Professional Documents

Culture Documents

Bs 610

Uploaded by

Houssam hallakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bs 610

Uploaded by

Houssam hallakCopyright:

Available Formats

BS-610

10 Zone Fire Detection Panel

Description

The panel consist 2 independent siren outputs, Alarm relay, Programmable output for telephone operators a relay pre

zone for the 2 first zones and connectors to connect the rest 8 zone relays. The required battery for the panel is the type

Α-986 (12V/7Ah). All functions and indications are according to European Norms ΕΝ 54-2 and ΕΝ-54-4.

Top cover retaining screws

1 2 3 4 5

6 7 8 9 10

Control Keyboard and

indication leds .

ZONE

Fire Alarm

Control Panel

Mains voltage connection

terminal block (220-240V AC).

Mounting holes.

1 2 3 4 5

6 7 8 9 10

MODE selection

ZONE micro switch

Fire Alarm

Control Panel

Zone connection terminals

Connection terminals

for BS-613

4 zone relay expansion module

Operation adjustment

of zone relay

Battery compartment Mounting hole. General output connection (Sirens, Relay per zone

Α-986 relay alarm,24V) connection terminals .

Page 1 from 8 921610000_09_007

Indication LED description

The schematic shows the control keyboard and the

indications plate of a BS-610 panel. Starting from the

top left indicators we can see 2 indicators marked 1 2 3 4 5

'Disable'. The 'Siren' LED lights to indicate a disabled 6 7 8 9 10

siren, whereas the 'Zone' LED lights when a disabled

zone is only one and blinks when we have more than one

disabled zone.

Going towards the right we can see tree LEDs with the

marking 'General'.

ZONE

The 'Fault' LED lights in every FAULT condition and Fire Alarm

blinks when we have a FAULT and the buzzer is Control Panel

silenced. The 'Alarm' LED lights when we have an ALARM condition and blinks when we have an ALARM and the

buzzer is silenced. The 'Disable' LED lights when we have disabled one zone or a siren. The next group of indicators

is the 'Zone' indications LEDs(one for each zone). These indicators light (red) when a corresponding zone issues an

ALARM condition. If the fault is caused by a short circuit then the corresponding LED will blink, and when the zone is

Disabled the yellow led will light continuously. The Alarm condition has priority to this marking.

Below the `Disable` and the `General` indicator groups we can find another indication group called `Fault`. The LEDs

marked 'Siren1' and 'Siren2' correspond to the siren outputs. If a siren out has a short circuit then the corresponding

LED will blink whereas the LED will remain continuously lighted if the siren output is open circuited. The 'Batt' LED

and 'Power' LED in combination, show us faults concerning the power supply. These combination are shown in the

panel below.

Lack of Battery Battery Battery Charger

AC voltage Overcharging Discharged Absent Error

Power Fault Lights Lights Lights Blinks Blinks

Batt Fault ---- Lights Blinks Lights Blinks

The 'CPU' LED lights to indicate a problem with the main processor unit.

The green 'Power' LED lights to indicate valid internal voltages and blinks when the mains AC power supply is absent.

Control keyboard description/operation The panel is controlled/ operated using the six numeric

keys (1 to 6) found on the front panel. When a key is pressed a short tone is issued.

The panel has three operation levels.

Operation level 1 has all the functions that can be done directly from the user without using a code.

These operations are:

Buzzer silence / Buzzer reactivation . If an alarm of fault condition is issued then the internal buzzer will sound. Pressing

the "1" key will silence the buzzer. ( The buzzer sounds periodically once every minute.) Pressing this key again will

reactive the buzzer.

Viewing zones fault / Led test. Pressing the "2" key will have the following effect. If any fault condition is present in the

zones then the panel will issue 3 short tones, by lighting the ‘General Fault’ LED, and the fault zone will be shown by lighting

the corresponding 'Fault' LEDs (yellow) to this zone. If the yellow led blinks then we have a short circuit in this zone, and

when the yellow led light continuously then we have an open circuit. The panel then returns to normal operation after a Leds

control . These operations can be conducted only if the panel is in quiescent state (No alarm condition).

Operation level 2 has all the functions that the user can do and an access code is required. The code is "345", it is the

same for all panels and cannot be changed. The functions that can be implemented using this code are the following:

Siren Silence. When an alarm is issued and we want to silence the sirens then we must enter the user code ( 345 ) and

then the key number '5'. The sirens are silenced but the internal buzzer continues to sound. The panel remains in normal

operation. A new alarm from another zone will resound the sirens.

Panel Reset. When an alarm or fault condition has occurred and we want to reset the panel we must enter the user code (

345 ) and then the key number '6'. The panel lights all LEDs in sequence and then enters normal operation.

Zone enable/disable. If we want to disable the operation of specific zones the we must enter the user code ( 345 ) and then

the key number '4'. The LEDs marked 'Zone disable' and 'General disable' start to blink. Also blinks the red Led from the

first zone , and if a zone is disabled the corresponding yellow LED lights to indicate this. To deactivate or reactivate a zone

Page 2 from 8 921610000_09_007

we can use the '1' key to go in lower zone or the '2' key to go in higher zonne. With the'5' key we deactivate or reactivate a

zone and with the '6' key this operation can be terminated . The panel exits this mode if no key is pressed for more than 30

seconds. The panel then conducts an automatic RESET and enters normal operation mode.

i.e In this operation if you want to deactivate the zone 6, press 5times the '2' key. Then the red led of the 6 zone blinks.

Press the '5' key and for this zone light the yellow led. Finaly press the '6' key to restart.

All disabled zones are supplied with the proper voltage but cannot issue an alarm or fault condition. If we have disabled

zones then this is indicated with the indicators 'General disable' and 'Zone disable' and the buzzer sounds once every

minute.

Operation level 3 functions are functions that are implemented during the installation and need the technical code to be

accessed. The technical code is "364", it is the same for all panels and cannot be changed. The functions that can be

implemented using the technical code are activation methods used for the relays and can be done only if the panel has

not issued an alarm or fault condition. These methods of programming are:

Evacuation. By pressing the technical code ( 364 ) and then the '4' key the evacuation mode is activated. The General

Alarm Led lights and the panel is in Alarm mode.

Siren enable/disable: If we want to disable the operation of specific sirens the we must enter the code ( 364 ) and then the

key number '6'. The LEDs marked 'Sirene disable' and 'General disable' start to blink, and if a siren is disabled, the "Fault

Siren1" LED lights for siren 1 and the "Fault Siren2" LED lights for the siren 2. Using the keys 1 and 2 we can enable or

disable the respective sirens. The disabled sirens have a respective LED lighted. The panel exits this mode if no key is

pressed for more than 30 seconds. The panel then conducts an automatic RESET and enters normal operation mode. All

disabled sirens are supplied with the proper voltage but the panel cannot enable them or read their condition. If we have

disabled sirens then this is indicated with the indicators 'General disable', 'Disable Siren' and the buzzer sounds once

every minute.

AUX RELAY programming. If we want to program the operation behaviour of the AUX RELAY we must enter the

technical code ( 364 ) and then press the number key '5'. The 'General fault' and 'General alarm' LEDs start to blink . The

Alarm LED (red) of zone 1 and zone 2 show the way the AUX RELAY is programmed according to the table below.

General Alarm General Alarm General Alarm General Fault

Direct activation Delay 45 sec Delay 2 min Direct activation

The default setting of this relay is set to activate from a general alarm and immediately with no delay. In this programming

mode if theLED

keysAlarm zone'2'

'1' and LED Off, we can toggle

1 are pressed LED the

On LEDs ON or LED Offuntil we reach

OFF LEDthe

Ondesired activation

behaviour according to the table above. In order to exit this programming mode and to store the settings in memory press

the key '6' LED

or doAlarm zoneany

not press 2 key for LED Offthan 30 seconds.

more LED Off LED

This system will On an automatic

conduct LED RESET

On and will enter

normal operation mode.

ZONE RELAY programming. If we want to program the operation behaviour of the zone relays then we must enter the

technical code ( 364 ) and then press the number key '5'. The 'General fault' and 'General alarm' LEDs start to blink. The

yellow LEDs of zone 6 and zone 7 show the programmed activation method of the zone relays according to the table

below.

The default operation method for the zone relay is set to permanent activation. Using the keys '3' and '4' we can

toggle the ON or OFF state of the Permanent

LEDs

activation

Activated for

until the desired Activated for

activation programming

10 sec 30 sec

Activated for

has been reached.

60 sec

In order to exit this

programming mode and to store the settings in memory press the key '6' or do not press any key for more than 30

seconds. ThisFault

system will1 conduct an

zone automatic

LED Off RESETLEDand will

On enter normalLEDoperation

Off mode. LED On

We can also program the RELAY so that it can cooperate with BS-680 or BS-684 type electrovalves by shorting

the adjustment jumper

Fault zone CN2.

2 In this case

LED Off the RELAYS LED are

Offactivated forLED

10sec.

On during the LEDalarm.

On After 10sec. they

are deactivated.

Connections

Connecting detectors and break-glass call points to zones.

By default each zone terminal block has a pre-installed terminal resistor (5Κ6). This resistor is removed and

Page 3 from 8 921610000_09_007

installed on the last device of the zone or is left connected on the zone terminals if the zone is not used. The

connections to all the zone are identical. What is shown in figures 1, 2 and 3 for zone 1 is valid for all the

zones.

Figure 2 shows the connection with BS-631 unit. This unit is similar with the terminal resistor. The advantage on this unit

(relative to the terminal resistor) is the following. When a detector is off or disabled the rest of the detectors will work and

the panel will detect a Fault condition, and when a detector gives an Alarm signal the panel recognise it.

On the other hand if a simple resistance was used then the panel could not detect any Alarm signal from the

detectors after the disabled detector.

Detectors Detectors Detectors Detectors

base base base base

-R I -R I -R I -R I

N

N

+L

+L

+L

+L

Ζ1

+R

+R

+R

+R

IN-

IN-

IN-

IN-

OU

OU

OU

UT

UT

UT

UT

U

T T T T

O

O

-L -L -L -L

Ζ2

5Κ6 R

Terminal

resistor

Ζ3

BS-572

remote

LED

Figure 1. Connecting 4 detector bases to zone 1. Each base can accept BS-655, BS-660 or BS-667

detectors. A remote indication LED BS-572 is connected to one of the detectors.

Detectors Detectors

base base

Break-glass

call point

-R -R

BS-536

R

R

O UT +

O UT +

IN +L

IN +L

Ζ1

OUT IN

BS-631 IN-OUT -L IN-OUT -L

Ζ2

BS-631/D

Ζ3

Figure 2. Connecting a call point BS-536, 2 detector bases and BS-631 unit

to the same zone.

24V_M F_OUT

BS-685 BS-685 BS-685

Gas Gas Gas

Detector Detector Detector

Siren - Sounder Connections

Each panel offers 2 independent circuits for connecting sirens, bells or other devices that need 24Vdc in order

to operate.10-30V

Each ZONEcircuit

NO C NC can10-30V

supply aCmaximum

ZONE NO NC 10-30V consumption

ZONE NO C NC of 300mA. Each terminal block by default has a

pre-installed terminal resistor (5Κ6). This terminal resistor is either removed and installed on the last siren of

Ζ1

the line or is left on the terminal block if the circuit is not used. The connections of both the circuits are

5Κ6

identical. Terminal

Resistor

Ζ2

Figure 3.Connecting 3 Gas detectors BS-685 or BS-686. Besides the connections to the zone terminals

these detectors must also be connected to the terminals 24V_M in order to be supplied with power.

Page 4 from 8 921610000_09_007

Besides the terminals that were described up to now the panel also has the following outputs :

BS-531 BS-531

24V_M: A 24Vdc output that is interrupted in the event

Siren with

of a panel reset. It is mainly used for powering gas

Siren with

detectors or other devices that

Beaconneed an interruptedBeacon

power supply when the panel is resetting. If this output

is short-circuited then the LED marked 'General fault' is lighted.

Terminal

5Κ6

24V_P: A 24Vdc power output that is not interrupted in the event of a reset. It can be used to power

ALARM1 ALARM2

Resistor

electromagnetic door latches.

Relay AUX : Voltage free relay contacts that by default are programmed to operate when the panel issues

an alarm condition.

Terminal

Resistor 5Κ6

F_OUT : This output is by default programmed to operate in every fault condition issued by the panel. If it

Figure 4. Connecting 2 BS-531 sirens to the ALARM 2 output. This connection requires

is required that this output be activated by an alarm condition then we must set the MODE switch 2 to the

the appropriate polarity.

ON position. This output is an open-collector output suitable for controlling the BS-489 telephone

operator.

Zone Relays : Voltage free relay contacts that are activated in the event of an ALARM on the

corresponding zone. All panels offer a relay per zone. We can use these contacts to activate devices or

operations that must be done when a specific zone issues an alarm ( i.e. Activating electromagnetic door

latches, activating electro-valves ). Figure 5 shows such an installation.

BS-510/24 BS-510/24

24V_P

24V DC 24V DC

NO C NC NO C NC

ZONE 1 ZONE 2

Figure 5. Connecting 2 electromagnetic door latches BS-510/24 to the panel. One is activated by

zone 1 and the other by zone 2.

The panel also has 2 battery connection cables. The red connector goes to the positive (+) terminal

whereas the black connector goes to the negative (-) terminal of the battery.

Page 5 from 8 921610000_09_007

BS-613

1 2 3 4 5

6 7 8 9 10

To connect the rest of the relays of the panel, we have to use 2 BS-631 units (figure 6). The connection is done by using a

flat wire. Each BS-613 unit includes 4 relays. The BS-613 unit that is connected to CN3 terminal (ZONE RELAYS 3-6)

will have the relays ofZONE

3,4,5 and 6 zones.So the other BS-613 unit will have the rest of the zones.On the PCB (BS-613) in

each relay, exist a white block that is used to mark the coresponding zone for each relay.

Fire Alarm

Control Panel

BS-613

ATTENTION: If automatic fire extinguishing fuses are used, they can be connected to

relays. The connection with the power supply must be at the final phase. Also in case of

maintainance activities the blasting caps must be disconnected first.

Figure 6. Connecting BS-613 units to the panel.

Connecting the BS-489 telephone operator

Fire Detection

Panel

24V_P

In order to use the BS-489 in alarm

conditions we must set the MODE

switch 2 to the ON position, while in F_OUT

fault conditions we must set the MODE

switch 2 to the OFF position. Mode 2 ON - Alarm

Mode 2 OFF - Fault + -

Figure 7. Connection diagram of BS-489 telephone operator.

Page 6 from 8 921610000_09_007

Connecting the mains power supply (220-240VAC)

The panel has knock outs on the back side for all the wiring to pass thru. You can connect cables with max.

diametre 2.5mm to the panels terminal blocks.

The mains power supply wiring must use a double insulation cable.

The connection with the mains power supply must be done to the terminal blocks located on the panels up left area.

Figure 8 (the midle terminal is not in use)

.

N

1 cm

220-240VAC

L

Fuse: 1A/5x20

1 cm

Figure 8. Panels connection with 220-240V AC. Figure 9. Panels connection with 220-240V AC. .

Warnings.

1. During the installation the connections to the mains power supply and the battery must be done after all

other connections are finished.

2. The panel connection with the mains supply must be done via a10A external fuse or an automatic circuit

breaker rated at 10A.

3. Always use cables with double insulation.

4. The diameter of the cable must be at least 1mm.(Figure 9)

5. The inner insulation of each cable must not be cut more than 1cm (Figure 9)

6. The outer insulation must not be cut more than 1cm away from the internal insulation.

7. The panel's internal fuse is 1A with 5x20 dimension.

Battery connection

The battery compartment has the appropriate dimensions for Α-986 battery of olympia electronics.

The charging unit on PCB is also calculated for the specific battery. Replace the battery only with one of

the same type.

From the PCB, are connected two battery wires with a special terminal on the edge. They must be connected to the two

battery poles. Connect the black wire to the negative pole (marked (-) or a black mark) and the red wire to positive pole

(marked (+) or a red mark).

Initial Installation

When the connections to the zones, sirens and other required outputs are finished then we must connect

the mains power supply and the battery. In order to aid the installer during the initial installation, the panel

offers a special configuration. This configuration is entered by setting MODE switch 1 to the ON position.

After entering this mode the panel conducts an auto reset and the 'General Test' LEDs blink. The special

functions that aid in working out various problems that might arise are :

When a zone has an open circuit then the internal buzzer sounds and the corresponding LED

lights. If the problem is corrected then the buzzer is deactivated and the LED is extinguished.

When a zone has a short circuit then the internal buzzer sounds and the corresponding LED blinks.

If the problem is corrected then the buzzer is deactivated and the LED is extinguished.

When a siren output has an open circuit then the internal buzzer is activated and the corresponding

fault LED lights. If the problem is corrected then the buzzer is deactivated and the LED is extinguished.

When a siren output has a short circuit then the internal buzzer sounds and the corresponding LED

blinks. If the problem is corrected then the buzzer is deactivated and the LED goes Off.

When a battery fault exists then the 'Batt fault' LED lights and the 'Power fault' LED blinks. If the

problem is corrected then the LEDs are deactivated.

Page 7 from 8 921610000_09_007

If all the problems are corrected and the installation is operating normally then the MODE switch 1 must be

placed in the OFF position. The panel conducts a auto-reset and is ready for operation.

Walk - Testing

By using a special operation mode we can conduct a walk test of the system. To enter walk-test mode set

the MODE switch 1 to the ON position. The 'Test' LED blink. If an alarm is manually given by either

activating a BS-536 call point or by activating a smoke detector with smoke or simulated smoke particles

the corresponding Alarm LED of the zone will light and the siren will sound for 2 seconds. Using this

method we can test the operation of the zones.

In this state if we press the number key 1 then the 1 and 5 relays will be activated or deactivated. The

same function standing for the number keys 2 to 5. So if the number key 6 is pressed then the auxiliary

relay AUX is activated or deactivated. By pressing the correspondent button, we can test the function of

the connected units. After finishing the walk test set the MODE switch 1 to the OFF position. The panel

conducts an automatic reset and enters normal operation mode.

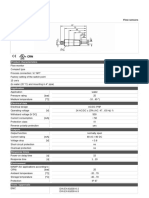

Technical Specifications

BS-610

10 zone fire detection panel

Mains power supply 220-240V AC/50-60Hz

Consumption 25VA

Battery type 12V / 7Ah

Charging circuit Stabilized power supply 13.8V / 400mA

Autonomous duration 36 hours (without using the outputs 24V_M and 24V_P)

Zone circuits 10 zones

with open and short circuit control

Alarm circuits Two 24V circuits that are monitored for open and short circuit conditions

1 Alarm relay, 2 zone relays , 24V permanent 24V reset interrupted

Outputs 2 connectors for external connection of zone relays

o

Operation temperature 0 to 50 C

Humidity Up to 95% relative humidity

Construction material ABS-polycarbonate

Dimensions 320 x 240 x 87 mm

Degrees of cover protection IP 30

Weight 2 Kgr

Produced in accordance to ΕΝ 54-2, ΕΝ 54-4

Guarantee 2 years

Page 8 from 8 921610000_09_007

You might also like

- Ax Series User ManualDocument15 pagesAx Series User ManualAl Fakhamah Lifts100% (1)

- SYLLABUS Ece 331Document3 pagesSYLLABUS Ece 331XackCollinsNo ratings yet

- National Pat DS160Document60 pagesNational Pat DS160Mazin Al KhateebNo ratings yet

- O1 Prisma Fox Door Drive PDFDocument11 pagesO1 Prisma Fox Door Drive PDFfirasalthiyabyNo ratings yet

- SW1070 Installation Manual PDFDocument40 pagesSW1070 Installation Manual PDFGabi RusNo ratings yet

- User/proqrammer Manual: CORY200 DaldossDocument12 pagesUser/proqrammer Manual: CORY200 DaldossDANIEL REYESNo ratings yet

- Tim Mellow 25w OTL Tube Amplifier PDFDocument6 pagesTim Mellow 25w OTL Tube Amplifier PDFmohamadazaresh100% (1)

- Edwin Gray Electronic Circuit PDFDocument6 pagesEdwin Gray Electronic Circuit PDFAvram StefanNo ratings yet

- Ieee C50.12Document4 pagesIeee C50.12david_rosemberg33% (3)

- Operating Manual MSF220V (VU) : - PTC-resistor RelayDocument8 pagesOperating Manual MSF220V (VU) : - PTC-resistor RelayMarko Maky ZivkovicNo ratings yet

- User/proqrammer Manual: CORY200 DaldossDocument12 pagesUser/proqrammer Manual: CORY200 DaldossDANIEL REYESNo ratings yet

- Project: Cgk-064 Electrical Power Discrimination Study by Using Etap SoftwareDocument2,948 pagesProject: Cgk-064 Electrical Power Discrimination Study by Using Etap SoftwareDanang Tri PermadiNo ratings yet

- BS-1632, 1 1 BS-634, BS - 636: Conventional Fire Alarm Panels 2, 4 and 6 ZoneDocument10 pagesBS-1632, 1 1 BS-634, BS - 636: Conventional Fire Alarm Panels 2, 4 and 6 ZonedkompogiorgasNo ratings yet

- Bs 636Document10 pagesBs 636ali kuşçuNo ratings yet

- Moog DINBufferAmplifier G123825001 TechnicalNote enDocument4 pagesMoog DINBufferAmplifier G123825001 TechnicalNote enMauricio GuanellaNo ratings yet

- Operating Instructions PIC152N: Keys DescriptionDocument4 pagesOperating Instructions PIC152N: Keys DescriptionSudipto MajumderNo ratings yet

- Application Notes: P-I Servoamplifier G122-829A001Document6 pagesApplication Notes: P-I Servoamplifier G122-829A001rimmer boyNo ratings yet

- FX4202-4 ManualDocument4 pagesFX4202-4 ManualAzilan AriaNo ratings yet

- FX4202-4 Manual PDFDocument4 pagesFX4202-4 Manual PDFAzilan AriaNo ratings yet

- Pic152 User ManualDocument4 pagesPic152 User ManualCak Rony100% (2)

- Flag RelayDocument4 pagesFlag RelaysanjusNo ratings yet

- 1 Position Regulator PEL 100 (Option)Document10 pages1 Position Regulator PEL 100 (Option)taleb 6269No ratings yet

- ABB-Ontrac BrochureDocument16 pagesABB-Ontrac BrochureAnnie De WildeNo ratings yet

- Addressable Relay Output Device: FeaturesDocument2 pagesAddressable Relay Output Device: FeaturesEdgardo Duque GonzalezNo ratings yet

- AVR300 (SM) PDFDocument91 pagesAVR300 (SM) PDFJory2005No ratings yet

- General Specifications: Model SC100 EXA100 Series Panel Mount Conductivity AnalyzerDocument4 pagesGeneral Specifications: Model SC100 EXA100 Series Panel Mount Conductivity AnalyzerHolicsNo ratings yet

- Ah 00212Document17 pagesAh 00212Đặng TrungNo ratings yet

- IMD Product Manual (Obsolete - For Reference Only)Document4 pagesIMD Product Manual (Obsolete - For Reference Only)Jonathan LujanNo ratings yet

- Fx32a Users Manual EngDocument4 pagesFx32a Users Manual EngSerg100% (1)

- Nice Mindy A01 enDocument9 pagesNice Mindy A01 enSinisaElezNo ratings yet

- Hxh2kz TCS9708 DatasheetDocument9 pagesHxh2kz TCS9708 DatasheetprreNo ratings yet

- Kea 081 AnlDocument17 pagesKea 081 Anlamin shirkhaniNo ratings yet

- SA19 SA12 Data SheetDocument3 pagesSA19 SA12 Data SheetM Kashif JunaidNo ratings yet

- 500 Ats DseDocument2 pages500 Ats DseThẩm DươngNo ratings yet

- Eaton Fire Addressable Control Panel Fx2000 Datasheet v1 1118Document2 pagesEaton Fire Addressable Control Panel Fx2000 Datasheet v1 1118Emmanuel ToretaNo ratings yet

- ISC Series: Signal ConvertersDocument8 pagesISC Series: Signal ConvertersMohammad HosseinNo ratings yet

- Fx32a Manual en R20160602Document4 pagesFx32a Manual en R20160602Khiareddine KadhemNo ratings yet

- SW1070 Installation ManualDocument40 pagesSW1070 Installation ManualGabi RusNo ratings yet

- 21 ModuloDocument2 pages21 ModulosuryaNo ratings yet

- 01F Addressable Input Module AcidDocument2 pages01F Addressable Input Module AcidmotaNo ratings yet

- 21modulo Smart OneDocument2 pages21modulo Smart OnePedroNo ratings yet

- LT8637Document33 pagesLT8637AnonNo ratings yet

- 4090-9120 6-Point IODocument4 pages4090-9120 6-Point IONgoc Son PhamNo ratings yet

- BF100R R0613 EfDocument24 pagesBF100R R0613 EfRYO YASS106No ratings yet

- SLP Konstanter 320W - Technical Data SheetDocument8 pagesSLP Konstanter 320W - Technical Data SheetMihai CherechesNo ratings yet

- DVR Pre-Commissioning and CommissioningDocument65 pagesDVR Pre-Commissioning and CommissioningPMG Bhuswal ProjectNo ratings yet

- Ame 8800Document20 pagesAme 8800AlekseyyyNo ratings yet

- 2-Fold Input Module 13 110 (Ex) I, Safety-RelatedDocument8 pages2-Fold Input Module 13 110 (Ex) I, Safety-RelatedAndy Kong KingNo ratings yet

- Planar 4 System FactsDocument2 pagesPlanar 4 System FactscruzleenoNo ratings yet

- Mitsubhishi Cop ProgrameDocument61 pagesMitsubhishi Cop ProgrameSunil KumarNo ratings yet

- Installation Detectores CAP320-CAH330-CAPT340Document2 pagesInstallation Detectores CAP320-CAH330-CAPT340Yuri OliveiraNo ratings yet

- Isolating Switching Amplifier 4-Channel IM1-451EX-RDocument4 pagesIsolating Switching Amplifier 4-Channel IM1-451EX-RJhon SanabriaNo ratings yet

- SMMANDocument21 pagesSMMANRayssa OliveiraNo ratings yet

- RTU Manual 8Document1 pageRTU Manual 8mudillaaNo ratings yet

- Remsdaq Callisto NXL Lite System BrochureDocument2 pagesRemsdaq Callisto NXL Lite System BrochureFarid AhmadNo ratings yet

- Safety Relay LC ControllerDocument5 pagesSafety Relay LC ControlleraguilavmNo ratings yet

- Preline RTA 421: ContactorDocument6 pagesPreline RTA 421: ContactorMarco Antonio Esquivel BarretoNo ratings yet

- Quick Start Guide: RSPS SeriesDocument15 pagesQuick Start Guide: RSPS SeriesGuillaume FoubertNo ratings yet

- Инструкция 536-549Document14 pagesИнструкция 536-549Andrey PrikhodkoNo ratings yet

- Timer Specifications Intermatic Grasslin FM1D50Document2 pagesTimer Specifications Intermatic Grasslin FM1D50MikeNo ratings yet

- Description Pin Configuration: (Top View)Document8 pagesDescription Pin Configuration: (Top View)Yaro CorralesNo ratings yet

- 1 User Guide: 2408 I Indicator and Alarm UnitDocument12 pages1 User Guide: 2408 I Indicator and Alarm UnitFernando BarraganNo ratings yet

- 95-8511 Heart Beat MonDocument6 pages95-8511 Heart Beat MonJhoan EspitiaNo ratings yet

- ATS Functional and Spec-JET POWERDocument12 pagesATS Functional and Spec-JET POWERView Computer Engineering100% (1)

- TPItL10 CtLv10 Com ENDocument2 pagesTPItL10 CtLv10 Com ENJose Yamid Jojoa GomezNo ratings yet

- 004-0357-001 Model HEC-4 ManualDocument7 pages004-0357-001 Model HEC-4 ManualCássio BrazNo ratings yet

- EMJ-04 Servo MotorDocument3 pagesEMJ-04 Servo MotorlaloNo ratings yet

- Company Profile Global Twin StarDocument6 pagesCompany Profile Global Twin StarJane Junita WorangNo ratings yet

- Experiment-1 - To Make A Center-Tap Full-Wave RectifierDocument5 pagesExperiment-1 - To Make A Center-Tap Full-Wave RectifierSKMNo ratings yet

- AC Motor Control CircuitDocument19 pagesAC Motor Control CircuitnawitsNo ratings yet

- Project Plan LampshadeDocument3 pagesProject Plan LampshadeJane Ariza-Tuason100% (2)

- VSX 820 KDocument126 pagesVSX 820 KWilson Rojas SantosNo ratings yet

- Model PPS Pulse Transmitter: GeneralDocument4 pagesModel PPS Pulse Transmitter: GeneralMerima BesicNo ratings yet

- User Manual: ETP4830-A1 V300R001Document39 pagesUser Manual: ETP4830-A1 V300R001HtourchianNo ratings yet

- Acessórios para Igs-Nt - Id-Dcu - IgavriDocument2 pagesAcessórios para Igs-Nt - Id-Dcu - IgavrileandrovaffonsoNo ratings yet

- Presentation 1Document66 pagesPresentation 1Vaneet GuptaNo ratings yet

- Charge Controller System PDF (Print)Document18 pagesCharge Controller System PDF (Print)Shubham Singh RathoreNo ratings yet

- ABB Solar Inverters: PVS800 Technical FeaturesDocument44 pagesABB Solar Inverters: PVS800 Technical FeaturesmillarsambasivamNo ratings yet

- New 1v6p Cams PartsDocument25 pagesNew 1v6p Cams PartsjoecentroneNo ratings yet

- Unit 4: Transmission Theory of The MOSFET: Landauer at Low and High BiasDocument18 pagesUnit 4: Transmission Theory of The MOSFET: Landauer at Low and High BiasIqra FarhanNo ratings yet

- Victron SmartSolar Charge Controller MPPT 250 60 250 100 Datasheet SolartopstoreDocument1 pageVictron SmartSolar Charge Controller MPPT 250 60 250 100 Datasheet SolartopstoreNelson Andres Entralgo Maldonado100% (1)

- 1N5333B - 1N5388B 5.0W Zener DiodesDocument5 pages1N5333B - 1N5388B 5.0W Zener DiodessergiogasNo ratings yet

- Buchholz Relay: (A Technical Description)Document6 pagesBuchholz Relay: (A Technical Description)Syed Muhammad Munavvar Hussain100% (1)

- Product Characteristics: Flow SensorsDocument2 pagesProduct Characteristics: Flow SensorsMichael MartinNo ratings yet

- Allen Bradley User Manual 1769Document7 pagesAllen Bradley User Manual 1769lin2m3No ratings yet

- Short Notes On Servo MotorDocument2 pagesShort Notes On Servo MotorHimansu Goswami100% (3)

- Electricity DiscussionDocument19 pagesElectricity DiscussionDitaS IdnayNo ratings yet

- Report On TransducersDocument36 pagesReport On Transducerspunith666No ratings yet