Professional Documents

Culture Documents

Personal Summary: M.Sc. - April 2012 Surface Coating Technology

Personal Summary: M.Sc. - April 2012 Surface Coating Technology

Uploaded by

Marikya Gupta0 ratings0% found this document useful (0 votes)

11 views2 pagesResume copy

Original Title

Vishal Chandarana resume.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentResume copy

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views2 pagesPersonal Summary: M.Sc. - April 2012 Surface Coating Technology

Personal Summary: M.Sc. - April 2012 Surface Coating Technology

Uploaded by

Marikya GuptaResume copy

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

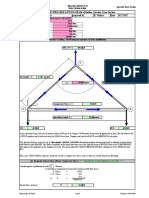

VISHAL CHANDARANA

+91 6356997929 vishal00988@gmail.com 17-Shiv Florence, Anand, Gujarat, India.

PERSONAL SUMMARY

M.Sc. in surface coating technology (paint tech.) With six plus years of experience in manufacturing of paints & coating.

SCHOLASTICS PROFESSIONAL ABRIDGEMENT

M.Sc. |April 2012 1. Production executive/operation |NOVEMBER 2015 to present

Surface coating technology REICHHOLD INC Dubai, UAE

Institute of science and

technology for advanced RESPONSBILITIES:

studies and research,

6.97 CGPA. Responsible for Reichhold’s process operations, quality control, coordinating.

workers & maintenance team to achieve the desired production targets. Leading

B.Sc. |April 2010

SCADA system operations with focus on safety, quality, accuracy and cost.

Industrial

chemistry(vocational) Prepare daily production plan by coordination with plant manager and sales

V.P & R.P.T.P Science team.

College, 68.88 % Coordinate with sales & customer service team about finished product

availability.

STRENGTH Coordinated with the Inventory department on optimum levels of stock for both

raw materials and finished goods.

Comprehensive problem

Review the stock of finished goods and raw material and report any deviation.

solving abilities,

Able to handle projects Working on a SAP system – process order release, inventory posting etc.

independently, To guide the operators for various quality tests of resin & gelcoat.

Good verbal and written Shade matching of gelcoat through spectrophotometer and bulk batch quality

communication skills, Corrections.

Ability to deal with people Lead a 15-member team, monitoring all processes & operations in the plant

effectively,

seeking quality and productivity. Imparted new ideas and created SOP’s for each

Willingness to learn,

process operations, and implemented new and innovative techniques to save

Team facilitator.

time and reduce overall manufacturing cost.

SKILLS Provide the progressive leadership and vision needed to support Reichhold

policy on quality & rendering high quality products to customers consistently.

Hands on experience in Guide QC team towards improving accuracy and precision to ensure and

operating SCADA program. maintain top quality standards.

User of SAP PP module. Optimized and maintained documentation for every operation with focus on

Working on high-pressure

transparency & traceability.

exothermic reaction.

Knowledge of Microsoft Assessed & introduced programs for analyzing workers performance, induced

office. training sessions for operators on good manufacturing practices, personal safety,

Crisis management general housekeeping and maintaining quality standards.

LISENCE

Having valid UAE driving

lisence.

TRAINING UNDERTAKEN 2. Chemist/In charge |OCTOBER 2013 to SEPTEMBER 2015

INTERCOLOR LLC Dubai, UAE

1. AKZONOBEL COATING INDIA

PVT. LTD RESPONSBILITIES:

Bangalore- May’11 to July 11 Decorative product development as per customer and company requirement.

Practical aspects of coil

To ensure developed product is working effectively at customer end provide

coating and improving the

quality of paint remedies for occurred problems.

Scope of project: Visit customer site regularly to take feedback of developed products.

The project involved working on Evolution of new raw materials for quality improvement and cost reduction.

specialty paints and solving Elaborate testing methods for the same and guide operators to carry different

different defects and thereby

quality testing for regular use.

improving the quality of paints,

replacement of extender in back Prepared the required records of the production and maintained the same in

coat. Also had done tinting system.

process. Managing plant operations with a view to ensure timely accomplishment of

2. ESDEE PAINTS LTD production.

Ahmedabad- May’09-June 09 Work force finalization & allocation according to process Requirement.

Quality analysis of paints. Machine wise production scheduling on daily basis & Handle Workers/Labour.

Scope of project: Make a plan for product dispatch to costumer end and ensure compliances.

The project involved various

Process cost reduction, batch time cycle reduction, capacity enhancement.

Quality tests of different

paints. Managing workflow, assuring timely availability of raw material, tracking &

follow-up all process.

Adhering to the system and process changes for qualitative improvement in

SEMINARS ATTENDED productivity and for reducing the rate of rejection of the finished products.

“INDUSTRIAL MOTIVATION

CAMPAIGN “-2011 3. Production Officer |May 2012 to July 2013

KANSAI NEROLAC PAINTS LTD Haryana, India

8th international symposium

on surface protective RESPONSBILITIES:

coating-SSPC 2011 Overseeing activities related to automotive Paint production.

Handling & utilization of labour for achieving targeted production plan.

PERSONAL SNIPPET Monitoring & controlling all parameters during chemical reaction.

Maintaining all safety parameters as per company standards during

Date of birth: 04/06/1989 operations.

Language: English, Hindi, Prepared the records of the production and maintained the same in SAP

Gujarati. System.

Address: 17, Shiv

Preparing & Maintaining log sheets, SOPs as per company standards.

Florence,

Valasan, To meet SKU wise volume requirement in each shifts.

Gujarat. To achieve KPM of Safety, Quality, Efficiency, Productivity and Cost.

Handling all quality activities and implementing effective Targets, techniques

to bring efficiency in operations to Improve quality standards & achieve

maximum cost savings.

Devised the shift schedule activities for production and testing of the samples

and the finished products.

Vishal Chandarana.

You might also like

- Techniques of Brazilian JiuDocument58 pagesTechniques of Brazilian JiuCesar LopezNo ratings yet

- Case - MR Brown BakeryDocument3 pagesCase - MR Brown BakeryVishek Agarwal100% (2)

- Unlocked 189537383 Spreader Beam BLOCK EDocument25 pagesUnlocked 189537383 Spreader Beam BLOCK EWalterNo ratings yet

- Very Good CV FormatDocument5 pagesVery Good CV FormatAhmad YaseenNo ratings yet

- DuasDocument94 pagesDuasMuhammad Iqbal Shaikh100% (1)

- Paint Defects PhotographDocument90 pagesPaint Defects PhotographMarikya GuptaNo ratings yet

- Mark Knofler: Career OverviewDocument2 pagesMark Knofler: Career OverviewknoflerNo ratings yet

- Delem: Installation Manual V3Document73 pagesDelem: Installation Manual V3Marcus ChuaNo ratings yet

- Career Objective:: Name Date of Birth Position Wanted Job Category E-Mail ID Permanent AddressDocument5 pagesCareer Objective:: Name Date of Birth Position Wanted Job Category E-Mail ID Permanent AddressvivekNo ratings yet

- CV of Muhammad Adeel RajputDocument4 pagesCV of Muhammad Adeel RajputFarhan SaghirNo ratings yet

- Key Skills: Sunil Kumar DalalDocument3 pagesKey Skills: Sunil Kumar DalalAvinashBatraNo ratings yet

- Midterm Reviewer 2022Document8 pagesMidterm Reviewer 2022Miren ParrenoNo ratings yet

- Atul Sangole: Key HighlightsDocument3 pagesAtul Sangole: Key Highlightsmark kdNo ratings yet

- Ravi Halleppanavar ResumeDocument5 pagesRavi Halleppanavar ResumeMNR SolutionsNo ratings yet

- Bilal Hameed-Manager ProductionDocument2 pagesBilal Hameed-Manager ProductionSehba NaseemNo ratings yet

- Adarsh Kumar-Resume2021Document3 pagesAdarsh Kumar-Resume2021Divyank AryaNo ratings yet

- Abhijtt-Resume: Profile SummaryDocument5 pagesAbhijtt-Resume: Profile SummaryDrSyed ShujauddinNo ratings yet

- Dharmendra CVDocument6 pagesDharmendra CVAmandeep SharmaNo ratings yet

- Ahmed Hassan - : Chemical Engineer (PEC Registered)Document3 pagesAhmed Hassan - : Chemical Engineer (PEC Registered)Engr AhmedNo ratings yet

- Samip C Gaikwad: Currently Associated Artheon Battery Company PVT - Ltd. As A Quality Deputy Manager.Document2 pagesSamip C Gaikwad: Currently Associated Artheon Battery Company PVT - Ltd. As A Quality Deputy Manager.Samip GaikwadNo ratings yet

- Career Objective: Senior Production EngineerDocument4 pagesCareer Objective: Senior Production Engineeramol thengNo ratings yet

- Abhijeet ResumeDocument2 pagesAbhijeet ResumeRaghunathNo ratings yet

- Mohd Ruzaini Ariffin: Profile Career ObjectiveDocument1 pageMohd Ruzaini Ariffin: Profile Career Objectivekamal habeebNo ratings yet

- Resume Girish Chandra: Mobile: 09839390491,8400333232 EmailDocument4 pagesResume Girish Chandra: Mobile: 09839390491,8400333232 EmailSAMSON GLOBALNo ratings yet

- AbhishekChopra CV 2023Document4 pagesAbhishekChopra CV 2023Abhishek ChopraNo ratings yet

- CV of Kushal PardeshiDocument5 pagesCV of Kushal PardeshiKushal PardeshiNo ratings yet

- Ritesh NavtharDocument3 pagesRitesh NavtharMayur ShindeNo ratings yet

- Naukri RAJESHMAKWANA (12y 0m)Document4 pagesNaukri RAJESHMAKWANA (12y 0m)Piyush SinghalNo ratings yet

- Manufacturing Engineer: Mobile: +91 99412 66601/+91 9880756357 - E-Mail: D@cvdesigner - inDocument3 pagesManufacturing Engineer: Mobile: +91 99412 66601/+91 9880756357 - E-Mail: D@cvdesigner - inmaheshnagarkarNo ratings yet

- Nilesh Panchal ResumeDocument3 pagesNilesh Panchal ResumeShanaNo ratings yet

- Skills: Industrial/Mechanical EngineerDocument4 pagesSkills: Industrial/Mechanical EngineerBivek SapkotaNo ratings yet

- Rashid-Ali (PRD Engr)Document4 pagesRashid-Ali (PRD Engr)Junaid EngrNo ratings yet

- CV-Muhammad IrfanDocument4 pagesCV-Muhammad IrfanMuhammad IrfanNo ratings yet

- Shrikant R S - Quality ManagerDocument2 pagesShrikant R S - Quality ManagerParag WadekarNo ratings yet

- Muzammil Khan ResumeDocument2 pagesMuzammil Khan ResumeMuzammil KhanNo ratings yet

- JohnDocument2 pagesJohnw john franklinNo ratings yet

- Rateek Awhney E Q: EY KillsDocument2 pagesRateek Awhney E Q: EY KillsMeer Hassan FarhadNo ratings yet

- Nabeel Ahmed Malik: ExperienceDocument3 pagesNabeel Ahmed Malik: ExperiencenabeelNo ratings yet

- CV2024Document4 pagesCV2024surajthonge14461No ratings yet

- Hamza ResumeDocument1 pageHamza ResumeSyed Owais Ali NaqviNo ratings yet

- Yash Resume 2 2Document2 pagesYash Resume 2 2BaljeetNo ratings yet

- Resume - Dhruv MishraDocument3 pagesResume - Dhruv MishraUvi BNo ratings yet

- CV IEA - 2024 Rev BDocument3 pagesCV IEA - 2024 Rev BErdiansyah SeputroNo ratings yet

- Ajay Kumar: Experience SummaryDocument4 pagesAjay Kumar: Experience SummarySAMSON GLOBALNo ratings yet

- Curriculum Vitae:: Akhil - Tripathi@yahoo - Co.in (M.) : 09891771791 9311142126Document3 pagesCurriculum Vitae:: Akhil - Tripathi@yahoo - Co.in (M.) : 09891771791 9311142126Anil SharmaNo ratings yet

- Johnson.p CVDocument2 pagesJohnson.p CVMayur ShindeNo ratings yet

- Naukri AbhishekFaujdar 15326740 - 04 10 - 1Document3 pagesNaukri AbhishekFaujdar 15326740 - 04 10 - 1Mayur ShindeNo ratings yet

- Mark Daniel Atienza. Bañarez: Barangay Real Calamba City, LagunaDocument2 pagesMark Daniel Atienza. Bañarez: Barangay Real Calamba City, LagunamarkNo ratings yet

- Souma Mazumdar Resume 2024Document5 pagesSouma Mazumdar Resume 2024Souma MazumdarNo ratings yet

- VenkataSaiSumanth Divili CV-6Document3 pagesVenkataSaiSumanth Divili CV-6saisumanthdv1902No ratings yet

- Gavin Chui: Professional ProfileDocument3 pagesGavin Chui: Professional ProfileMarkoNo ratings yet

- IBAD's ResumeDocument2 pagesIBAD's ResumeSyed Owais Ali NaqviNo ratings yet

- Engineering Project LeaderDocument3 pagesEngineering Project LeaderPhelep MounirNo ratings yet

- Manish CVDocument3 pagesManish CVManish ChauhanNo ratings yet

- Dditional SkillDocument3 pagesDditional SkillPraveen Singh BhagelNo ratings yet

- Saswat Kumar Mohapatra: Profile SummaryDocument3 pagesSaswat Kumar Mohapatra: Profile SummarySAMSON GLOBALNo ratings yet

- Priynka - Gupta - ResumeDocument2 pagesPriynka - Gupta - ResumeNavjot RihalNo ratings yet

- Kumud Ranjan RESUMEDocument3 pagesKumud Ranjan RESUMEAmit MondalNo ratings yet

- Sandipkumar Arjun ShindeDocument3 pagesSandipkumar Arjun ShindeAditya NaikNo ratings yet

- Murugesan-Operations ManagerDocument4 pagesMurugesan-Operations ManagerSoundhara Pandian SamuvelNo ratings yet

- Contact: Profile SummaryDocument2 pagesContact: Profile Summaryrajat guptaNo ratings yet

- Ramya D: Profile SummaryDocument2 pagesRamya D: Profile SummaryLakshmi JethendraNo ratings yet

- C C P S: YashpalDocument4 pagesC C P S: YashpalAyisha PatnaikNo ratings yet

- Ulises Eduardo Ruvalcaba Lugo Experience: Continuous Improvement EnginnerDocument3 pagesUlises Eduardo Ruvalcaba Lugo Experience: Continuous Improvement EnginnerCarmen LugoNo ratings yet

- Muhammad Adeel Quality AuditorDocument2 pagesMuhammad Adeel Quality AuditorFaisal AkhterNo ratings yet

- Naukri SharathA (7y 0m)Document2 pagesNaukri SharathA (7y 0m)RaghuNo ratings yet

- ACED Murugadoss PPT TAFEDocument91 pagesACED Murugadoss PPT TAFEMarikya GuptaNo ratings yet

- Introduction To Electrostatic ApplicatorsDocument27 pagesIntroduction To Electrostatic ApplicatorsMarikya GuptaNo ratings yet

- Prasanth Resume - Automotive PaintDocument4 pagesPrasanth Resume - Automotive PaintMarikya GuptaNo ratings yet

- Paint Application: ISO 9001 ISO 14001Document2 pagesPaint Application: ISO 9001 ISO 14001Marikya GuptaNo ratings yet

- FlaresDocument18 pagesFlaresEric WanNo ratings yet

- English Starter Level TestDocument3 pagesEnglish Starter Level TestSofia FassiNo ratings yet

- The Radiology Assistant - AdrenalsDocument9 pagesThe Radiology Assistant - Adrenalsseb2008No ratings yet

- Percentage NDTDocument5 pagesPercentage NDTFranz SchalkeNo ratings yet

- Process Flow For Issuance of Medical Clearance For PCG Applicants (2021)Document4 pagesProcess Flow For Issuance of Medical Clearance For PCG Applicants (2021)Aljen Rey BuenafeNo ratings yet

- TriReme Antares Brochure 011110Document2 pagesTriReme Antares Brochure 011110leboidsNo ratings yet

- Repair of Interference Hi-Lok Fastener With Beam RadiusDocument11 pagesRepair of Interference Hi-Lok Fastener With Beam Radiusברוך שרוןNo ratings yet

- Jennifer Nguyen: EducationDocument2 pagesJennifer Nguyen: Educationapi-251264967No ratings yet

- DCOM Volume II Book PrintReady PDFDocument187 pagesDCOM Volume II Book PrintReady PDFIvo MsodockiNo ratings yet

- Transcend New Stock & Update Price: Items SKU DiscriptionsDocument4 pagesTranscend New Stock & Update Price: Items SKU DiscriptionsAbu Bakar Siddik RajNo ratings yet

- Bahasa Inggris EditDocument7 pagesBahasa Inggris EditUmmu KhonsaNo ratings yet

- Amont of Substance (Multiple Choice) QPDocument24 pagesAmont of Substance (Multiple Choice) QPlmao lmaoNo ratings yet

- Kde en 923 0862Document32 pagesKde en 923 0862joseloaiza378No ratings yet

- 4 5918214429920462111Document3 pages4 5918214429920462111rmdarisaNo ratings yet

- The Key To Classroom Management: Appropriate Levels of DominanceDocument7 pagesThe Key To Classroom Management: Appropriate Levels of DominancejavibravogugleNo ratings yet

- Sheet 3Document33 pagesSheet 3Ahmed AdelNo ratings yet

- BSN 2F Discharge PlanDocument6 pagesBSN 2F Discharge Plan22 - Fernandez, Lyza Mae D.No ratings yet

- Cover Sheet For Individual Assignments: September'2009Document19 pagesCover Sheet For Individual Assignments: September'2009Povenesan Krishnan100% (1)

- Types of BreadDocument11 pagesTypes of BreadNadhira Azka AfifaNo ratings yet

- Fuse Bible CompleteDocument164 pagesFuse Bible CompleterbucholzNo ratings yet

- DefinitionDocument8 pagesDefinitionDhom Ortiz CandelariaNo ratings yet

- Best Practice Recommendations For Manufacturing Ceramic Pot Filters June2011Document187 pagesBest Practice Recommendations For Manufacturing Ceramic Pot Filters June2011Raihan Fiqri IrwandaNo ratings yet

- Tween 80Document11 pagesTween 80fvdxrgNo ratings yet

- Contoh Naskah Pidato Bahasa Inggris Tentang Kesehatan Bahaya RokokDocument2 pagesContoh Naskah Pidato Bahasa Inggris Tentang Kesehatan Bahaya RokokMona Haafidzah HsbNo ratings yet