Professional Documents

Culture Documents

Memória de Calculo Do Helice Lateral Rev01

Uploaded by

Paulo Vitor0 ratings0% found this document useful (0 votes)

17 views1 pageOriginal Title

Memória de calculo do helice lateral rev01

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 pageMemória de Calculo Do Helice Lateral Rev01

Uploaded by

Paulo VitorCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

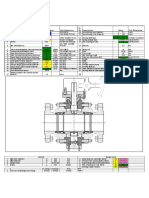

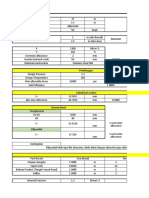

RINA - RULES FOR THE CLASSIFICATION OF SHIPS ( 2012 ) - Pt C, Ch 1, Sec 8

Item Requirement Value unit

Material : AISI 304L Stainless Steel - - -

2

Rm = Minimum ultimate tensile strenght of blade material ≥ 400 470 N/mm

2.1.1

d = Densityt of blade material - 7.950 Kg/dm³

f = Material factor ( table 3 ) - 9.000 -

D = Propeller diameter - 1.930 m

H0.7 = Pitch at 0.7 radius from propeller axis - 2.270 m

H = Mean pitch of propeller - 2.270 m

r = D/H - 0.850 -

P = Maximum continuous power of propulsion machinery - 759 KW

N = Rotational speed of the propeller - 257.5 rpm

2.2.1

MT = Continuous transmitted torque MT = 9.55 P / N - 28.15 KN.m

a)

B = Expanded area ratio - 0.70 -

h = Rake - 0.0 mm

l = Developed width of blade section at 0.25 radius from propeller axis - 492.7 mm

z = Number of blades - 4.0 -

Maximum thickness of

the propeller blade at

t0.25 = t0.25 ≥ 59.8 - mm

the section at 0,25

radius from the propeller

H0.6 = Pitch at 0.6 radius from propeller axis - 2.270 m

r0.6 = D / H0.6 - 0.850 -

2.2.1 l0.6 = Developed width of blade section at 0.6 radius from propeller axis - 686.2 mm

b) Maximum thickness of

the propeller blade at

t0.6 = t0.6 ≥ 30.1 - mm

the section at 0,6 radius

from the propeller axis

2.2.1

Radius at the blade root ≥ 0.75 t0.25 ≥ 44.8 mm

c)

Blade thickness at 0.25 radius of ducted propeller ≥ 1.1 t0.25 ≥ 65.7 66.3 mm

2.5.1

Blade thickness at 0.6 radius of ducted propeller ≥ 1.1 t0.6 ≥ 33.1 35.5 mm

Projetado Conferido Aprovado Data Data

Alvaro Fev/2013

Cliente Projeto Desenho Nº

Camorim / ETP Rebocador

Título Revisão Folha

MEMÓRIA DE CALCULO DO HÉLICE DO MOTOR LATERAL 1 1/1

You might also like

- Create PDF Book App in Android Studio - Download Free PDF Book Source Code PDFDocument6 pagesCreate PDF Book App in Android Studio - Download Free PDF Book Source Code PDFshafiq09090% (1)

- Spreader Beam: ASME BTH-1: InputsDocument17 pagesSpreader Beam: ASME BTH-1: InputsGokul AmarnathNo ratings yet

- 80Nm Manual - Aug 13Document36 pages80Nm Manual - Aug 13Paulo VitorNo ratings yet

- Memória de Calculo Do Helice Central Rev01Document1 pageMemória de Calculo Do Helice Central Rev01Paulo VitorNo ratings yet

- Fixed Normal 575Document8 pagesFixed Normal 575mohanNo ratings yet

- Agitator Calculation. - SPLDocument2 pagesAgitator Calculation. - SPLAbarajithan RajendranNo ratings yet

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- P/V '' Victoria'': Propulsion Shafting Dia + Engine Foundation CalculationDocument5 pagesP/V '' Victoria'': Propulsion Shafting Dia + Engine Foundation CalculationGEORGE SOLDATOSNo ratings yet

- Project: Jobno: Description: DateDocument2 pagesProject: Jobno: Description: DateJONAS NGNo ratings yet

- 23252-BEA-XL-K-MB1-C3: Spherical Roller BearingDocument2 pages23252-BEA-XL-K-MB1-C3: Spherical Roller BearingPhan Tuan AnhNo ratings yet

- Pile Cap DesignDocument14 pagesPile Cap DesignnandavarikNo ratings yet

- Design Calculation of Shaft/Pin/Axle: 1.0 Basic DataDocument3 pagesDesign Calculation of Shaft/Pin/Axle: 1.0 Basic DatapkvchoudharyNo ratings yet

- Bea XL MB1Document1 pageBea XL MB1CAT CYLINDERNo ratings yet

- KTR 250Document2 pagesKTR 250TheRedundant gamerNo ratings yet

- Column Strip: E+ve Above Na M+ve SupportDocument42 pagesColumn Strip: E+ve Above Na M+ve SupportShikha Dubey100% (1)

- Página Inicial - MITCalc - CompletaDocument8 pagesPágina Inicial - MITCalc - CompletaDomingos AzevedoNo ratings yet

- 8 Panel - Bom - 06-12-2023 - R03Document2 pages8 Panel - Bom - 06-12-2023 - R03balrajbonthaNo ratings yet

- PIle FoundationDocument6 pagesPIle FoundationsaravananNo ratings yet

- Collets+BT Selon EN13121-3Document6 pagesCollets+BT Selon EN13121-3Ben Abdallah BecemNo ratings yet

- 3 Inch NB Design Calulation For Varible ThicknessDocument5 pages3 Inch NB Design Calulation For Varible ThicknessSACHIN PATELNo ratings yet

- Project Sports Complex Date: V Max ActDocument2 pagesProject Sports Complex Date: V Max ActShanil BussooaNo ratings yet

- HDD-LC-0001 Rev 0Document24 pagesHDD-LC-0001 Rev 0SAUGAT DUTTANo ratings yet

- Gantry Grider FinalDocument8 pagesGantry Grider Finalasvenk309No ratings yet

- FOOTING Excel SheetDocument2 pagesFOOTING Excel SheetPrantik Adhar Samanta100% (1)

- Perhitungan Shaft Pulley ConveyorDocument5 pagesPerhitungan Shaft Pulley ConveyorRiska DamayantiNo ratings yet

- Cutit CaneluraDocument3 pagesCutit CaneluraTurcanu ClaudiuNo ratings yet

- Burner CalculationDocument9 pagesBurner CalculationAbul QasimNo ratings yet

- Angrenaj MelcatDocument4 pagesAngrenaj MelcatDiana Maria CozmaNo ratings yet

- Drilling Machine CalculationDocument8 pagesDrilling Machine CalculationAakash SNo ratings yet

- CK Tourqe CalculationDocument7 pagesCK Tourqe Calculationamit amity100% (1)

- Design Sheet For 24F ADSS Cable-350 Metre SpanDocument2 pagesDesign Sheet For 24F ADSS Cable-350 Metre Spanlalitendu jenaNo ratings yet

- Clariflocculator: Description Unit Input Calculated Range Value Value 54000 Mim M 492 M MDocument6 pagesClariflocculator: Description Unit Input Calculated Range Value Value 54000 Mim M 492 M MAnonymous EKxXjqyVHNo ratings yet

- Separator S-101: Vessel Diameter and HeightDocument29 pagesSeparator S-101: Vessel Diameter and HeightAjeng FadillahNo ratings yet

- 4PB Pilecap DesignDocument2 pages4PB Pilecap DesignJONAS NGNo ratings yet

- 1) Basic Data: Design of Simply Supported Doubly-Reinforced Beam Using IS 456-2000Document3 pages1) Basic Data: Design of Simply Supported Doubly-Reinforced Beam Using IS 456-2000Khaja100% (1)

- Main Component For Two2Document3 pagesMain Component For Two2اسعد الماوريNo ratings yet

- SRB DesignDocument3 pagesSRB DesignRam LangheNo ratings yet

- Spur Gears Component GenDocument6 pagesSpur Gears Component GendexterisNo ratings yet

- Slab Design Excel FileDocument4 pagesSlab Design Excel FileSuman Resolved NeupaneNo ratings yet

- Beam Design SheetDocument10 pagesBeam Design SheetmudithaNo ratings yet

- RC Pile CapDocument6 pagesRC Pile CaptriNo ratings yet

- Design of Steel BeamDocument1 pageDesign of Steel Beamgaurav sharmaNo ratings yet

- Foundation Design - 5110-P-001ABC - Rev 0Document11 pagesFoundation Design - 5110-P-001ABC - Rev 0Yatendra TyagiNo ratings yet

- POT Design R0Document9 pagesPOT Design R0VB665No ratings yet

- Design and Calculation AgitationDocument18 pagesDesign and Calculation AgitationGLENDA CASINONo ratings yet

- Flange DesignDocument12 pagesFlange DesignSantoshNo ratings yet

- 23132-E1A-XL-M: Spherical Roller BearingDocument2 pages23132-E1A-XL-M: Spherical Roller BearingvivianaNo ratings yet

- DW 2560 EngDocument2 pagesDW 2560 EngWaldemar JęczewskiNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaSamir SabicNo ratings yet

- Combined Footing DesDocument7 pagesCombined Footing Desansar700No ratings yet

- Technical Data Sheet Machine: Ll30T L7 CNC LatheDocument4 pagesTechnical Data Sheet Machine: Ll30T L7 CNC LathearzonspacesNo ratings yet

- Excel AprosDocument13 pagesExcel Aprossarah hadisuryaNo ratings yet

- Proračun 4.brzinaDocument11 pagesProračun 4.brzinaJurmanNo ratings yet

- Base Plate DesignDocument14 pagesBase Plate Designsoumi bhattacharyaNo ratings yet

- Pile Cap Analysis & Design (Aci318-19 (22) ) in Accordance With ACI318-19Document7 pagesPile Cap Analysis & Design (Aci318-19 (22) ) in Accordance With ACI318-19kheang amgNo ratings yet

- Shear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationDocument4 pagesShear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationNitin SakpalNo ratings yet

- Base Plate Design Is 800 2007Document147 pagesBase Plate Design Is 800 2007pandian100% (1)

- Design of Steel Structure For SiloDocument30 pagesDesign of Steel Structure For SilosrinivasNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- ECU 100, GCU 100, Parameter List 4189340796 UK - 2013.07.01Document80 pagesECU 100, GCU 100, Parameter List 4189340796 UK - 2013.07.01Paulo VitorNo ratings yet

- GCU 100 Operators Manual 4189340800 UK - 2013.07.01Document15 pagesGCU 100 Operators Manual 4189340800 UK - 2013.07.01Paulo VitorNo ratings yet

- Twin Disc: Installation ManualDocument185 pagesTwin Disc: Installation ManualPaulo Vitor100% (1)

- Twin Disc: System Operation ManualDocument68 pagesTwin Disc: System Operation ManualPaulo VitorNo ratings yet

- Operator's Manual: Engine-Powered Articulated Lifts, 12 - 26 MDocument124 pagesOperator's Manual: Engine-Powered Articulated Lifts, 12 - 26 MPaulo VitorNo ratings yet

- AKSINDO (Mr. Ferlian), 11 - 13 Mar 2016 (NY)Document2 pagesAKSINDO (Mr. Ferlian), 11 - 13 Mar 2016 (NY)Sunarto HadiatmajaNo ratings yet

- One Tequila, Two Tequila, Three Tequila, Floor!: The Science Behind A HangoverDocument3 pagesOne Tequila, Two Tequila, Three Tequila, Floor!: The Science Behind A Hangoverkristal eliasNo ratings yet

- BMW I3 Wheel Airbag RemovalDocument6 pagesBMW I3 Wheel Airbag RemovalAjmaster.ltNo ratings yet

- RMK Akl 2 Bab 5Document2 pagesRMK Akl 2 Bab 5ElineNo ratings yet

- Bernard New PersDocument12 pagesBernard New PersChandra SekarNo ratings yet

- Song FlowDocument4 pagesSong FlowEhij ZheyNo ratings yet

- Hellinger, Bert - GenoGraph 2.1 ManualDocument16 pagesHellinger, Bert - GenoGraph 2.1 ManualGladys Achurra DíazNo ratings yet

- Understanding The School Curriculum Close Encounter With The School Curriculum SPARK Your InterestDocument12 pagesUnderstanding The School Curriculum Close Encounter With The School Curriculum SPARK Your InterestJoshua Lander Soquita CadayonaNo ratings yet

- Rhavif's ResumeDocument1 pageRhavif's ResumeRhavif BudiboyNo ratings yet

- Missions ETC 2020 SchemesOfWarDocument10 pagesMissions ETC 2020 SchemesOfWarDanieleBisignanoNo ratings yet

- Karbohidrat: Gula, Pati & SeratDocument20 pagesKarbohidrat: Gula, Pati & SeratAlfi Syahrin SiregarNo ratings yet

- The Manuals Com Cost Accounting by Matz and Usry 9th Edition Manual Ht4Document2 pagesThe Manuals Com Cost Accounting by Matz and Usry 9th Edition Manual Ht4shoaib shakilNo ratings yet

- Aci - The Financial Markets Association: Examination FormulaeDocument8 pagesAci - The Financial Markets Association: Examination FormulaeJovan SsenkandwaNo ratings yet

- C Programming Bit Bank U-1, U-2Document17 pagesC Programming Bit Bank U-1, U-2HariahNo ratings yet

- Intj MbtiDocument17 pagesIntj Mbti1985 productionNo ratings yet

- Parkin 8e TIF Ch27Document51 pagesParkin 8e TIF Ch27Pranta SahaNo ratings yet

- Week 1Document34 pagesWeek 1Mitchie Faustino100% (1)

- Guidelines On Setting Up A Newman Fellowship 2017-2018Document6 pagesGuidelines On Setting Up A Newman Fellowship 2017-2018Liz McFeelyNo ratings yet

- 12-List of U.C. Booked in NGZ Upto 31032017Document588 pages12-List of U.C. Booked in NGZ Upto 31032017avi67% (3)

- Digital Image Processing Unit-8Document4 pagesDigital Image Processing Unit-8Kpsteja TejaNo ratings yet

- Chapter 1: Introduction Aviation Industry: Mini Project On Vistara AirlinesDocument84 pagesChapter 1: Introduction Aviation Industry: Mini Project On Vistara Airlinesselvaraj rapakaNo ratings yet

- Rapid Prototyping and Rapid Tooling TheDocument24 pagesRapid Prototyping and Rapid Tooling TheGopinath GangadhariNo ratings yet

- Lingua Franca Core: The Outcome of The Current Times: Yue ShuDocument4 pagesLingua Franca Core: The Outcome of The Current Times: Yue ShuThaiNo ratings yet

- Registrable and Non-Registrable Adverse ClaimsDocument18 pagesRegistrable and Non-Registrable Adverse ClaimsJacob Castro100% (1)

- My Cook BookDocument66 pagesMy Cook BookAkshay KumariNo ratings yet

- Business Management Business ManagementDocument31 pagesBusiness Management Business ManagementDoyieNo ratings yet

- 3D Picture: The Acts of The Apostles: A Miraculous EscapeDocument6 pages3D Picture: The Acts of The Apostles: A Miraculous EscapeMyWonderStudio100% (7)

- Project Documentation - Sensorflex 30G Data SheetDocument15 pagesProject Documentation - Sensorflex 30G Data SheetOmar HectorNo ratings yet

- Brocade MIB ReferenceDocument1,212 pagesBrocade MIB ReferencejessiwattsNo ratings yet