Professional Documents

Culture Documents

Intend To Extend: Cover Series: Installation Best Practices

Uploaded by

Lisa FosterOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intend To Extend: Cover Series: Installation Best Practices

Uploaded by

Lisa FosterCopyright:

Available Formats

Sept05PUMPS&SYSp18-21 8/22/05 11:51 PM Page 18

Cover Series: Installation Best Practices

Intend

to

Extend

John Petersen, Viking Pump, Inc.

“The root cause of many pump failures can

be traced back to how well – or how poorly

– the pump system is installed. Here are

some proper installation principles that will

extend the life of your pump.”

accept the applied loads of torque without deflecting.

A

rigid foundation prevents structural move-

ment that causes other components to fail. In certain applications, the baseplate design must be

This is why a poorly mounted baseplate reinforced underneath, perhaps grouted, to allow the

wields a destructive effect, similar to constructing a base plate to float for temperature variation.

For example, consider a process that starts oper-

multi-million dollar home on loosely-set bricks.

ating with a cold pump. The pipes expand as heat

A rigid baseplate is the backbone of shaft and

builds to 350 degrees during the process. A com-

coupling alignment. We’ve all heard horror stories

mon practice in high-temp applications is to allow

about crews trying to make up two inches in the line the base plate to “float” rather than constraining it

by prying open a discharge port for slack. A non- and creating more loads on the pump system.

rigid base, combined with non-aligned shafts, Piping designers determine the amount of float by

results in excess vibration, mechanical seal failure, calculating the maximum growth in the piping dur-

leakage and possible premature bushing wear. These ing the process cycle.

installation problems are all root causes of prema- Using expansion joints next to the pump

ture failure to pumps. accomplishes the same purpose. Expansion joints

Here are some tips on proper installation prin- provide the support necessary to absorb any piping

ciples that will extend the life of the pump. expansion that occurs and effectively remove this

issue from the equation.

Baseplate Mounting For pumps running at higher temperatures,

A typical positive displacement pump operates another common practice is to hot-align the whole

as a lower-speed higher-torque device. This trans- unit. This involves initially running the pump and

lates into some twisting motion in a non-rigid base, bringing the process up to temperature. Next, the

because applying power to this pump through a gear system is shut down and everything locked out.

reducer generates some fairly significant reaction Then, everything is realigned at operating tempera-

forces that tend to turn the base and distort the shaft ture using special safety precautions due to every-

alignment. When this happens, unusually high thing being hot.

forces within the pump create higher bearing loads Sound baseplate design is absolutely critical to

and premature wear. pump longevity. Its rigidity must match the applica-

The baseplate for this application must be tion, but be flexible enough to allow shaft and cou-

designed with enough rigidity to allow the shaft to pling alignment without making compromises.

18 SEPTEMBER 2005 www.pump-zone.com PUMPS & SYSTEMS

Sept05PUMPS&SYSp18-21 8/23/05 8:07 AM Page 19

1

To realign a pump

system , ensure the

power is off and lock

out the unit before 5

starting any work.

Make sure the base

is level and support- Pipe up the pump. After piping

ed. Do not stress the the pump, check all the align-

base. Tighten the ments again. Do not have in any

foundation bolts. Re- strain or twisting. Final align-

move the coupling ment. Above 300-deg operating

guards to expose the temperatures, check the clear-

couplings. ances at running temperature.

Check all alignments one last

time. Replace all coupling

guards prior to startup.

2

Align the pump to the piping. Make sure

the ports and pipes are square. Shim and

align as required. Tighten the pump

mounting bolts. Do not move pump dur-

ing alignment! All other components are

aligned to the pump.

3

Align the reducer to the pump. Check

the coupling between the pump and

reducer. Correct by shimming or

moving the reducer. Tighten the

reducer mounting bolts.

4

Align the motor to the reducer. Check

the coupling between the reducer and

motor. Correct by shimming or moving

the motor. Tighten the motor bolts.

Recheck the alignment between the

pump and reducer.

PUMPS & SYSTEMS www.pump-zone.com SEPTEMBER 2005 19

Sept05PUMPS&SYSp18-21 8/22/05 11:51 PM Page 20

Coupling Alignment

Coupling alignment must always be inspected during new instal-

lations or whenever a component is removed for repair or mainte-

nance. For example, pumps are commonly pulled from service due to

seal leakage caused from incorrect seal installation or misalignment,

not from a mechanical problem with the seal itself.

Parallel or offset coupling

alignment aligns the driver

and driven shaft to a common

center line using a straight

edge, dial indicator, or laser

level. In this example, the

straightedge should rest

squarely and evenly on the

coupling hubs. Every 90

degrees should be checked.

Some users discover that coupling alignment has a larger impact

on mechanical seal leakage than all other causes, so their baseplate

Circle 129 on Reader Service Card

design allows them to dial-in coupling alignments and dramatically

reduce their amount of seal maintenance.

A factory-aligned unit must still be realigned when received and

installed on site, because certain system components may shift or be

disturbed during shipment. Because typical bases are totally flat, many

users mistakenly attempt to level the unit by tightly drawing down the

base with bolts during installation.

20 SEPTEMBER 2005 www.pump-zone.com PUMPS & SYSTEMS

Sept05PUMPS&SYSp18-21 8/22/05 11:51 PM Page 21

Always check the gap on

coupling alignment — the man-

ufacturer’s recommended dis-

tance between coupling halves.

If the piping goes in first

during plant construction, align

the existing piping with the

pump without springing the

piping into place. The key here

is positioning and locating

everything before locking any-

thing down. Piping changes will

be necessary if there is too

much distance to make up.

Angular coupling alignment If no piping is installed, start

aligns the faces of the coupling

with the pump and run out

parallel to each other using feel-

er gages, a spacer bar, a mic- from there. Remember to sup-

rometer, or calipers. The spacing port the piping next to the

between the coupling should be pump. From this point, attach

checked against the manufac-

turer’s specification. Every 90 the parts to the pump and work

degrees should be checked. backward through the align-

ment process. All piping should

be aligned (with the base prop-

If the unit is not completely tion one way or another with a erly shimmed) before tightening

level, position and locate the base soft hammer. everything down.

and start the bolts. If a gap exists

between the foundation and the The Grace of Space

base plate, insert a shim under- Behind all of these installa- advantage, and the root cause of

neath so the base is not distorted tion and alignment procedures many pump failures can be

from its original position. Next, lies the fact that many facilities traced back to how well – or how

realign the piping and bolts with fail to allow access to the pump poorly – the pump system is

the shimmed base, then tighten

system for efficient maintenance installed. Following these princi-

down the bolts.

and repairs. Forethought should ples of proper installation will

When using laser alignment

as the reference for tightening be given to front and side access preserve the health of the pump

down the system, jack screws to the pump system during – and your bottom line. P&S

offer an effective and easy way to design, so that installation and

dial-in incremental thousandths alignments can be effectively per- John Petersen is vice president for

formed to minimize downtime. technical customer service at Viking Pump,

of movement that matches the

Inc., 406 State Street, Cedar Falls, IA

precision of the laser reading. The bottom line here is the

50613, 319-273-8152, Fax: 319-273-

This eliminates the imprecise actual bottom line. Fewer pump 8157, www.idexcorp.com, jpetersen@i-

tapping of the motor into posi- failures equates to competitive dexcorp.com.

PUMPS & SYSTEMS www.pump-zone.com SEPTEMBER 2005 21

You might also like

- Installation Operation Maintenance Mission 2500 Supreme PDFDocument16 pagesInstallation Operation Maintenance Mission 2500 Supreme PDFRAHULNo ratings yet

- IOM MANUAL 250 SERIES CENTRIFUGAL PUMP GUIDEDocument17 pagesIOM MANUAL 250 SERIES CENTRIFUGAL PUMP GUIDEhebert perez50% (2)

- Swan Teasmade Instructions 14140Document8 pagesSwan Teasmade Instructions 14140Roy RussellNo ratings yet

- Vertical and Horizontal End Suction Pumps Installation, Operation and Maintenance ManualDocument12 pagesVertical and Horizontal End Suction Pumps Installation, Operation and Maintenance ManualOlawale John AdeotiNo ratings yet

- 450 PumpDocument15 pages450 PumpJader David Rocha MoralesNo ratings yet

- Circuit Setter ManualDocument4 pagesCircuit Setter ManualAnonymous 7xHNgoKE6eNo ratings yet

- Design Envelope - 6800 Ivs Booster SystemsDocument28 pagesDesign Envelope - 6800 Ivs Booster SystemsRohitNo ratings yet

- Am, Ap & Al Series Pumps Owners Manual: Safety InstructionsDocument10 pagesAm, Ap & Al Series Pumps Owners Manual: Safety InstructionsQC RegianNo ratings yet

- Iom A Series-Roper PDFDocument8 pagesIom A Series-Roper PDFvictor gomezNo ratings yet

- Service Instructions: Oilgear Type "PVV 540" Open Loop PumpsDocument14 pagesService Instructions: Oilgear Type "PVV 540" Open Loop PumpsAxel LetonaNo ratings yet

- Auburn Tune Up 14pagesDocument14 pagesAuburn Tune Up 14pagesjorge Angel LopeNo ratings yet

- Disassemble IMBRC PartsDocument4 pagesDisassemble IMBRC PartsJoseph DavidNo ratings yet

- Aurora Pump MaintenanceDocument35 pagesAurora Pump MaintenancemetropumpsNo ratings yet

- Bombas 3344 Manual Mantenimiento y ReparaciónDocument14 pagesBombas 3344 Manual Mantenimiento y ReparaciónHECTORNo ratings yet

- Grout Bombas AnsiDocument39 pagesGrout Bombas AnsiAtahualpa Yopasa PerezNo ratings yet

- Hydraulic System Initial Start-Up and MaintenanceDocument4 pagesHydraulic System Initial Start-Up and MaintenanceLuisNo ratings yet

- Catalog ISO Soverreign Southon CrossDocument21 pagesCatalog ISO Soverreign Southon CrossAndi AlfianNo ratings yet

- Install and Operation Manual B&S Pump BSM PumpDocument7 pagesInstall and Operation Manual B&S Pump BSM Pumppr_oilNo ratings yet

- Multistage Centrifugal Pumps: Vertical Inline ModelsDocument16 pagesMultistage Centrifugal Pumps: Vertical Inline ModelsBang MatNo ratings yet

- 605JMIOMDocument4 pages605JMIOMEduardo SolisNo ratings yet

- Installation and Maintenance Information: Turbine Powered StartersDocument12 pagesInstallation and Maintenance Information: Turbine Powered StartersAbdelkader AbdelkaderNo ratings yet

- 3300 Series Installation ManualDocument2 pages3300 Series Installation ManualMarceloGonçalvesNo ratings yet

- PCF Valve Guide Inspection GuideDocument13 pagesPCF Valve Guide Inspection GuideoscarNo ratings yet

- Installation & Maintenance Instructions for Mark 57 Pressure RegulatorsDocument4 pagesInstallation & Maintenance Instructions for Mark 57 Pressure Regulatorsbenzerga karimNo ratings yet

- Pearl Manual PWP PWSDocument12 pagesPearl Manual PWP PWSMANUEL HINCAPIENo ratings yet

- Manual BOOK AR SERIESDocument4 pagesManual BOOK AR SERIESchandra atmaNo ratings yet

- Model BX: Industrial PumpsDocument8 pagesModel BX: Industrial PumpsF81No ratings yet

- 50B-4KG1/2050B-4KG1: Pressure Relief ValveDocument2 pages50B-4KG1/2050B-4KG1: Pressure Relief ValveIngeniero aicNo ratings yet

- WaterWorker Vertical Well Tank Installation ManualDocument12 pagesWaterWorker Vertical Well Tank Installation ManualS100% (1)

- Troubleshooting Centrifugal Pumps-2Document3 pagesTroubleshooting Centrifugal Pumps-2vignesh guru100% (1)

- Plentyc6000 ManualDocument22 pagesPlentyc6000 Manualsumu123No ratings yet

- Trick Flow Camshaft Degreeing Kit: Instructions ForDocument4 pagesTrick Flow Camshaft Degreeing Kit: Instructions ForROYALNo ratings yet

- JK Quick Start Guide (UFH)Document7 pagesJK Quick Start Guide (UFH)ross.jm.fullerNo ratings yet

- AC4 - AC5 Horizntal Series ManualDocument8 pagesAC4 - AC5 Horizntal Series ManualDaniel RibeiroNo ratings yet

- Bronze Rotary Gear Pumps Installation, Operation, and Maintenance InstructionDocument4 pagesBronze Rotary Gear Pumps Installation, Operation, and Maintenance InstructionGlenn Bryan AntonioNo ratings yet

- Pump installation tips: General piping guidelinesDocument9 pagesPump installation tips: General piping guidelinesYe tun KyawNo ratings yet

- DPC 2802 Startup ProcedureDocument6 pagesDPC 2802 Startup ProcedureMuhammad Asad100% (1)

- Operating Instructions for VOGEL Lubrication SystemsDocument5 pagesOperating Instructions for VOGEL Lubrication Systemsli geneNo ratings yet

- FI/FE Base Mounted Pumps: Installation and Operation InstructionsDocument4 pagesFI/FE Base Mounted Pumps: Installation and Operation Instructionsh2odavidNo ratings yet

- Plunger Pump Service Manual: Installation and Start-Up InformationDocument6 pagesPlunger Pump Service Manual: Installation and Start-Up InformationDark CenobiteNo ratings yet

- Install and operate end suction pumpsDocument16 pagesInstall and operate end suction pumpsAUX PRESUPUESTONo ratings yet

- O&m RGVDocument7 pagesO&m RGVNur NaziraNo ratings yet

- Fordson Major Systeme HydrauliqueDocument23 pagesFordson Major Systeme HydrauliqueNicolas100% (1)

- Circuit Setter Plus Model MC: Instruction ManualDocument4 pagesCircuit Setter Plus Model MC: Instruction Manualmacanipharoldf6220No ratings yet

- 卧式离心泵说明书英文(大连双龙)Document16 pages卧式离心泵说明书英文(大连双龙)kamal arabNo ratings yet

- Install and service L series pumpsDocument10 pagesInstall and service L series pumpsmalex841007No ratings yet

- Boiler Pressure Controllers: Power PlusDocument5 pagesBoiler Pressure Controllers: Power PlusJhosthin Diaz AlveoNo ratings yet

- Horizontal Split Case Fire Pumps Installation and Operating ManualDocument12 pagesHorizontal Split Case Fire Pumps Installation and Operating ManualNguyễn Đức CườngNo ratings yet

- Attention: Installation GuideDocument2 pagesAttention: Installation GuideDaniel EcheverriaNo ratings yet

- Installation AND Operation Manual: PremierDocument23 pagesInstallation AND Operation Manual: Premieralejandro jimenezNo ratings yet

- Installation and Service Instructions: Excellence at Work. Excellence in LifeDocument12 pagesInstallation and Service Instructions: Excellence at Work. Excellence in LifeDiogenes Rafael TorresNo ratings yet

- Installation, Operation and Maintenance Manual: AC-Centrifugal Roof and Wall ExhaustersDocument8 pagesInstallation, Operation and Maintenance Manual: AC-Centrifugal Roof and Wall ExhaustersRichard Rodriguez MedinaNo ratings yet

- CB Series Installation ManualDocument8 pagesCB Series Installation ManualJuan Jose Ramirez CorralesNo ratings yet

- Circuit SetterDocument4 pagesCircuit SetterHVACRNIC2005No ratings yet

- I & M 6800HP Series: Ideal Installation SchematicDocument4 pagesI & M 6800HP Series: Ideal Installation SchematicMultilibros VillamontesNo ratings yet

- Ddownload 251Document24 pagesDdownload 251David CastilloNo ratings yet

- Hotstart - Model OLA or OLE - Oil Circulating Heating System Hazardous LocationDocument16 pagesHotstart - Model OLA or OLE - Oil Circulating Heating System Hazardous Locationdiego106No ratings yet

- Series 400 Piston Pilot POPRV Maintenance InstructionsDocument26 pagesSeries 400 Piston Pilot POPRV Maintenance InstructionsCristiam BejaranoNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Part-7 EDocument38 pagesPart-7 ELisa FosterNo ratings yet

- hotpermit-frontDocument1 pagehotpermit-frontLisa FosterNo ratings yet

- C-17 Hot Work PermitDocument9 pagesC-17 Hot Work PermitAbi GemalaNo ratings yet

- hot_work_permitDocument1 pagehot_work_permitLisa FosterNo ratings yet

- ChemicalEngineering - Chemical Engineering April 2023Document68 pagesChemicalEngineering - Chemical Engineering April 2023Lisa FosterNo ratings yet

- Sensor Selection Getting It Right For Flammable GasesDocument8 pagesSensor Selection Getting It Right For Flammable GasesLisa FosterNo ratings yet

- Brosse Miscanthus Yr5Document19 pagesBrosse Miscanthus Yr5Lisa FosterNo ratings yet

- Energies 05 03856Document18 pagesEnergies 05 03856Lisa FosterNo ratings yet

- ChemicalEngineering - Chemical Engineering March 2023Document48 pagesChemicalEngineering - Chemical Engineering March 2023Lisa Foster100% (1)

- MiscanthusDocument2 pagesMiscanthusLisa FosterNo ratings yet

- The A3 ReportDocument24 pagesThe A3 ReportLisa Foster100% (1)

- PresskitDocument2 pagesPresskitLisa FosterNo ratings yet

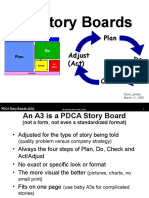

- A3 Story Boards: Plan Do Check Adjust (Act)Document9 pagesA3 Story Boards: Plan Do Check Adjust (Act)BharathNo ratings yet

- 7.8 Malaysia: 7.8.1 Biomass Energy Utilization in MalaysiaDocument6 pages7.8 Malaysia: 7.8.1 Biomass Energy Utilization in MalaysiaLisa FosterNo ratings yet

- Test Your PDCA Thinking by Reading Your A3 BackwardsDocument2 pagesTest Your PDCA Thinking by Reading Your A3 BackwardsLisa FosterNo ratings yet

- Heat Transfer Fluid System VentingDocument1 pageHeat Transfer Fluid System VentingLisa FosterNo ratings yet

- Self Assessment Toolkit For Safety, Health and Environmental AssuranceDocument105 pagesSelf Assessment Toolkit For Safety, Health and Environmental AssuranceLisa FosterNo ratings yet

- A3+Guide Markovitz ConsultingDocument10 pagesA3+Guide Markovitz ConsultingLisa FosterNo ratings yet

- No. 127 More About Modifications and InstrumentsDocument8 pagesNo. 127 More About Modifications and InstrumentsLisa FosterNo ratings yet

- No. 125 Preparation For Maintenance and EntryDocument9 pagesNo. 125 Preparation For Maintenance and EntryLisa FosterNo ratings yet

- AzmanDocument1 pageAzmanLisa FosterNo ratings yet

- 11 - Using A DiffuserDocument2 pages11 - Using A DiffuserLisa FosterNo ratings yet

- No. 123 The Man in The Middle: An Engineer's Casebook - Fatigue Failure of Small BranchesDocument11 pagesNo. 123 The Man in The Middle: An Engineer's Casebook - Fatigue Failure of Small BranchesLisa FosterNo ratings yet

- 10 - BackdropsDocument2 pages10 - BackdropsLisa FosterNo ratings yet

- 14 - Adobe Colour WheelDocument3 pages14 - Adobe Colour WheelLisa FosterNo ratings yet

- The INSET - Toolkit Inherent SHE Evaluation ToolDocument481 pagesThe INSET - Toolkit Inherent SHE Evaluation ToolLisa FosterNo ratings yet

- No. 124 Movements of Tankers and Liquids Atthe Wrong Time or Intothe Wrong PlaceDocument8 pagesNo. 124 Movements of Tankers and Liquids Atthe Wrong Time or Intothe Wrong PlaceLisa FosterNo ratings yet

- 12 - Foldable SawhorseDocument2 pages12 - Foldable SawhorseLisa FosterNo ratings yet

- 13 - Adobe PortfolioDocument3 pages13 - Adobe PortfolioLisa FosterNo ratings yet

- 15 - Tracing Paper RollDocument2 pages15 - Tracing Paper RollLisa FosterNo ratings yet

- Autopilot Servo - Maintenance PracticesDocument16 pagesAutopilot Servo - Maintenance PracticesEleazarNo ratings yet

- Ns/Gs A-598 Manual Transaxle 21 - 5: SERVICE PROCEDURES (Continued)Document3 pagesNs/Gs A-598 Manual Transaxle 21 - 5: SERVICE PROCEDURES (Continued)Luca TrottaNo ratings yet

- Clutch SystemDocument18 pagesClutch SystemKavinda MadhusankaNo ratings yet

- Execution ScheduleDocument5 pagesExecution ScheduleBagadi AvinashNo ratings yet

- Bahasa Inggris Part 5Document4 pagesBahasa Inggris Part 5Fauzi athiNo ratings yet

- Fig. 21 Inching Valve (Tor-Con Type) :, JCPQD20/25N-RW11, S CPQD20/25N-RW7Document3 pagesFig. 21 Inching Valve (Tor-Con Type) :, JCPQD20/25N-RW11, S CPQD20/25N-RW7Walter FormigoniNo ratings yet

- Finolexpricelist PDFDocument1 pageFinolexpricelist PDFhimanshi khivsaraNo ratings yet

- 9500 MPR5.1 - 5.2 Installation Test and Turn Up - Module 3 - Installation - Ed3Document58 pages9500 MPR5.1 - 5.2 Installation Test and Turn Up - Module 3 - Installation - Ed3Atanda Babatunde MutiuNo ratings yet

- CTA Chillers Industrial Water ChillersDocument1 pageCTA Chillers Industrial Water Chillersagyapongsamuel93No ratings yet

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Document1 pagePipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Theodosios StergiouNo ratings yet

- Modifikasi Sistem CBP 90 I-MATRIX SICOMA 4 SILO Ke Sistem Manual Dan AUTO PT Nindya Karya - MaumereDocument6 pagesModifikasi Sistem CBP 90 I-MATRIX SICOMA 4 SILO Ke Sistem Manual Dan AUTO PT Nindya Karya - Maumerearif fatoniNo ratings yet

- Enjoy crystal clear home entertainment wirelessly with GADMEI GM2400Document8 pagesEnjoy crystal clear home entertainment wirelessly with GADMEI GM2400WarNaWarNiNo ratings yet

- Spare Parts Catalog for Crane Model 105905Document69 pagesSpare Parts Catalog for Crane Model 105905Gora Fedotov100% (1)

- Appleton Cord HubDocument6 pagesAppleton Cord HubFarid HadeNo ratings yet

- Delonghi Alicia Electric Espresso Maker User ManualDocument8 pagesDelonghi Alicia Electric Espresso Maker User ManualBufnita AlbaNo ratings yet

- Yz426f 2001Document63 pagesYz426f 2001Cristian Cerna100% (1)

- Chess Robot Materials List Guide Under 40 CharactersDocument2 pagesChess Robot Materials List Guide Under 40 CharactersDavid ThomasNo ratings yet

- Pump ServiceDocument22 pagesPump Serviceahmad adelNo ratings yet

- Hand Tool Register Checksheet - DailyDocument1 pageHand Tool Register Checksheet - DailygrantNo ratings yet

- Close Circuit Circuito de CierreDocument6 pagesClose Circuit Circuito de CierreGabriel Maxo PapagalloNo ratings yet

- Bearing and Their Types PDFDocument6 pagesBearing and Their Types PDFOsaid Haq83% (6)

- Overview: 1) Wiper Function Coupled Auto WasherDocument7 pagesOverview: 1) Wiper Function Coupled Auto WashermanualNo ratings yet

- JJ104 Workshop Technology Chapter6 Milling MachineDocument8 pagesJJ104 Workshop Technology Chapter6 Milling MachineAh TiangNo ratings yet

- Speed JetDocument74 pagesSpeed Jetdc30No ratings yet

- XHHW-2: XLP Insulation, 600 VoltsDocument2 pagesXHHW-2: XLP Insulation, 600 VoltsNaveedNo ratings yet

- Cub Cadet Parts Manual For Model 7252 Tractor 54ag742 100Document6 pagesCub Cadet Parts Manual For Model 7252 Tractor 54ag742 100otis100% (44)

- A330 Aircraft Oil System DiagramDocument1 pageA330 Aircraft Oil System Diagramessid zouhaierNo ratings yet

- AUMA Gear OperatorsDocument30 pagesAUMA Gear OperatorssrdNo ratings yet

- Tools and Materials For Eim nc2Document6 pagesTools and Materials For Eim nc2rowell ramosNo ratings yet