Professional Documents

Culture Documents

Procedure For Problem Solving

Uploaded by

Ravindra shindeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure For Problem Solving

Uploaded by

Ravindra shindeCopyright:

Available Formats

Document No: QMS/PR-11

Anusaya Auto Press Parts Pvt. Ltd.

Effective Date: 01.06.2017

Revision No: 01

Procedure for Problem Solving

Revision Date: 16.10.2017

1 PURPOSE : This process ensures that Problem Solving methods are defined to initiate systematic

actions to prevent Non-conformity recurrence

2 SCOPE :-Applicable to all Non-conformity/Problems.

3 PROCESS :

S.No. Activity Responsibility Document/Record

Problem Solving Method :

On detection of various types & scale of problems (New 8D - Problem Resolution

Report , FM / QA / 16,

product development, current manufacturing issues, field Rev No.,Date : 01,

failure, audit findings, in-house rejections, customer rejection CFT Leader 01.06.2017

1.

& any other non-conformity) the Respective Dept. Head

decides containment, interim actions, and related activities

necessary for control of nonconforming outputs.

.

Respective Dept. Head investigates the root cause(s).

Root cause is identified with the help of Why – Why analysis, 8D - Problem Resolution

Report , FM / QA / 16,

2. Brainstorming, Cause& Effect diagram, Lessons learned. CFT Leader

Rev No.,Date : 01,

The investigation normally looks in to resources and process 01.06.2017

and the documented process if applicable.

3. Once the root cause identified, take the action on it to prevent CFT Leader 8D - Problem Resolution

the re-occurrence of then on conformity. After taking the Report , FM / QA / 16,

action, monitor the effectiveness of corrective action. Do the Rev No.,Date : 01,

horizontal deployment in the similar process & product 01.06.2017

(Corrective action impact )

4. The DH takes necessary action to rectify any inadequacy or CFT Leader 8D - Problem Resolution

inappropriate provision for the process, including better Report , FM / QA / 16,

supervision, verification of effectiveness. And to ensure that Rev No.,Date : 01,

the documented process if any, is strictly followed 01.06.2017

5. The corrective action may identify needs for training, up- CFT Leader 8D - Problem Resolution

dation of procedures and work instructions, control plan, Report , FM / QA / 16,

Rev No.,Date : 01,

FMEA wherever applicable. 01.06.2017

6. A record of non-conformities is maintained and the corrective QA Engineer Format

No.:CUSTOMER

action taken in Customer complaint Register. COMPLAINT

REGISTER, FM / QA /

23, Rev No., Date : 01,

01.06.2017

Approved By: Approved By:

Process Owner / DH MR

Document No: QMS/PR-11

Anusaya Auto Press Parts Pvt. Ltd.

Effective Date: 01.06.2017

Revision No: 01

Procedure for Problem Solving

Revision Date: 16.10.2017

7. A record of non-conformities for Internal-Inprocess rejection Production WEEKLY

Engineer MANUFACTURING

is maintained and the corrective action recorded in inhouse NON CONFORMANCE

complaint register. REPORT, FM / PRD /

27, Rev No., Date : 00,

01.06.2017

8. Nonconformity of QMS is identified in process of Internal MR

system Audit and how to take related corrective actions are Audit Noncompliance

explained in the same procedure. Report NCR, FM/

MR / 06 / 01

9. MR ensures that all-important Corrective actions are MR

discussed in the Management Review Meeting and Management Review

appropriate actions taken as decided upon in the Management Meeting, FM / MR /

Review. 08, Rev No. Date : 01,

01.06.2017

10. If the customer has prescribed the specific processes, tools or HOD Quality

systems, for problem solving, AAPPPL uses it, otherwise take 8D - Problem Resolution

Report , FM / QA / 16,

approval from the customer for any other method. Rev No.,Date : 01,

AAPPPL has identified such customer specific requirement in 01.06.2017

CSR matrix.

5.0 Process Measurement

Sr.

Measurement Type Measurement Indicator Target & UOM Monitoring Frequency

No.

Corrective action completed

1 Effectiveness 100%. Monthly

on time

Repeated NC for same root

2 Efficiency Zero NC Monthly

cause

Revision History

Sr. Revised Revised

Revised Contents Cause of contents

No. Date Article

Approved By: Approved By:

Process Owner / DH MR

Document No: QMS/PR-11

Anusaya Auto Press Parts Pvt. Ltd.

Effective Date: 01.06.2017

Revision No: 01

Procedure for Problem Solving

Revision Date: 16.10.2017

Approved By: Approved By:

Process Owner / DH MR

You might also like

- 3 3bb0aDocument7 pages3 3bb0aEleandro JoaquimNo ratings yet

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument36 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Painting RecordDocument1 pagePainting RecordHimawan SetyarsoNo ratings yet

- 8.fixture Inspection ReportDocument1 page8.fixture Inspection ReportBASAVA ENGINEERINGNo ratings yet

- SMCPGL Ims MRM - 2022Document37 pagesSMCPGL Ims MRM - 2022Smc PowerNo ratings yet

- Document NumberingDocument8 pagesDocument NumberingRaja RehaNo ratings yet

- Supplier Assessment (F - 003 - QF-SQ-COM - 002 Rev. 02) .Document50 pagesSupplier Assessment (F - 003 - QF-SQ-COM - 002 Rev. 02) .muthuselvanNo ratings yet

- OCP of HR Process-03Document2 pagesOCP of HR Process-03sathyabalaramanNo ratings yet

- Pallava Granite Industries (India) PVT - LTD Manubolu Maintenance Prevetive Maintenance PlanDocument13 pagesPallava Granite Industries (India) PVT - LTD Manubolu Maintenance Prevetive Maintenance Planp kishorNo ratings yet

- Final Inspection - Tata Ace DiscDocument3 pagesFinal Inspection - Tata Ace DiscazadNo ratings yet

- 17.work Instruction For CNC-CLGDocument1 page17.work Instruction For CNC-CLGSAKTHIVEL ANo ratings yet

- Audit ComplianceDocument1 pageAudit ComplianceNitin SharmaNo ratings yet

- Control of Non-Conforming ProductsDocument10 pagesControl of Non-Conforming ProductsSachin KumbharNo ratings yet

- Standard Operating Procedures: Enquiry, Pricing & Payment Terms FinalizationDocument5 pagesStandard Operating Procedures: Enquiry, Pricing & Payment Terms FinalizationIan YongNo ratings yet

- Management Review Programme (Insert Year) : ISO 9001:2015 QMSDocument2 pagesManagement Review Programme (Insert Year) : ISO 9001:2015 QMSFrench Sarah NeraNo ratings yet

- Manufacturing Process Audit: RatingDocument3 pagesManufacturing Process Audit: Ratingrajesh.bNo ratings yet

- Process Validation Record: Format No.: - DateDocument2 pagesProcess Validation Record: Format No.: - DateRaja DuraiNo ratings yet

- TGR TGW SheetDocument3 pagesTGR TGW Sheetsumit_saraf_5No ratings yet

- Day 1Document3 pagesDay 1Sandeep kulkarniNo ratings yet

- FIR-garments PDFDocument4 pagesFIR-garments PDFTarun PariharNo ratings yet

- F-QC-05 Deviation NoteDocument1 pageF-QC-05 Deviation NoteKaran MalhiNo ratings yet

- Statistical Process Control For Attribute Data (SPC)Document45 pagesStatistical Process Control For Attribute Data (SPC)RajanishshettyNo ratings yet

- WI-R&D-33 - Field Validation of ClutchDocument3 pagesWI-R&D-33 - Field Validation of ClutchDisha ShahNo ratings yet

- Supplier APQP TrainingDocument32 pagesSupplier APQP TrainingvivekNo ratings yet

- KAIZEN IDEA - TemplateDocument3 pagesKAIZEN IDEA - TemplateKranthi Kumar100% (1)

- 4M Change Management Matrix-Rane NSK-signedDocument1 page4M Change Management Matrix-Rane NSK-signednitin rathoreNo ratings yet

- VSA Audit Preparation Plan: Legends Activity Planned Activity Done Activity PendingDocument1 pageVSA Audit Preparation Plan: Legends Activity Planned Activity Done Activity PendingrakeshNo ratings yet

- DS-04-01 R0 Competency Requirements of Internal AuditorsDocument2 pagesDS-04-01 R0 Competency Requirements of Internal AuditorsDhinakaranNo ratings yet

- 5s Zone Wise LeaderDocument36 pages5s Zone Wise LeadershalinmishraNo ratings yet

- JBM Group 12 Pillar Internal Auditor Exam 2022-23Document30 pagesJBM Group 12 Pillar Internal Auditor Exam 2022-23Ravi javaliNo ratings yet

- Bureau Veritas India (Iatf 16949) (Page 3 of 6) OptionalDocument9 pagesBureau Veritas India (Iatf 16949) (Page 3 of 6) Optionalashish mehtaNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- 23.sop - HRDDocument4 pages23.sop - HRDrishi gautamNo ratings yet

- PDF Process Audit Vda 63Document9 pagesPDF Process Audit Vda 63Shahrazed ZineNo ratings yet

- Daily Instrument Check SheetDocument8 pagesDaily Instrument Check SheetRaju RaiNo ratings yet

- QAD Procedure - Lab Management P2Document1 pageQAD Procedure - Lab Management P2sumanNo ratings yet

- Bgl-Fm-Qa - Red Bin Analysis RuleDocument1 pageBgl-Fm-Qa - Red Bin Analysis RuleMohit SinghNo ratings yet

- Heat Treatment - Furnace TreatmentDocument19 pagesHeat Treatment - Furnace Treatmentkumar QANo ratings yet

- Furnace Validation Report-2021Document1 pageFurnace Validation Report-2021Harjeet SinghNo ratings yet

- Anicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateDocument9 pagesAnicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateAnicon Flowcontols llpNo ratings yet

- Coherence PlanDocument2 pagesCoherence PlanAman JasujaNo ratings yet

- Iatf-Qm-08 - Operation 8.5.1.1Document22 pagesIatf-Qm-08 - Operation 8.5.1.1SATISH HALGEKARNo ratings yet

- Punch Ratna Fasteners PVT LTD, Chennai - 5S Audit Plan For 2019 - 20Document1 pagePunch Ratna Fasteners PVT LTD, Chennai - 5S Audit Plan For 2019 - 20R KumarNo ratings yet

- Qav Observation Closer Sheet FormatDocument1 pageQav Observation Closer Sheet FormatDEVENDERNo ratings yet

- Meenakshi Polymers PVT LTD.: Rework Inspection ReportDocument1 pageMeenakshi Polymers PVT LTD.: Rework Inspection ReportKaran MalhiNo ratings yet

- Excel Template Machine Wise Production Capacity v.2Document9 pagesExcel Template Machine Wise Production Capacity v.2pankaj66668100% (1)

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- 7.2.3 A List of Internal Auditors QMSDocument2 pages7.2.3 A List of Internal Auditors QMSPrakash kumarTripathiNo ratings yet

- NC Analysis Report 3L5Y-Blank FormatDocument160 pagesNC Analysis Report 3L5Y-Blank Formatshobha shelarNo ratings yet

- C8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnDocument1 pageC8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnBAlaNo ratings yet

- Production Validation TemplateDocument1 pageProduction Validation TemplatesathyabalaramanNo ratings yet

- Packaging Details: Vendor Name & AddressDocument4 pagesPackaging Details: Vendor Name & AddressPk NimiwalNo ratings yet

- Department Quality & FS Objective (Revision2015) - SampleDocument1 pageDepartment Quality & FS Objective (Revision2015) - SampleRachel YapNo ratings yet

- Format No - Qf-As-02 - Daily Production Log BookDocument2 pagesFormat No - Qf-As-02 - Daily Production Log BookDisha ShahNo ratings yet

- Audit Evidence Evaluation Comments: Internal Audit Check List Mr/Cip/Training/Customer ComplaintsDocument3 pagesAudit Evidence Evaluation Comments: Internal Audit Check List Mr/Cip/Training/Customer ComplaintsganrashNo ratings yet

- P018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Document9 pagesP018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Álvaro Martínez Fernández100% (1)

- In-House Calibration SheetDocument4 pagesIn-House Calibration SheetKannan MurugesanNo ratings yet

- Test Paper: Name: DateDocument2 pagesTest Paper: Name: DateDhinakaranNo ratings yet

- Roles & Responsibilities: Ref.: QAD-Annex-3 Page: 1 of 18 Rev.: 0 Date: 15.07.2017Document18 pagesRoles & Responsibilities: Ref.: QAD-Annex-3 Page: 1 of 18 Rev.: 0 Date: 15.07.2017DhinakaranNo ratings yet

- QMP-06 - Preventive ActionDocument5 pagesQMP-06 - Preventive Actionom cnc100% (1)

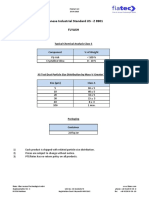

- Japanese Industrial Standard JIS - Z 8901 Flyash: Typical Chemical Analysis Class 5Document1 pageJapanese Industrial Standard JIS - Z 8901 Flyash: Typical Chemical Analysis Class 5Ravindra shindeNo ratings yet

- Inventory Management PDFDocument73 pagesInventory Management PDFJeampierr JIMENEZ MARQUEZNo ratings yet

- CSSGB Insert HirenDocument12 pagesCSSGB Insert Hirenhirjosh15No ratings yet

- NDT Audit Check ListDocument7 pagesNDT Audit Check ListShrikant Utekar50% (6)

- Product Costs TemplateDocument2 pagesProduct Costs TemplateFrank MtetwaNo ratings yet

- 06 VP PowderDocument70 pages06 VP PowderUrban Renewal DevelopmentNo ratings yet

- BS VI Fuel Spec Working Paper VFDocument4 pagesBS VI Fuel Spec Working Paper VFYajuvendra JhalaNo ratings yet

- Ceramic Fiber Product: CatalogDocument11 pagesCeramic Fiber Product: CatalogRavindra shindeNo ratings yet

- Body Temperature PDFDocument56 pagesBody Temperature PDFBanupriya-No ratings yet

- Astm A513 PDFDocument20 pagesAstm A513 PDFpradelles89% (9)

- En1a PDFDocument1 pageEn1a PDFRavindra ErabattiNo ratings yet

- Content Sheet 3-1: Equipment Management Overview: Role in Quality Management SystemDocument13 pagesContent Sheet 3-1: Equipment Management Overview: Role in Quality Management SystemmhafizanNo ratings yet

- Annexure - 3 Net Metering Connection Agreement (On Rs.200/-Stamp Paper)Document4 pagesAnnexure - 3 Net Metering Connection Agreement (On Rs.200/-Stamp Paper)Mahendi PatilNo ratings yet

- An Lab Qual StatementDocument1 pageAn Lab Qual StatementAbhijit ParmarNo ratings yet

- Nabl 151Document12 pagesNabl 151Satavisa BhattacharjeeNo ratings yet

- Control Systems EngineeringDocument19 pagesControl Systems EngineeringAhmad RazaNo ratings yet

- ISO 9001 2008 Audit ChecklistDocument20 pagesISO 9001 2008 Audit ChecklistTorres EnriqueNo ratings yet

- MIS Basics and MIS Other Academic DisciplinesDocument26 pagesMIS Basics and MIS Other Academic DisciplinesSarikaSaxena100% (1)

- Prelim ProgramDocument18 pagesPrelim ProgramCao Chen-RuiNo ratings yet

- Lean and Jit Systems: Originated From: Operations Management, 8 Edition, William J Stevenson Mcgraw-HillDocument33 pagesLean and Jit Systems: Originated From: Operations Management, 8 Edition, William J Stevenson Mcgraw-HillMuhammad HarizNo ratings yet

- A Frequency Domain Method For Tuning Hydro GovernorsDocument4 pagesA Frequency Domain Method For Tuning Hydro GovernorsadinamartinsNo ratings yet

- Chapter 3Document39 pagesChapter 3Soe Thi Ha AungNo ratings yet

- Deep Learning Based Eye Gaze Tracking For Automotive Applications An Auto-Keras ApproachDocument4 pagesDeep Learning Based Eye Gaze Tracking For Automotive Applications An Auto-Keras ApproachVibhor ChaubeyNo ratings yet

- FMSE Lecture 1Document35 pagesFMSE Lecture 1Muhammad BilalNo ratings yet

- Project Proposal PI ControllerDocument10 pagesProject Proposal PI ControllerMuhammad ArsalNo ratings yet

- Software Engineering 1 Prelim ExamDocument31 pagesSoftware Engineering 1 Prelim ExamAlec BrentNo ratings yet

- Control Approaches For Magnetic LevitationDocument11 pagesControl Approaches For Magnetic Levitationambachew bizunehNo ratings yet

- ML Lec 2Document33 pagesML Lec 2Areej EhsanNo ratings yet

- Robust Control of Active Vehicle Suspension Systems Using Sliding Modes and Differential Flatness With MATLABDocument18 pagesRobust Control of Active Vehicle Suspension Systems Using Sliding Modes and Differential Flatness With MATLABAVALDERNo ratings yet

- Country Ranking Olevel 2023Document279 pagesCountry Ranking Olevel 2023musokerogers291No ratings yet

- Comparison of Pid and MPC Controllers For Continuous Stirred Tank Reactor (CSTR) Concentration ControlDocument9 pagesComparison of Pid and MPC Controllers For Continuous Stirred Tank Reactor (CSTR) Concentration ControlLuis ZapataNo ratings yet

- Lecture 17 - Hyperplane Classifiers - SVM - PlainDocument16 pagesLecture 17 - Hyperplane Classifiers - SVM - PlainRajachandra VoodigaNo ratings yet

- MAE - 476 - Mech Control Systems IDocument2 pagesMAE - 476 - Mech Control Systems ITyler GriesingerNo ratings yet

- QB SoftDocument10 pagesQB Softjoydeep12No ratings yet

- MSAI 04 - JidokaDocument44 pagesMSAI 04 - JidokaUlriksenNo ratings yet

- Machine Learning PPT For StudentsDocument18 pagesMachine Learning PPT For Studentsrajesh67% (3)

- Digital Control System Analysis and Design 4th Edition Phillips Solutions ManualDocument9 pagesDigital Control System Analysis and Design 4th Edition Phillips Solutions ManualDouglasColeybed100% (28)

- Lecture Notes Set 1 - Introduction To Mechatronics System DesignDocument16 pagesLecture Notes Set 1 - Introduction To Mechatronics System DesignMark AzzopardiNo ratings yet

- Aiops Done Right BankingDocument20 pagesAiops Done Right Bankingkeertan zalaNo ratings yet

- IIMKA OSCM B4f8edda51Document21 pagesIIMKA OSCM B4f8edda51અનુરુપ સોનીNo ratings yet

- Process Control QuestionsDocument15 pagesProcess Control QuestionsSatyamGuptaNo ratings yet

- Adapting UML For An Object Oriented SystemsDocument8 pagesAdapting UML For An Object Oriented SystemsjenyrennyNo ratings yet

- Chap 12 Marlin 2013Document45 pagesChap 12 Marlin 2013AnisaNo ratings yet

- Arne Schuldt - Multiagent Coordination Enabling Autonomous LogisticsDocument284 pagesArne Schuldt - Multiagent Coordination Enabling Autonomous LogisticsLeandru5No ratings yet

- Software Development Life Cycle (SDLC) : Waterfall ModelDocument2 pagesSoftware Development Life Cycle (SDLC) : Waterfall ModelmohanNo ratings yet