Professional Documents

Culture Documents

Meghmani Industries Limited Quality Control Laboratory, Unit-2

Uploaded by

Himali LimbasiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Meghmani Industries Limited Quality Control Laboratory, Unit-2

Uploaded by

Himali LimbasiaCopyright:

Available Formats

Meghmani Industries Limited

Quality Control Laboratory, Unit-2

Plot No. 27, Phase–1, GIDC Industrial Estate, Vatva, Ahmedabad,

Pin–382 445, Gujarat, India Tel. No. +91–81550 02071, Fax No. +91–79–2589 3495

E Mail qc@mil2.meghmanidyes.com, Web www.meghmanidyes.com

01-09-

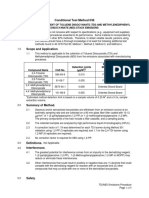

Doc. No. W/OPN/70 ANALYSIS METHOD FOR Date of Issue

2016

Issue No. 01 METOLACHLOR TECHNICAL Page No. 1 of 2

A-1 Purpose

Metolachlor content determined by gas chromatography (GC) method.

.

A-2 Scope

These work instructions apply for determination of Metolachlor content in the Metolachlor

Technical.

A-3 Responsibility

Technical Manager /QC-officer / QC-Chemist.

A-4 Principle

Metolachlor is dissolved in Acetone along with internal standard and determined by gas liquid

chromatograph equipped with flame ionization detector (FID).

A-5 Apparatus

A-5.1 Gas Liquid Chromatograph (GLC)

Equipped with a FID and a printer-plotter cum- integrator. The suggested operating

parameters are given below which may be varied provide standardization is done:

Column – Glass packed 1.83m X 2(I.D) mm Packed with 3% OV-101 on

Gas Chrom Q (80 – 100 mesh) Condition at 240°C for at least 24 h

Using carrier gas at about 20 ml/min

.

Temperature Condition–

Column oven - 180°C

Injection port - 250°C

Detector - 250°C

Gas Flow-Carrier gas (Nitrogen) - 25 ml/minute

Hydrogen - 30 ml/ minute

Air -300 ml/minute

A-5.2 Volumetric Flask - 50-ml capacity.

A-5.3 Micro Syringe - 2 µL

A-6 Reagents

A-6.1 Acetone- AR grade.

A-6.2 Metolachlor Reference Standard-of known purity.

A-6.3 Internal Standard-Di pentyl pthalate, AR grade.

A-7 Procedure

A-7.1 Preparation of Internal Standard Solution

Weigh about 4 gm of Dipentyl pthalate into a 1000-ml volumetric flask and make up the

volume to the mark with Acetone.

Prepared By Approved & Issued By

Technical Manager Quality Manager

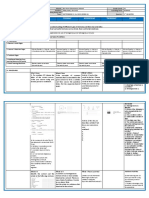

Meghmani Industries Limited

Quality Control Laboratory, Unit-2

Plot No. 27, Phase–1, GIDC Industrial Estate, Vatva, Ahmedabad,

Pin–382 445, Gujarat, India Tel. No. +91–81550 02071, Fax No. +91–79–2589 3495

E Mail qc@mil2.meghmanidyes.com, Web www.meghmanidyes.com

01-09-

Doc. No. W/OPN/70 ANALYSIS METHOD FOR Date of Issue

2016

Issue No. 01 METOLACHLOR TECHNICAL Page No. 2 of 2

A-7.2 Preparation of Reference Standard Solution

Weigh 0.20 gm of the reference standard Metolachlor into a 50-ml volumetric flask and

add 50 ml of the internal standard solution (see A-7.1). and shake well for 10 Min.

A-7.3 Preparation of Sample Solution

Weigh a quantity of sample so as to contain0.20 gm of the reference standard Metolachlor

into a 50-ml volumetric flask and add 50 ml of the internal standard solution(see A-7.1). and

shake well for 10 Min.

A-8 Estimation

Inject 2 µl of the reference standard solution into the gas chromatograph followed by the

sample solution with the help of syringe and measure the peak areas of standard and

Sample solutions. Compute the percentage of Metolachlor in sample.

A-9 Calculation

M 1× A 1 × A 3

Metolachlor content, percent by mass = ×P

M 2× A2× A4

Where,

M1=mass in g of reference standard Metolachlor,

A1= peak area of internal standard in the standard solution,

A3= peak area of Metolachlor in the sample solution,

M2= mass in gm of sample taken for the test,

A2= peak area of Metolachlor in the standard solution,

A4= peak area of internal sample solution, and

P= percent purity of Metolachlor reference standard.

Reference : CIPAC D 400/TC/M

Prepared By Approved & Issued By

Technical Manager Quality Manager

You might also like

- DMA-80 Tips and Techniques - DMA 8204Document20 pagesDMA-80 Tips and Techniques - DMA 8204Yeisson MoraNo ratings yet

- Boldenone UndDocument2 pagesBoldenone UndAhmedNo ratings yet

- DMA-80 Tips and TechniquesDocument15 pagesDMA-80 Tips and TechniquesJuan CarlosNo ratings yet

- Ap-M8000-010 SRM 2782 Epa 245 5 Cvafs-SgtaDocument4 pagesAp-M8000-010 SRM 2782 Epa 245 5 Cvafs-Sgtaeddie mendozaNo ratings yet

- Certiicate of Analysis: Certiied Reference MaterialDocument2 pagesCertiicate of Analysis: Certiied Reference MaterialAris RahmanNo ratings yet

- 1.open Part DMF of Omeprazole For Themis With Mass, NMRDocument78 pages1.open Part DMF of Omeprazole For Themis With Mass, NMRVishnu Vardhan A100% (2)

- Cement Flame Photometry Issue 5Document16 pagesCement Flame Photometry Issue 5Mansueta StefanusNo ratings yet

- IMPCA MethanolDocument13 pagesIMPCA MethanolHito Jimenez SalinasNo ratings yet

- Aas PQ Protocol For ZincsulphateDocument7 pagesAas PQ Protocol For Zincsulphateshaik janiNo ratings yet

- Technical SpecificationDocument6 pagesTechnical SpecificationAyse ClkNo ratings yet

- STD-INSP-0123 IGC Practice - A - (ASTM G28)Document7 pagesSTD-INSP-0123 IGC Practice - A - (ASTM G28)Akshay KalraNo ratings yet

- Sn-Qc-Sapp-015 Xegtin 20MG Caps.Document5 pagesSn-Qc-Sapp-015 Xegtin 20MG Caps.daizhussain004No ratings yet

- An1804 Crude Oil Astm d5708-d1548 Prodigyplus Icp OesDocument4 pagesAn1804 Crude Oil Astm d5708-d1548 Prodigyplus Icp OesyuliaNo ratings yet

- Lrac3125Document2 pagesLrac3125egpharma1No ratings yet

- D 2804 - 98 - Rdi4mdqtukveDocument5 pagesD 2804 - 98 - Rdi4mdqtukveRaphael CordovaNo ratings yet

- Title Determine The Inclusion Content of Steel Level 5 Credits 10Document3 pagesTitle Determine The Inclusion Content of Steel Level 5 Credits 10Anket DeshmukhNo ratings yet

- CoA P873870Document3 pagesCoA P873870madalin danilNo ratings yet

- 8.cezaf 250mg Injection Im IVDocument3 pages8.cezaf 250mg Injection Im IVSehrish AslamNo ratings yet

- Microcoulomb AnalyzerDocument4 pagesMicrocoulomb Analyzersaurabh_acmasNo ratings yet

- Reactor and Catalyst DesignDocument19 pagesReactor and Catalyst Designbakhtyar21100% (1)

- Determination of Aldehyde and Ketone Emissions From Interior MaterialsDocument10 pagesDetermination of Aldehyde and Ketone Emissions From Interior MaterialsJefferson CruzNo ratings yet

- Reference Material CertificateDocument2 pagesReference Material CertificateAGATHA RIA BUDIYANANo ratings yet

- Afla B2 - TAS-M12LA1-10 220225-22187Document2 pagesAfla B2 - TAS-M12LA1-10 220225-22187Irowati PurwaningsihNo ratings yet

- Stack Emission Analysis: Lafargeholcim Bangladesh Ltd. (LHBL)Document12 pagesStack Emission Analysis: Lafargeholcim Bangladesh Ltd. (LHBL)Adroit ConsultantNo ratings yet

- TCVN 6882-2001 PH Gia Khoáng Cho Xi MăngDocument9 pagesTCVN 6882-2001 PH Gia Khoáng Cho Xi MăngNam HuynhNo ratings yet

- DR Astuti - Strategy of Hospital Clinical Laboratory Examination Fulfillment With Quality, Time and Cost EfficiencyDocument23 pagesDR Astuti - Strategy of Hospital Clinical Laboratory Examination Fulfillment With Quality, Time and Cost EfficiencyTaufan LutfiNo ratings yet

- D 5845 Method For Determination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and Tert-Butanol in Gasoline by Infrared SpectrosDocument9 pagesD 5845 Method For Determination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and Tert-Butanol in Gasoline by Infrared SpectrosMarlon AgustínNo ratings yet

- Sn-Qc-Sapp-001 Fitcid 30MG Caps.Document7 pagesSn-Qc-Sapp-001 Fitcid 30MG Caps.daizhussain004No ratings yet

- CE Test ReportDocument14 pagesCE Test ReportCamilo WispNo ratings yet

- Material and Equipment Standard: IPS-M-TP-672Document7 pagesMaterial and Equipment Standard: IPS-M-TP-672RezaNo ratings yet

- E-Cigarette Aerosol Analysis ReportDocument6 pagesE-Cigarette Aerosol Analysis ReportUman KinapNo ratings yet

- Solder Heat Resistance TestDocument3 pagesSolder Heat Resistance TestGopinathan BalakrishnanNo ratings yet

- A2V2D6 - Condition 17 - Field Joining Program - Appendix B4 - Magnetic Part PDFDocument11 pagesA2V2D6 - Condition 17 - Field Joining Program - Appendix B4 - Magnetic Part PDFaditya rahmanNo ratings yet

- Uop303 97Document7 pagesUop303 97Anix DiazNo ratings yet

- GMW14872 March 2013Document27 pagesGMW14872 March 2013Joao Pedro Rendeiro Correia de SousaNo ratings yet

- Reference Material Certificate I S O 1 7 0 3 4Document2 pagesReference Material Certificate I S O 1 7 0 3 4ROBINNo ratings yet

- A Study On Elimination of Defects For Enhancement of Cost-Effectiveness in Wire Rod Mills in Indian ScenarioDocument8 pagesA Study On Elimination of Defects For Enhancement of Cost-Effectiveness in Wire Rod Mills in Indian ScenarioSmruti Ranjan PattanayakNo ratings yet

- GBH Enterprises, LTD.: GBHE-PEG-RXT-806Document7 pagesGBH Enterprises, LTD.: GBHE-PEG-RXT-806Sankar SasmalNo ratings yet

- Process Performance Qualification Protocol For Autoclave - Pharmaceutical Guidelines 2Document12 pagesProcess Performance Qualification Protocol For Autoclave - Pharmaceutical Guidelines 2MykolaNo ratings yet

- Method 7c 1Document14 pagesMethod 7c 1operaciones2.labsolutionNo ratings yet

- UOP971Document8 pagesUOP971Do Duc ThanhNo ratings yet

- QC - 08 PTCDocument5 pagesQC - 08 PTCmahendraNo ratings yet

- AA37N-5. Estándar Niquel. 29-12-2025Document2 pagesAA37N-5. Estándar Niquel. 29-12-2025calidadlaboratoriocgrNo ratings yet

- Con2-25 R2-Cond696405 McaDocument3 pagesCon2-25 R2-Cond696405 McaclaudioNo ratings yet

- D 5008 - 97 - RduwmdgtukveDocument5 pagesD 5008 - 97 - RduwmdgtukveHHans MSilvaNo ratings yet

- Application of Nano Material Based Hybrid Pour Point Depressant For Long Distance Waxy Crude PipelineDocument8 pagesApplication of Nano Material Based Hybrid Pour Point Depressant For Long Distance Waxy Crude PipelineMarcelo Varejão CasarinNo ratings yet

- IS 2062 E250A 25mm PlateDocument3 pagesIS 2062 E250A 25mm PlateKandula RajuNo ratings yet

- Stability Data For Amitraz, 98%Document6 pagesStability Data For Amitraz, 98%Ronald NyamurowaNo ratings yet

- Microlab: M/s. Microtech Precision EngineeringDocument2 pagesMicrolab: M/s. Microtech Precision EngineeringSHYAMNo ratings yet

- CTM 036 TDI EmisionesDocument8 pagesCTM 036 TDI EmisionesNicolas ZeballosNo ratings yet

- Analysis of Shrinkage Defect IDocument11 pagesAnalysis of Shrinkage Defect IYoseph Anggit Yanno PutraNo ratings yet

- Analysis Method of Cypermethrin TechnicalDocument5 pagesAnalysis Method of Cypermethrin TechnicalDaniel Martins PortoNo ratings yet

- SN-QC-SAPP-029 Neamin 500mcg TabletDocument4 pagesSN-QC-SAPP-029 Neamin 500mcg Tabletdaizhussain004No ratings yet

- Irjet V4i877Document6 pagesIrjet V4i877Roselle LasagasNo ratings yet

- D 329 - 99 - Rdmyos1sruq - PDFDocument3 pagesD 329 - 99 - Rdmyos1sruq - PDFgravity castNo ratings yet

- Coulometric Sulfur AnalyzerDocument4 pagesCoulometric Sulfur Analyzersaurabh_acmasNo ratings yet

- Silicate (Silicic Acid) Test: SpectroquantDocument1 pageSilicate (Silicic Acid) Test: SpectroquantmuryaspNo ratings yet

- Group 4 - EH2206M - A2Document50 pagesGroup 4 - EH2206M - A2NNNo ratings yet

- Astm D95Document6 pagesAstm D95time4521No ratings yet

- Pharma Manual PDFDocument24 pagesPharma Manual PDFLawrence Agada86% (7)

- PDMS Thickness VS Spin SpeedDocument2 pagesPDMS Thickness VS Spin SpeedGopal Chandra PalNo ratings yet

- TEST 02 September 2ndDocument10 pagesTEST 02 September 2ndNayyir Mumtasir Rahman 2323059047No ratings yet

- Hcu Chemistry 2018 PDFDocument9 pagesHcu Chemistry 2018 PDFSatyajit biswasNo ratings yet

- Melc-Based Science DLL Quarter 1 Week 4Document4 pagesMelc-Based Science DLL Quarter 1 Week 4Czarina DalunagNo ratings yet

- TDS - LD 2023 CC PDFDocument1 pageTDS - LD 2023 CC PDFYasir SiddiquiNo ratings yet

- Analysis of ToothpasteDocument29 pagesAnalysis of Toothpasteanushka chadha100% (1)

- Chemistry Practical Class 12 InstructionsDocument7 pagesChemistry Practical Class 12 InstructionsCR7STUDIO 7No ratings yet

- Chemical Reactions: Amedeo Avogadro 1776-1856Document38 pagesChemical Reactions: Amedeo Avogadro 1776-1856ade dosmaria100% (1)

- EEC4Document127 pagesEEC4iammextNo ratings yet

- Coating Thickness Gauge: TipsDocument1 pageCoating Thickness Gauge: TipsJhon Alexis Cardona HerreraNo ratings yet

- Enzyme and Enzyme Kinetics - 202204261936Document9 pagesEnzyme and Enzyme Kinetics - 202204261936Ej AgsaldaNo ratings yet

- Diagnostic Test All Subjects - Docx Version 1Document22 pagesDiagnostic Test All Subjects - Docx Version 1Junelle Joy CatbaganNo ratings yet

- Required Practical 7 Exam Questions and MSDocument10 pagesRequired Practical 7 Exam Questions and MSMaliha RiazNo ratings yet

- Himachal Pradesh University SHIMLA - 171005Document39 pagesHimachal Pradesh University SHIMLA - 171005Sahil KumarNo ratings yet

- Edexcel International GCSE Chemistry Workbook Robert WensleyDocument97 pagesEdexcel International GCSE Chemistry Workbook Robert WensleyMochiro ZzZ100% (1)

- Free Radical Substitution Questions: Ex. Methane + ChlorineDocument2 pagesFree Radical Substitution Questions: Ex. Methane + ChlorineVimal AathithanNo ratings yet

- Drainage Time of PulpDocument13 pagesDrainage Time of PulpAndrei MurillonNo ratings yet

- Hydrate Phase Equilibrium Data of Mixed Methane-Tetrahydrofuran Hydrates in Saline WaterDocument7 pagesHydrate Phase Equilibrium Data of Mixed Methane-Tetrahydrofuran Hydrates in Saline Water4 AMNo ratings yet

- Amonium Sulfate Improve DetectionDocument6 pagesAmonium Sulfate Improve DetectionNguyen NghiNo ratings yet

- TD3 DIESEL API 650 Calculation ReportDocument72 pagesTD3 DIESEL API 650 Calculation ReportDaniel Gómez100% (3)

- Hands-On ManagementDocument3 pagesHands-On ManagementKeily VilcarromeroNo ratings yet

- Surface Observation FormDocument4 pagesSurface Observation Formhadprince2023No ratings yet

- Errata of Jee Main Question Bank: Subject: ChemistryDocument2 pagesErrata of Jee Main Question Bank: Subject: ChemistryMmonster GirirajNo ratings yet

- Dat Examinee GuideDocument23 pagesDat Examinee Guidekjk khkNo ratings yet

- Topic 07 StereochemistryDocument52 pagesTopic 07 StereochemistryJhunessa Mae JalagatNo ratings yet

- University of Zambia School of Natural Sciences Chemistry Department Tutorial Sheet 6 2021/2022Document2 pagesUniversity of Zambia School of Natural Sciences Chemistry Department Tutorial Sheet 6 2021/2022SAVIOUR BANDANo ratings yet

- Rate of ReactionDocument16 pagesRate of ReactionRohmatul FaizahNo ratings yet

- Instrutech®: Rohs Compliance StatementDocument3 pagesInstrutech®: Rohs Compliance StatementsolNo ratings yet

- Introduction: Matter and Measurement: - Chemistry Is The Study of Matter, Its PropertiesDocument21 pagesIntroduction: Matter and Measurement: - Chemistry Is The Study of Matter, Its PropertiesRitney Jean AgpalasinNo ratings yet