Professional Documents

Culture Documents

Material Inspection Reports::::: Form QT3

Uploaded by

Lee Jia QingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Inspection Reports::::: Form QT3

Uploaded by

Lee Jia QingCopyright:

Available Formats

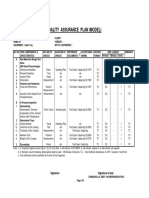

MATERIAL INSPECTION REPORTS Form QT3

Page 1 of 2

Name of Development :

:

:

Project Reference No. :

1. Inspection on Pipes

Supplier/

Manufacturer :

Instrument Used : Calipers / Ultrasonic Thickness Equipment / Micrometer/ Others

Total Number Pipes

Inspected :

Delivery Order No. :

Inspection Date

Type of

Water Thickness Of Pipe (mm) Remark

Fittings/ Pipe Int. Lining

Pipe No./ ID Comment

Thickness

Diameter Socket Spigot Passed Failed

Middle

(mm) End End (/) (X)

2. Inspection on Water Fittings

Supplier/

Manufacturer :

Instrument Used :

Total Number Water

Fitting Inspected :

Delivery Order No. :

Inspection Date

Remarks (Visual

Type of Fittings and Product Brands Sample No./ ID Inspection)

Good/ Fair/ Poor

a. All types of valves

b. All types of specials and fittings

c. All types of panel tanks

Note: a. Thickness Measurement shall be at random check and not less than 5% of the number of pipes

supplied in each delivery order.

b. All pipe tested shall be confirmed according to rules 3, 4, and 5 of the Water Services Industry Act

2006.

c. Product details with technical specifications (or any other supporting documents) according to

appropriate standards attached for reference.

**Please use additional sheet if necessary

MATERIAL INSPECTION REPORTS Form QT3

Page 2 of 2

Project Reference No. :

Checked By

Name :

Firm :

CP Registration No :

NRIC. No. :

Signature of Competent Person

Date :

Witnessed By

Name :

Staff No :

Signature of AIR SELANGOR;

Executives/ Technician

Regional Development Unit

Date :

You might also like

- Penetrant Testing: Principles, Techniques, Applications and Interview Q&AFrom EverandPenetrant Testing: Principles, Techniques, Applications and Interview Q&ANo ratings yet

- Form QT 3Document2 pagesForm QT 3Asma FarahNo ratings yet

- Hydrostatic Test (Log) : Quality Control FormDocument22 pagesHydrostatic Test (Log) : Quality Control FormAnonymous 4e7GNjzGWNo ratings yet

- ITR INL (Insulation)Document2 pagesITR INL (Insulation)mahmoudNo ratings yet

- Liquid Penetrant Test Report: JBM-GA-MMX-08-01, REV. 01 1008.01/03/19-20Document12 pagesLiquid Penetrant Test Report: JBM-GA-MMX-08-01, REV. 01 1008.01/03/19-20virajNo ratings yet

- QC Form 6Document1 pageQC Form 6rashid ahmadiNo ratings yet

- Pipe Insulation: Qa / QC FormDocument1 pagePipe Insulation: Qa / QC FormShyam Sundar GayenNo ratings yet

- Final Welding Inspection ReportDocument1 pageFinal Welding Inspection ReportKish Shan S SubediNo ratings yet

- Check List - Air Compressor InspectionDocument1 pageCheck List - Air Compressor Inspectiondndudc100% (4)

- Material Traceability Inspection ReportDocument32 pagesMaterial Traceability Inspection ReportBalmiki SinghNo ratings yet

- 4.22 Airflow Test ReportDocument1 page4.22 Airflow Test Reportعكاش عكاشNo ratings yet

- Liquid Penetrant Testing Report SummaryDocument1 pageLiquid Penetrant Testing Report SummaryAbdul NaveedNo ratings yet

- Notice - 03Document1 pageNotice - 03Amir MortazaviNo ratings yet

- Liquid Penetrant Examination ReportDocument1 pageLiquid Penetrant Examination ReportBalmiki SinghNo ratings yet

- Form AMI-WI-P-QAC-1-2 Inspection ReportDocument1 pageForm AMI-WI-P-QAC-1-2 Inspection Reportgusyahri001No ratings yet

- SIMO Research Engineers Pvt. LTDDocument7 pagesSIMO Research Engineers Pvt. LTDunicorn pressure vasselsNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- 4.3.3 Coating Application: Sheet No.Document2 pages4.3.3 Coating Application: Sheet No.Alex KuvoricNo ratings yet

- Incoming Inspection Form RevDocument1 pageIncoming Inspection Form RevMesfin Derbew100% (1)

- IR SAMPLE (Blank)Document5 pagesIR SAMPLE (Blank)Niraj PandeyNo ratings yet

- Petronas Carigali Sdn. Bhd. Inspection Test Record (Itr) - B Safety Shower / Eyewash S02-BDocument6 pagesPetronas Carigali Sdn. Bhd. Inspection Test Record (Itr) - B Safety Shower / Eyewash S02-BWael ChouchaniNo ratings yet

- Sample MRB Index For ENIDocument1 pageSample MRB Index For ENIAnanthu Krishnan100% (1)

- Itr-Pgr (GRP Piping)Document10 pagesItr-Pgr (GRP Piping)mahmoudNo ratings yet

- PIPING INSPECTION REQUESTDocument10 pagesPIPING INSPECTION REQUESTAnand NarayananNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report FormsugiantobarusNo ratings yet

- B - 924JXH PO Box 592 Coolum Beach QLD 4573-08-09-2020-15995274455f56da155cda7Document2 pagesB - 924JXH PO Box 592 Coolum Beach QLD 4573-08-09-2020-15995274455f56da155cda7Kah Ho TanNo ratings yet

- Model Qap Cable TrayDocument2 pagesModel Qap Cable Trayveerendra100% (3)

- Material Inspection Check ListDocument2 pagesMaterial Inspection Check ListSERT-QA/QC- BUZNo ratings yet

- 1) Material/ Equipment Inspected:: Inspection Visit ReportDocument3 pages1) Material/ Equipment Inspected:: Inspection Visit ReportsahandstmNo ratings yet

- Surge Arrestor Commissioning ChecklistDocument7 pagesSurge Arrestor Commissioning ChecklistSyed Abbas100% (1)

- Structure ChecklistDocument59 pagesStructure Checklistdeepak9250% (1)

- Liquid Penetrant Test Record: Examinaion DetailsDocument1 pageLiquid Penetrant Test Record: Examinaion DetailschandraNo ratings yet

- Aplication For Airworthiness Certificate RevisiDocument5 pagesAplication For Airworthiness Certificate RevisiGranita pru24No ratings yet

- Concrete traceability reportDocument1 pageConcrete traceability reportum erNo ratings yet

- Blasting & Painting Report: Surface PreparationDocument1 pageBlasting & Painting Report: Surface PreparationSandra SandersNo ratings yet

- USM Vision 1.2Document8 pagesUSM Vision 1.2pokeboy19No ratings yet

- Expansion TankDocument2 pagesExpansion TankSHARAFUDHEEN TKNo ratings yet

- Piping N.D.T RequestDocument7 pagesPiping N.D.T RequestRicardo LourençoNo ratings yet

- لابئري)Document2 pagesلابئري)Mohamed SelimNo ratings yet

- Alstom IRDocument4 pagesAlstom IRkasi reddyNo ratings yet

- Ventsand DrainsDocument1 pageVentsand DrainsGabriel MistreanuNo ratings yet

- INSPECTION REPORTDocument3 pagesINSPECTION REPORTsheikmoinNo ratings yet

- Penstock Leakage Record SheetDocument1 pagePenstock Leakage Record Sheetmujahed_muhammedNo ratings yet

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: Mud / Gas SeparatorDocument2 pagesIntermediate Well Control Equipment Inspection Criteria: Equipment Group: Mud / Gas SeparatorKaleem Ullah0% (1)

- Liquid Penetrant Examination Report: Asme Sec-Viii 10 Minute Spray 32 CDocument4 pagesLiquid Penetrant Examination Report: Asme Sec-Viii 10 Minute Spray 32 CEngr Saeed AnwarNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report FormMHT allamNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFAdhi PrihastomoNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFNatarajan Raja100% (2)

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFRadhakrishna VachaNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFมินคุง เอโอซีNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFJaco CalitzNo ratings yet

- Inspection Report and Leak Test FormatDocument2 pagesInspection Report and Leak Test Formatmujahed_muhammedNo ratings yet

- 2 - Checklist FormDocument5 pages2 - Checklist FormAs As0% (1)

- Itr Ew 05a - EngDocument1 pageItr Ew 05a - Engwassim nasriNo ratings yet

- Subh (Pipe Inspection Procedure)Document3 pagesSubh (Pipe Inspection Procedure)subhashaheer524No ratings yet

- ITR-FPR (Fire Proofing)Document6 pagesITR-FPR (Fire Proofing)mahmoudNo ratings yet

- IVR-DYC.M.1.22.0004-Sr - No. 41 - Rev 00Document6 pagesIVR-DYC.M.1.22.0004-Sr - No. 41 - Rev 00Parag WadekarNo ratings yet

- Subcontractor: Equipment / Ref.: Manufacturer: Model: Serial NoDocument1 pageSubcontractor: Equipment / Ref.: Manufacturer: Model: Serial NoAzwan SunlineNo ratings yet

- Site Lab Checklist1Document4 pagesSite Lab Checklist1layaljamal2No ratings yet

- Itr-Pug (Ug Piping)Document12 pagesItr-Pug (Ug Piping)mahmoudNo ratings yet

- Submission QT Forms To Syabas - 2016: ITE M NO. Form NO. Description Signatory by RemarkDocument2 pagesSubmission QT Forms To Syabas - 2016: ITE M NO. Form NO. Description Signatory by RemarkLee Jia Qing100% (1)

- Preparation of Platform (LHS of Abut. A) Laying of Layer 150mm Sand (LHS of Abut. A) Laying of Layer PEC200 (LHS of Abut. A)Document3 pagesPreparation of Platform (LHS of Abut. A) Laying of Layer 150mm Sand (LHS of Abut. A) Laying of Layer PEC200 (LHS of Abut. A)Lee Jia QingNo ratings yet

- QT1 1Document2 pagesQT1 1Lee Jia QingNo ratings yet

- Drainage MSMA CalculationDocument3 pagesDrainage MSMA CalculationLee Jia QingNo ratings yet

- Guideline To Use Water Jet Paver For The Laying of Road Base MaterialDocument4 pagesGuideline To Use Water Jet Paver For The Laying of Road Base MaterialLee Jia QingNo ratings yet

- HSS Integrated Sdn Bhd Laboratory Request ScheduleDocument1 pageHSS Integrated Sdn Bhd Laboratory Request ScheduleLee Jia QingNo ratings yet

- WCE1 Method Statement For Bridge Structure WorkDocument53 pagesWCE1 Method Statement For Bridge Structure WorkLee Jia QingNo ratings yet

- Kinetic Study of The Catalytic Reforming of Methane With Carbon Dioxide To Synthesis Gas Over Ni - La2O3 Catalyst PDFDocument8 pagesKinetic Study of The Catalytic Reforming of Methane With Carbon Dioxide To Synthesis Gas Over Ni - La2O3 Catalyst PDFMarcus NguyễnNo ratings yet

- Logging Levels in Log4j - Tutorialspoint ExamplesDocument3 pagesLogging Levels in Log4j - Tutorialspoint ExamplesJai PannuNo ratings yet

- Last Lesson: How Did Franz Feelings About M Hamel and School Change ?Document4 pagesLast Lesson: How Did Franz Feelings About M Hamel and School Change ?RitikaNo ratings yet

- New Product Performance Advantages For Extending Large, Established Fast Moving Consumer Goods (FMCG) BrandsDocument18 pagesNew Product Performance Advantages For Extending Large, Established Fast Moving Consumer Goods (FMCG) Brandssmart_kidzNo ratings yet

- Writing Part 2 - An Essay: (120-180 Words)Document7 pagesWriting Part 2 - An Essay: (120-180 Words)María Daniela BroccardoNo ratings yet

- QMM: Exercise Sheet 8 - Structural Equation Model: Structural RegressionDocument3 pagesQMM: Exercise Sheet 8 - Structural Equation Model: Structural Regressionlaurine.hoyoNo ratings yet

- HW3 - Chapter 9-2Document3 pagesHW3 - Chapter 9-2Zachary MedeirosNo ratings yet

- 286129Document23 pages286129Cristian WalkerNo ratings yet

- AST Study Centers 2021 Updated Till 25oct2021 GOVT DATADocument33 pagesAST Study Centers 2021 Updated Till 25oct2021 GOVT DATAprasadNo ratings yet

- Regina Downtown Community Support Team ReportDocument28 pagesRegina Downtown Community Support Team ReportJeremy SimesNo ratings yet

- Introduction To Engineering Economy: Title of The LessonDocument16 pagesIntroduction To Engineering Economy: Title of The LessonsdanharoldNo ratings yet

- How English Works - A Grammar Handbook With Readings - Answer Key PDFDocument38 pagesHow English Works - A Grammar Handbook With Readings - Answer Key PDFAlessio Bocco100% (1)

- First Aid KitDocument15 pagesFirst Aid Kitdex adecNo ratings yet

- PDF DocumentDocument10 pagesPDF DocumentNIKHIL DASARINo ratings yet

- Seagate WD Hard Drive Price List From Billion HoDocument4 pagesSeagate WD Hard Drive Price List From Billion HoALi RAzaNo ratings yet

- 7Document19 pages7Maria G. BernardinoNo ratings yet

- Power Grid FailureDocument18 pagesPower Grid Failurechandra 798No ratings yet

- Set 1Document24 pagesSet 1TutorTutorNo ratings yet

- VELMATIC Well Service Air ValveDocument2 pagesVELMATIC Well Service Air Valvecarlos37No ratings yet

- Grade 7 Lesson: Module 4 - Acids and BasesDocument3 pagesGrade 7 Lesson: Module 4 - Acids and BasesJoedelyn Wagas100% (4)

- Central Bank Digital Currency:: The Future of Payments For CorporatesDocument29 pagesCentral Bank Digital Currency:: The Future of Payments For CorporatesknwongabNo ratings yet

- Ho'oponopono ! - The Power of ForgivenessDocument6 pagesHo'oponopono ! - The Power of ForgivenessParainNo ratings yet

- Death of Frank LangamanDocument6 pagesDeath of Frank LangamanPaul ToguayNo ratings yet

- Sidhil - ICT Design EngineerDocument3 pagesSidhil - ICT Design Engineeratif_aman123No ratings yet

- Calculate the proof strength of 70% v/v alcohol.Step 1) 70% v/v x 1.753 = 122.71Step 2) 122.71 - 100 = 22.71The proof strength of 70% v/v alcohol is 22.71% over proofDocument46 pagesCalculate the proof strength of 70% v/v alcohol.Step 1) 70% v/v x 1.753 = 122.71Step 2) 122.71 - 100 = 22.71The proof strength of 70% v/v alcohol is 22.71% over proofPrashant307100% (1)

- Probability Concepts and Random Variable - SMTA1402: Unit - IDocument105 pagesProbability Concepts and Random Variable - SMTA1402: Unit - IVigneshwar SNo ratings yet

- Rapid Web Development With Python/Django: Julian HillDocument37 pagesRapid Web Development With Python/Django: Julian Hilljppn33No ratings yet

- CSB 211102 1 FCT EMS 702 Upgrade Process With Security FeaturesDocument2 pagesCSB 211102 1 FCT EMS 702 Upgrade Process With Security FeaturesCedric NkongoNo ratings yet

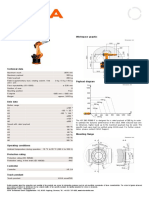

- KR 280 R3080 F technical specificationsDocument1 pageKR 280 R3080 F technical specificationsDorobantu CatalinNo ratings yet

- Accenture Sustainable ProcurementDocument2 pagesAccenture Sustainable ProcurementAnupriyaSaxenaNo ratings yet