaginal Gel Medication Leafletmarisa apriliaNo ratings yet

- Jisicom - Smart System of Fast Internet Access Development Using Backbone Network MethodDocument9 pagesJisicom - Smart System of Fast Internet Access Development Using Backbone Network MethodVerdi YasinNo ratings yet

- History of Operating SystemDocument16 pagesHistory of Operating SystemBryan John BerzabalNo ratings yet

- Analytic Solutions of A Two Dimensional Rectangular Heat Equation PDFDocument5 pagesAnalytic Solutions of A Two Dimensional Rectangular Heat Equation PDFreff1694No ratings yet

- Embedded Modules: Pci Express Minicard and Lga Modules High-Speed Multi-Mode 3GDocument4 pagesEmbedded Modules: Pci Express Minicard and Lga Modules High-Speed Multi-Mode 3GYaSeregaNo ratings yet

- Introduction To Public Policy: Course DescriptionDocument15 pagesIntroduction To Public Policy: Course DescriptionJericko Perez AvilaNo ratings yet

- Councillor Danny Thorpe: Leader, Royal Borough of GreenwichDocument2 pagesCouncillor Danny Thorpe: Leader, Royal Borough of GreenwichDr-Syed Ali TarekNo ratings yet

- Grammar - File12 C ROMERO VIDALDocument3 pagesGrammar - File12 C ROMERO VIDALYuy Oré Pianto50% (2)

- Industrial Development Economic Growth in Andhra PradeshDocument9 pagesIndustrial Development Economic Growth in Andhra PradeshMurali Krishna ReddyNo ratings yet

- Civil Engineering MCQ'sDocument1 pageCivil Engineering MCQ'sNISHIKANTA MONDALNo ratings yet