Professional Documents

Culture Documents

Torsion TEST Torsion TEST: Lab Strength (Universiti Teknologi MARA) Lab Strength (Universiti Teknologi MARA)

Uploaded by

Winter NaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Torsion TEST Torsion TEST: Lab Strength (Universiti Teknologi MARA) Lab Strength (Universiti Teknologi MARA)

Uploaded by

Winter NaiCopyright:

Available Formats

lOMoARcPSD|10287828

Torsion TEST

lab strength (Universiti Teknologi MARA)

StuDocu is not sponsored or endorsed by any college or university

Downloaded by sdasd ddasd (int9ii9t@uuf.me)

lOMoARcPSD|10287828

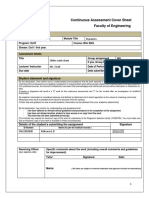

FACULTY OF MECHANICAL ENGINEERING

Teamwork Assessment Form

Name : RIYAN SHAHABY BIN SHUIB

Student ID : 2019695446

BIl Name Matrix Number

1. WAN HANIS IZYAN BT WAN ABDUL SALAM 2019893158

2. SYAHMIE IDHAM BIN MOHD SHARULNIZAM 2019801558

3. WAN MUHAMMAD SYAKIR AIMAN BIN WAN SUPIAN 2019495924

4. SYED AHMAD IZZAT AMIR BIN SYED OMAR 2019893266

1 2 3 4 5

Scale

Level Poor Acceptable Excellent

You will rate yourself and your team members on the following criteria

Earned Assessment

Element Members

Self

1 2 3 4

I was ready to work with my team 5 5 5 5 5

I did my assigned work well and always on time 5 5 5 5 5

I was fair to my teammates and myself 5 5 5 5 5

I listened to others appreciatively and was supportive 5 5 5 5 5

I was very committed and focused in my team 5 5 5 5 5

I put extra efforts to finish or accomplish our task 5 5 5 5 5

I encouraged others in my team and was helpful 5 5 5 5 5

I managed and coordinated team efforts effectively 5 5 5 5 5

I was able to lead discussions and provide solutions 5 5 5 5 5

Overall, I was very satisfied and enjoyed my work 5 5 5 5 5

50 5 5 5 5

Total

0 0 0 0

Comment

Self: Helpful and understanding

Member 1: Helpful

Member 2: Asked a lot of good question

Member 3: Quiet but informative

Member 4: Leadership skill at its finest

Downloaded by sdasd ddasd (int9ii9t@uuf.me)

lOMoARcPSD|10287828

RIYAN SHAHABY BIN SHUIB (2019695446) EMD4M1B

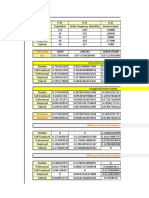

RESULTS

1. Plot torque angle against angle of twist of the specimen. Observe the elastic point,

maximum torque point and at fracture.

Elastic point Maximum torque point Fracture

Downloaded by sdasd ddasd (int9ii9t@uuf.me)

lOMoARcPSD|10287828

RIYAN SHAHABY BIN SHUIB (2019695446) EMD4M1B

2. Tabulate your result in the following table

Material type =Mild Steel, Length =0.084m, Diameter =0.006m

Scale reading at Twisting angle Twisting angle Load Torque Shear Stress Shear Strain

the worm gear at the specimen in Radian in Nm (Pa)

input in rev in degrees

0 0 0 0 0 0

0.25 1.45 0.03 0.2 4716981.132 0.001

0.5 2.90 0.05 0.95 22405660.38 0.002

0.75 4.35 0.08 2.6 61320754.72 0.003

1 5.80 0.10 5.05 119103773.6 0.004

1.5 8.70 0.15 10.35 244103773.6 0.005

2 11.60 0.20 15.4 363207547.2 0.007

2.5 14.50 0.25 18.65 439858490.6 0.009

3 17.40 0.30 20.45 482311320.8 0.011

4 23.21 0.40 22 518867924.5 0.014

5 29.02 0.50 22.8 537735849.1 0.018

6 34.83 0.60 22.95 541273584.9 0.021

7 40.64 0.70 22.65 534198113.2 0.025

8 46.45 0.81 22.7 535377358.5 0.029

9 52.26 0.91 22.8 537735849.1 0.033

10 58.07 1.01 22.85 538915094.3 0.036

11 63.88 1.11 22.75 536556603.8 0.039

12 69.69 1.21 22.75 536556603.8 0.043

13 75.50 1.31 22.6 533018867.9 0.047

14 81.31 1.41 22.7 535377358.5 0.051

15 87.12 1.51 22.7 535377358.5 0.054

16 92.93 1.61 22.75 536556603.8 0.058

17 98.74 1.71 22.8 537735849.1 0.061

18 104.55 1.82 22.8 537735849.1 0.065

Scale reading at Twisting angle Twisting angle Load Torque Shear Stress Shear Strain

the worm gear at the specimen in Radian in Nm (Pa)

input in rev in degrees

19 110.36 1.92 22.8 537735849.1 0.069

20 116.17 2.02 22.8 537735849.1 0.072

21 121.98 2.12 22.8 537735849.1 0.076

22 127.79 2.22 22.75 536556603.8 0.079

23 133.60 2.32 22.8 537735849.1 0.082

Downloaded by sdasd ddasd (int9ii9t@uuf.me)

lOMoARcPSD|10287828

24 139.41 2.42 22.75 536556603.8 0.086

25 145.22 2.52 22.85 538915094.3 0.090

26 151.03 2.62 22.85 538915094.3 0.094

27 156.84 2.72 22.8 537735849.1 0.097

28 162.65 2.83 22.8 537735849.1 0.101

29 168.46 2.93 22.8 537735849.1 0.105

30 174.27 3.03 22.8 537735849.1 0.108

31 180.08 3.13 22.8 537735849.1 0.112

33 191.69 3.33 22.75

536556603.8 0.119

(Fracture)

RIYAN SHAHABY BIN SHUIB (2019695446) EMD4M1B

SAMPLE OF CALCULATION

1. Angle of twist (degree to radian),

Given, θ = 90°

2π

= 90° ×

360

¿ 0.25 rad

2. Polar moment of inertia,

π

J= ( Radius , R)4

2

Downloaded by sdasd ddasd (int9ii9t@uuf.me)

lOMoARcPSD|10287828

π

J= (0.003)4

2

−10 4

J = 1.272 × 10 m

3. Shear Stress,

( Torque , T ) ×( Radius , R)

τ=

(Polar moment of inertia , J )

0.2× 0.003

τ=

1.272 ×10−10

τ = 4716981.132 Pa @ 4.717 MPa

4. Shear Strain,

( Radius , R ) ×( Angle of Twist , ϴ)

γ=

( Length , L)

0.003× 0.03

γ=

0.084

γ = 0.001

Downloaded by sdasd ddasd (int9ii9t@uuf.me)

lOMoARcPSD|10287828

RIYAN SHAHABY BIN SHUIB (2019695446) EMD4M1B

DISCUSSION

1. Compare the values of G obtained from this experiment with the value obtain

from the manufacturer.

The theoretical value for mild steel is 78 GPa. By torsional test, the rigidity modulus

values of materials can be determined. Modulus of rigidity also known as a shear modulus.

The ratio of shear stress to the corresponding shear strain within the proportional limit of a

material is the modulus of rigidity (G). the modulus of rigidity is the elastic coefficient when

a shear force is applied resulting in lateral deformation. In this experiment, type of specimen

used is mild steel. From the experiment, value for modulus of rigidity can be calculated as

below:

Modulus of rigidity:

G= ( Shear Strain , γ )

Shear Stress , τ

G= ( 244103773.6

0.005 )

G=48.82GPa

2. Comment on any discrepancies.

Error happened during the experiment was conducted is one of the reasons

why there is difference between experimental and theoretical value. All the errors

happened are not always due to mistake while performing the experiment. Firstly,

systematic error, Errors of this type result in measured values that are consistently too

high or consistently too low. For example, observational error, parallax in reading a

meter scale and also instrumental errors when the instrument is having some

troubleshoot. Next, Random errors are positive and negative fluctuations that cause

about one-half of the measurements to be too high and one-half to be too low. Sources

of random errors cannot always be identified In this experiment, student might not

twist the specimen to the exact angle as stated in the procedure. While the meter is not

stable, student already taking the reading from the torsion meter. These two situations

Downloaded by sdasd ddasd (int9ii9t@uuf.me)

lOMoARcPSD|10287828

might lead to the inaccurate data recorded and will affected the calculation in the

result section. The errors can be reduced by taking the average reading of the results.

RIYAN SHAHABY BIN SHUIB (2019695446) EMD4M1B

3. Does your T vs angle of twist plot obey Hooke’s Law and what is the value of the

shearing stress at the yield point? Is this value compare favourably with actual

value?\

Error= |TheoreticalTheoretical

value−Experimental value

value |×100 %

Error= |78−48.82

78 |×100 %

Error=37.41 %

The magnitude of the torque exerted on the specimen must be equal to the forces

exerted on any cross section of the shaft. At this phase, the entire shaft will be assumed to be

in elastic range until it fractured (plastic range). In this experiment, the graph of torque (T)

against angle of twist ( θ ) obey the Hooke’s Law. As the revolution increase, the torque

also increases and started to obtain constant value until the specimen fractured. The value of

shear stress at yield point is 537.74 MPa. The experimental value for shear stress not much

difference compared to the actual value of shear stress for mild steel which is 504.6 MPa.

Downloaded by sdasd ddasd (int9ii9t@uuf.me)

lOMoARcPSD|10287828

RIYAN SHAHABY BIN SHUIB (2019695446) EMD4M1B

4. Discuss the fracture surface of your specimen. Does it seemed like any typical

ductile fracture?

Ductile fractures contain some of the characteristics which is there is considerable

gross permanent or plastic deformation in the region of ductile fracture. The characteristic

appearance of the surface of a ductile fracture is dull and fibrous. Generally, for ductile

materials, fracture in torsion occurred in the plane of maximum shear stress perpendicular to

the axis of bar. On the specimen (mild steel), ductile torsion failure reveals a flat, transverse

break having a smooth shear surface and microvoid formation

5. Is your experiment follows any standard of practice?

This experiment followed the standards of practice. All standards practise is being

followed step by step to minimize the errors in the experiment. The machine is being set up

perfectly and also the specimen used is correctly measured. All the reading is being set to

zero to get a perfect result. It is necessary to follow the specifications given in the standard

while conducting this experiment to make sure that the results obtained are correct.

Downloaded by sdasd ddasd (int9ii9t@uuf.me)

lOMoARcPSD|10287828

RIYAN SHAHABY BIN SHUIB (2019695446) EMD4M1B

CONCLUSION

The difference between theoretical and experimental value is not so big, that is why

this experiment has fulfilled the objectives requirement. The value of error between

theoretical and experimental value is only 37.41% and still can be reduced by avoiding the

errors while performing the experiment. From the slope of the shear stress against shear strain

graph, the modulus of rigidity (G) of the specimen can be obtained. The value of modulus of

rigidity for mild steel is 48.82 GPa. The difference of maximum shear stress value between

experimental and actual value is little. The actual value of shear stress for mild steel is 504.6

MPa while for the experimental value is 537.74%. The angle of twist linearly increased with

torque before yield point shown that the relationship between torque (T) and angle of twist (

θ ) obey the Hooke’s Law. Finally, the type of fracture surface under pure torque of mild

steel rod was determined. Data between experimental and theoretical values had been

validated and also all of the steps when doing the experiment were by following the

experimental procedure. In conclusion, the experiment was a success.

Downloaded by sdasd ddasd (int9ii9t@uuf.me)

You might also like

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- Triangle Velocity For Centrifugal PumpDocument27 pagesTriangle Velocity For Centrifugal PumpWinter NaiNo ratings yet

- Modulus of Rigidity of RubberDocument5 pagesModulus of Rigidity of RubberMuneeb IrfanNo ratings yet

- User Group: Sum of SQ SQRTDocument12 pagesUser Group: Sum of SQ SQRTMangal SNo ratings yet

- Initial Vertical Static Load Test: AgencyDocument5 pagesInitial Vertical Static Load Test: AgencyRavi kumarNo ratings yet

- Van Der Hoven SpectrumDocument4 pagesVan Der Hoven SpectrumFirdous Ul NazirNo ratings yet

- 3500 Nozzle Performance 3500 Nozzle Performance Metric: Pressure PressureDocument1 page3500 Nozzle Performance 3500 Nozzle Performance Metric: Pressure PressuresabummathewNo ratings yet

- Proj Tit Proj Des M Grand Proj Tit Proj Des M GrandDocument2 pagesProj Tit Proj Des M Grand Proj Tit Proj Des M GrandNitish NehraNo ratings yet

- Acknowledgement For Summer Internship Project ReportDocument23 pagesAcknowledgement For Summer Internship Project ReportBadisa NaveenNo ratings yet

- 1 2 3 4 5 Average Appraiser R Trial/Part NDocument7 pages1 2 3 4 5 Average Appraiser R Trial/Part NN12No ratings yet

- Vissim Training - 5. Traffic SpeedsDocument14 pagesVissim Training - 5. Traffic SpeedsBagja Bintang GumelarNo ratings yet

- A Level Psychology Paper 2 QPDocument52 pagesA Level Psychology Paper 2 QPM.A. HassanNo ratings yet

- October 2018 QPDocument24 pagesOctober 2018 QPYağmur ÖzçelikNo ratings yet

- 18mba0011 BA Lab 5Document12 pages18mba0011 BA Lab 5brammaasNo ratings yet

- Wyniki Repetytorium Z Chemii Lekow 14.03.2024Document3 pagesWyniki Repetytorium Z Chemii Lekow 14.03.2024mery200256No ratings yet

- Espectro de Aceleraciones. TallerDocument3 pagesEspectro de Aceleraciones. TallerMario Andrés BelloNo ratings yet

- EN22302830 Kithsara.G, D G 1 ADocument15 pagesEN22302830 Kithsara.G, D G 1 ADenuka KithsaraNo ratings yet

- Libro 1Document7 pagesLibro 1PIZARRO SUNCION JEAN PIERNo ratings yet

- Notas Finales Seccion 2 2022 SubirDocument4 pagesNotas Finales Seccion 2 2022 SubirMario RivasNo ratings yet

- Estadística Descriptiva - Willam - Delarosa9ADocument8 pagesEstadística Descriptiva - Willam - Delarosa9ADAVID REY AVILA NICASIONo ratings yet

- Plantilla de Calificaciones y Asistencia v2-G1-2020Document3 pagesPlantilla de Calificaciones y Asistencia v2-G1-2020Deimy TorresNo ratings yet

- Plate Bearing Test: Time Dial Gauge Readings, MM Load Guage 1 Gauge 2 Average ReadingDocument13 pagesPlate Bearing Test: Time Dial Gauge Readings, MM Load Guage 1 Gauge 2 Average ReadingmaherNo ratings yet

- PCT-original PCT MergedDocument11 pagesPCT-original PCT MergedBryan GiranoNo ratings yet

- Step 1: Step Activity Clock ActivityDocument12 pagesStep 1: Step Activity Clock ActivityHosnaNo ratings yet

- Mid-Statyes - Carbon Steel Pipe Fitting - Straight TEEDocument2 pagesMid-Statyes - Carbon Steel Pipe Fitting - Straight TEETamer BannaNo ratings yet

- Mid-Statyes - Carbon Steel Pipe Fitting - Straight TEEDocument2 pagesMid-Statyes - Carbon Steel Pipe Fitting - Straight TEETamer BannaNo ratings yet

- Quiz Exercise ClassDocument7 pagesQuiz Exercise ClassSidik AbdullahNo ratings yet

- Block Gauges - احمد نادر إبراهيم الغوانمةDocument10 pagesBlock Gauges - احمد نادر إبراهيم الغوانمةG. Dancer GhNo ratings yet

- Ahs Ppupr 2016Document113 pagesAhs Ppupr 2016Rafael TaimeNo ratings yet

- Steel FormDocument5 pagesSteel FormAbanoub ShakerNo ratings yet

- Fase Aquosa Extratoresv Naoh (MC Naoh (Mmol de Nav Solução C Ácido Acmassa Ácidmassa Amostra (G) Fração ÁciDocument3 pagesFase Aquosa Extratoresv Naoh (MC Naoh (Mmol de Nav Solução C Ácido Acmassa Ácidmassa Amostra (G) Fração ÁciiagosfNo ratings yet

- Practice #9: Pumps in Series and in Parallel: Hydraulics Lab Professor: Jose Manuel Molano MartínezDocument12 pagesPractice #9: Pumps in Series and in Parallel: Hydraulics Lab Professor: Jose Manuel Molano MartínezMikeNo ratings yet

- WPS02 01 Que 20190116 PDFDocument32 pagesWPS02 01 Que 20190116 PDFNour AbouzeidNo ratings yet

- Latihan 3 - Kelompok 3Document11 pagesLatihan 3 - Kelompok 3InnabilaNo ratings yet

- Detailed CalculationDocument4 pagesDetailed CalculationNavin GolyanNo ratings yet

- Paediatrics Drug ChartDocument4 pagesPaediatrics Drug ChartRanjith MeelaNo ratings yet

- Plan BREDocument171 pagesPlan BREShabrina AmaliaNo ratings yet

- Book 1Document3 pagesBook 1Aneesh KumarNo ratings yet

- I V Characterstics of PN Junction DiodeDocument10 pagesI V Characterstics of PN Junction Diodeمعاً إلى الجنةNo ratings yet

- Tensile Test Lab ReportDocument9 pagesTensile Test Lab ReportHaneef AzmiNo ratings yet

- Employee Retention in Private SectorDocument9 pagesEmployee Retention in Private Sectorsaurabh pathakNo ratings yet

- Cetyltrimethylammonium Bromide (CTAB) : Table 2: Measured and Calculated Values For The Determination of CMC of TheDocument3 pagesCetyltrimethylammonium Bromide (CTAB) : Table 2: Measured and Calculated Values For The Determination of CMC of TheArpan GhoshNo ratings yet

- Lab 06Document6 pagesLab 06jose123 pachas quispeNo ratings yet

- Regresi LinearDocument20 pagesRegresi Linear【Blank】No ratings yet

- Computation of Taxable Income For The F.Y 01.04.13 To 31.03.14 of Mr. RDocument10 pagesComputation of Taxable Income For The F.Y 01.04.13 To 31.03.14 of Mr. RAshutosh SinghNo ratings yet

- 5000 Series Std. Angle Rain Curtain™ Nozzle Performance 5000 Series Std. Angle Rain Curtain™ Nozzle Performance METRICDocument4 pages5000 Series Std. Angle Rain Curtain™ Nozzle Performance 5000 Series Std. Angle Rain Curtain™ Nozzle Performance METRICLeo MedinaNo ratings yet

- Questionpaper Paper2 (Wps02) January2019Document32 pagesQuestionpaper Paper2 (Wps02) January2019xx2qxgnppzNo ratings yet

- Unit 6. Work and Kinetic EnergyDocument2 pagesUnit 6. Work and Kinetic EnergyRussel Jane BaccayNo ratings yet

- Jadval Sath RangDocument1 pageJadval Sath RangAlireza KhodabandehNo ratings yet

- Datos y Cálculos de La Sección TransversalDocument5 pagesDatos y Cálculos de La Sección TransversalCRISTIANNo ratings yet

- PsychologyDocument516 pagesPsychologyShakeela ShanmuganathanNo ratings yet

- A Level Psychology Paper 1 QPDocument40 pagesA Level Psychology Paper 1 QPM.A. HassanNo ratings yet

- Hypothesis Test: Mean vs. Hypothesized Value: Source SS DF MS F P-ValueDocument11 pagesHypothesis Test: Mean vs. Hypothesized Value: Source SS DF MS F P-ValueJuan Carlos ObesoNo ratings yet

- Shear Box Test ReportDocument6 pagesShear Box Test Reportnishan_ravin50% (2)

- Uji Sifat Fisik: Wn Ww Ws Wo σn σs σd SG App Sg Tr W (%) A S n% n/100 e (%)Document5 pagesUji Sifat Fisik: Wn Ww Ws Wo σn σs σd SG App Sg Tr W (%) A S n% n/100 e (%)Dodhy SetiawanNo ratings yet

- Numerical Aperture of The Optical FiberDocument4 pagesNumerical Aperture of The Optical FiberSarthak KathpaliaNo ratings yet

- Bisection Method Calculator - High Accuracy CalculationDocument3 pagesBisection Method Calculator - High Accuracy CalculationSusrianti JamalNo ratings yet

- Chi-Square Table of Observed ValuesDocument3 pagesChi-Square Table of Observed ValuesAhmed BaharNo ratings yet

- JETIR2010279Document5 pagesJETIR2010279Rajni KumariNo ratings yet

- Edited - L. - Ass. - Mod. - 9-11. - DocxDocument18 pagesEdited - L. - Ass. - Mod. - 9-11. - DocxArboleda, Mark Kenneth F.No ratings yet

- WPS01 01 Que 20190111 PDFDocument24 pagesWPS01 01 Que 20190111 PDFNour AbouzeidNo ratings yet

- Metric DIN 916 SpecDocument5 pagesMetric DIN 916 SpecJUAN CARDONANo ratings yet

- CHAPTER 6. Risk ManagementDocument23 pagesCHAPTER 6. Risk ManagementWinter NaiNo ratings yet

- CHAPTER 7. Managing Secured Systems NewDocument146 pagesCHAPTER 7. Managing Secured Systems NewWinter NaiNo ratings yet

- CHAPTER 4. Information SecurityDocument44 pagesCHAPTER 4. Information SecurityWinter NaiNo ratings yet

- 1 Circuit TheoryDocument44 pages1 Circuit TheoryWinter NaiNo ratings yet

- 4a Digital System - Number System & ConversionDocument59 pages4a Digital System - Number System & ConversionAhmad IzzuddinNo ratings yet

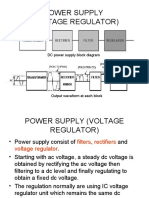

- 2 Power Supply (Voltage Regulator) - 2Document78 pages2 Power Supply (Voltage Regulator) - 2Winter NaiNo ratings yet

- 3 BJT IntroductionDocument17 pages3 BJT IntroductionWinter NaiNo ratings yet

- Chapter Fluid Machinery - PART 1Document22 pagesChapter Fluid Machinery - PART 1Winter NaiNo ratings yet

- Lectures 10-12: Torsion Members: Lecture Book: Chapter 8 Joshua Pribe Fall 2019Document10 pagesLectures 10-12: Torsion Members: Lecture Book: Chapter 8 Joshua Pribe Fall 2019Winter NaiNo ratings yet

- 5.1 - Microcontroller and Microprocessor ArchitectureDocument35 pages5.1 - Microcontroller and Microprocessor ArchitectureWinter NaiNo ratings yet

- Laplace Transform: Week1 MAT485/565Document9 pagesLaplace Transform: Week1 MAT485/565Winter NaiNo ratings yet

- Chapter Fluid Machinery - PART 2Document27 pagesChapter Fluid Machinery - PART 2Winter NaiNo ratings yet

- TABULAR MethodDocument2 pagesTABULAR MethodSyafiq FauziNo ratings yet

- Revision Integ by PartDocument1 pageRevision Integ by PartWinter NaiNo ratings yet

- Chapter Fluid Machinery - PART 3Document9 pagesChapter Fluid Machinery - PART 3Winter NaiNo ratings yet

- Chapter Fluid Machinery - PART 4Document21 pagesChapter Fluid Machinery - PART 4Winter NaiNo ratings yet

- Chap03-A QQQQQ PDFDocument36 pagesChap03-A QQQQQ PDFFiseha MekonnenNo ratings yet

- Solid An20170829a2 1Document143 pagesSolid An20170829a2 1Winter NaiNo ratings yet

- Dynamics Sample ExerciseDocument8 pagesDynamics Sample ExerciseWinter NaiNo ratings yet

- c04 Catia v5r15 Sketched Based FeaturesDocument39 pagesc04 Catia v5r15 Sketched Based FeaturesMan Scha100% (1)

- 99 253 Testing Machines and Testing Systems For Metals E enDocument48 pages99 253 Testing Machines and Testing Systems For Metals E enWinter NaiNo ratings yet

- Dynamics Sample ExerciseDocument8 pagesDynamics Sample ExerciseWinter NaiNo ratings yet

- Mechanics of Material Chapter 1: StressDocument26 pagesMechanics of Material Chapter 1: StressWinter NaiNo ratings yet

- Operation ManagementDocument19 pagesOperation ManagementWinter NaiNo ratings yet

- Dynamics Sample ExerciseDocument10 pagesDynamics Sample ExerciseWinter NaiNo ratings yet

- Dynamics Sample ExerciseDocument5 pagesDynamics Sample ExerciseWinter NaiNo ratings yet

- Chapter 2 StrainDocument11 pagesChapter 2 StrainMaipenrai Memee100% (1)

- Process Selection and Facility Layout: Learning ObjectivesDocument25 pagesProcess Selection and Facility Layout: Learning ObjectivesWinter NaiNo ratings yet

- UNIT-5 SpringsDocument6 pagesUNIT-5 SpringsUday Narasimha100% (2)

- Experiment # 8: Modulus of ElasticityDocument6 pagesExperiment # 8: Modulus of ElasticityUsamaNo ratings yet

- Experiment 5: Modulus of Rigidity: Spring ConstantDocument3 pagesExperiment 5: Modulus of Rigidity: Spring ConstantGhulam FaridNo ratings yet

- Experiment 3 MOMDocument6 pagesExperiment 3 MOMHafiz HamzaNo ratings yet

- 09 Torsion Moment & Torsion Angle of ShaftDocument7 pages09 Torsion Moment & Torsion Angle of ShaftElaine PuiNo ratings yet

- Rubber in ShearDocument18 pagesRubber in ShearHassan BhinderNo ratings yet

- Experiment # 1: Modulus of Rigidity of The RubberDocument6 pagesExperiment # 1: Modulus of Rigidity of The RubberUsamaNo ratings yet

- Units: Young'S ModulusDocument15 pagesUnits: Young'S ModulusAl BorromeoNo ratings yet

- MODULUS OF RIGIDITY XI ProjectDocument5 pagesMODULUS OF RIGIDITY XI ProjectWasim JavedNo ratings yet

- Exp.4 - Torsion TestDocument6 pagesExp.4 - Torsion TestG. Dancer GhNo ratings yet

- Exp.3 - Rubber Shear TestDocument6 pagesExp.3 - Rubber Shear TestG. Dancer GhNo ratings yet

- Modulus of RigidityDocument5 pagesModulus of RigidityMuhammad Talha Sajid Muhammad SajidullahNo ratings yet

- Shear Modulus - WikipediaDocument7 pagesShear Modulus - WikipediaFatih AdamNo ratings yet

- Ciz Shapiro Fluid Solid SubstitutionDocument5 pagesCiz Shapiro Fluid Solid SubstitutionGlusmNo ratings yet

- Shear Force Refers To The Force Acting Along On A Surface. Basically, The Force Forms NoDocument4 pagesShear Force Refers To The Force Acting Along On A Surface. Basically, The Force Forms Nodolar buhaNo ratings yet

- Experiment # 2: Objective: Apparatus: Theory: Shear Stress Shear StrainDocument2 pagesExperiment # 2: Objective: Apparatus: Theory: Shear Stress Shear Strainjon aeliaNo ratings yet

- Shear Stress, Shear Strain and Modulus of RigidityDocument7 pagesShear Stress, Shear Strain and Modulus of RigiditynioNo ratings yet

- Experiment 1 UzairDocument7 pagesExperiment 1 UzairUzair IqbalNo ratings yet

- 2.0 Theory: at The End of The Lab Session Students Should Be AbleDocument5 pages2.0 Theory: at The End of The Lab Session Students Should Be AbleMuhammad Danish Mohd SizaNo ratings yet