Professional Documents

Culture Documents

Coding Guidelines For MESC and Spare Parts PDF

Uploaded by

Mehdi_Mashayekhi_172Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coding Guidelines For MESC and Spare Parts PDF

Uploaded by

Mehdi_Mashayekhi_172Copyright:

Available Formats

Guidelines for MESC coding

of items and spare parts

INDEX

1. INTRODUCTION........................................................................................................................... 2

2. OBJECTIVE .................................................................................................................................. 2

3. SCOPE .......................................................................................................................................... 2

4. PURPOSE ..................................................................................................................................... 2

5. REFERENCE DOCUMENTS ........................................................................................................ 2

5.1 Project E-SPIR 2000 review procedure .............................................................................. 2

6. THE MESC SYSTEM .................................................................................................................... 2

6.1 The MESC Licence ............................................................................................................. 2

6.2 General Description ............................................................................................................ 2

6.3 Structure of the "MESC” number ........................................................................................ 3

6.4 Coding example .................................................................................................................. 3

6.5 MESC indicators ................................................................................................................. 3

6.6 Creating the MESC number for an item (non spare parts) ................................................. 4

6.7 MESC coding of catalogue items ........................................................................................ 4

6.8 Generic items ...................................................................................................................... 5

6.9 MESC coding in E-SPIR 2000 ............................................................................................ 5

7. ITEM SPECIFICATIONS............................................................................................................... 5

7.1 Formated item specifications .............................................................................................. 5

7.2 Unformatted item specifications.......................................................................................... 6

8. SPECIMEN CODING METHODS ................................................................................................. 7

LIST OF MESC MAIN GROUPS ............................................................................................................. 8

BOUGHT-OUT (COMMERCIAL) ITEMS ................................................................................................ 9

Date: 1 May 2006

Guidelines for coding of spare parts

1. INTRODUCTION

This procedure provides some guide lines on the coding of spare parts and the information

required from Suppliers to identify the correct code for generic spare parts. The coding policy

can be different per Company should be agreed upfront. In some Companies the coding of

spare parts is not required any more.

2. OBJECTIVE

To set out a guideline for coding of spare parts in projects.

3. SCOPE

Project items and spare parts are covered by the Main MESC Groups as described in Appendix

1.

4. PURPOSE

To promote uniformity, guidelines and consistency in the coding of spare parts.

5. REFERENCE DOCUMENTS

- Spare Parts Management for Projects (available from SGSI-GSEMH), or

- DEP 70.10.90.11-gen for spare parts (identical, however for Shell Companies).

This document defines the responsibilities of personnel and Contractors involved in the spare

parts review process. It specifies requirements and provided recommendations for the

coordination, review, selection, purchase and disposal of spare parts for new projects with the

aim of applying the principles of standardisation and variety control.

5.1 Project E-SPIR 2000 review procedure

This document is the user manual for the E-SPIR 2000 program in projects. It helps the user to

set up the databases, start a project, describes the program functionality, such as importing and

exporting E-SPIRs, reviewing the various screens, coding, providing advice and order

recommendations. It also describes the various reports. The documents is available on the

website www.E-SPIR.com under Advisor Guide.

6. THE MESC SYSTEM

6.1 The MESC Licence

The MESC catalogue is available via the Customer Wide Web of Shell Global Solutions for

Shell and non-Shell Companies, who have a MESC license agreement and their Contractors

working on site. Suppliers and Manufacturers can obtain a subscription via SGSI-GSEMH for

the purposes of viewing the MESC data to support and assist those companies who have a

MESC license agreement. http://www.shell.com/cww

6.2 General Description

The MESC is a system for materials and equipment standards, their classification and coding.

The system is precise, has flexibility and extendibility, and provides a logical and indexed order

for the vast assortment of goods produced all over the world. It is maintained by the Cataloguing

section (GSEMH) of Shell Global Solutions International B.V., The Hague, The Netherlands.

The MESC is system consisting of three main components:

Coding procedure - Rev. 03 Page 2/9

Guidelines for coding of spare parts

6.2.1 The "Classification structure", helps you to find the specifications of materials and equipment

based on Nouns, modifiers and synonyms.

6.2.2 The “Coding Schedule”, providing the coding framework for materials and equipment.

6.2.3 The “MESC Catalogue”, containing details of types and sizes of materials and equipment

recognized as “standard”. Approximately 110,000 standard material items can be found in the

catalogue. Each standard material item is listed complete with buying specification and

technical details. Where applicable reference is made to international, national or industry

standards. The specifications have been written in close co-operation with Technical Functions,

and where appropriate supplemented by drawings and illustrations.

6.3 Structure of the "MESC” number

Each MESC number consists of ten digits, divided as follows: (see figure below)

• The first six digits refer to the classification by Main Group, Sub-Group & Sub-Sub Group.

• The next three digits are an item number which identifies the material and equipment

uniquely within its Sub-Sub Group.

• The last digit indicates the MESC number category.

Main Sub Sub-Sub Item Indicator

Group Group Group Number

XX . XX . XX . XXX . X

Indentifi- Categori-

Classification

cation zation

6.4 Coding example

A concentric reducer, butt-welded, carbon steel, schedule 80, end to end dimensions 64 mm,

Nom. size 1 1/2 in x 1 in:

MESC number: 76.30.72.187.1

This MESC number has been composed as follows:

Main Sub Sub Item Indi-

sub number cator

76. Fittings and flanges

30. Fittings, butt-welding

72. Reducers, concentric, BW, CS

187. Size 1 1/2 x 1 in - sched. 80, end to end 64 mm

1 Centrally coded

6.5 MESC indicators

Centrally coded items normally formatted specifications have a xxx.1 indicator.

Locally coded items normally formatted specifications have a xxx.9 indicator.

Locally assigned MESC codes for spare parts should have a xxx.3 indicator.

In the event that xxx.9 items are created, the formats of similar xxx.1 items might be used as a

specimen. For a sample format see paragraph 8.1.

Coding procedure - Rev. 03 Page 3/9

Guidelines for coding of spare parts

6.6 Creating the MESC number for an item (non spare parts)

When new item codes are to be created the following steps should be followed. Classify the

item with the MESC Main and Sub Sub Groups with help from the coding schedule (paragraphs

6.3 and 6.4). This information is available from the MESC Website.

After the classification (MESC Sub Sub) has been found a unique identification number is

allocated. This item number identifies the material. See also samples in paragraph 9.

6.7 MESC coding of catalogue items

6.7.1 Definitions

Spare parts

A part or component of a piece of equipment, which can be used as a replacement, usually

when the original part fails or wears out.

Spare parts with unique part numbers

A spare part number is unique when it shall apply exclusively and be the only reference of a part

within the manufacturers organisation.

6.7.2 Use of coding schedule

When an item cannot be coded within the existing coding schedule, a local subsub group, which

comes closest should be choosen. In most cases this will be a subsub group defined by SGSI

on the MESC web site (http://www.shell.com/cww) with the indication “nos” (not otherwise

specified).

When substantial ranges of the same material are to be expected, a new local subsub group

can be requested from Shell Global Solutions International.

6.7.3 Piping class materials

Wall thicknesses of piping class materials (MESC Main Groups 74, 76, 77 and 85) can be

specified in MESC buying descriptions with the characteristics “Schedule” or “Wall thickness in

MM”. When a wall thickness is covered by the Schedules STD, XS, XXS, 10, 20, 30, 40, 80,

120, 160, 5S, 10S, 40S, 80S as per API 5L, only the characteristic “Schedule” should be filled in

the value of the format (see paragraph 8.1). When a wall thickness is not covered by the API 5L

schedules, a MM size shall be entered in the value of the format. To avoid duplication of items,

wall thicknesses shall first be checked whether they are covered by a Schedule.

Buying descriptions for Piping Class Materials will only indicate “metric” sizes. Only OCTG (Oil

Country Tubular Goods) materials are listed with “imperial” sizes.

6.7.4 Unique spare parts for equipment

Spare parts for different models fabricated by one equipment manufacturer should be coded in

one nominated Sub Sub group or within a reserved range of one specific Sub group. For this

purpose the MESC Coding Schedule on the MESC website, where the coding schedule

recommends different Sub Sub groups for different equipment from one manufacturer it is

recommended to use one group only.

The alternative for the described method is using MESC group 35, whereby unique spare parts

can be coded against a manufacturers subgroup, regardless of the type of equipment.

The in random order selected items should be coded sequentially starting from xx.xx.xx.001.3

until xx.xx.xx.999.3.

Where the coding schedule does not provide Sub Sub groups for the relevant equipment, a

locally allocated Sub-Sub group in line with the general coding schedule should be allocated.

Also projects may allocate their own Sub Sub groups for this purpose.

6.7.5 Spare parts with unique part numbers for items with generic descriptions

Spare parts manufactured by one manufacturer for items with generic descriptions (e.g. valve

parts, luminair parts, telecom parts) should be generalised and coded in a nominated Sub Sub

group or within a reserved range of a specific Sub Sub group of the MESC coding schedule.

Coding procedure - Rev. 03 Page 4/9

Guidelines for coding of spare parts

6.8 Generic items

6.8.1 Generic items are items of a general nature like bearings, gaskets, instruments, etc. (see

Appendix 2), which can be purchased with a specification without mentioning a manufacturers

name. Those items are not manufactured by the main equipment manufacturer. Such items

should be coded in the appropriate MESC groups (e.g. 58, 60, 67, 70 and 85). For many of

those items there are formats available in the CMT catalogue with or without the relevant values

Where a format is available it shall be used, and incomplete information shall be requested from

the manufacturer.

Generalising typical Bought-out items will save a lot of money and parties involved should insist

to receive the information required to identify this type of spares from the Suppliers.

6.8.2 If there is insufficient information to generalise a questionable spare part (see Appendix 2.) and

the supplier is unwilling to cooperate, it is recommended to inspect the relevant details of the

item when it is received. That will allow to generalise the item and complete the records.

6.8.3 It should be noted that generalisation might have consequences for the technical integrity of the

main equipment. The penalty of failure or losing guarantee on expensive equipment should be

compared with the savings of a few dollars for e.g. generalising an o-ring. It is recommended

to generalise only those spare parts where a substantial saving can be achieved by purchasing

the parts from the original manufacturer, or where a reasonable consumption pattern is

expected. Typical "non" moving items should not be generalised.

6.9 MESC coding in E-SPIR 2000

For the coding of new MESC items, a special coding facility was developed in the E-SPIR 2000

program to increase the speed of coding. The facility shows all the spare parts attached to the

equipment(s) in one SPIR on one screen. Refer to the Project E-SPIR 2000 review procedure

7. ITEM SPECIFICATIONS

The CMT Catalogue system is designed to contain Formatted and Unformatted material

specifications.

The Shell Global Solutions MESC catalogue contains mainly Formatted item specifications,

which are based on the know-how developed in the centre and experience from Group

Companies.

The Unformatted item specifications are mainly used for spare parts, whereby the spare part is

identified by the part number and the short description

7.1 Formated item specifications

7.1.1 Terminology

Format (CMT = Noun + Modifiers + Characteristics

Format (CMT) = Classification (SAP) = Class + Characteristics (SAP)

Format name (CMT) = Class name (SAP) = Noun + Modifier

7.1.2 Nouns, Modifiers an Characteristics

A format is defined by a set of Noun, Modifiers and Characteristics. To prepare a specification

the values required shall be entered in the selected format. Those values can only be selected

from tables, thereby ensuring consistent descriptions.

7.1.3 Creating locally formatted items

Where users in Operating Companies create new items in the CMT system the descriptions of

the Nouns, Modifiers and Characteristics shall never be changed in centrally made formats.

When a material specification is created by using an existing format only the values may be

altered. If certain item details cannot be identified with the existing characteristics, that

information shall be entered in the long text of the description. This rigid system ensures that

the formats of annual revision uploads of the Central Catalogue do not crash with formats

changed locally.

Coding procedure - Rev. 03 Page 5/9

Guidelines for coding of spare parts

7.1.4 Short item description

In most catalogues items are also presented as a one line description. In CMT the one line

descriptions is automatically created with selected abbreviated values of the format. For this

purpose key characteristics have been selected.

7.1.5 On the example below a formatted item is presented.

Nouns & Modifiers Specimen Noun & Modifiers

A set of Nouns & Modifiers facilitates Noun Bearings

searches in the catalogue. Modifier 1 Ball

User-access to catalogue information is

very user friendly without the necessity to Modifier 2 Metric

know article or stock numbers. Modifier 3

Formats or templates Specimen Format

A format is a description defined by a set Bearings, Ball, Metric

of Nouns and Modifiers, supported by a

set of Characteristics with value fields. Characteristics Values

Formats have been created for items, Type self aligning

which require for commercial reasons a Series 1200

generic description.

Rows double

The Shell Catalogue contains more than

Design spec ISO 15 / DIN 630

1200 Formats & 110.000 Formatted items.

Style raceway of outer ring

Formatted items Mat, cage pressed steel

A formatted item is specified by Values Designation (SKF no) 1209 EJ

against the fixed Characteristics, which Type of bore mm 45

describe the item technically or Diameter, od mm 85

functionally. Width/height mm 19

The item contains information such as MESC No 58.02.07.509.1

MESC number, Units of Measure, Short

Unit of Measure PC

Description, Product Group, Custodian

and Company Reference(s). Short Description BRG BALL MTR 1209EJ

45mm 85mm

7.2 Unformatted item specifications

The unformatted option in CMT is set up for the use of proprietary spare parts complete with a

manufacturers part number and description. It also contains information such as Article no,

Units of Measure, Product Group, Custodian and Company Reference(s). For unformatted

items the short text in is not automatically generated. The convention for the manual creation of

short item descriptions should be in line with the set up of the Nouns and Modifiers in CMT.

First the Noun, than the Modifiers in order of importance.

Two examples:

- Ball valve should read: Valve, ball.

- High voltage resin insulated transformer should read: Transformer, high voltage, resin

insulated.

Typical spare parts are normally not loaded under a Noun Modifier Combination.

Searches of spare parts in the catalogue are carried out on part number and/or supplier.

Coding procedure - Rev. 03 Page 6/9

Guidelines for coding of spare parts

8. SPECIMEN CODING METHODS

Method 1. Spare part ranges (with unique part nrs) per manufacturer in a centrally

allocated Sub group

Randomly coded items in MESC Sub group 27.99 (paragraph 6.6)

27.99 Pumps, reciprocating: continental manf. nos (not otherwise specified).

27.99.00.001.3 PART NO 21CA789 SHAFT type A

27.99.00.002.3 PART NO 41BB234 SHAFT type B

27.99.00.003.3 PART NO 21AA456 GASKET type A + B

27.99.00.004.3 PART NO 21AA234 IMPELLER type A

27.99.00.005.3 PART NO 21AB123 WEAR RING type A

27.99.00.006.3 PART NO 31BB789 IMPELLER type B

27.99.00.007.3 PART NO 31BC456 WEAR RING type A

Method 2. Spare parts ranges per manufacturer for spare part nrs in one allocated

Sub-Sub group within MESC main group 31 (paragraph 6.6)

31.13.10 Pump type A, manufacturer X.

31.13.10.101.3 PART NO AB212 IMPELLER type A

31.13.10.102.3 PART NO AB213 ** GASKET type A + B

31.13.10.103.3 PART NO AB214 SHAFT type A

31.13.10.104.3 PART NO AB215 WEAR RING type A

31.13.10 Pump type B, manufacturer X.

31.13.10.105.3 PART NO BB322 SHAFT type B

31.13.10.106.3 PART NO BB323 WEAR RING type B

31.13.10.107.3 PART NO BB324 IMPELLER type B

31.13.10.102.3 PART NO AB213 ** GASKET type A + B

**( Part No identical for pump A and B)

Samples of selecting a Sub Sub Group in the MESC system

Item to be coded Solution

Transformer, High Voltage, Sub-group, 65.43, already exists for local use, therefore, choose your

Resin Insulated own sub-sub group within the sub-group.

Level transmitter, New subsubgroup not required: Magnetostrictive is float type transmitter.

Magnetostrictive type Use local coding 60.21.69.

Guard Pipe, Schedule 40 If this is all information submitted, this item should be coded as part of

the equipment it is used for.

Batten Plate, 400x80x6mm Use Local coding: 78.43.90

thick flat steel plate

EL T RTD TW PT100, This is not enough information for proper MESC coding. A complete

0-100 DEG.C specification (length, thickness, type of connection, etc) is required, or a

manufacturer’s name and partnumber, if the specification is not available.

TR T EL 4-20MA, 24VDC, This is not enough information for proper MESC coding. A complete

0-100 DEG.C specification is required, or manufacturer’s name and partnumber, if the

specification is not available.

Coding procedure - Rev. 03 Page 7/9

Guidelines for coding of spare parts

Appendix 1.

LIST OF MESC MAIN GROUPS

DRILLING & PRODUCTION MACHINERY ACCESSORIES

01 - drilling machinery, mud equipment & accessories 58 - machinery accessories & transmissions

02 - production surface equipment

PROCESS INSTRUMENTATION

03 - drilling tools & retrievable production tools

59 - process instrumentation: parts

04 - casing, tubing & accessories

60 - process instrumentation

05 - cementing equipment & liner hanger systems

06 - fishing & repair tools (drilling) BUILDINGS, TANKS & SHOP EQUIPMENT

07 - drilling & mud control instruments 61 - buildings, structures & tanks

08 - production well test & monitoring instruments 62 - machine tools with attachments & accessories

09 - wellhead equipment & accessories 63 - pneumatic tools & accessories

10 - production string components & subsurface pumps 64 - general shop equipment (including welding)

11 - derricks & accessories

ELECTRICAL

12 - geological & geophysical operating equipment

65 - electric power sources & power converters

PLANT & MACHINERY 66 - electric motors, accessories & parts

13 - boilers & accessories 67 - switch/control gear & electrical instruments

14 - engines gas or oil (nos) 68 - wires, cables, terminating & connecting material

15 - steam engines (reciprocating) 69 - lamps, luminaires, lighting control gear

16 - steam turbines & parts 70 - fuses, conduit & domestic electric material

17 - engines, gas or oil (continent) 71 - telecommunication, electronic systems & components

18 - engines, gas or oil & parts (GB) 72 - computers, computer peripherals, accessories & software

19 - engines, gas or oil & parts (US)

TUBULAR GOODS, VALVES & FITTINGS

20 - gas turbines & parts

73 - hoses & hose assemblies

21 - ----

74 - tubular goods

22 - compressors or vacuum pumps & parts (continent)

75 - obsolete (do not use)

23 - compressors or vacuum pumps & parts (GB)

76 - fittings & flanges

24 - compressors or vacuum pumps & parts (US)

77 - valves & accessories

25 - compressors or vacuum pumps & parts (nos)

26 - pumps, reciprocating & parts (nos) BUILDING MATERIAL, METALS & HARDWARE

27 - pumps, reciprocating & parts (continent) 78 - metals & non-metals in bars, plates, sheets, wire products

28 - pumps, reciprocating & parts (GB) 79 - wire ropes, cordage chains & tackles

29 - pumps, reciprocating & parts (US) 80 - builders hardware & building material

30 - pumps, centrifugal or rotary & parts (nos) 81 - fasteners, etc.

31 - pumps, centrifugal or rotary & parts (continent) 82 - ----

32 - pumps, centrifugal or rotary & parts (GB)

TOOLS & PACKING

33 - pumps, centrifugalor rotary & parts (US)

83 - small tools

34 - pumps, other types & parts

84 - ----

35 - proprietary spare parts MESC main groups 14 - 33

36 - hoisting & lifting equipment 85 - jointing (gaskets), packing & insulating materials

37 - road making, excavating & construction equipment PLANTS, OILS, CHEMICALS & LABORATORY

38 - mining equipment 86 - paints

39 - forestry, paper and pulp mill equipment

87 - oils & oil products

40 - refinery plants & components

88 - abrasives, polishes & compounds

41 - chemical industrial equipment

89 - chemicals

42 - auxiliary plants & components (nos)

90 - laboratory requisites

43 - plant elements & parts

44 - packing plant & LPG marketing components MEDICAL

91 - medical equipment & supplies

TRANSPORTATION

45 - motor-cars (european) HOUSEHOLD, OFFICE, FIRE & SAFETY

46 - motor-cars (other than european) 92 - furniture, household & club requisites

47 - trucks & buses (european) 93 - office & warehouse equipment & materials

48 - trucks & buses (other than european) 94 - ----

49 - tractors & trailers 95 - textiles, fabrics, clothing & leather goods

50 - tractors & trailers 96 - fire, safety, security & environmental equipment

51 - locomotives, cars & rail equipment

SERVICES

52 - ----

97 - ----

53 - marine & offshore installations

98 - ----

54 - ----

55 - vehicles & vehicle accessories (nos) GENERAL

56 - garage & retail outlet equipment 99 -

57 - aircraft & aircraft fuelling equipment

Coding procedure - Rev. 03 Page 8/9

Guidelines for coding of spare parts

Appendix 2.

BOUGHT-OUT (COMMERCIAL) ITEMS

List of minimum required details for commercial items.

Non-Manufacturer related:

Ball bearings : Bearing designation, preferably SKF number.

V-belts : BS/API specification no. with dimensions, cross section, nominal top width,

standard length designation, oil resistant, anti-static, fire resistance. If ribbed,

number of ribs.{correct typo}

Gaskets : Type, material, pressure rating, nominal pipe size,

gasket ID & OD, thickness.

To: ANSI, BS, MSS, API. Or standard configuration e.g.

MESC IL 85/170.

Bolts & nuts : Design spec, Material spec, size

Circlips : Internal - outside dia, thickness, for bore size.

External - inside dia, thickness, for shaft dia.

Fuses : Voltage, current, type to BS, DIN, IEC

Bulbs/lamps : Voltage, Wattage, dimensions, cap type, shape,

IEC publication No.

E-motors : Type number, voltage, power, All name plate details.

Manufacturer related:

Instruments : Original manufacturers name, unique partnumber, name plate details.

Relays/contactors : Original manufacturers name, unique partnumber, name plate details.

Mechanical Seals : Original manufacturers name, type and size, material specification, seal

arrangement.

Couplings : Original manufacturers name, type, model, size, order code.

Coding procedure - Rev. 03 Page 9/9

You might also like

- CAD StandardsDocument34 pagesCAD StandardsJohn Ray Esmama CalasicasNo ratings yet

- Technical Bid Evaluation FormDocument2 pagesTechnical Bid Evaluation Formshyam100% (3)

- 30.99.00.8517-1 Rev. 0 (1) Criticality Rating SpecsDocument40 pages30.99.00.8517-1 Rev. 0 (1) Criticality Rating Specsvishnuvarthan50% (2)

- NORSOK Z-006 - PreservationDocument20 pagesNORSOK Z-006 - Preservationjoaocavti100% (4)

- List of Mesc Spe - 2014Document4 pagesList of Mesc Spe - 2014Robert Michaelraj67% (3)

- 9com No PDFDocument2 pages9com No PDFbalajiNo ratings yet

- Biryani Research PaperDocument11 pagesBiryani Research PaperRaamji Mp100% (1)

- Guidelines For Vendor Documentation ReviewDocument4 pagesGuidelines For Vendor Documentation ReviewCostin GhenescuNo ratings yet

- 77 - 103Document13 pages77 - 103raja100% (2)

- 31 Samss 009Document7 pages31 Samss 009Sivareddy InduriNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistரமேஷ் பாலக்காடுNo ratings yet

- SP-1246 1Document31 pagesSP-1246 1Ahmad Zaid75% (4)

- Petroleum Development Oman L.L.C.: KeywordsDocument21 pagesPetroleum Development Oman L.L.C.: Keywordsravi00098No ratings yet

- MESC - SPE - 77-170 February 2017Document14 pagesMESC - SPE - 77-170 February 2017NIKESHNo ratings yet

- Technical Specification For Pressure Relief Valves PDFDocument7 pagesTechnical Specification For Pressure Relief Valves PDFat35100% (1)

- Advanced Isometric Configuration in AutoCADPlant3DDocument49 pagesAdvanced Isometric Configuration in AutoCADPlant3DRoobens SC Lara100% (1)

- I. Matching Type 1: Letter OnlyDocument8 pagesI. Matching Type 1: Letter OnlyJohn Lloyd LlananNo ratings yet

- 74-002 Carbon Steel Pipe To Astm A106 2021 MESC 14DDocument9 pages74-002 Carbon Steel Pipe To Astm A106 2021 MESC 14Dkuttub28No ratings yet

- Cyber Security BusinessDocument33 pagesCyber Security BusinessEnkayNo ratings yet

- Stainless Steel Fittings (Amendments/Supplements To Astm A403)Document8 pagesStainless Steel Fittings (Amendments/Supplements To Astm A403)kuttub28100% (1)

- MR For Ball ValvesDocument12 pagesMR For Ball Valvesengr_umer_01100% (1)

- 04 Samss 035Document16 pages04 Samss 035liuyx866No ratings yet

- Edoc - Pub - 248602254 Shell Dep List PDFDocument25 pagesEdoc - Pub - 248602254 Shell Dep List PDFShubhodeep SarkarNo ratings yet

- List Shell Dep Amp Mesc Spe PDFDocument9 pagesList Shell Dep Amp Mesc Spe PDFAzhar Ahmad100% (1)

- Paint Quantity Estimation: Application LossDocument4 pagesPaint Quantity Estimation: Application LossChethanNo ratings yet

- 70109011 (2)Document28 pages70109011 (2)finiteinjustice50% (2)

- Audit of InventoriesDocument57 pagesAudit of Inventoriessethdrea officialNo ratings yet

- Safety Audit MethodologyDocument5 pagesSafety Audit MethodologyLalit Kumar Das MohapatraNo ratings yet

- Valve Testing ProcedureDocument10 pagesValve Testing Proceduremoytabura96100% (5)

- Saep 16 PDFDocument19 pagesSaep 16 PDFbrecht1980No ratings yet

- Chemical Injection SkidDocument6 pagesChemical Injection SkidAszrol Poniman100% (3)

- Alloy and Stainless Steel Forgings (Amendments/Supplements To Astm A182)Document12 pagesAlloy and Stainless Steel Forgings (Amendments/Supplements To Astm A182)kuttub28100% (1)

- Spe 76-031Document9 pagesSpe 76-031manuneedhi0% (1)

- Spare Part Philosophy - XX PDFDocument27 pagesSpare Part Philosophy - XX PDFharmlesdragon50% (2)

- Piping - Spec - 요약본 Rev1Document3 pagesPiping - Spec - 요약본 Rev1vangie3339515No ratings yet

- List Shell Dep & Mesc SpeDocument9 pagesList Shell Dep & Mesc Spewawan80% (5)

- Flare Tip and Ignition PackageDocument8 pagesFlare Tip and Ignition Packageemartinez_bernal5989100% (2)

- ATTACHMENT 1-TECHNICAL BID EVALUATION FOR VALVES ATTACHEMENT AG 1 Rev 1Document4 pagesATTACHMENT 1-TECHNICAL BID EVALUATION FOR VALVES ATTACHEMENT AG 1 Rev 1eko123No ratings yet

- Flange Insulation Sets: Technical SpecificationDocument6 pagesFlange Insulation Sets: Technical SpecificationNor Azlan AwangNo ratings yet

- Mesc Spe 74-002 A106 14aDocument7 pagesMesc Spe 74-002 A106 14akuttub28No ratings yet

- Bagging and Tagging ProcedureDocument21 pagesBagging and Tagging ProcedureKingsley EtimNo ratings yet

- Technical Bid Evaluation FormDocument2 pagesTechnical Bid Evaluation Formanon_213471744No ratings yet

- Spare Part PhilosophyDocument27 pagesSpare Part Philosophyavaisharma50% (2)

- Process Industry Practices Insulation: PIP INIH1000 Hot Insulation Installation DetailsDocument25 pagesProcess Industry Practices Insulation: PIP INIH1000 Hot Insulation Installation DetailsSarwar KhanNo ratings yet

- Part Labeling SpecificationDocument9 pagesPart Labeling SpecificationJosué PérezNo ratings yet

- Scope of Work For Metering SkidDocument5 pagesScope of Work For Metering SkidmusaveerNo ratings yet

- SDV, BDV, Esdv ChecklistDocument2 pagesSDV, BDV, Esdv ChecklistMusab Shabbir67% (3)

- Orifice FlangeDocument70 pagesOrifice FlangePaulo SousaNo ratings yet

- SpoDocument49 pagesSpoCristinel NechiforNo ratings yet

- KKS Tagging Philosophy For Power Generating StationDocument61 pagesKKS Tagging Philosophy For Power Generating Stationchandakbera100% (1)

- MBN 10317 1 2006 07 PDFDocument17 pagesMBN 10317 1 2006 07 PDFDewi Lanjarsari Purnama SastriNo ratings yet

- MESC SPE 85-103 Feb 2014 PDFDocument8 pagesMESC SPE 85-103 Feb 2014 PDFaleeimeran100% (1)

- Saudi Aramco: Company General UseDocument1 pageSaudi Aramco: Company General UseParthiban RNo ratings yet

- Engineering Guide For Instrument Installation Design Infor PDFDocument18 pagesEngineering Guide For Instrument Installation Design Infor PDFNguyenCanhBaoNo ratings yet

- FS HippsDocument8 pagesFS Hippsscribd_thakurNo ratings yet

- 01 T121-HA-02005 Specification For Metering Skid PDFDocument13 pages01 T121-HA-02005 Specification For Metering Skid PDFMayur Patel100% (3)

- KIW03616 PED Poster A3 NL Web 1Document1 pageKIW03616 PED Poster A3 NL Web 1Vasko PlevnikNo ratings yet

- Valve Leakage Rates Test STDDocument6 pagesValve Leakage Rates Test STDbreizhonekNo ratings yet

- 76 204 16Document7 pages76 204 16finiteinjusticeNo ratings yet

- 175 170200Document2 pages175 170200Vijay BhaleraoNo ratings yet

- MESC SPE 74-019, June 2007 - Nickel Alloy Pipe To ASTM B423Document7 pagesMESC SPE 74-019, June 2007 - Nickel Alloy Pipe To ASTM B423sathi11189100% (1)

- 77 170 2012 PDFDocument15 pages77 170 2012 PDFsathi11189No ratings yet

- DM 00023899Document634 pagesDM 00023899Yurli KusnediNo ratings yet

- MsciAsm User ManualDocument74 pagesMsciAsm User ManualbkzzNo ratings yet

- CWS H08 PBDocument23 pagesCWS H08 PBErivelto AntunesNo ratings yet

- HCS08 Peripheral Module Quick Reference: Users GuideDocument116 pagesHCS08 Peripheral Module Quick Reference: Users GuideDaniel KarasaniNo ratings yet

- Web SlingsDocument25 pagesWeb SlingsParthiban RNo ratings yet

- Saudi Arabian Oil Company: End of SpecificationDocument1 pageSaudi Arabian Oil Company: End of SpecificationParthiban RNo ratings yet

- Direct Charge Purchase Requisition ERDD Maintenance DivisionDocument1 pageDirect Charge Purchase Requisition ERDD Maintenance DivisionParthiban RNo ratings yet

- Notes: Total Amount (USD) 15% VAT (USD) Net Total Amount (USD)Document1 pageNotes: Total Amount (USD) 15% VAT (USD) Net Total Amount (USD)Parthiban RNo ratings yet

- Saudi Arabian Oil Company: 2.1 Project DocumentsDocument1 pageSaudi Arabian Oil Company: 2.1 Project DocumentsParthiban RNo ratings yet

- Saudi Arabian Oil Company: 18.0 Packing and Preparation For ShipmentDocument1 pageSaudi Arabian Oil Company: 18.0 Packing and Preparation For ShipmentParthiban RNo ratings yet

- Saudi Arabian Oil CompanyDocument1 pageSaudi Arabian Oil CompanyParthiban RNo ratings yet

- Saudi Arabian Oil Company: 21.0 Pre-Commissioning and CommissioningDocument1 pageSaudi Arabian Oil Company: 21.0 Pre-Commissioning and CommissioningParthiban RNo ratings yet

- Saudi Arabian Oil Company: 19.0 LubricationDocument1 pageSaudi Arabian Oil Company: 19.0 LubricationParthiban RNo ratings yet

- Saudi Arabian Oil Company: 14.0 Coating/PaintingDocument1 pageSaudi Arabian Oil Company: 14.0 Coating/PaintingParthiban RNo ratings yet

- Saudi Arabian Oil Company: 13.0 Instrumentation and ControlDocument1 pageSaudi Arabian Oil Company: 13.0 Instrumentation and ControlParthiban RNo ratings yet

- Saudi Arabian Oil Company: 17.2 TestingDocument1 pageSaudi Arabian Oil Company: 17.2 TestingParthiban RNo ratings yet

- Chapter 1Document1 pageChapter 1Parthiban RNo ratings yet

- Saudi Arabian Oil Company: 12.0 ElectricalDocument1 pageSaudi Arabian Oil Company: 12.0 ElectricalParthiban RNo ratings yet

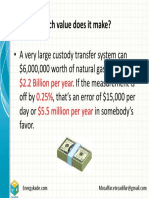

- How Much ValueDocument1 pageHow Much ValueParthiban RNo ratings yet

- How Much Value PDFDocument1 pageHow Much Value PDFParthiban RNo ratings yet

- Schedule of BenefitsDocument1 pageSchedule of BenefitsParthiban RNo ratings yet

- What Is Fiscal MeteringDocument1 pageWhat Is Fiscal MeteringParthiban RNo ratings yet

- Agenda PDFDocument1 pageAgenda PDFParthiban RNo ratings yet

- Higgins - A 9 PDFDocument1 pageHiggins - A 9 PDFParthiban RNo ratings yet

- How Much Value PDFDocument1 pageHow Much Value PDFParthiban RNo ratings yet

- Design of PadDocument1 pageDesign of PadParthiban RNo ratings yet

- 8 PDFDocument1 page8 PDFParthiban RNo ratings yet

- Master 'S Thesis: Faculty of Science and TechnologyDocument1 pageMaster 'S Thesis: Faculty of Science and TechnologyParthiban RNo ratings yet

- Agenda PDFDocument1 pageAgenda PDFParthiban RNo ratings yet

- Terms, Definitions and Abbreviations: Breaking Load (Breaking Force)Document1 pageTerms, Definitions and Abbreviations: Breaking Load (Breaking Force)Parthiban RNo ratings yet

- CellularDocument1 pageCellularParthiban RNo ratings yet

- NotchedDocument1 pageNotchedParthiban RNo ratings yet

- Name: Titian Nursaida Pratiwi NIM: 17320206Document2 pagesName: Titian Nursaida Pratiwi NIM: 17320206Titian NursaidaNo ratings yet

- 824pm - 22.EPRA JOURNALS 15646Document7 pages824pm - 22.EPRA JOURNALS 15646garimanevtiyaNo ratings yet

- Xuv700 DieselDocument1 pageXuv700 DieselSUDHIR SINGH PATYALNo ratings yet

- BT FinalDocument28 pagesBT Finalzala ujjwalNo ratings yet

- Assignment 1Document4 pagesAssignment 1Janani PriyaNo ratings yet

- Pakistan International Airlines, Pia: Strategic ReportDocument21 pagesPakistan International Airlines, Pia: Strategic ReportMuhammad AwaisNo ratings yet

- 3.2 Equity Securities Hand OutDocument8 pages3.2 Equity Securities Hand OutAdyangNo ratings yet

- Overview of Co-Operative BankingDocument14 pagesOverview of Co-Operative BankingDr. Meghna DangiNo ratings yet

- Assignment 1Document6 pagesAssignment 1aakanksha_rinniNo ratings yet

- Upwork Profile - Job Experience ProfileDocument4 pagesUpwork Profile - Job Experience ProfileKim NatividadNo ratings yet

- Collection of Land RevenueDocument13 pagesCollection of Land Revenuemanuarora81No ratings yet

- Report On Angel BrokingDocument102 pagesReport On Angel BrokingRashid SiddiquiNo ratings yet

- SWOT Analysis: Strengths WeaknessesDocument2 pagesSWOT Analysis: Strengths WeaknessesALALADE VICTOR aNo ratings yet

- Accounting Principles - AllDocument104 pagesAccounting Principles - AllAHMED100% (1)

- Lasu External Campus - Docx2Document5 pagesLasu External Campus - Docx2Bukola BukkyNo ratings yet

- 91 Fla BJ19Document5 pages91 Fla BJ19Juanito de MontalbanNo ratings yet

- Blank Risk Assessment TemplateDocument4 pagesBlank Risk Assessment TemplateMNo ratings yet

- Welfare State BritainDocument2 pagesWelfare State BritainekcccNo ratings yet

- MASTER NILAI VIRTUAL Batch 30Document12 pagesMASTER NILAI VIRTUAL Batch 30Lola SeptiyantiNo ratings yet

- Mekane Yesus Bulcha Area Local Church Business PlanDocument11 pagesMekane Yesus Bulcha Area Local Church Business Planpenna belewNo ratings yet

- Report: Mean (Expected Value) of A Discrete Random Variable 100%Document2 pagesReport: Mean (Expected Value) of A Discrete Random Variable 100%abel mahendraNo ratings yet

- Statistics For Business and Economics: Anderson Sweeney WilliamsDocument48 pagesStatistics For Business and Economics: Anderson Sweeney WilliamsHạnh SumiNo ratings yet

- A Methodology For Cisco Business Architects (v1.0)Document19 pagesA Methodology For Cisco Business Architects (v1.0)chindi.comNo ratings yet

- Account CurrentDocument13 pagesAccount Currentfathima.comafug23No ratings yet

- HGDDDDocument2 pagesHGDDDsatyamgill7875No ratings yet