Professional Documents

Culture Documents

11 Gas Cutting

Uploaded by

Prakash PalaiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

11 Gas Cutting

Uploaded by

Prakash PalaiCopyright:

Available Formats

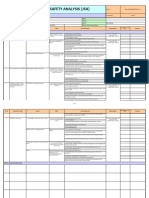

JHA on gas cutting and welding

Tools and tackles required : Cutting Machine, Gas cutting, oxy –

acetylene/LPG Cylinders,Hoses,torch etc

PPE required : Hard Hat, Safety Shoes, Apron, and Welding

Shield, Safety Goggles, Hand Gloves.

Authorization required : Work permit

Sl. Sequence of Potential Hazards Protective measures to be taken

No. the job Action By

Ensure the worksite is free from Site

flammable / toxic vapor or liquid by Engineer

Presence of

safe preparation (isolation,

flammable / toxic

depressurizing, draining, venting,

Vapor or Liquid

flushing, purging as required)

The entry of non – certified tools / Site

equipment (Welding Transformer, Engineer

Generator, Mobile Plant etc) to be

1 Planning

authorized under Permit to Work

Fire & Explosion System.

Keep the fire extinguishers & fire

hoses in ready condition.

Keep trained fire watch

supervisor/safety steward.

Take a Hot Work Permit and other

Unauthorized Work Site

associated permits from company.

Engineer

Ensure the welding equipment

(torch, cable, electrode holder, Site

transformer, generator, cable Engineer

Defective Tools

connector, plugs, sockets etc) are

free from defect and earthed as

2 needed.

Cutting / Radiation from UV / Wear protective goggles. Site

Welding IR Rays (Flash Eye) Engineer

Ensure proper ventilation and fume Site

Exposure to Welding

extraction equipment in case of Engineer

Fumes

welding inside an enclosure

Wear long sleeved coverall, leather Site

Burns

apron; welder’s hood. Engineer

Falling of Sparks / Enclose the welding area through Site

hot bids wool blanket. Engineer

Provide a check valve (flash back Site

Flash Back Fire

arrester) between oxy- Engineer

Sl. Sequence of Potential Hazards Protective measures to be taken

No. the job Action By

acetylene/LPG hose& gas regulator.

Ensure the cables have proper Site

insulation and connector as well as Engineer

termination joints are safe for the

Electric Shock

purpose.

Locate the emergency stop switch

for immediate power isolation.

Keep oxy – acetylene/LPG cylinders Site

at least 5 meters away from hot Engineer

Cylinder near the Hot

work area.

Work area

Isolate the cylinder when not in

use.

Keep Welding Generator at least 5 Site

Transformer / meters away from hot work area. Engineer

Generator near the

Hot Work area Stop the generator when not in

use.

Ensure proper wind up &

3 housekeeping at worksite.

The accessories (torch, cable, Site

Windup &

Scattered Material electrode holder) not being used engineer

Housekeeping

must be disconnected from

transformer / generator and stored

separately.

Gas leakage detection to be Store officer

installed at above the gas cylinder

4 store area. It immediately gives

Storage area Gas leakage signal /siren in cense of any

leakage detected.

Fully cylinder shall be stored

vertically.

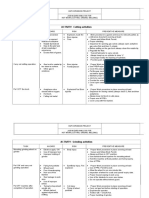

Kakrapar Atomic power Project-3 & 4

Check List for Gas cutting and welding

Date:

SL. REMARK

NO S

DESCRIPTION STATUS

Available of flashback arrester on both side of the cylinder

1 YES NO

Soap water for checking of gas leakage

2 YES NO

Damage in hose

3 YES NO

Availability and condition of trolley

4 YES NO

Welding Equipment/tools are contained in good working

5 YES NO

Condition

Whether fire extinguisher and fire point is available

6 YES NO

Welders are were boiler suit

7 YES NO

Work site free from flammable /toxic vapor or liquid

8 YES NO

Keep Welding Generator at least 5 meters away from hot

9 YES NO

work area

whether all the workmen wearing required PPE’s

10 YES NO

Condition of torch & nozzle of gas cutting set.

11 YES NO

Scrap material are store at separate place

12

Position of cylinder whether it is in upward or not

13 YES NO

Availability of Chuckey for open and closing of cylinders

14 YES NO

Availability of lugs & local earthing to the welding machine

15 YES NO

Work permit is taken

16 YES NO

Whether plug available to the welding machine

17 YES NO

18 YES NO

150 lux illumination shall be available

Asbestos Sheet is layed avoiding of sparks fall on ground

19 YES NO

from height

20 YES NO

Welding Shield/Gas cutting goggles wear

Checked by Authorized by

Site Engineer Safety Engineer

Signature :

Name :

Date :

You might also like

- JSA of Glass FixingDocument5 pagesJSA of Glass FixingPAVANKUMAR50% (2)

- Jsa For Welding, Grinding, Gas CuttingDocument2 pagesJsa For Welding, Grinding, Gas Cuttingwahyu nugroho50% (2)

- Jsa For Dewatering PumpDocument1 pageJsa For Dewatering PumpMobin Thomas Abraham100% (3)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyanNo ratings yet

- Gas Cutting JsaDocument4 pagesGas Cutting JsaMohammed Minhaj100% (1)

- JSA For Concrete, Brecking, ExavationDocument6 pagesJSA For Concrete, Brecking, ExavationBinay0% (1)

- JSa For Operation of Jack HammeringDocument3 pagesJSa For Operation of Jack Hammeringyc safety0% (1)

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- Scrap Material Handling & Loading Jha - 1Document2 pagesScrap Material Handling & Loading Jha - 1Dwitikrushna Rout100% (1)

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (2)

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseDocument9 pagesJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- JHA - Installation of Pipe & Support For Fire Protection 1Document7 pagesJHA - Installation of Pipe & Support For Fire Protection 1Ralph Castillo100% (2)

- Vehicular Movement Job Safety Analysis (JSA)Document2 pagesVehicular Movement Job Safety Analysis (JSA)sudam kumar raut100% (2)

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- JSA # 3 Column ErectionDocument6 pagesJSA # 3 Column ErectionRaghava Richhu100% (2)

- TEIPL-JSA-058 Carpentry Wood WorkDocument3 pagesTEIPL-JSA-058 Carpentry Wood Workba ratnaparkheNo ratings yet

- JSA SK Erection DismantlingDocument1 pageJSA SK Erection DismantlingSamuel Hugos100% (4)

- JSA Appendix Cutting, Grinding ConcreteDocument8 pagesJSA Appendix Cutting, Grinding ConcreteĐặng Quang Huy100% (1)

- Sinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Document3 pagesSinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Nora Afzam Abd WahabNo ratings yet

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- HT & PWHT JsaDocument3 pagesHT & PWHT JsaNature BeautiesNo ratings yet

- Scrap Material Cutting, Handling & Loading Jha - 2Document3 pagesScrap Material Cutting, Handling & Loading Jha - 2Dwitikrushna Rout100% (5)

- JSA For Cutting, Grinding and WeldingDocument4 pagesJSA For Cutting, Grinding and Weldingyc safety100% (3)

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectionjithin shankarNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- ASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricDocument14 pagesASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricSinan Chen100% (1)

- JSA Hot WorkDocument2 pagesJSA Hot Workchhotelal kumar100% (1)

- Shifting of Material & Equipment.: Job Safety Analysis JobDocument6 pagesShifting of Material & Equipment.: Job Safety Analysis JobPrabir PujariNo ratings yet

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDocument5 pagesJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (4)

- JSA For DuctDocument13 pagesJSA For DuctRakeshkasarlaNo ratings yet

- JHA 08 On Erection of Roofing SheetsDocument3 pagesJHA 08 On Erection of Roofing SheetsAkhilesh KumarNo ratings yet

- Jsa Cable TerminationDocument4 pagesJsa Cable TerminationSyed Yousuf Ali100% (1)

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Document7 pagesHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe Ewomazino50% (2)

- Job Hazard Analysis (Drilling)Document2 pagesJob Hazard Analysis (Drilling)jay RNo ratings yet

- JHA PlumberDocument3 pagesJHA PlumberEko Susanto100% (1)

- General Biology 2: Nutrition of Plants and AnimalsDocument19 pagesGeneral Biology 2: Nutrition of Plants and AnimalsBea Bayona Jolo50% (2)

- 12-JSA Pipe Erection Work - Existing Pipe RackDocument4 pages12-JSA Pipe Erection Work - Existing Pipe RackSwaminathan ThayumanavanNo ratings yet

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDocument5 pagesJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANNo ratings yet

- Jobs Safety Analysis (JSA)Document9 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- Job Safety Analysis Sheet: Electrical IsolationDocument1 pageJob Safety Analysis Sheet: Electrical IsolationLal Dhwoj100% (2)

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Raman SawNo ratings yet

- JSA For Fabrication WorksDocument11 pagesJSA For Fabrication Workssurendra behera100% (3)

- Job Safety and Environmental Analysis WorksheetDocument2 pagesJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson Escamillan100% (1)

- JSA Unloading & SHIFTING by Manually 10-01-2017Document16 pagesJSA Unloading & SHIFTING by Manually 10-01-2017PAVANKUMAR100% (1)

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- Jsa forOperatingAForkliftDocument2 pagesJsa forOperatingAForkliftsupahing supahingNo ratings yet

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 pageJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingGudduNo ratings yet

- Yanmar 6EY17W Op ManualDocument213 pagesYanmar 6EY17W Op ManualEdwin Paskal50% (4)

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNo ratings yet

- JHA Chain HoistDocument1 pageJHA Chain HoistKrishna Patil100% (2)

- JSA For Cable Tray Installation-Reviewed by CBREDocument10 pagesJSA For Cable Tray Installation-Reviewed by CBREPrakash Tiwari88% (8)

- Tie in Hot Work JHADocument4 pagesTie in Hot Work JHAmalik jahan100% (2)

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Document1 pageJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- EXPT 4 - Production of Liquid Detergent - Post LabDocument16 pagesEXPT 4 - Production of Liquid Detergent - Post LabYnno88% (8)

- JHA For Installation of Boiler AccessoriesDocument2 pagesJHA For Installation of Boiler Accessoriesperquino oasan100% (3)

- Final Interview Script ScienceDocument3 pagesFinal Interview Script ScienceSean Gong67% (3)

- Job Safety Analysis Erection SiloDocument3 pagesJob Safety Analysis Erection SiloDanangNo ratings yet

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Anonymous voA5Tb0No ratings yet

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- Job Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Document5 pagesJob Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Madhan KannanNo ratings yet

- Jsa Slip FormDocument5 pagesJsa Slip Formputrasejahtra50% (2)

- Job Hazard AnalysisDocument1 pageJob Hazard AnalysisReynaldo PesqueraNo ratings yet

- Module 3Document30 pagesModule 3Dheemanth DNo ratings yet

- Decontamination - Managing Spills of Blood and Body Fluids and SubstancesDocument2 pagesDecontamination - Managing Spills of Blood and Body Fluids and SubstancespriyaNo ratings yet

- 2019 Container LabelDocument31 pages2019 Container Labeljoevil andayaNo ratings yet

- Chapter 1 (Lecture 1)Document29 pagesChapter 1 (Lecture 1)Fnur FatihahNo ratings yet

- Solid Lipid Microparticles As Carriers of Vaccinium Myrtillus and Schinus Molle Linn Additives For Food ApplicationDocument8 pagesSolid Lipid Microparticles As Carriers of Vaccinium Myrtillus and Schinus Molle Linn Additives For Food ApplicationHerald Scholarly Open AccessNo ratings yet

- Ebbing of The Guardian: A Dissection of The Law Protecting The Ozone LayerDocument9 pagesEbbing of The Guardian: A Dissection of The Law Protecting The Ozone LayerLAW MANTRANo ratings yet

- Dishwashing Liquid Is A Detergent Used To Assist in DishwashingDocument3 pagesDishwashing Liquid Is A Detergent Used To Assist in DishwashingLeonilo BacalsoNo ratings yet

- Chapter 1 - Radiator System ProductsDocument28 pagesChapter 1 - Radiator System ProductsFeras BatarsehNo ratings yet

- Household & Public Health: Ticks - Biology and Their ControlDocument4 pagesHousehold & Public Health: Ticks - Biology and Their ControlmdollNo ratings yet

- Experiment 3: Redox Titration: Group: 3 Section: Thursday Afternoon Date: 7/3/2019Document6 pagesExperiment 3: Redox Titration: Group: 3 Section: Thursday Afternoon Date: 7/3/2019Bùi Nhật MaiNo ratings yet

- Cellular Organiztationpf The CellDocument2 pagesCellular Organiztationpf The CellKathleen NocheNo ratings yet

- Physiology Summary Chapter 32Document6 pagesPhysiology Summary Chapter 32gail018No ratings yet

- SPL Konfort 7xx Full en Rev01Document8 pagesSPL Konfort 7xx Full en Rev01kallatisNo ratings yet

- En Lucitone 199 PowderDocument6 pagesEn Lucitone 199 Powderpmg000No ratings yet

- Project Simualtion DR ShawalliahDocument17 pagesProject Simualtion DR ShawalliahharrisNo ratings yet

- June 2017 CI Franklin Avenue Bridge ArticleDocument10 pagesJune 2017 CI Franklin Avenue Bridge ArticleFernando Castillo HerreraNo ratings yet

- G-Study and Revision Skills - IGCSE Chemistry Scool CDDocument13 pagesG-Study and Revision Skills - IGCSE Chemistry Scool CDPrincess Kim100% (1)

- Erbil H.Y. - Surface Chemistry of Solid and Liquid Interfaces (2006) (352s) - 12-21Document10 pagesErbil H.Y. - Surface Chemistry of Solid and Liquid Interfaces (2006) (352s) - 12-21amaterasu31416No ratings yet

- Correlation AND Prediction of Mineral Solubilities in The Reciprocal Salt System (Na+, K') (CL-, SO:-) - Hz0 AT 0-100°CDocument10 pagesCorrelation AND Prediction of Mineral Solubilities in The Reciprocal Salt System (Na+, K') (CL-, SO:-) - Hz0 AT 0-100°CJuliano MilherNo ratings yet

- 9th Matter in Our SurroundingsDocument3 pages9th Matter in Our SurroundingsAmmär MasòódNo ratings yet

- Stoichiometry 3 MSDocument5 pagesStoichiometry 3 MSEbaad RehmanNo ratings yet

- Regulation of Histidine and Hut OperonsDocument11 pagesRegulation of Histidine and Hut Operonsaditi_joshee419No ratings yet

- Analitycal Methods AADocument164 pagesAnalitycal Methods AAPaola Solange Cardozo CastilloNo ratings yet

- Folheto Anapat v.02 IngDocument1 pageFolheto Anapat v.02 IngesteriplasNo ratings yet