Professional Documents

Culture Documents

Plant Warm Start

Uploaded by

Minh Hoang Nguyen0 ratings0% found this document useful (0 votes)

21 views5 pagesThe document provides step-by-step instructions for performing a warm start-up of a plant. It lists 36 steps to bring systems online and synchronize the turbine generator to the grid, gradually increasing load on the turbine from 0% to 100% load over multiple steps. Key steps include starting condenser vacuum systems, boilers, feedwater heaters, bypass systems, starting the turbine in reverse mode before synchronization, and gradually increasing turbine load by starting motor-driven pumps.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides step-by-step instructions for performing a warm start-up of a plant. It lists 36 steps to bring systems online and synchronize the turbine generator to the grid, gradually increasing load on the turbine from 0% to 100% load over multiple steps. Key steps include starting condenser vacuum systems, boilers, feedwater heaters, bypass systems, starting the turbine in reverse mode before synchronization, and gradually increasing turbine load by starting motor-driven pumps.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views5 pagesPlant Warm Start

Uploaded by

Minh Hoang NguyenThe document provides step-by-step instructions for performing a warm start-up of a plant. It lists 36 steps to bring systems online and synchronize the turbine generator to the grid, gradually increasing load on the turbine from 0% to 100% load over multiple steps. Key steps include starting condenser vacuum systems, boilers, feedwater heaters, bypass systems, starting the turbine in reverse mode before synchronization, and gradually increasing turbine load by starting motor-driven pumps.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

PLANT WARM START-UP

A.PLANT WARM START-UP READY

- MCWS A On and MCWS B On

- CCWS Normal

- Air Compressor Sys Normal

- Gen Stator Cooling Water Sys Normal

- Auxiliary Steam Sys Normal

- HP Bypass Hydraulic Sys Normal

- LP Bypass Hydraulic Sys Normal

- Water Level In Storage Condenser Normal

- Water Level In Feedwater Storage TNK is Normal

- MECH CLNG is In Service

- U1 Chlo Sys On

- LDO Forwarding Sys In Service

- Condenser Water Box Vacuum Sys In Service

- Condenser Sys In Service

- Circulating Water Sys In Service

- CPP In Service

- Scanner Cooling Air Fan In Service

- BFPT A Lube Oil & Turning Gear In Service

- BFPT B Lube Oil & Turning Gear In Service

- TBN LUBE Oil Sys Normal

- Generator Seal Oil Sys Normal

- H2 Gas Fill Up Complete In Gen

- Steam Turbine Turning Gear In Service

- ACW Sys In Service

- DM Water Storage & Transfer Sys In Service

- Service Water & F/F Sys In Service

- CEMS Normal

- TBN Steam Seal Sys Normal

- Operation Verification

- Unit In Warm Start Mode

Node: The Operator shall verify the following Condition before Plant Start-up Sequence

- Water Treatment System Normal

- Condensate Storage & Trabsfer Sys Normal

- Condenser Hot Well FW Storage TNK Filled

- CTCS In Service

- Debris Filter In Service

- All Manual Valves In all System Properly Positioned

- All Equipment (Train Group, Pumps) Preselected

- BLR Fill Up Complete

- Clean Up of Condensate Sys Complete

- BLR Flushing Complete

- Flow Path FW 1,2,3,4 Available

- ESP Heating Complete

- Samoling System Normal

B. STEP BY STEP WARM START-UP

Step Conditions Step by Step

No

01 - PB Start - Common Sys Group Auto

- Plant Warm Start Ready

02 - Auxiliary PRDS Group Auto Mode - Dealy 2s to Next Step

- DM Water SPLY PP Group

Control Auto Mode

- COND XFP Group Control Auto

Mode

- PW PP Group Control Auto Mode

- Service WTR PP GRP CTL Auto

Mode

- DO FWD PP GRP CTL Auto

Mode

- CCW GRP CTL Master Auto

Mode

- FGD CCWP GRP CTL Master

Auto Mode

- ACW GRP CTL Master Auto

Mode

- CVP GRP CTL Master Auto Mode

03 - - Start CVP Sys

04 - Any CVP Running - Main Steam & Reheat Drain Sys Auto

05 - Main Steam & Reheat Drain Sys In - Line-Up Flow Path FW HTR #6,7,8

Auto

06 - Flow Path FW HTR #6,7,8 Line- - FW HTR Vent Sys To Start-up Position

Up

07 - FW HTR Vent Sys In Start-up - Start S-U BFP

Position

08 - S-U BFP Running - Start Automatic Boiler Sequence

09 - Automatic Boiler Sequence In - Set FW HTR STM DRN SYS To Start

Process Position

10 - FW HTR STM DRN SYS In Start - Start ESP Sys

Position

- ESP A RDY to Start-up

- ESP B RDY to Start-up

- Remode Mode Selected

11 - ESP A Running - HP/LP Bypass to Start Mode

- ESP B Running

12 - HP BP Auto Mode - To Next Step

- HP BP A M/A Auto Mode

- HP BP B M/A Auto Mode

- LP BP Auto Mode

- LP BP A M/A Auto Mode

- LP BP B M/A Auto Mode

13 - - Reset STG

14 - STG Reset Complete - Start FGD Sys

- FGD Sys Ready

- FGD Sys Remote

15 - FGD Sys Running - Start Fly Ash Handling System

- Fly Ash Handling System Start

Permissive

16 - Fly Ash Handling System Start - Start SDCC for BAHS

- SDCC for BAHS Start Permissive

17 - SDCC for BAHS Running - BFPT A Reset CMD

- All TBN Drain VLV Opened - BFPT B Reset CMD

- TBN Ready to Start - STG Auto Start

18 - TBN Rolling In Reverse Flow - Verify TBN Speed 2600 rpm

Mode

19 - TBN Speed > 2600 rpm - Verify TBN Speed 3000 rpm

20 - TBN Speed > 3000 rpm - Release to STG Synchronization

21 - STG Synchronized - LP FW HTR #2, 3, 4 Start Vent MOV

Closed At HTR LVL Normal

22 - FW HTR 4 Vent MOV Closed - Delay 10s to Next Step

- FW HTR 3 Vent MOV Closed

- FW HTR 2 Vent MOV Closed

23 - - Enable UMC Command

24 - TBN In UMC Mode - Set TBN Master Control Auto

25 - TMC Auto Mode - Set BLR Master CTL Auto

- Both HP Bypass VLV Closed

26 - BMC Auto Mode - Set UMC Target 50% Load

27 - TBN Actual MW > 150 MW (25%) - Start 1ST TBN Driven BFP

- BFPT A Duty Selection

- BFPT A RDY to Start

- Or BFPT B Duty Selection

- BFPT B RDY to Start

28 - BFPT A Duty Selection - Verify Motor Driven Stop

- And BFPT A Running

- Or BFPT B Duty Selection

- And BFPT B Running

- BFP Discharge Pres Equlized

29 - S-U BFP Stopped - Verify FW 100% MOV Open

30 - FW HTR to Economizer Inl MOV - Set UMC Target 100% Load

Opened

31 - TBN Actual MW > 240%(40%) - Start 2nd TBN Driven BFP

- BFPT A Duty Selection

- BFPT A RDY to Start

- Or BFPT B Duty Selection

- BFPT B RDY to Start

32 - BFP B Running - Start 2nd CEP

- BFP A Running

33 - More Than Two CEP Running - Verify 50% Load (300MW) Reach

34 - TBN Actual MW > 300MW(50%) - Verify 70% Load (420MW) Reach

35 - TBN Actual MW > 420MW(70%) - Verify 90% Load (540MW) Reach

36 - TBN Actual MW > 540MW(70%) - Verify 100% Load (600MW) Reach

- Plant Cold Start-up Complete

You might also like

- UH-1H Huey Checklist V2Document2 pagesUH-1H Huey Checklist V2Jacobite Bond100% (1)

- CMCDocument28 pagesCMCHemant Patil100% (1)

- Fibretherm FT12Document47 pagesFibretherm FT12Dana Iulia Moraru50% (2)

- Syllabus 330C SystemsDocument1 pageSyllabus 330C SystemsDANIEL VARGAS RODRIGUEZNo ratings yet

- Generic Roadmap For The Counties of Kenya V1.1Document33 pagesGeneric Roadmap For The Counties of Kenya V1.1ICT AUTHORITYNo ratings yet

- A.Plant Hot Start-Up ReadyDocument5 pagesA.Plant Hot Start-Up ReadyMinh Hoang NguyenNo ratings yet

- Plant Cold StartDocument6 pagesPlant Cold StartMinh Hoang NguyenNo ratings yet

- SOP TG Rolling and SynchronisationDocument13 pagesSOP TG Rolling and Synchronisationmoovendan pNo ratings yet

- Presentation On NSTPS VISITDocument46 pagesPresentation On NSTPS VISITACHAL AGRAWALNo ratings yet

- HP LP Bypass System (MB Power) 10june15Document18 pagesHP LP Bypass System (MB Power) 10june15dilbagh_scribd100% (3)

- HP-LP Bypass FDocument16 pagesHP-LP Bypass FSolaiNo ratings yet

- RTR RHSG Start-Up Time Chart (Cold Start-Up)Document8 pagesRTR RHSG Start-Up Time Chart (Cold Start-Up)Sarah FrazierNo ratings yet

- TURBINE Logics and InterlocksDocument62 pagesTURBINE Logics and Interlockskalyanm20351586% (7)

- Turbine Prestartup ChecklistDocument4 pagesTurbine Prestartup ChecklistSCE SOLAPURNo ratings yet

- Presentation OnDocument28 pagesPresentation OnAnonymous umnT4ZZcuNo ratings yet

- Power Plant EmergencyDocument22 pagesPower Plant Emergencysekhar_ntpc75% (4)

- 500MW Starting ProceduresDocument38 pages500MW Starting Proceduresthangarajm1984No ratings yet

- 500 MW Unit Startup ProcedureDocument39 pages500 MW Unit Startup ProcedureMohammad Asif50% (2)

- TURBINE Logics and Interlocks PDFDocument62 pagesTURBINE Logics and Interlocks PDFLakshmi Narayan100% (1)

- Adani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorDocument4 pagesAdani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorBryan ScofieldNo ratings yet

- Cold Srat UpDocument21 pagesCold Srat Upthiagu1989100% (1)

- Improved (Ccb2) Knorr Bremse Brake System Fitted in 3phase Electric LocomotivesDocument38 pagesImproved (Ccb2) Knorr Bremse Brake System Fitted in 3phase Electric Locomotivesjohn peter100% (11)

- A Brief Idea About Automatic Process Control: Controlling What?Document33 pagesA Brief Idea About Automatic Process Control: Controlling What?Shiva Kotamraju100% (1)

- Inst Mar 2016Document102 pagesInst Mar 2016Dhilip AnNo ratings yet

- Co Ordinated Master Control (CMC) : by V.HariayyappanDocument25 pagesCo Ordinated Master Control (CMC) : by V.HariayyappanRavi Satyapal100% (2)

- Main Turbine: 1 General LayoutDocument16 pagesMain Turbine: 1 General LayoutPrakash Choudhary100% (1)

- Lecture On ATRS & Speed-Load ControlDocument44 pagesLecture On ATRS & Speed-Load Control06nikhil100% (1)

- DDCP SF 04 04aDocument6 pagesDDCP SF 04 04aMohammad FarajNo ratings yet

- BFP Changeover ProcedureDocument10 pagesBFP Changeover ProcedureDevendr Prakash100% (1)

- Power PlantDocument42 pagesPower PlantMuhammad Faizan100% (1)

- Idamalayar Hydro Electric ProjectDocument100 pagesIdamalayar Hydro Electric ProjectRajesh TKNo ratings yet

- Gas Turbine Start-UpDocument36 pagesGas Turbine Start-UpHeryanto Syam100% (2)

- 660 MW Warm Startup Procedures Warm Start Up After 36 Hrs Shutdown and HPC Temperature 340 C and Ipc 320 C With Boiler PR 1 To 30 KSCDocument6 pages660 MW Warm Startup Procedures Warm Start Up After 36 Hrs Shutdown and HPC Temperature 340 C and Ipc 320 C With Boiler PR 1 To 30 KSCdjfffNo ratings yet

- Submitted To GM/BTPP: Sub: NLC-BTPP-2X125 MW-Write-up On HP-LP BYPASS SYSTEMS - RegDocument7 pagesSubmitted To GM/BTPP: Sub: NLC-BTPP-2X125 MW-Write-up On HP-LP BYPASS SYSTEMS - RegPrakash ChoudharyNo ratings yet

- Cold Startup and ShutdownDocument28 pagesCold Startup and ShutdownFSTPS Switch-YardNo ratings yet

- Power Plant Emergency Operation InstructionDocument2 pagesPower Plant Emergency Operation Instructionvyrman1208No ratings yet

- Engine Room Simulator: Ers-L11 Man B&W-5L90Mc VLCCDocument36 pagesEngine Room Simulator: Ers-L11 Man B&W-5L90Mc VLCCJøn Bilbao Mallona100% (1)

- CCPP Cold Start ProcedureDocument3 pagesCCPP Cold Start ProcedureSahariar Bin ShafiqueNo ratings yet

- Unit Planned Shutdown OperationsDocument3 pagesUnit Planned Shutdown Operationschandan mishraNo ratings yet

- Npti Training ManualDocument34 pagesNpti Training Manualsanju0156No ratings yet

- Procedure For Condenser Vacuum PullingDocument4 pagesProcedure For Condenser Vacuum PullingPulkit AgarwalNo ratings yet

- Stg-2 Turbine - Fast - Cooling CHECKLISTDocument7 pagesStg-2 Turbine - Fast - Cooling CHECKLISTscentpcbarauni BARAUNINo ratings yet

- Index-Sop & SMPDocument44 pagesIndex-Sop & SMPNilamani Umashankar JenaNo ratings yet

- Sop 01-Turbine Cold StartupDocument12 pagesSop 01-Turbine Cold Startuptpplant100% (1)

- Ioties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3Document23 pagesIoties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3pramodtryNo ratings yet

- Q.1 in Case of Grid Supply Fail in KCW Substation. How Can The Restore The Grid in Blackout Condition? SolutionDocument4 pagesQ.1 in Case of Grid Supply Fail in KCW Substation. How Can The Restore The Grid in Blackout Condition? SolutionbbbbbNo ratings yet

- Runback TestingDocument1 pageRunback TestingshashankNo ratings yet

- HRSGDocument4 pagesHRSGnivasssvNo ratings yet

- Tata Projects Limited: Doc. No: Operation & Control PhilosophyDocument10 pagesTata Projects Limited: Doc. No: Operation & Control Philosophyvenkatraman JNo ratings yet

- Trip Analysis Recommendation For The FY 2020-21 (660 MW Units)Document45 pagesTrip Analysis Recommendation For The FY 2020-21 (660 MW Units)sudhakarautomatic9940No ratings yet

- (Simhadri Stpp-Ii - 2 X 500 MW) : Cat-IDocument5 pages(Simhadri Stpp-Ii - 2 X 500 MW) : Cat-IBalaji AllupatiNo ratings yet

- 60 Ton Per HR Advance Empire Boiler Operation ManualDocument15 pages60 Ton Per HR Advance Empire Boiler Operation Manualrozg788152100% (1)

- Checklist B757 CaptainSimDocument15 pagesChecklist B757 CaptainSimanas9889No ratings yet

- Cold Start Up Procedure: - NTPC, SimhadriDocument29 pagesCold Start Up Procedure: - NTPC, SimhadriAhemadNo ratings yet

- 210 MW Generator Operating Instructions Stage-2Document9 pages210 MW Generator Operating Instructions Stage-2raghavendran raghuNo ratings yet

- Control & Automation For Super Critical UnitsDocument46 pagesControl & Automation For Super Critical Unitsbsiva9No ratings yet

- Check The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001Document5 pagesCheck The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001jose Alberto uribe Minier100% (1)

- Check List GT Ready To Start Condition: No. Item Keterangan Status CatatanDocument9 pagesCheck List GT Ready To Start Condition: No. Item Keterangan Status Catatanmail_mulyadi5151No ratings yet

- Unit Start UpDocument8 pagesUnit Start UpDebabrata TantubaiNo ratings yet

- 200mw Volume 2Document316 pages200mw Volume 2Sam100% (2)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- SH1.RFP - P4 OTR - Ch2 Design Concept & System Description - 140601Document28 pagesSH1.RFP - P4 OTR - Ch2 Design Concept & System Description - 140601Minh Hoang NguyenNo ratings yet

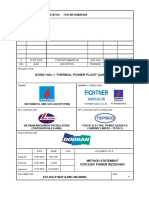

- Song Hau 1 Thermal Power Plant (2X600Mw) : Document Submission Status: For ConstructionDocument20 pagesSong Hau 1 Thermal Power Plant (2X600Mw) : Document Submission Status: For ConstructionMinh Hoang NguyenNo ratings yet

- SH1.RFP - P4 OTR - Ch1 General Description - 140530Document18 pagesSH1.RFP - P4 OTR - Ch1 General Description - 140530Minh Hoang NguyenNo ratings yet

- HP LP Bypass System: Ravi Pal SinghDocument36 pagesHP LP Bypass System: Ravi Pal SinghMinh Hoang NguyenNo ratings yet

- Method StatementDocument16 pagesMethod StatementMinh Hoang Nguyen100% (1)

- GPS Vehicle Tracker: User ManualDocument9 pagesGPS Vehicle Tracker: User ManualFeJuniorNo ratings yet

- Eurotherm 2604 PDFDocument2 pagesEurotherm 2604 PDFLorena100% (1)

- JeeleDocument9 pagesJeeleAnonymous SZDGk7SvGNo ratings yet

- Compressor Service ProcedureDocument22 pagesCompressor Service ProcedureFriget Rusianto100% (2)

- Dyatlov Interview 1995 enDocument6 pagesDyatlov Interview 1995 enmhulot100% (1)

- A330 Tire Inspn PDFDocument21 pagesA330 Tire Inspn PDFRithesh Ram NambiarNo ratings yet

- Slide Akuntansi ManahemenDocument10 pagesSlide Akuntansi ManahemenHandaru Edit Sasongko0% (1)

- Animal and Human Brain Work With Treatment Its Malfunction: Pijush Kanti BhattacharjeeDocument6 pagesAnimal and Human Brain Work With Treatment Its Malfunction: Pijush Kanti BhattacharjeeNilakshi Paul SharmaNo ratings yet

- SBI Clerk Mains Bolt 2023 OliveboardDocument160 pagesSBI Clerk Mains Bolt 2023 OliveboardMaahi ThakorNo ratings yet

- OTL R12 ImplementationDocument288 pagesOTL R12 ImplementationSarah Kay MortelNo ratings yet

- Case StudyDocument80 pagesCase Studybravo deltafoxNo ratings yet

- Vestron VideoDocument3 pagesVestron VideoMIDNITECAMPZNo ratings yet

- Chapter 7 Series Parallel CircuitsDocument70 pagesChapter 7 Series Parallel CircuitsAbdullrahman Al-ShammaaNo ratings yet

- 220 Cipher TechniqueDocument10 pages220 Cipher Techniquecagedraptor100% (1)

- The Role of Social Media and Its Implication On Economic Growth On Society in IndiaDocument3 pagesThe Role of Social Media and Its Implication On Economic Growth On Society in IndiaSara EmamiNo ratings yet

- Heat Loss and Gain CalculationDocument84 pagesHeat Loss and Gain Calculationafraz_xecNo ratings yet

- Modelling and Simulation of Absorption Solar Air Conditioning SystemDocument20 pagesModelling and Simulation of Absorption Solar Air Conditioning SystemShadi KarkabaNo ratings yet

- p20 PDFDocument12 pagesp20 PDFpraphul gamangoNo ratings yet

- Crimp HandbookDocument24 pagesCrimp Handbookrony_lesbtNo ratings yet

- Lab 7Document12 pagesLab 7api-25252422380% (5)

- Mathematical Modelling of Gear Tooth Stiffness: Bachelor of Technology in Mechanical EngineeringDocument40 pagesMathematical Modelling of Gear Tooth Stiffness: Bachelor of Technology in Mechanical EngineeringVishal ShasiNo ratings yet

- Electricalprep Com Transformers More 5Document16 pagesElectricalprep Com Transformers More 5gokulchandruNo ratings yet

- Broaching PrsDocument41 pagesBroaching PrsParag PatelNo ratings yet

- 7sd610 CatalogueDocument35 pages7sd610 CatalogueTntngn Petualang100% (1)

- HMA Road Design NotesDocument86 pagesHMA Road Design NotesFarooq AhmadNo ratings yet

- Assessment of Reinforcement CorrosionDocument5 pagesAssessment of Reinforcement CorrosionClethHirenNo ratings yet

- Kumbh Mela 2019 Presentation Mela AuthorityDocument35 pagesKumbh Mela 2019 Presentation Mela AuthorityBanibrataChoudhuryNo ratings yet