Professional Documents

Culture Documents

AGR75515711 Process Time Analysis and Optimization

Uploaded by

Sameer SaxenaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AGR75515711 Process Time Analysis and Optimization

Uploaded by

Sameer SaxenaCopyright:

Available Formats

AGR75515711

18.5725

15.6515

12.42 12.075

11.408 11.27 11.73

10.764 11.0745

9.6025 10.12

9.0045 9.131 8.7515

8.28 8.119 8.0615

5.3475

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

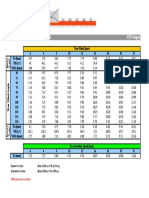

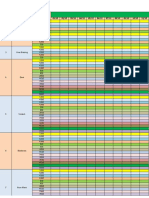

S.No STAGES M/P T/TIME 15% LOSS

1 TAPE PASTING + SOLDERING 1 16.15 18.5725

R20 BENDING + CAPILLARY BROKE+

2 CONNECTOR INSERT

1 13.61 15.6515

3 BRAZING 1 7.83 9.0045

4 LEAK CHECK 2 8.35 9.6025 T.ST 212.26

5 FOAM PASTING + TAPE PASTING 1 9.92 11.408 Nack Time 18.57

6 R70 BENDING 1 10.8 12.42 UPH 193.8

7 SILVER TAPE PASTING 2 9.8 11.27 UPPH 9.7

8 FINAL BENDING 1 10.2 11.73

9 FOAM PASTING + TAPE PASTING 1 8.8 10.12 Total Time Sec 212.26

10 DOUBLE FOAM PASTING 1 7.2 8.28 Nack Time Sec 18.57

11 TIE TIGHTING 1 7.06 8.119 No of Process Noc 18

12 DOUBLE TAPE 1 9.36 10.764 Line of Efficiency % 63%

13 GUM CLEANING 1 4.65 5.3475 Average Time Sec 10.63

14 TIE TIGHTING & CUTTING OF TIE 1 10.5 12.075

15 CAPILLARY CAP 1 7.94 9.131

16 AIR FLUSHING & CAP COVERING 1 9.63 11.0745

17 CAP FIT 2ND END 1 7.61 8.7515

18 VISUAL INSPECTION + PACKAGING 1 7.01 8.0615

TOTAL 20 184.57 212.2555

.

.

12

9.775 9.775

10 8.74 8.51 8.97

7.82 8.165

8 6.44 6.9 7.475 7.36 7.4175 7.59 7.544

6.21

6

4

2

0

1 D G G G 1 2 1 2 1 G 1 2 NG

1 ING EN STIN NIN DIN

ING TING TING TING ING T TIN ING S IDE C KI

ER M A A N T P U T

IN

G

LD TTO EP CL

E BE PA

S

PA

S

PA

S

PA

S

AR IEC FIT IN

G PA

R O P C E E W T P T &

A S BO TA

I M M P P TIE + CA FIT N

FL G & S ON OA OA TA TA G & P TIO

IT N G RA

F F LE LE IN G A EC

AS TIN LT BL

E

BL

E

UB UB AR

P

IN +C SP

P R U U U O O SH G IN

PE SE + DO DO D D W U IN

TA IN G

2 IRE FL A RK

SH R

IN W AI M

BU LAR ING

F EP

KE

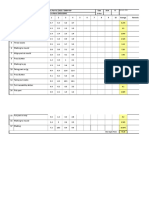

S.No PROCESS M/P T/TIME 15% LOSS

1 FLARING 1 1 5.6 6.44

2 SOLDERING 1 1 7.6 8.74

3 TAPE PASTING BOTTOM END 1 6 6.9

4 BUSH INSERTING & TAPE PASTING 1 6.5 7.475

5 FLARING 2 + ULTRASONIC CLEANING 1 6.4 7.36

6 BENDING 2 8.5 9.775

7 DOUBLE FOAM PASTING 1 1 7.4 8.51

8 DOUBLE FOAM PASTING 2 1 6.8 7.82

9 DOUBLE TAPE PASTING 1 1 5.4 6.21

10 DOUBLE TAPE PASTING 2 1 6.45 7.4175

11 TIE WARPING 1 1 6.6 7.59

KEEPING WIRE WARPING + TIE CUTTING

12 1 7.8 8.97

13 AIR FLUSHING & CAP FITTING 1 1 7.1 8.165

14 MARKING + CAP FITTING SIDE 2 1 8.5 9.775

15 INSPECTION & PACKING 1 6.56 7.544

TOTAL 16 111.71 128.4665

Total Time Sec 128.47 T.ST 128.47

Nack Time Sec 9.78 Nack Time 9.78

No of Process Noc 15 UPH 368.3

Line of Efficiency % 88% UPPH 23.0

Average Time Sec 7.91

30

25 24.15

20.125

20

17.825

16.3875

15.18 15.18

15

12.3625

10.637510.81 10.35

10 9.2

8.05

5.175

5 3.45 3.45 3.45 3.45 4.025

2.53

0

0

g ng g e s g s k t d g g n

in di in

g in pl d

ee azin

g

Pc Fee

d

zin Pc ec 1s 2n shin urin tio stin

g ng ng

lF ar en an

i m

p

Dim l F r al l r a al Ch

in g

ng u t ser a asti kagi

e B l x

C

B

EC

l Cr ria B Fin eria Fin Leak Siz i

Siz Air

F Fi In P r P Pac

te t in am cke

CN TC

M

a

M

a

r P F o ti

n so +S

Se o n

e cti

sp

al In

su

Vi

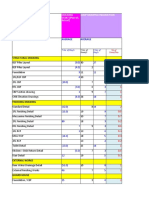

S.No STAGES M/P T/TIME 15% LOSS

2 Flaring 1 8 9.2

2 CNC Bending 1 21 24.15

3 TCE Cleaning 1 2.2 2.53

4 Crimping 1 0

5 Dimple 1 3 3.45

6 Material Feed 1 9.25 10.6375

7 Brazing 1 9.4 10.81

8 Final Pcs 1 10.75 12.3625

9 Material Feed 1 13.2 15.18

10 Brazing 1 14.25 16.3875

11 Final Pcs 1 13.2 15.18

12 Leak Check 2 15.5 17.825

13 Sizing 1st 1 3 3.45

14 Sizing 2nd 1 4.5 5.175

15 Air Flushing 1 3 3.45

16 Fixturing 1 17.5 20.125

17 Sensor Pin Insertion 1 3 3.45

18 Foam Pasting 1 7 8.05

19 Visual Inspection + Sticker Pasting 1 9 10.35

20 Packaging 1 3.5 4.025

TOTAL 21 176 202.4

Total Time Sec 202.40 T.ST 202.40

Nack Time Sec 24.15 Nack Time 24.15

No of Process Noc 16 UPH 149.1

Line of Efficiency % 52% UPPH 7.1

Average Time Sec 9.79

You might also like

- DistDocument13 pagesDistTUSAR singhNo ratings yet

- Mec Proba Lab2Document17 pagesMec Proba Lab2Richard PucaNo ratings yet

- Sta104 Nur HusninaDocument1 pageSta104 Nur HusninaNur NieynaNo ratings yet

- 11.Data For ppt Feb-22.Document195 pages11.Data For ppt Feb-22.Sachin KumbharNo ratings yet

- 07.Data For ppt OCT-21Document94 pages07.Data For ppt OCT-21Sachin KumbharNo ratings yet

- 21S1 1SCH Class Data CompilationDocument5 pages21S1 1SCH Class Data CompilationserenafcfNo ratings yet

- G 82 (Kontrol)Document29 pagesG 82 (Kontrol)fadhilahkhairyNo ratings yet

- Esp - Fahu-01 SupplyDocument5 pagesEsp - Fahu-01 Supplyvijayrisingstar93No ratings yet

- Esp - Fahu-01 SupplyDocument13 pagesEsp - Fahu-01 Supplyvijayrisingstar93No ratings yet

- Hypothesis Test DataDocument4 pagesHypothesis Test Datacharanau6No ratings yet

- Perhitungan Praktik Pengujian TanahDocument100 pagesPerhitungan Praktik Pengujian Tanah16Hikia Hanifam MuslimaNo ratings yet

- Accltd.: Profitability Ratios: Dec 2010 - Dec 2019: Non-Annualised: Rs. CroreDocument6 pagesAccltd.: Profitability Ratios: Dec 2010 - Dec 2019: Non-Annualised: Rs. Crorehardik aroraNo ratings yet

- S4 - Ejercicio - Optimizacion de Rutas (Actualizado)Document3 pagesS4 - Ejercicio - Optimizacion de Rutas (Actualizado)SHISCETH GOMEZ SERRANONo ratings yet

- Profundidad (FT) Peso Del Lodo (LB/GAL) Diametro de La Broca (In) ROP (FT/H) Peso de La Broca (LB)Document2 pagesProfundidad (FT) Peso Del Lodo (LB/GAL) Diametro de La Broca (In) ROP (FT/H) Peso de La Broca (LB)Ivan BMNo ratings yet

- Module 2Document18 pagesModule 2KittyNo ratings yet

- Table of Section Properties For IPE, HEA, HEB, HEM Profiles - Eurocode 3Document22 pagesTable of Section Properties For IPE, HEA, HEB, HEM Profiles - Eurocode 3Daniel OkereNo ratings yet

- Slope Stability Analysis TemplateDocument16 pagesSlope Stability Analysis TemplateScarlet SalayonNo ratings yet

- Ignation Spark PlugDocument15 pagesIgnation Spark PlugHartanto Hari SusestroNo ratings yet

- Gypsum Rate AnalysisDocument11 pagesGypsum Rate AnalysisshankNo ratings yet

- Prevent Condensation with Insulation ThicknessDocument5 pagesPrevent Condensation with Insulation ThicknessAbhijeet SahuNo ratings yet

- 90 Tonne Liebherr Crane Load Chart and SpecsDocument3 pages90 Tonne Liebherr Crane Load Chart and SpecsclaudobaNo ratings yet

- For Constant CBR Value of Embankment 1.5 2 2.5 3 5 7 Effective CBR of SubgradeDocument1 pageFor Constant CBR Value of Embankment 1.5 2 2.5 3 5 7 Effective CBR of SubgradeAkshay Aithal KandoorNo ratings yet

- Bored Pile Capacity EvaluationDocument3 pagesBored Pile Capacity EvaluationChowdhury PriodeepNo ratings yet

- Themo_Assessment_MarksDocument2 pagesThemo_Assessment_MarksBikash GhimireNo ratings yet

- 14 - Liquid Measurements With OrificeDocument5 pages14 - Liquid Measurements With OrificekumarNo ratings yet

- Electrical Estimate SampleDocument4 pagesElectrical Estimate SampleAngelli Juelar NaiganNo ratings yet

- D1275 - Hallberg-Rassy 64 (Half Load) VPP OutputDocument1 pageD1275 - Hallberg-Rassy 64 (Half Load) VPP OutputmentolNo ratings yet

- Friction Pipe Loss Chart: GPM GPM Pipe Size IN. Pipe Size INDocument2 pagesFriction Pipe Loss Chart: GPM GPM Pipe Size IN. Pipe Size INOscar PettersNo ratings yet

- 5 Stairs SN Description Dia NO. Length Total Length WT/FT Total WT (KG) Sub Total Estimated Total Remarks 240.908 A Basement StairDocument1 page5 Stairs SN Description Dia NO. Length Total Length WT/FT Total WT (KG) Sub Total Estimated Total Remarks 240.908 A Basement StairBibek JoshiNo ratings yet

- Unemployment Rate Statistics and Analysis of 144 PeriodsDocument56 pagesUnemployment Rate Statistics and Analysis of 144 PeriodsStefany albarracin bordaNo ratings yet

- Reporte-Análisis de Talud02Document6 pagesReporte-Análisis de Talud02Vladimir Jerson Alferez VargasNo ratings yet

- PDF 1 Upto Plinth Area 20 Ce 190Document1 pagePDF 1 Upto Plinth Area 20 Ce 190Eng TariqNo ratings yet

- Sigma-Bridas SoldablesDocument1 pageSigma-Bridas SoldablesRegistro HexaNo ratings yet

- Compaction Test: Bandar Udara Bintan ResortDocument9 pagesCompaction Test: Bandar Udara Bintan ResortRizky Rahmandhito0% (1)

- SneakerDocument2 pagesSneakerJayanth DeshmukhNo ratings yet

- Stats AsssignmentDocument4 pagesStats Asssignmentjunaid aalamNo ratings yet

- Introduction to Aerospace Engineering ReportDocument14 pagesIntroduction to Aerospace Engineering ReportVijay ArniNo ratings yet

- CRJ-200 Calculator v1.1Document26 pagesCRJ-200 Calculator v1.1Raph 1123No ratings yet

- Balance Sheet - Subros: Optimistic Senario Normal ScenarioDocument9 pagesBalance Sheet - Subros: Optimistic Senario Normal ScenarioAnonymous tgYyno0w6No ratings yet

- Cutoff Units Bought Cost HP Revenue LP Prod Cost Max Surplus Midpoint Unit Value Cum Value Price Paid Surplus ProfitDocument4 pagesCutoff Units Bought Cost HP Revenue LP Prod Cost Max Surplus Midpoint Unit Value Cum Value Price Paid Surplus ProfitYugant NNo ratings yet

- Inspection Timings of M&M Clutch HousingDocument2 pagesInspection Timings of M&M Clutch HousingaNo ratings yet

- Balling / Brix - Density - Oechsle - BauméDocument1 pageBalling / Brix - Density - Oechsle - BauméRemus GheorghițăNo ratings yet

- Developing a ConeDocument11 pagesDeveloping a ConeK C Tharun KumarNo ratings yet

- COMPUTATIONDocument1 pageCOMPUTATIONXaira Alexa Mari CastroNo ratings yet

- Untitled NotebookDocument1 pageUntitled NotebookNoof AlmarriNo ratings yet

- RCUSS Weak Link Investigation: R&D - Jan 2022Document6 pagesRCUSS Weak Link Investigation: R&D - Jan 2022TINo ratings yet

- 13 - Gas Orifice and Gas Rate CalculationsDocument5 pages13 - Gas Orifice and Gas Rate CalculationsAnik AichNo ratings yet

- Air QualityDocument4 pagesAir QualityMario JuradoNo ratings yet

- Cascade ControllerDocument5 pagesCascade Controllerblub blueNo ratings yet

- ChannelsDocument2 pagesChannelssaravoot_jNo ratings yet

- C E B U P: Apacity Valuation of Ored Nderreamed ILEDocument1 pageC E B U P: Apacity Valuation of Ored Nderreamed ILEChowdhury PriodeepNo ratings yet

- Wall Thickness CalculatorDocument5 pagesWall Thickness CalculatorbillyNo ratings yet

- Time Study After (CTS)Document12 pagesTime Study After (CTS)Abdul MuizNo ratings yet

- Batch Settling - AVIRALDocument10 pagesBatch Settling - AVIRALsaurabhNo ratings yet

- AbdulwahabDocument8 pagesAbdulwahabferhan loveNo ratings yet

- Drawing Description: Average AverageDocument4 pagesDrawing Description: Average Averagejucar fernandezNo ratings yet

- OPERATIONDocument2 pagesOPERATIONVelasco, BernardoNo ratings yet

- Schedule ChartDocument4 pagesSchedule Chartaslam.ambNo ratings yet

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- Futur improvement planDocument1 pageFutur improvement planSameer SaxenaNo ratings yet

- Manpower allocationDocument2 pagesManpower allocationSameer SaxenaNo ratings yet

- Worksheet in Book1Document21 pagesWorksheet in Book1Sameer SaxenaNo ratings yet

- Tact Time Operation (2)Document5 pagesTact Time Operation (2)Sameer SaxenaNo ratings yet

- Daily Kick Off (14-20) PJADocument35 pagesDaily Kick Off (14-20) PJASameer SaxenaNo ratings yet

- Production Department: Subros Audit Non-Confirmity PointDocument4 pagesProduction Department: Subros Audit Non-Confirmity PointSameer SaxenaNo ratings yet

- F-QA-19, Layout Inspection PlanDocument4 pagesF-QA-19, Layout Inspection PlanSameer SaxenaNo ratings yet

- Production Department: Subros Audit Non-Confirmity PointDocument4 pagesProduction Department: Subros Audit Non-Confirmity PointSameer SaxenaNo ratings yet

- Sonaliraj0311Document1 pageSonaliraj0311Sameer SaxenaNo ratings yet

- The Nuts and Bolts of Business PlansDocument42 pagesThe Nuts and Bolts of Business PlansgboobalanNo ratings yet

- 4M Change Control Management Work InstructionDocument2 pages4M Change Control Management Work InstructionSameer Saxena100% (2)

- Initial Product Quality Control ProcessDocument3 pagesInitial Product Quality Control ProcessSameer SaxenaNo ratings yet

- Esskay ESH Audit Report FEB-2018Document3 pagesEsskay ESH Audit Report FEB-2018Sameer SaxenaNo ratings yet

- Process Validation PlanDocument1 pageProcess Validation PlanSameer SaxenaNo ratings yet

- Experience LetterDocument1 pageExperience LetterSameer SaxenaNo ratings yet

- Om Sample Project 2Document74 pagesOm Sample Project 2Jamsheed0% (1)

- RESP./ Date Verification (Qa Pic) Improvement Action Root Cause / Analysis Issue Detail StatusDocument2 pagesRESP./ Date Verification (Qa Pic) Improvement Action Root Cause / Analysis Issue Detail StatusSameer SaxenaNo ratings yet

- Internal KPIDocument3 pagesInternal KPISameer SaxenaNo ratings yet

- Salary SlipDocument1 pageSalary SlipSameer SaxenaNo ratings yet

- Daily Kick Off (14-20) PJADocument35 pagesDaily Kick Off (14-20) PJASameer SaxenaNo ratings yet

- Part Traceability Process Flow: Customer FeedbackDocument1 pagePart Traceability Process Flow: Customer FeedbackSameer SaxenaNo ratings yet

- S.No Stages M/P T/Time 1: UPH UpphDocument4 pagesS.No Stages M/P T/Time 1: UPH UpphSameer SaxenaNo ratings yet

- SWOT Analysis Worksheet v2Document3 pagesSWOT Analysis Worksheet v2Sigfrid MsokeNo ratings yet

- Packing Style Format DaikinDocument28 pagesPacking Style Format DaikinSameer SaxenaNo ratings yet

- Defect History: Sr. No Typeof Defect Action StatusDocument22 pagesDefect History: Sr. No Typeof Defect Action StatusSameer SaxenaNo ratings yet

- Fire Extinguisher Check SH: MonthDocument10 pagesFire Extinguisher Check SH: MonthSameer SaxenaNo ratings yet

- PFMEA Process Failure Mode and Effect Analysis for Distribution AssemblyDocument50 pagesPFMEA Process Failure Mode and Effect Analysis for Distribution AssemblySameer SaxenaNo ratings yet

- Daily Rejection ReportDocument9 pagesDaily Rejection ReportSameer SaxenaNo ratings yet

- Assy Parts PFD R-32 Model Brazing 10Document7 pagesAssy Parts PFD R-32 Model Brazing 10Sameer SaxenaNo ratings yet

- Settlement Management + COPADocument24 pagesSettlement Management + COPArameshNo ratings yet

- Raken QPA Checklist For PCBADocument135 pagesRaken QPA Checklist For PCBAphamtienkhang100% (1)

- What Is The Difference Between Inventory and StockDocument3 pagesWhat Is The Difference Between Inventory and StockVivian MonteiroNo ratings yet

- NServiceBus SagaDocument6 pagesNServiceBus SagadujeZ08991No ratings yet

- Thriving Business in The Digital Era: Strategic Marketing of Traditional Shop Owners For Revenue Optimization I. Chapter SummaryDocument4 pagesThriving Business in The Digital Era: Strategic Marketing of Traditional Shop Owners For Revenue Optimization I. Chapter SummaryMary ann ForteNo ratings yet

- Business Canvas Fresh Fruit MealsDocument1 pageBusiness Canvas Fresh Fruit MealsNur JieyaNo ratings yet

- Purchase Order Requisition R-1910-0318 Rev 0Document27 pagesPurchase Order Requisition R-1910-0318 Rev 0AnaNo ratings yet

- What Are The Most Important Changes in Incoterms 2020Document5 pagesWhat Are The Most Important Changes in Incoterms 2020frNo ratings yet

- INVEN HW7 Solution RevisedDocument7 pagesINVEN HW7 Solution RevisedYolo PhongNo ratings yet

- Product Design and Business Model Strategies For A Circular EconomyDocument14 pagesProduct Design and Business Model Strategies For A Circular EconomyPl TorrNo ratings yet

- Topic:: Enterprise Architecture & IntegrationDocument45 pagesTopic:: Enterprise Architecture & IntegrationHamza FarrukhNo ratings yet

- Analysis of Supply Chain InventoryDocument28 pagesAnalysis of Supply Chain Inventoryprithviraj1990100% (1)

- Fire Service Valves CatalogueDocument76 pagesFire Service Valves Cataloguearvint_1999No ratings yet

- Oracle AIM MethodologyDocument33 pagesOracle AIM MethodologyNarayanaNo ratings yet

- Acc466 Excercise Chapter1Document6 pagesAcc466 Excercise Chapter1nur hadhirahNo ratings yet

- JBLFMU Tourism Marketing CourseDocument35 pagesJBLFMU Tourism Marketing CourseIvy Joy GarruchaNo ratings yet

- Welding A Cast IronDocument9 pagesWelding A Cast Ironjatin jainNo ratings yet

- Zero Acceptance Number Sampling Plans V4 To V5 - ASQDocument11 pagesZero Acceptance Number Sampling Plans V4 To V5 - ASQDDDNo ratings yet

- Sheet Metal and TinsmithryDocument22 pagesSheet Metal and TinsmithryVictor EvangelioNo ratings yet

- EhubDocument8 pagesEhubscm2012No ratings yet

- QUALITY MANUAL FOR VALVE MANUFACTURERDocument45 pagesQUALITY MANUAL FOR VALVE MANUFACTURERzae nuddinNo ratings yet

- Humana Ca2Document11 pagesHumana Ca2Lazim YoonusNo ratings yet

- Rishabh Instruments Industry Visit ReportDocument3 pagesRishabh Instruments Industry Visit ReportSanjeev SinghNo ratings yet

- Max Final ProjectDocument76 pagesMax Final ProjectAvinash JosephNo ratings yet

- Itdumpsfree: Get Free Valid Exam Dumps and Pass Your Exam Test With ConfidenceDocument5 pagesItdumpsfree: Get Free Valid Exam Dumps and Pass Your Exam Test With Confidencesho sayNo ratings yet

- LAMINATION SUITABILITYDocument3 pagesLAMINATION SUITABILITYSwapnesh GoswamiNo ratings yet

- Business Analyst role in Supply Chain Transformation with GEPDocument2 pagesBusiness Analyst role in Supply Chain Transformation with GEPAlberrtodNo ratings yet

- Gear Heat TreatmentDocument40 pagesGear Heat TreatmentvishnuNo ratings yet

- 671.2023 Residential AssignmentDocument5 pages671.2023 Residential Assignmentmisheck mwapeNo ratings yet

- Growing Share of a Customer's Business: Infosys' Proposal to Develop PFS' Procurement SoftwareDocument7 pagesGrowing Share of a Customer's Business: Infosys' Proposal to Develop PFS' Procurement SoftwareSumit RajpurohitNo ratings yet